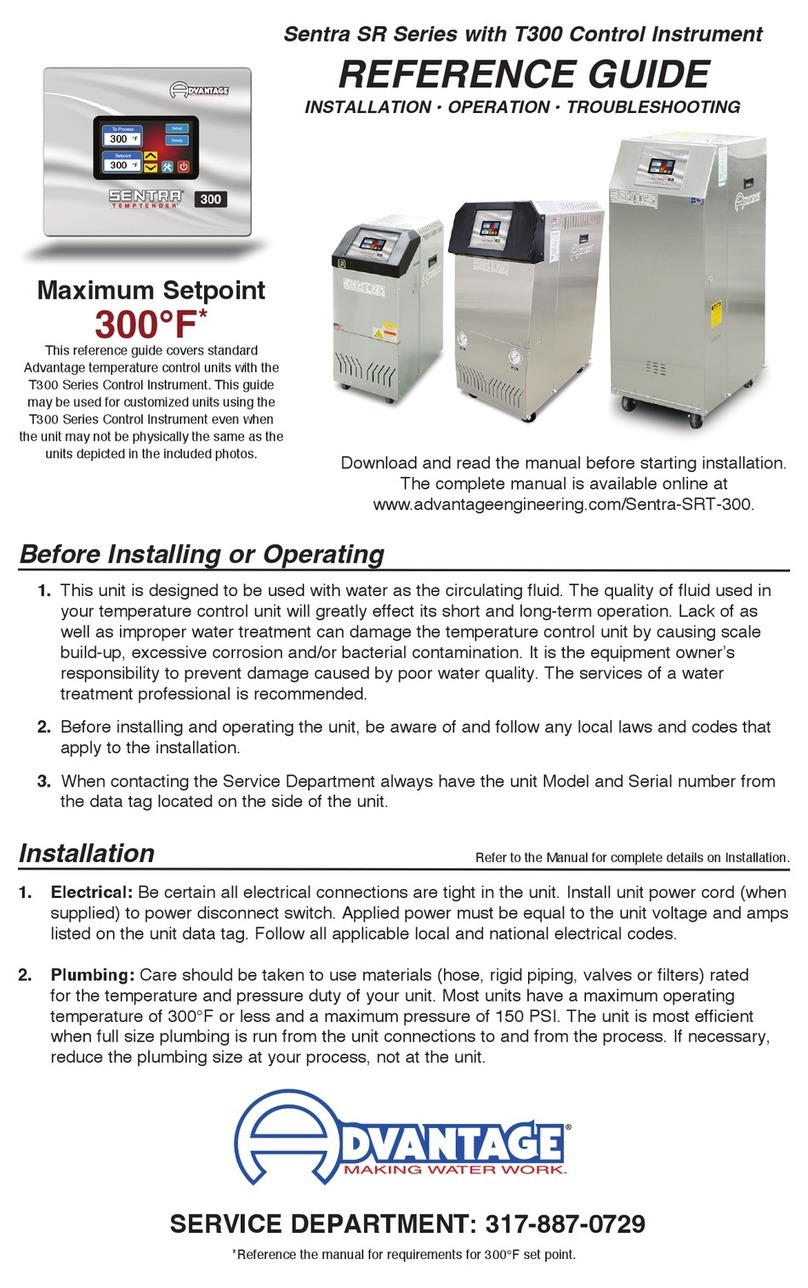

Operating Temperature

Water Supply Pressure

180°F

20 PSI

190°F

25 PSI

200°F

30 PSI

210°F

35 PSI

220°F

40 PSI

230°F

45 PSI

250°F

50 PSI

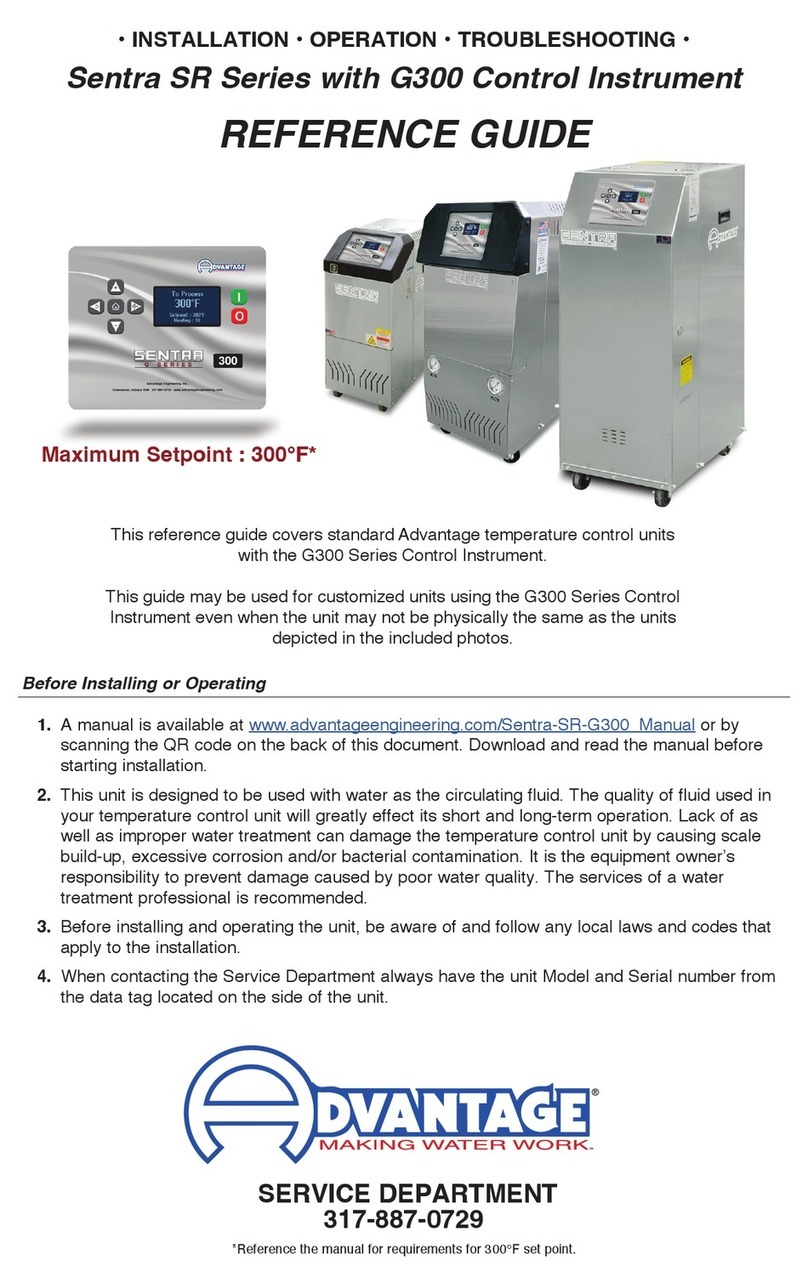

Alert

AC 3-Phase

Setpoint

200

°F

Setup

Ready

Standby

Alert

Sensor (From)

Alert

Sensor (To)

Alert

High Temperature

Alert

Sensor Probe

Alert

Cooling Valve

Alert

Water Pressure

3. Connect the unit’s To Process port to the

Water In port on the process manifold.

4. Connect the unit’s From Process port

to the Water Out port on the process

manifold.

5. Please note: Process water piping

circuitry should be designed to avoid an

excessive use of elbows and/or lengths

of pipe or hose. If hose is the material

of choice, avoid tight twists or curls and

excessive lengths.

6. Valves and lters may be installed in the

process water piping circuitry to facilitate

service and maintenance, provided that

such devices maintain the full inside

diameter of the process connection. If

installed, all such devices must be open

and clean during unit operation.

7. Connect Unit drain to plant’s open drain,

tower water system return or chilled water

system return. The factory recommends

a minimum of 20 psi pressure differential

between the water supply and drain line.

A larger differential may be required for

larger cooling needs.

8. Connect Unit water supply to plant’s city

water or well water source or tower water

supply or chilled water supply. Water

supply pressure requirements vary with

operating temperatures as shown in the

chart below.

Drain

To Process

From Process

Water Supply

Start Unit Refer to the Manual for complete details on start up and operations information.

1. Fill unit with water.

2. Apply power. The Standby screen will

illuminate. When Standby is displayed,

the unit is not running.

3. A System Fault may prevent startup.

Probe, cooling valve, water supply

pressure, pump overload or high

temperature limit may display once power

is applied and must be corrected prior to

operation.

4. This unit features a touch screen interface panel. Press gently on the screen to navigate. Do not

press the screen with tools or other foreign objects when navigating.

5. Determine that the pump is rotating in a clockwise direction when viewed from the rear of the

motor. Follow the instructions in Section 3.2 of the factory operations manual.

Typical unit with ¾ - 3 HP pump and/or 10 - 16 kW heater.