AEM Lambrecht Meteo u[sonic]WS7 User manual

Manual

Weather Sensor u[sonic]WS7

(16480) u[sonic]WS7 Manual

Advantages at a Glance

■Extremely robust, compact weather sensor with high-

quality, pollutant-resistant housing made of anodized

aluminium

■Ideal for use in extreme environmental conditions, e.g.

deserts, tropics, high mountains

■Version with integrated heating system for year-round

icing-free operation

■Lamella shelter for accurate measurements of the

temperature-humidity sensors

■ASCII data protocol according to NMEA 0183

■Power supply 6...60 VDC with integrated overvoltage

protection

■Storage, evaluation and display of the measured values

using the “MeteoWare CS” evaluation software

■Easy, space-saving mounting on 50 mm standard pipe

The Perfect Weather Sensor

■For industrial use as well as under extreme environmen-

tal conditions

■6+1 parameters in one and at the same time

Wind direction

Wind speed

Air temperature

Air humidity

Barometric pressure

Global radiation

Dew point temperature (calculated value)

■With independent, integrated sensors for high accura-

cies of each individual parameter

■Without movable measuring elements, i. e. no abrasion,

low maintenance and very easy to service

Applications

•Land applications under any conditions

•Wind turbines

• Railway line monitoring

• Trac meteorology

• Weather services and Oces for the Environment

• Chemical and industrial facilities

• Power plants, sewage plants and landlls

1

Manual

Weather Sensor u[sonic]WS7

(16480) u[sonic]WS7 Manual

Contents

1 Introduction 3

1.1 Warranty 3

2 Setting to work 3

2.1 Installation conditions 3

2.1.1 Generally 3

2.2 Tools and installation aids 4

2.3 Unpacking the sensor 4

2.4 Goods inspection 4

2.5 Power supply 4

2.6 Installation procedure (short instruction) 4

2.7 Mounting 4

2.7.1 North alignment of wind sensor 4

2.7.2 Power and signal connection 5

2.7.3 Safety regulations 5

3 Maintenance 5

3.1 Regular maintenance and calibration 5

3.2 Visual check and cleaning 5

4 Transports 5

5 Dimensional drawings and electrical connections u[sonic]WS7 6

6 Data protocols u[sonic]WS7 7

7 Modbus data protocols u[sonic]WS7 8

7.1 General 8

7.2 Data encoding 8

7.3 Standard conguration - default 8

7.4 Available Modbus commands 8

7.5 Instantaneous values / realtime values (Input Register) 9

7.6 Period data - Average, maximum and minimum (Input Register) 9

7.7 Descriptive sensor parameter registers (Holding Register) 10

7.8 Sensor parameters / conguration-parameters 11

7.9 Autoconguration 11

8 SDI-12 Interface 12

9 Technical data 17

10 Disposal 17

2

Manual

Weather Sensor u[sonic]WS7

(16480) u[sonic]WS7 Manual

1 Introduction

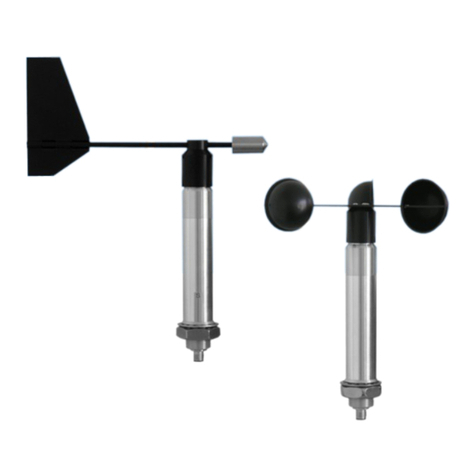

The sensors of the u[sonic] family are very robust, compact

and extremely reliable.

The sensors embody the experience of more than 150 years

of development and production of LAMBRECHT wind sensors.

The system acquires the horizontal air ow and processes

the measuring data to the meteorological parameters wind

speed and wind direction. Furthermore the weather-module

of the u[sonic]WS7 acquires the meteorological parameters

air temperature, relative humidity, barometric pressure and

global radiation. Based on the measured data u[sonic]WS7

calculates the dew point temperature and provides for its serial

output along with the measuring data.

The sensors and further system components are mounted in

a splash water- and dust proof metal housing.

The measuring data are automatically transmitted via se-

rial interface RS-485 in talker mode, when power supply is

switched on.

Due to their shock- and vibration proof construction the sen-

sor u[sonic]WS7 is particularly qualied for use under severe

environmental conditions. The housing is made of anodised

seawater resistant aluminium.

An electronically controlled heating device enables the sen-

sor to operate in between the wide range of -40 up to 70 °C.

1.1 Warranty

Please note the loss of warranty and non-liability by unau-

thorised manipulation of the system. You need a written

permission of the LAMBRECHT meteo GmbH for changes

of system components. These activities must be operated

by a qualied technician.

The warranty does not cover:

1. Mechanical damages caused by external impacts (e. g.

icefall, rockfall, vandalism).

2. Impacts or damages caused by over-voltages or elec-

tromagnetic elds which are beyond the standards and

specications in the technical data.

3. Damages caused by improper handling, e. g. by wrong

tools, incorrect installation, incorrect electrical installation

(false polarity) etc.

4. Damages which are caused by using the device beyond

the specied operation conditions.

Static measuring principle for wind measurements means:

• Determination of data works without moving measuring

elements, i.e. none abrasion, least maintenance and none

recalibration because of this method.

• The wind parameter can be measured also in winter time

accurate and precise, because of the electronic controlled

heating for the immovable measuring elements. This

heating is particularly eective against ice and snow in all

climatic zones.

• The measuring principle allows very low starting values

and high repeat accuracy.

• The sensor rapidly can be installed. Due to the special

measuring principle minor changes from the angle of pitch

can be disregarded.

Advantages of the sensor:

• Apart from the sensors for wind speed and direction the

compact housing also contains built-in sensors for air

temperature, relative humidity, barometric pressure and

global radiation.

• The built-in test function of the station, enabled by the

tight integration of the meteorological sensors into the

enclosure, can perform cyclic self-testing and notify the

user of erroneous data or failure.

• The compact design of this sensor with 7 meteorological

parameters is eliminating the traditional cabling and instal-

lation work signicantly. Distribution boxes, power supply

units and other accessories can be reduced to a minimum

expense.

2 Setting to work

Wind can be represented by a vector quantity. For a complete

description of the wind it is necessary to specify its speed

and direction. The two components are subject to spatial and

temporal variations; thus, strictly speaking, they are valid only

for the site where the measuring instrument is installed. We

therefore recommend selecting the place of installation very

carefully.

2.1 Installation conditions

2.1.1 Generally

For professional wind measurements according to meteoro-

logical standards (e. g. VDI 3786, Part 2) location and height

of the wind sensor are important for representative and ac-

curate results. Generally, wind measuring instruments should

not measure the specic wind conditions of a limited area,

but indicate the typical wind conditions of a wider area. To

obtain results which are representative for a wider area and

comparable to values measured at dierent places, the sen-

sor must not be mounted under the lee of higher obstacles.

The distance to any obstacle should be at least 10 times the

obstacle‘s height (corresponding to the denition of an undis-

turbed area). In general a measuring height of 10 m above

ground is regarded ideal.

If an undisturbed terrain of this kind does not exist the sen-

sor have to be put up at an height of at least 6 m above the

obstacle height.

If the above mentioned requirements are not feasible e. g. on

mobile measurements at vehicles or at measuring containers

compromises have to be found and documented.

If the sensor must be installed on a roof top the place of instal-

lation must be in the middle of the roof to avoid predominant

wind directions.

3

Manual

Weather Sensor u[sonic]WS7

(16480) u[sonic]WS7 Manual

2.7 Mounting

The sensor can be installed on a standard pipe with an outer

diameter of 50 mm and an inner diameter of maximum 40 mm.

Before tightening the two M8x12 grub screws and attaching

the sensor you have to draw the cable through the pipe and

align the sensor into driving direction.

For this purpose the housing is marked accordingly (see

drawing). Before the screws of the sensor are tightened, the

sensor is adjusted to north.

Use only the supplied fixing screws and do not

tighten the north screw tightly. Please pay attention

to a rm mounting of the sensor at the mast!

2.7.1 North alignment of wind sensor

For wind direction measurements the north mark on the sen-

sor must be aligned with the geographical north direction.

To adjust the wind sensor in a rm and correct manner into

the north direction this item is equipped with an integrated

mounting aid. Inside the inner bottom of the sensor a small bolt

pointing to the north is integrated to be set into a correspond-

ing slot of the mounting pipe (if available). Thus the sensor is

safely attached. If needed you can turn in or unscrew the pin

by means of in-hex wrench.

To set up the sensor’s north orientation select a landmark

which is as far as possible up north with regard to the nal

position of the wind direction sensor.

The reference point can be selected using a topographical

map (1:25000). The exact position of the reference point is

determined using an amplitude compass that can be adjusted

horizontally on a stand.

Compass declination has to be considered!

To align the sensor ahead (on ships) locate a point outside

the ship in the landscape which is located in the ship ahead

direction respectively in the centre line or in case of the sen-

sor is mounted far away from the middle line a line parallel

to the centre line.

Once the sensor is adjusted, it can be xed with the two grup

screws. Finally the earth screw has to be connected to the

ship’s ground. Acid-free contact grease is recommended to

protect contact surfaces against corrosion.

Note: Follow all safety instructions while setting up

the sensor onto a mast.

The place of installation should not be in the

operation elds of radar devices (radar scanners

or radar transmitters), generators or antennas. We

recommend a minimum distance of 2 m to these

installations. Furthermore a minimum distance of

5 m to MF-/ HF- and Satcom- (e. g. Inmatsat, VSat)

antennas has to be kept. The maximum electric eld

intensity may not exceed 10 V/m (tested according to

EMC standard). When indicated a greater distance

should be kept.

To avoid possible measurement errors due to heat sources as

hot or warm fumes, hot surfaces etc. next to the sensor, the

mounting site should be chosen accordingly.

2.2 Tools and installation aids

There are no special tools or materials required for the instal-

lation works. All work can be carried out with commercially

available tools such as screwdrivers and in-hex wrenches.

2.3 Unpacking the sensor

The sensor is packed in a separate box, carefully protected

against mechanical inuences during transport.

Please verify that the following parts and documents are

enclosed:

· 1 sensor u[sonic]WS7

· 1 operating manual

Accessories: (depend on order size, in all cases separately

packed)

Connecting cable with plug and core cable ends

2.4 Goods inspection

Please thoroughly check the delivery with regard to complete-

ness and eventual transport damages. In case of eventual

claims please contact us in writing immediately.

2.5 Power supply

The u[sonic]WS7 has a supply voltage range of 6...60 VDC.

The sensor heater is supplied with 24 VDC and can be factory

congured to 60 W, 120 W or 200 W. 200 W assuming the

default setting.

2.6 Installation procedure (short instruction)

The installation of the sensor involves 3 steps:

(1) Mounting the cable at the sensor and if necessary

draw the cable through the mast.

(2) Mounting the sensor at the mast, but before

tightening the screws you must align the sensor to

the north.

(3) Attaching the cable to the power supply and the

signal acquisition system.

4

Manual

Weather Sensor u[sonic]WS7

(16480) u[sonic]WS7 Manual

2.7.2 Power and signal connection

The u[sonic]WS7 sensor requires a 8-pole M16 plug connec-

tor. The cable shield should be connected with both ends at

the ground wire (PE).

To reduce the risk of inductive interference the sensor

must be properly grounded (screening on both sides).

The external connection is via central connector which is

located in housing base. For further details about electrical

connection please see chapter „Connecting diagrams“.

If the sensor is mounted in correct manner and connected

with the right cable (accessory), you can attach the wires to

power supply and signal outputs to data acquisition equipment

(computer).

The typical power supply requirements of the u[sonic]WS7

sensor are 24 Volts with a maximum current drain of 50 mA.

The input range is max. 6... 60 VDC.

The heating of the u[sonic]WS7 is supplied with 24 VDC. When

the heating is activated, the current consumption increases to

a maximum of 10 A.

The output signal of the sensor corresponds to the RS-485

standard in talker mode, whereby only the transmit lines

(TX) are used. The line drivers are capable of transmitting

data over cable lengths up to 1,220 meters (4,000 feet). This

maximum distance will vary depending upon the ope-rational

environment, the wire gauge used, and the baud- rate of the

attached devices.

When the power supply of the sensor is switched on, after

5 seconds the sensor cyclically starts sending data protocols.

2.7.3 Safety regulations

Because the wind sensor often is mounted on ex-

posed locations in dangerous heights the installation

personnel has to pay attention to the relevant safety

regulations for such works. During the electrical

installation and termination works the external circuit-

breaker must be switched o. It is not permitted to

open those housings by unauthorized persons!

3 Maintenance

3.1 Regular maintenance and calibration

The sensor u[sonic]WS7 is service reduced and designed for

a very long lifetime. Recommended is a regular visual check

regarding dirt of surface caused by the weather and if so, to

clean up. The radiation sensor glass dome should be cleaned

with a soft towel at least every 2 weeks. For stubborn stains,

the glass dome can be handled with soapy water or alcohol.

If reference measurements should be necessary

stringently must be noted that a comparability of the

measured values is given only if the measurements

take place under same conditions. I.e. the reference

equipment must be used very close to the sensor!

The sensor is a measuring instrument and thus apply user

specic standards regarding period of recalibration.

Recommendation: 2 years.

3.2 Visual check and cleaning

The use of the sensor under the respective environmental

conditions requires certain steps. It is thus recommendable

to clean the outside of the housing and shelter within specic

intervals. The intervals are dependant on the environmental

conditions and the degree of soiling. We recommend a regular

sight and functional check.

In case you should be faced with any specic problems please

contact the LAMBRECHT meteo service under:

Tel.: +49-(0)551-4958-0

E-Mail: [email protected]

4 Transports

In case it is necessary to ship or to transport the sensor must

be carefully packed to prevent damages during transport.

5

Manual

Weather Sensor u[sonic]WS7

(16480) u[sonic]WS7 Manual

5 Dimensional drawings and electrical connections u[sonic]WS7

6

WeitergabesowieVervielfältigungdieserUnterlage,VerwertungundMitteilungihresInhaltsnicht

gestattet,sowienichtausdücklichzugestanden.ZuwiderhandlungverpflichtenzuSchadensersatz.

AlleRechtefürdenFallderPatenterteilungoderGebrauchsmuster-Eintragungvorbehalten.

Passingonandduplicationofthisdocument,utilizationandcommunicationof

it'scontentsprohibitedunlessdefinitelypermitted.Infringementisboundto

compensation.Allrightsreservedforpatentorregisteredpattern.

Maße ohne Toleranzangabe nach

Zust. Änderungen Datum Name Dateiname Ersatz für:

Blatt

Bl

Maßstab

Material

Bearb.

Gepr.

Datum Name

Artikelnummer

DIN ISO 2768-m

Benennung

80.16480.001000.idw

1 / 1

23.09.2019 kreitz

80.16480.001000

Oberfläche

Ultraschall Multiparameter-Sensor

WTHPS

1

A4

Norm.

Revision

A

51Ø

40

79

Male side pin assignment

Pin Pin assignment

RS 485

Pin assignment

SDI-12

Cable color

32.16470.060000

1n.c. n.c. black

2 Data - SDI-12 Data brown

3

Heating

Control

(configurable)

Heating

Control

(configurable)

red

4n.c. n.c. orange

5 Data + SDI-12 GND yellow

6n.c. n.c. green

7+ 24V AC/DC

nominal

+ 24V AC/DC

nominal blue

8- 24V AC/DC

nominal

- 24V AC/DC

nominal violet

Stecker Pinbelegung

Pin Pinbelegung RS

485

Pinbelegung

SDI-12

Kabelfarbe

32.16470.060000

1n.c. n.c. schwarz

2 Data - SDI-12 Data braun

3

Heizungs-Steuer

ung

(konfigurierbar)

Heizungs-Steue

rung

(konfigurierbar)

rot

4n.c. n.c. orange

5 Data + SDI-12 GND gelb

6n.c. n.c. grün

7+ 24V AC/DC

nominal

+ 24V AC/DC

nominal blau

8- 24V AC/DC

nominal

- 24V AC/DC

nominal lila

286,3

199

APIN 3 Heizung 26.07.2022 Curdt

Manual

Weather Sensor u[sonic]WS7

(16480) u[sonic]WS7 Manual

6 Data protocols u[sonic]WS7

NMEA Communication parameters

Baudrate: 4800 Baud

Data Bits: 8

Parity Bit: None (none)

Stop Bits: 1 (or more)

Handshake: without

Wind direction and wind speed

Example of data sequence with comma separated

elds: $WIMWV,357.0,R,5.2,M,A*CS<CR><LF>

eld delimiter: , (comma)

header: $WIMWV

wind direction: 0.0...360.0

R: relative wind direction

wind speed: 0.1...85.0

M metric units m/s

status A (valid) / V (not valid)

stop delimiters: <CR><LF>

error code: WD 999.9

error code: WS 999.9

Message string WIMTA air temperature

Example of data sequence with comma separated

elds: $WIMTA,-25.0,C*CS<CR><LF>

eld delimiter: , (comma)

header: $WIMTA

temperature: -40.0...+70.0

C: °C

stop limiters: <CR><LF>

error code: 999.9

Message string WIMHU relative humidity

Example of data sequence with comma separated

elds: $WIMHU,100.0,,-40.0,C*CS<CR><LF>

eld delimiter: , (comma)

header: $WIMHU

rel. humidity: 000.0...100.0

dew point temp.: -40.0...+70.0

C: °C

stop limiters: <CR><LF>

error code: 999.9

Message string WIMMB barometric pressure

Example of data sequence with comma separated

elds: $WIMMB,,,1050.0,B*CS<CR><LF>

eld delimiter: , (comma)

header: $WIMMB

barometric pressure: 600.0...1100.0

B: air pressure in hPa

stop limiters: <CR><LF>

error code: 9999.9

Global radiation

Example of data sequence with comma separated

elds: $WIXDR,,,500.0,W,01*CS<CR><LF>

eld delimiter: , (comma)

header: $WIXDR

global radiation: 0.0...1600.0

W: global radiation in W/m²

stop limiters: <CR><LF>

error code: 9999.9

Important! Please note:

Field length

The development of a NMEA decoder should not be pro-

ceeded from rm eld lengths. The NMEA denition proceeds

from a variable eld length. The comma character (“,”) serves

as eld disconnecting switch. Numeric values in a eld can be

presented dierently. In case a eld is not sent, it has a length

of 0 characters (,,) [comma-comma].

Check sum

The check sum “CS” is covered to two ASCII characters

hexadecimal value. “CS” calculated by XOR operation of each

character in the sentence between “$” and “*”, but excluding

“$” and “*”.

Error code

In case, that the sensor cannot generate a measuring value

because e.g. a sensor element is defect or implausible (raw)

values are collected the sensor outputs in the corresponding

data protocol the above mentioned error code (e.g. 999.9) and

sets the status from “A” (valid) to “V” (not valid).

Example: $WIMWV,999.9,R,999.9,M,V*37<CR><LF>

Particular characteristics wind direction value

Theoretically the value for the wind direction can take any

value between 0.0° and 360.0°. It should be noted, that in

a full circle the values “0.0” and “360.0” are describing the

same direction. According to the international valid recom-

mendations of the WMO (World Meteorological Organization)

in the “Guide to Meteorological Instruments and Methods of

Observation” (WMO-No.8) the wind direction value 0.0° just

has to be output at calm. The u[sonic]WS7 follows the recom-

mendation of the WMO and outputs at wind from the north the

value “360.0” respectively “0.0” at calm (lull).

7

Manual

Weather Sensor u[sonic]WS7

(16480) u[sonic]WS7 Manual

7 Modbus data protocols u[sonic]WS7

This manual covers the general Modbus specication common to all Modbus sensors from LAMBRECHT meteo. The manual

allows easy operation of all LAMBRECHT meteo Modbus sensors. Some sensors of the Modbus family oer additional regis-

ters and functions, which are described in separate documents via the registers and functions described here. The registers

and functions described in this manual are sucient for general operation of Modbus sensors in a weather station or PLC.

7.1 General

The Lambrecht meteo Modbus sensors follow the specication of the Modbus organization: “MODBUS APPLICATION PRO-

TOCOL SPECIFICATION V1.1b3”.

(See www.modbus.org).

7.2 Data encoding

MODBUS uses the “Big-Endian” format for addresses and data. This means that if a value is transmitted with a number format

which is larger than a single byte, that the “most signicant byte” is sent rst.

Example Big-Endian:

Register size value 16 - bits

0x1234 is transmitted in the sequence: 0x12 0x34.

To obtain the real measuring value, divide the received register value by the divisor (provided in 6.5, 6.6).

Values of -9999 indicate an internal sensor error.

7.3 Standard conguration - default

Baud rate: 19200 Baud

Byte frame according: 8E1 (1 start bit, 8 data bits, 1 parity bit (even parity), 1 stop bit)

RTU Sensor address: 13

Default addresses of the LAMBRECHT sensors:

Address Sensor

1 Wind speed

2 Wind direction

3 Precipitation rain[e]

4 THP

5 EOLOS IND · u[sonic]WS6

6 com[b]

7 PREOS

8 ARCO

9 u[sonic]

10 Pyranometer 2nd Class

11 Secondary standard Pyranometer

12 PT100 to Modbus converter (temperature)

13 u[sonic]WS7

7.4 Available Modbus commands

The LAMBRECHT Modbus sensors support the following commands:

• “Read Holding Register” command: 0x03 (descriptive sensor data registers)

• “Read Input Register” command: 0x04 (measured values registers)

(every measured value is to be requested individually)

• “Write Multiple Register” command: 0x10 (Write to conguration registers)

8

Manual

Weather Sensor u[sonic]WS7

(16480) u[sonic]WS7 Manual

7.5 Instantaneous values / realtime values (Input Register)

The following measured values are provided by LAMBRECHT meteo sensors.

Register address Parameter name Unit Divisor Quantity of registers Access type

30001 Wind speed m/s 10 1 Read only

30201 Wind direction ° 10 1 Read only

30401 Air temperature °C 10 1 Read only

30601 Relative humidity %r.h. 10 1 Read only

30701 Dew point °C 10 1 Read only

30801 Air pressure hPa 10 1 Read only

31401 Global radiation W/m² 10 1 Read only

Example: Retrieve wind speed

0D 04 75 31 00 01 7A C5 0D 04 02 00 1F E8 F9

LEN

6

Transmission

Query =>

Source

Master

Dest

Slave 13

Function

Read Input Register (4)

Func Desk

Address=30001, Quantity of Register=1

Checksum

OK:C57A

LEN

5

Transmission

Response <=

Source

Slave 13

Dest

Master

Function

Read Input Register (4)

Func Desk

Byte count=2

Data

00 1F

Checksum

OK:F9E8

7.6 Period data - Average, maximum and minimum (Input Register)

Register Parameter name Unit Divisor Quantity of registers Access type

30002 Wind speed average m/s 10 1 Read only

30003 Wind speed maximum m/s 10 1 Read only

30004 Wind speed minimum m/s 10 1 Read only

30202 Wind direction average ° 10 1 Read only

30203 Wind direction maximum ° 10 1 Read only

30204 Wind direction minimum ° 10 1 Read only

30402 Air temperature average °C 10 1 Read only

30403 Air temperature maximum °C 10 1 Read only

30404 Air temperature minimum °C 10 1 Read only

30602 Relative humidity average % r.h. 10 1 Read only

30603 Relative humidity maximum % r.h. 10 1 Read only

30604 Relative humidity minimum % r.h. 10 1 Read only

30702 Dew point average °C 10 1 Read only

30703 Dew point maximum °C 10 1 Read only

30704 Dew point minimum °C 10 1 Read only

30802 Air pressure average hPa 10 1 Read only

30803 Air pressure maximum hPa 10 1 Read only

30804 Air pressure minimum hPa 10 1 Read only

31402 Global radiation average W/m² 10 1 Read only

31403 Global radiation maximum W/m² 10 1 Read only

31404 Global radiation minimum W/m² 10 1 Read only

The data are valid for the period between the current request and the previous request. The maximum range of a period is

1 hour. Recalling the average value of a minimum, maximum and average group will erase the appropriate registers.

Retrieve the values of a group in the sequence minimum, maximum, average.

Use command: 0x03

9

Manual

Weather Sensor u[sonic]WS7

(16480) u[sonic]WS7 Manual

Example: Retrieve wind speed (min. max. avr.) and erase the register content

01 04 75 34 00 01 6A 08 01 04 02 00 00 B9 30 01

04 75 33 00 01 DB C9 01 04 02 00 D6 38 AE 01 04

75 32 00 01 8A 09 01 04 02 00 14 B9 3F

LEN

6

Transmission

Query =>

Source

Master

Dest

Slave 1

Function

Read Input Register (4)

Func Desk

Address=30004, Quantity of Register=1

Checksum

OK:86A

LEN

5

Transmission

Response <=

Source

Slave 1

Dest

Master

Function

Read Input Register (4)

Func Desk

Byte count=2

Data

00 00

Checksum

OK:30B9

LEN

6

Transmission

Query =>

Source

Master

Dest

Slave 1

Function

Read Input Register (4)

Func Desk

Address=30003, Quantity of Register=1

Checksum

OK:C9DB

LEN

5

Transmission

Response <=

Source

Slave 1

Dest

Master

Function

Read Input Register (4)

Func Desk

Byte count=2

Data

00 D6

Checksum

OK:AE38

LEN

6

Transmission

Query =>

Source

Master

Dest

Slave 1

Function

Read Input Register (4)

Func Desk

Address=30002, Quantity of Register=1

Checksum

OK:98A

LEN

5

Transmission

Response <=

Source

Slave 1

Dest

Master

Function

Read Input Register (4)

Func Desk

Byte count=2

Data

00 14

Checksum

OK:3FB9

7.7 Descriptive sensor parameter registers (Holding Register)

Register Parameter name Quantity of registers Remark Access type

40050 Device identication number

(15 characters)

8 (2 characters in each

register)

The returned data are

in form of a 16 byte null

terminated string

Read only

40100 Serial number

(11 characters)

6 (2 characters in each

register)

The returned data are

in form of a 12 byte null

terminated string

Read only

40150 Firmware version

(up to 25 characters)

13 (2 characters in each

register)

The returned data are

in form of a 26 byte null

terminated string

Read only

Example: Retrieve the device identication number

(The identication number shown in the example is sensor-dependent. It is only used here for demonstration purposes).

0D 03 9C 72 00 08 CA 8B 0D 03 10 30 30 2E 31 36

00.16480.000130

34 38 30 2E 30 30 31 31 33 30 00 E8 6B

LEN

6

Transmission

Query =>

Source

Master

Dest

Slave 13

Function

Read Holding Register (3)

Func Desk

Address=40050, Quantity of Register=8

Checksum

OK:8BCA

LEN

19

Transmission

Response <=

Source

Slave 13

Dest

Master

Function

Read Holding Register (3)

Func Desk

Byte count=16

Data

30 30 2E 31 36 34 38 30 2E 30 30 31 31 33 30 00

Checksum

OK:6BE8

10

Manual

Weather Sensor u[sonic]WS7

(16480) u[sonic]WS7 Manual

7.8 Sensor parameters / conguration-parameters

Register Parameter name Allowed values Quantity of registers Access type

40001 Modbus device address 1 Write only

40200 Baud rate 96 = 9600

192 = 19200

384 = 38400

1 Write only

40201 Parity 1 = even

0 = none

1 Write only

The device must be restarted after each change of a setting!

Example: Change the RTU address from 13 to 1

0D 10 9C 41 00 01 02 00 01 61 88 0D 10 9C 41 00

01 7F 41

LEN

9

Transmission

Query =>

Source

Master

Dest

Slave 13

Function

Write Multiple Register (16)

Func Desk

Address=40001, Quantity=1

Byte count

2

Register values

00 01

Checksum

OK:8861

LEN

6

Transmission

Response <=

Source

Slave 13

Dest

Master

Function

Write Multiple Register (16)

Func Desk

Address=40001, Quantity=1

Checksum

OK:417F

7.9 Autoconguration

All Lambrecht Modbus sensors oer the experienced user the possibility to implement an auto-conguration in his Modbus

master based on additional information stored in the sensor.

The necessary information can be found in the document “Lambrecht_Modbus_Autoconguration”.

11

Manual

Weather Sensor u[sonic]WS7

(16480) u[sonic]WS7 Manual

8 SDI-12 Interface

SDI-12 has to be precongured ex works.

Please specify when ordering: Id-No. 97.16470.000002 Conguration SDI-12

The communication using SDI-12 protocol via SDI-12 interface is based on the ‘SDI-12 A Serial-Digital Interface Standard for

Microprocessor-Based Sensors, Version 1.4, 2017’. The u[sonic] can be used in bus mode parallel to other u[sonic].

The following subset of SDI-12 commands were implemented into the u[sonic].

For more information on the SDI-12 protocol, please refer to the standard documentation mentioned above or the website

www.SDI-12.org.

Implemented SDI-12 commands:

Command Function Answer of the sensor

a! Acknowledge Active a<CR><LF>

aI! Send Identication allccccccccmmmmmmvvvxx...xx<CR><LF>

aAb! Change Address b<CR><LF>

aC! Start Concurrent Measurement atttnn<CR><LF>

aCC! Start Concurrent Measurement and Re-

quest CRC checksum

atttnn<CR><LF>

aD0! Send Data (Buer 0) a<data<CR><LF>

a<data><CRC><CR><LF>

aV! Start Verication atttn<CR><LF>

aX! Resetting the Addresses a<CR><LF>

a = address of the respective sensor;

Standard sensor address = 0

SDI-12 commands always start with the address of the appropriate sensor. Therefore all other sensors on the same bus will

ignore these commands. SDI-12 commands end with ‘!’. All answers from sensors start with its address, too, but end with the

ASCII characters ‘Carriage Return’ <CR> and ‘Line Feed’ <LF>.

The SDI-12 protocol is based on the ASCII character set. The baud rate of the SDI-12 protocol is 1200 Bd and has the byte

frame format:

1 start bit

7 data bits (least signicant bit transmitted rst)

1 parity bit (even parity)

1 stop bit

Acknowledge Active - a!

This command ensures that the sensor responds to requests. Basically it asks the sensor to conrm that it is connected to

the bus.

The sensor returns its address and <CR><LF>.

Syntax

Command Answer

a! a<CR><LF>

a– Sensor address a– Sensor address

!– End of command <CR><LF> – End of answer

12

Manual

Weather Sensor u[sonic]WS7

(16480) u[sonic]WS7 Manual

Example:

Command Answer

0! 0<CR><LF>

1! 1<CR><LF>

Send Identication - aI!

The command aI! is used to ask the sensor for its model number and rmware version.

Syntax

Command Answer

aI! a14LMGmbH151647011.1<CR><LF>

a– Sensor address a– Sensor address

I – Command "Send Identication"

a14LMGmbH151647011.1

14 – 2 characters SDI-12 version-No. 14 = version 1.4

LMGmbH15 – 8 characters manufacturer’s

(= Lambrecht meteo GmbH)

164701 – 6 characters sensor type

1.1 – Firmware version

!– End of command <CR><LF> – End of answer

Example:

Command Answer

0I! 014LMGmbH1514582S1.1<CR><LF>

1I! 114LMGmbH1514582D1.1<CR><LF>

Change address - aAb!

The factory setting for the address is "0".

If there are several sensors connected to one bus, the sensor address can be changed with the command aAb!.

The address is always a single ASCII character. Standard for addresses are the ASCII characters "0" to "9" (decimal 48 to

57). If there are more than 10 sensors connected to one bus, using the characters "A" to "Z" (decimal 65 to 90) and "a" to "z"

(decimal 97 to 122) is allowed. The sensor answers with its new address and <CR><LF>.

After the address is changed, one should not send further commands to the sensor for a period of one second.

(See also "SDI-12 Standard, Version 1.4, 2017")

Syntax

Command Answer

aAb! b<CR><LF>

a– Old sensor address b– New sensor address

A – Command ‘Change Address’

b – New sensor address

! – End of command <CR><LF> – End of answer

13

Manual

Weather Sensor u[sonic]WS7

(16480) u[sonic]WS7 Manual

Example:

Command Answer

0A1! 1<CR><LF>

Start Concurrent Measurement - aC!

The "Concurrent Measurement" enables the data logger to measure simultaneously with multiple sensors on the same bus.

The "aC!" command requests the sensor to process the available measurement data and write them to an output string. Unlike

the standard sensors described in the SDI-12 documentation, the u[sonic] measures continuously. This is why the u[sonic] al-

ways responds with "a000". The data is therefore immediately available. This is also the reason why the u[sonic] does not send

a "service request" and ignores measurement interruption commands. The data can be retrieved with the command "aD0!" (see

below under "Send data"). The data is not overwritten until the next "C" or "M" command and can be retrieved several times.

Syntax

Command Answer

aC! a00004<CR><LF>

a– Sensor address a– Sensor address

C – Command ‘Start Concurrent Measurement’ 000 – Seconds the sensor needs until the

measured data can be returned

(= 0 s – Data immediately available)

4– Number of provided measured data

! – End of command <CR><LF> – end of answer

Example:

Command Answer

1C! 100004<CR><LF>

The measured data can be requested with the command aD0! (see "Send Data").

Start Concurrent Measurement and Request - CRC aCC!

Same command as "aC!" but in addition to the generated data the sensor returns a 3-digit checksum. For information on how

the CRC checksum gets generated, please consult ‘SDI-12 Standard Version 1.4, 2017, chapter 4.4.12’.

Syntax

Command Answer

aCC! a00004<CR><LF>

a– Sensor address a– Sensor address

C – Command ‘Start Concurrent Measurement’ 000 – Seconds the sensor needs until the

measured data can be returned with "CRC"

(= 0 s – Data immediately available)

C – Request for transmission of the CRC checksum 04 – Number of provided measured data

! – End of command <CR><LF> – End of answer

Example:

Command Answer

1CC! 100004<CR><LF>

14

Manual

Weather Sensor u[sonic]WS7

(16480) u[sonic]WS7 Manual

Send Data - aD0!

The data requested by the sensor with the commands "C" or "M" can be retrieved with the command "aD0!". The sensor

uses the corresponding signs ("+" or "-") as eld separators. If the data was requested with a "CC" or "MC" command, a CRC

checksum is also returned. For more information on how to generate this CRC checksum, see "SDI-12 Standard, Version 1.4,

2017, chapter 4.4.12".

After the measurement, the data is stored in the buer "D0" and retrieved with the command "aD0!".

Denition SDI-12 u[sonic]WS7

C! and CC!

No. Parameter Description Unit

D0! 1 wind speed instantaneous value m/s

2 wind speed minimum value m/s

3 wind speed maximum value m/s

4 wind speed average value m/s

5 wind direction instantaneous value deg

6 wind direction minimum value deg

7 wind direction maximum value deg

8 wind direction average value deg

D1! 9 temperature instantaneous value °C

10 temperature minimum value °C

11 temperature maximum value °C

12 temperature average value °C

13 humidity instantaneous value %

14 humidity minimum value %

15 humidity maximum value %

16 humidity average value %

D2! 17 dew point instantaneous value °C

18 dew point minimum value °C

19 dew point maximum value °C

20 dew point average value °C

21 air pressure instantaneous value mbar

22 air pressure minimum value mbar

23 air pressure maximum value mbar

24 air pressure average value mbar

25 global irradiance instantaneous value W/m2

26 global irradiance minimum value W/m2

27 global irradiance maximum value W/m2

28 global irradiance average value W/m2

D3! 29 acoustic virtual temperature instantaneous value °C

30 acoustic virtual temperature minimum value °C

31 acoustic virtual temperature maximum value °C

32 acoustic virtual temperature average value °C

D4! 33 status code 8 bit value

34 error code 8 bit value

Minimal, maximum and average value refer to the time since last C! or CC! command.

15

Manual

Weather Sensor u[sonic]WS7

(16480) u[sonic]WS7 Manual

Syntax for measurements with command "aC!" or "aM!"

Command Answer

aD0! a<values><CR><LF>

a– Sensor address a– Sensor address

D– Command ‘Send Data’ <values> – Requested data separated by

0 – Request for the data in buer 0 resp. sign ("+" or "-")

or

1 = buer 1

2 = buer 2

!– End of command <CR><LF> – End of answer

Example:

Command Answer

0C! 000004<CR><LF>

0D0! 0+0.1+0.1+0.1+0.1<CR><LF>

Syntax for measurements with command "aCC!" or "aMC!"

Command Answer

aD0! a<values><CRC><CR><LF>

a– Sensor address a– Sensor address

D– Command ‘Send Data’ <values> – Requested data separated by

0 – Request for the data in buer 0 resp sign ("+" or "-")

or

1 = buer 1 <CRC> – 3-digit CRC checksum

!– End of command <CR><LF> – End of answer

16

Manual

Weather Sensor u[sonic]WS7

(16480) u[sonic]WS7 Manual

Subject to change without notice.

Dimensions: H 284 mm; Ø 199 mm; mast adapter

Ø 50 mm for mounting on standard pipe

Housing: seawater resistent aluminium;

IP 66, IP 67

Weight: approx. 3.4 kg

Standards

• NMEA 0183

• Standard of construction: VDE 0100

• Low voltage guide line: 72/23 EWG

• EMC/ EMI: DIN EN 60945 and DIN EN 61000-4-2, 3, 4, 6, 11

• Salt fog: EN 60945

• Protection class: DIN EN 60529

Accessories: (please order separately)

32.16420.066100 Sensor cable, 15 m, 8 pole M16 plug

Options: (please order separately)

36.09340.000000 Visualization and evaluation software

MeteoWare-CS3

(except for global radiation)

00.95800.010000 Data logger met[LOG]

00.14742.401002 Display unit METEO-LCD/IND

(except for global radiation)

1 Temperature inuence of the shelter: accuracy +1.5 °C at v < 2 m/s and

intensive solar radiation

2 Temperature inuence of the shelter: ± < 0.1 % r.h. at +10…+40 °C

3 Shelter inaccuracy: < 4 % r.h. dependant on v > 2 m/s and solar radiation

10 Disposal

LAMBRECHT meteo GmbH is listed and registered at the

Stiftung Elektro-Altgeräte Register ear under:

WEEE-Reg.-No. DE 45445814

In the category of monitoring and control instruments, device

type: “Monitoring and control instruments for exclusively com-

mercial use”.

Within the EU

The device has to be disposed according

to the European Directives 2002/96/EC and

2003/108/EC (Waste Electrical and Elec-

tronic Equipment). Do not dispose the old

device in the household waste! For an

environmentally friendly recycling and dis-

posal of your old device, contact a certied

disposal company for electronic waste.

Outside the EU

Please follow the regulations in your country regarding the

appropriate disposal of waste electronic equipment.

9 Technical data

(16480) Weather Sensor u[sonic]WS7

ID 00.16480.001000

Range of application: -40...+70 °C (heated: -50...+70 °C);

0...100 % r. h.

Parameters:

Wind direction

Measuring principle: ultrasonic

Measuring range: 0...359.9°

Accuracy: < 2° (>1 m/s) RMSE

Resolution: 0.1°

Wind speed

Measuring principle: ultrasonic

Measuring range: 0...65 m/s

Accuracy: 0.2 m/s RMSE(v < 10 m/s)

2 % RMSE(10 m/s < v < 65 m/s)

Resolution: 0.1 m/s

Temperature

Measuring principle: digital temperature sensor

Measuring range: -40...+70 °C

Accuracy: 0.1 K (0...60 °C) 1)

0.2 K (-40...0 °C) 1)

Resolution: 0.1 °C

Relative humidity

Measuring principle: capacitive, digital

Measuring range: 0...100 % r. h.

Accuracy: 1.5 % (0...80 %) r. h. 2)3)

2 % (>80 %) r. h.

Resolution: 0.1 % r. h.

Barometric pressure

Measuring principle: piezoresistive

Measuring range: 300...1100 mbar

Accuracy: 0.5 mbar

Resolution: 0.1 mbar

Global radiation

Measuring principle: thermoelectric

Measuring range: 0...2000 W/m²; global radiation in the

range of 285...3000 nm

Accuracy: Second class

Resolution: 0.2 W/m²

Dew point temperature

Measuring principle: passive; calculated from air tempera-

ture and humidity

Measuring range: -40...+70 °C

Resolution: 0.1 °C

Trigger threshold: 0.1 m/s

Interface: RS 485 / 422; SDI-12 (optional)

Protocols: NMEA 0183 (default);

Modbus and SDI-12 (optional)

Measuring rate: 0.1...10 Hz

Supply voltage: 6...60 VDC

heating: 24 VAC/DC ± 20 %

Current consumption: sensor: typically 50 mA at 24 VDC

heating: max. 10 A at 24 VAC/DC

Heating data: factory congurable:

60 W / 120 W / 200 W (standard)

17

16480_WS7_b-de.indd 35.22

LAMBRECHT meteo GmbH Tel +49-(0)551-4958-0

Friedländer Weg 65-67 Fax +49-(0)551-4958-312

Germany Internet www.lambrecht.net

This manual suits for next models

2

Table of contents

Other AEM Accessories manuals