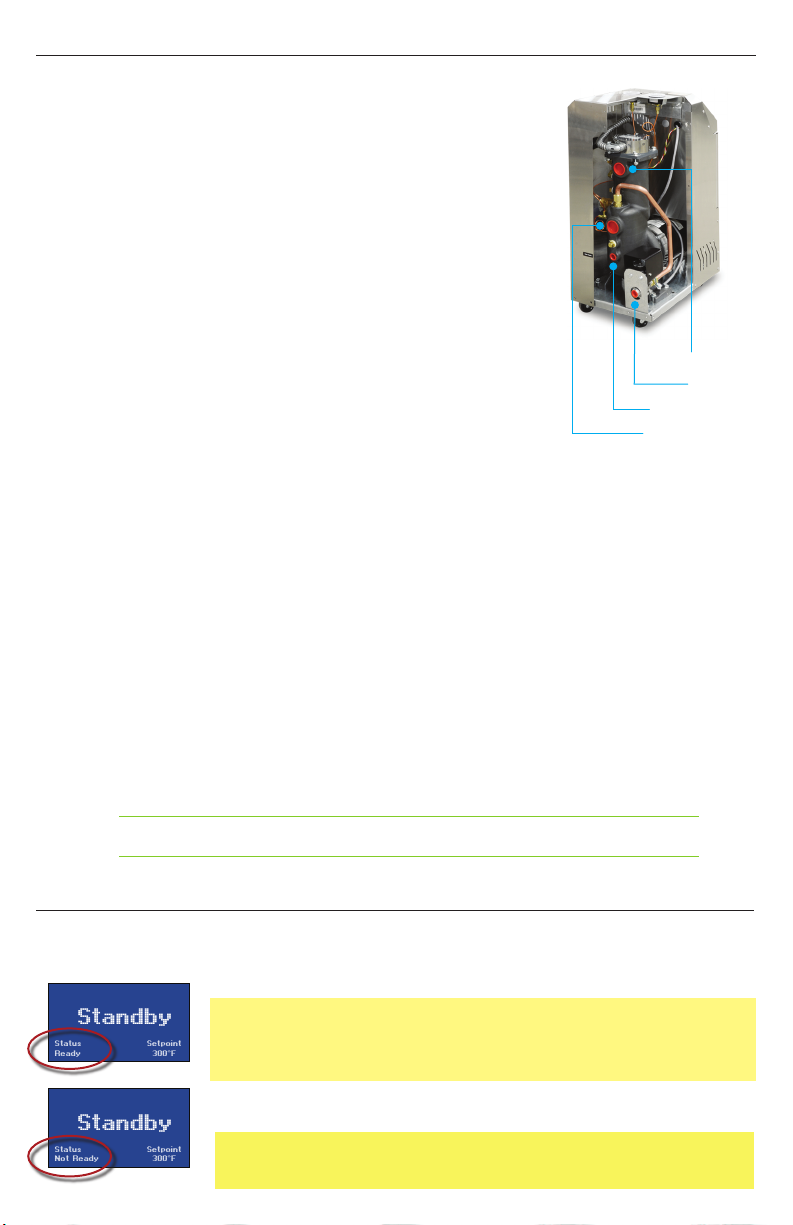

Standby

Status

Not Ready

Setpoint

300°F

Standby

Status

Ready

Setpoint

300°F

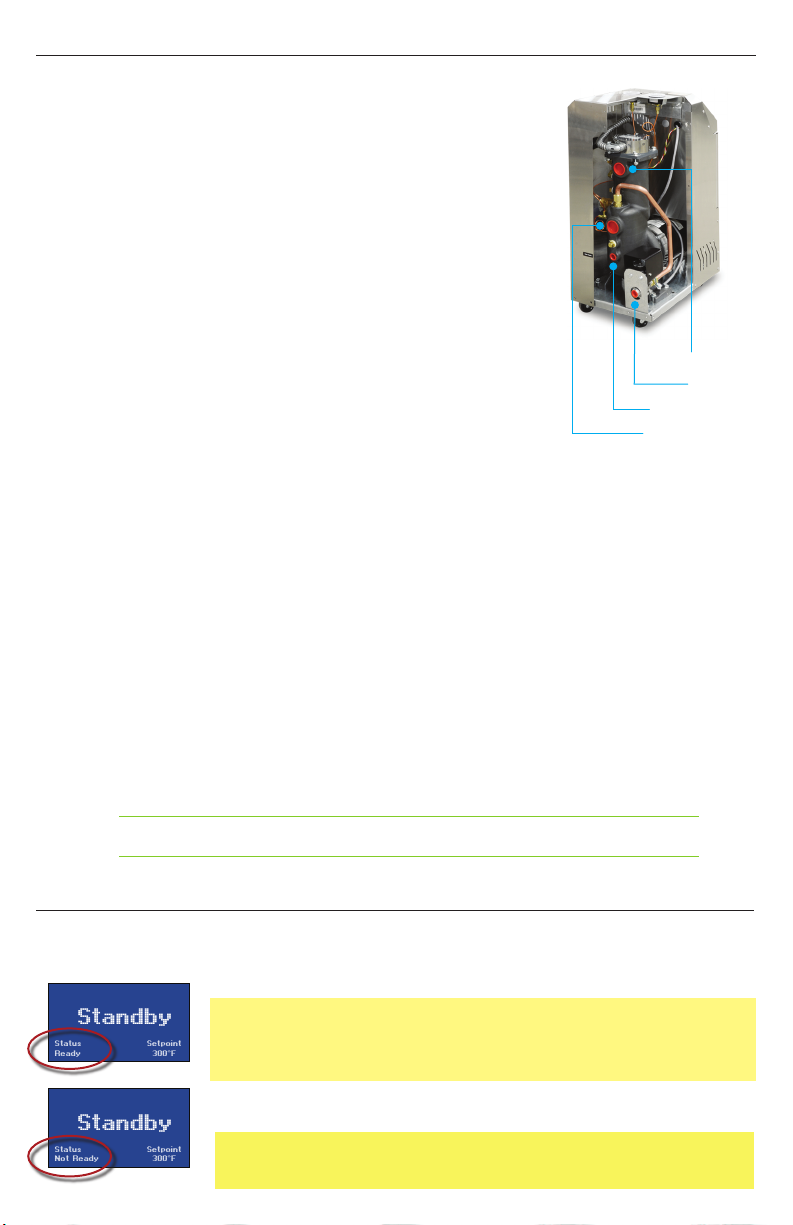

Operating Temperature

Water Supply Pressure

200°F

30 PSI

210°F

35 PSI

220°F

40 PSI

240°F

50 PSI

250°F

50 PSI

275°F

50 PSI

300°F

50 PSI

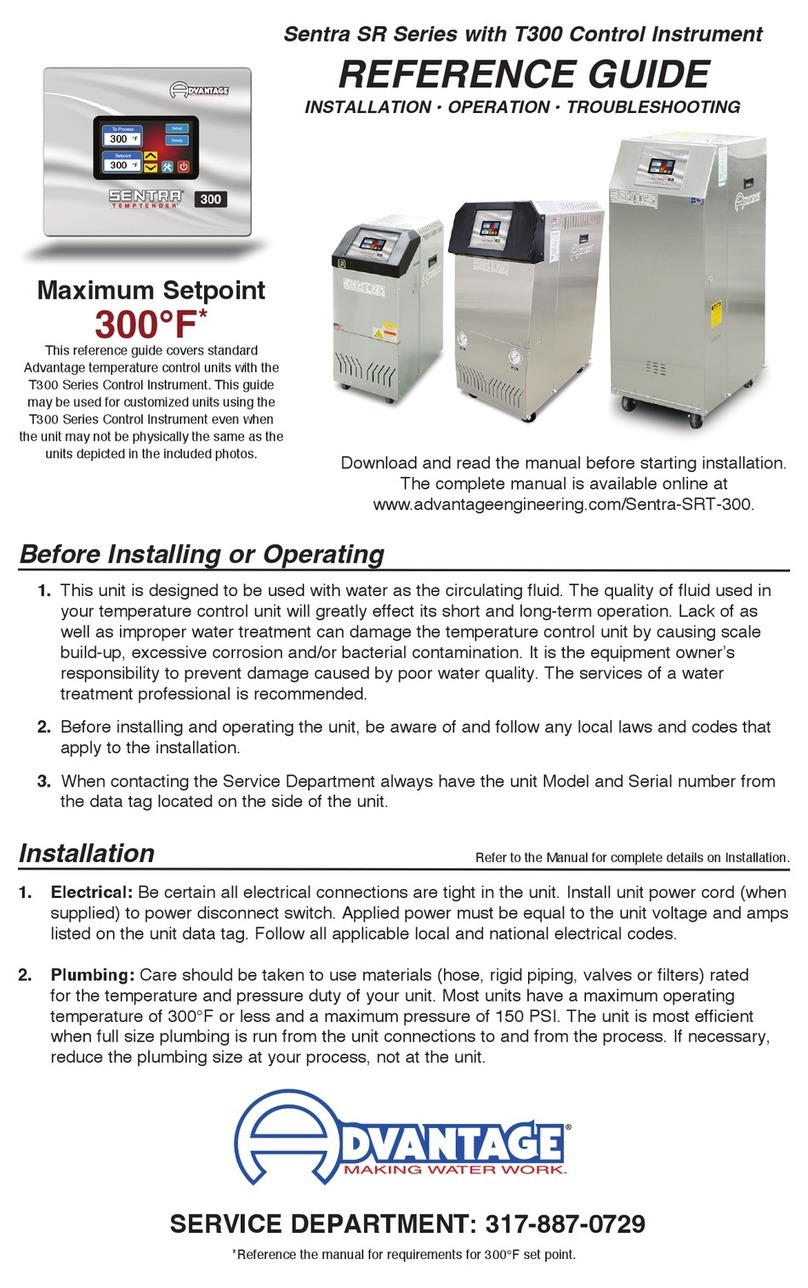

Installation

1. Electrical: Be certain all electrical connections are tight in

the unit. Install unit power cord (when supplied) to power

disconnect switch. Applied power must be equal to the unit

voltage and amps listed on the unit data tag. Follow all

applicable local and national electrical codes.

2. Plumbing: Care should be taken to use materials (hose,

rigid piping, valves or filters) rated for the temperature and

pressure duty of your unit. Most units have a maximum

operating temperature of 300°F or less and a maximum

pressure of 150 PSI. The unit is most efficient when full

size plumbing is run from the unit connections to and from

the process. If necessary, reduce the plumbing size at your

process, not at the unit.

3. Connect the unit’s To Process port to the Water In port on

the process manifold.

4. Connect the unit’s From Process port to the Water Out port

on the process manifold.

5. Note: Circuitry should avoid an excessive use of elbows

and/or lengths of pipe or hose. If hose is the material of

choice, avoid tight twists or curls and excessive lengths.

6. Valves and lters may be installed in the process water

piping circuitry to facilitate service and maintenance,

provided that such devices maintain the full inside diameter

of the process connection. If installed, all such devices must

be open and clean during unit operation.

7. Connect Unit drain to plant’s open drain, tower water

system return or chilled water system return. The factory

recommends a minimum of 20 psi pressure differential

between the water supply and drain line. A larger differential

may be required for larger cooling needs.

8. Connect Unit water supply to plant’s city water or well

water source or tower water supply or chilled water supply.

Water supply pressure requirements vary with operating

temperatures as shown in the chart below.

WARNING: proper care should be employed when checking pump rotation as

power is applied to the unit at this point.

Drain

To Process

From Process

Water Supply

Starting Unit

1. Fill unit with water. Apply power. The Standby screen will illuminate. When Standby is displayed,

the unit is not running.

• Status : Ready. Indicates the unit is ready to start.

• Status : Not Ready. Indicates the presence of a sensor probe,

pressure switch or motor overload fault. See the troubleshooting and

maintenance portions of the manual for Information. The fault must be

corrected in order to continue operation of the unit.

2. Determine the pump is rotating in a clockwise direction when viewed

from the rear of the motor. Instructions are in the operations manual.