56

The air outlet must not be connected to chimney flues or combustion

gas ducts. The air outlet must under no circumstances be connected

to ventilation ducts for rooms in which fuel-burning appliances are

installed.

The air outlet installation must comply with the regulations laid down

by the relevant authorities.

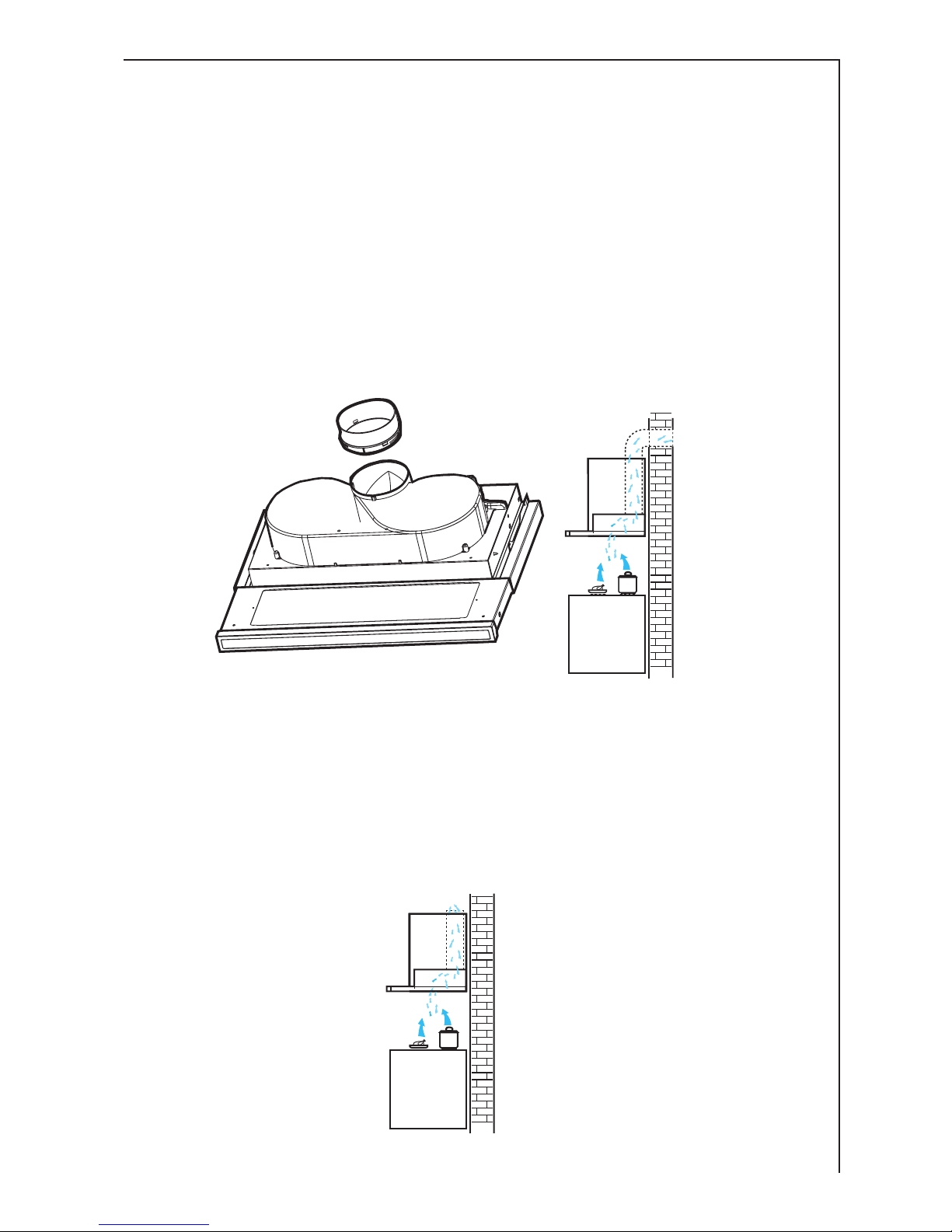

When the unit is used in its extractor version, a sufficiently large

ventilation hole must be provided, with dimensions that are

approximately the same as the outlet hole.

National and regional building regulations impose a number of

restrictions on using hoods and fuel-burning appliances connected to

a chimney, such as coal or oil room-heaters and gas fires, in the

same room.

Hoods can only be used safely with appliances connected to a

chimney if the room and/or flat (air/environment combination) is

ventilated from outside using a suitable ventilation hole approximately

500-600 cm2 large to avoid the possibility of a depression being

created during operation of the hood.

If you have any doubts, contact the relevant controlling authority or

building inspectors office.

Since the rule for rooms with fuel burning appliances is outlet hole of

the same size as the ventilation hole, a hole of 500-600 cm2, which

is to say a larger hole, could reduce the performance of the extractor

hood.

If the hood is used in its recirculation function, it will operate simply

and safely in the above conditions without the need for any of the

aforementioned measures.

When the hood is used in its extractor function, the following rules

must be followed to obtain optimal operation:

short and straight outlet hose

keep bends in outlet hose to a minimum

never install the hoses with an acute angle, they must

always follow a gentle curve only

keep the hose as large as possible (preferably the same diameter

as the outlet hole).

Failure to observe these basic instructions will drastically reduce the

performance and increase the noise levels of the extractor hood.