Hella C2 Setup guide

Installation Instructions and Instructions for Use

These instructions must be read

prior to installation

and use!

Cassette awning C2

Operating guidelines

Installation Instructions and Instructions for Use

Table of Contents

Preliminary remarks HELLA Cassette awning C2 ................................................................3

General notes.......................................................................................................................4

CE marking...........................................................................................................................5

Safety instructions ................................................................................................................6

Designated use ..................................................................................................................10

Servicing, maintenance and repair .....................................................................................11

Before installation...............................................................................................................18

Overview Cassette awning C2 ...........................................................................................19

Overview tensioning bracket types.....................................................................................20

Installation of wall / ceiling brackets....................................................................................23

Rafter bracket installation...................................................................................................27

Installation on concrete.......................................................................................................28

Installation on concrete up to 60 mm ETICS ......................................................................29

Installation on concrete 60-200 mm ETICS........................................................................30

Installation on brickwork .....................................................................................................31

Installation on brickwork 60-170 mm ETICS.......................................................................32

Installation on wood............................................................................................................33

Installation on wood 60-170 mm ETICS .............................................................................34

Installation of the awning....................................................................................................35

Adjusting the awning ..........................................................................................................41

Overview Linking Elements ................................................................................................49

Installation linked units .......................................................................................................50

Installation of linked awnings: Special Situation .................................................................57

Retrofitting of the Varioplus roller blind...............................................................................58

Installation of the Wall Connection Profile ..........................................................................60

Electric commissioning and overview table power .............................................................61

Activation guidelines for electric drives...............................................................................63

Wiring diagram for motors with switch operation ................................................................64

Wiring diagram for motors with Somfy io............................................................................65

Wiring diagram for motors with elero radio.........................................................................66

Wiring diagram for motors with ONYX.NODE ....................................................................67

Wiring diagram for motors with ONYX.CONNECTOR........................................................68

Commissioning/functional check ........................................................................................70

Adjustment - Somfy Eolis 3D radio-controlled wind sensor ................................................71

Adjustment - elero Protero 868 radio-controlled wind sensor.............................................71

Removal and Disposal........................................................................................................72

Handing over report (for the fitter) ......................................................................................73

Handing over report (for the user) ......................................................................................74

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 3

Preliminary remarks HELLA

Cassette awning C2

With this HELLA product you have opted for a high-quality product with a most up-to-date

technology that can nevertheless be easily installed and operated. In these instructions we

describe the basic installation, commissioning and use.

For authorized specialist staff

For the consumer (user)

The following symbols will assist you with the installation or use and require a safety-

conscious conduct:

Attention!

This symbol indicates instructions that, if disregarded, can put the user in

danger.

Attention!

This symbol indicates instructions that, if disregarded, can potentially result

in damage to the product.

This symbol indicates instructions for use or helpful information.

This symbol requires you to act.

Attention!

This symbol indicates a risk of injury or danger to life due to an electric

shock.

This symbol indicates parts of the product, for which you will find important

information in these installation instructions.

Installation Instructions and Instructions for Use

4 Subject to technical modifications – Date of issue January/2023

General notes

Questions

In case of questions concerning the installation or the use of your product, please consult

your authorized specialist shop.

Spare parts/repairs

Spare parts are available at your HELLA specialist shop. Only spare parts that are

approved by HELLA are allowed to be used.

Warranty/guarantee

Precondition for warranty and guarantee is a correct and regular maintenance of the sun

protection device (at least once a year).

Warranty claims are subject to statutory limitation periods. Service parts are excluded

from the warranty; the same applies for changes in color and changes in characteristics

caused by UV radiation.

Liability

In case of non-observance of the directions and information given in these instructions

and in case of improper operation or unintended use, the manufacturer shall not accept

any warranty claims concerning any damage to the product. In these cases, the liability

for consequential damage to any parts or persons is ruled out as well.

Legal notes

The graphs and texts of these instructions were carefully prepared. We cannot be held

liable for any errors and their potential consequences! Subject to technical modifications

to the product and to these instructions! These instructions include copyrighted

information. All rights reserved! The listed product or brand names are trademarks of the

respective owners.

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 5

CE marking

The HELLA cassette awning C2 is in compliance with the declaration of performance

according to the Construction Products Regulation; if the unit is operated with a motor drive

it is additionally in compliance with the Machinery Directive and the Guideline for

Electromagnetic Compatibility; in case of proper use, the awning corresponds to the basic

requirements of the harmonised standard EN 13561. The respective declarations are

deposited with the manufacturers.

The CE identification applies for the delivery status of the product. Exceptions and

specifications regarding the wind resistance of the installed awning are given in the

respective product documentations. The product mounted meets the requirements of the

specified standard only, if

the awning is installed with the recommended type and number of brackets.

during installation the information and instructions given in these instructions as well

as the information and instructions of the manufacturers of the screws / dowels have

been observed,

the product is installed with the recommended type and number of fasteners /

screws.

No changes, rebuildings or extensions, with the exception of those described in these

instructions, are allowed with this product. The fixed CE-label expires with any change,

rebuilding or extension.

HELLA Sonnen- und Wetterschutztechnik GmbH

A-9913 Abfaltersbach, Nr. 125

23

LE-GGAM-01-002

EN 13561:2004+A1:2008

Cassette awning

C2

Exterior textile sun protection

Wind resistance: class 1

Installation Instructions and Instructions for Use

6 Subject to technical modifications – Date of issue January/2023

Safety instructions

These installation instructions refer to prefabricated elements, that (1) for

100% are made from parts, which are defined by us, and (2) which are

made in manufacturing processes, which are defined by us too; in all other

cases we do not provide any guarantee!

The safety instructions as well as the appropriate instructions must be read

carefully before installation and use. In case of non-observance of the

directions and information given in these instructions and in case of

improper installation and operation or unintended use, the manufacturer

shall not accept any warranty claims concerning any damage to the

product. In these cases, the liability for consequential damage to any parts

or persons is ruled out as well.

- Follow the described installation steps and pay attention to

recommendations and notes.

- Keep these instructions in a safe place.

- All installation and removal works, as well as maintenance and repair

works are only allowed to be carried out by authorised and qualified

specialist staff.

- If switching, automatic or radio control devices are used to operate the

units, the information given in the enclosed instructions of the

manufacturer must be observed.

- During operation do not put your hand into or touch movable parts.

- Ensure that clothing or body parts cannot get caught on the unit.

- Observe the regulations for prevention of accidents of the employer's

liability insurance association!

- Before operation check the unit for visible damage. If the unit is

damaged, it should not be used; please consult authorized specialist

staff immediately.

- Risk of injury and accident due to the weight of the product!

- Take safety measures against the danger of squashing, especially when

operating the unit with automatic devices.

- Place the operating switch within sight of the unit, but not near any of the

moving parts.

- Never let children play with the unit.

A sun protection device with electric drive cannot be retracted without

current. We therefore recommend the use of an emergency power

generating unit or a motor with an emergency crank handle, especially in

regions with frequent power failures.

Danger of suffocation!

Ensure that the foil cannot get into the hands of children. Keep the foil in a

safe place.

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 7

Safety instructions

Attention! Risk of injury or danger to life due to an electric shock!

- Set-up, examination, commissioning and error correction of the unit must

only be performed by authorised or trained expert staff (as per VDE

0100).

- Switch off the current to the connecting lines when working at the unit.

There is danger to life! Take safety precautions against unintentional

switching on!

- Check the electrical wires regularly for damage. Do not use the unit if

any damage is found.

- Our electrically driven units are in accordance with the regulations for

power plants acc. to VDE 0100. We cannot guarantee for the operational

reliability of the unit with non-approved modifications.

- White motor cables are not UV-resistant and must therefore be routed in

empty conduits, cable ducts, or similar.

- The enclosed installation instructions of the electrical devices supplied

must be observed.

Units with motor drive:

The drives used are operated with a voltage of AC 230V/50Hz. Please

check the power supply provided by your utility company before connecting.

Any other voltage can destroy the drives.

Danger of squashing

To avoid at the best the danger of squashing in the area of movable parts,

such as roller tube, cassette, folding arms, front rail etc., especially when

automatic devices are used or when the unit is for example operated

automatically by a wind controller or rain sensor, it is mandatory that the

awning is installed in a height of at least 2,5 m or above, measured from the

floor or a permanent access way.

Hereby it must be observed, that a distance of at least 0.40 m between the

front rail and a fixed object is ensured, if the front rail, due to the inclination

of the awning, goes below a height of 2.5 m, measured from the floor or a

permanent access way.

If such an installation is due to the local situation not possible , the client

has to take appropriate safety measures, such as a cover or placing the

operating switch (touch contact switch) within sight of the awning.

Installation Instructions and Instructions for Use

8 Subject to technical modifications – Date of issue January/2023

Safety instructions

If it is necessary to lift the awning via ropes at a higher altitude, the awning

must

- be removed out of the packaging.

- be tied to the pull ropes in such a way, that a slipping out of the awning is

prevented,

- lifted evenly in a horizontal position.

The same applies for the removal of the awning.

It is not allowed that climbing aids are leaned against or fixed to the awning.

They must have a stable base and provide a firm support. Only use

climbing aids with an appropriate carrying capacity.

When working at higher heights, there is risk of falling. Please make sure

that suitable fall protection devices are used.

Awnings are only allowed to be used for the purpose specified in the

instructions for use. Changes, such as extensions or rebuildings, that are

not provided by the manufacturer, are only allowed to be carried out with

the manufacturer’s written approval.

Additional loadings such as objects that are sticked to the awning or cable

tensionings can damage the awning or lead to its crashing, and are

therefore not allowed.

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 9

Safety instructions

Winter operation:

Snow or ice can destroy the unit.

The unit may only be operated, if no ice or snow is lying on the cover.

During this time automatic control devices must be switched to

manual operation.

To prevent damage, please retract your sun protection device with rain,

snowfall or wind.

If automatic control devices are used, adjust the wind controller analogously

to the installed wind resistance class of your sun protection device.

Wind resistance class 0

= wind force <4 (Beaufort),

a performance not required or not measured (according to DIN 13561) or a

product, that does not comply with the requirements of the wind resistance

class 1.

Wind resistance class 1 = wind force 4 (Beaufort),

moderate breeze, moderate wind, moves twigs and thin branches, whirls up

dust and loose paper

Velocity 20 – 27 km/h = 5.5 – 7.4 m/s

Wind resistance class 2 = wind force 5 (Beaufort),

fresh breeze, fresh wind. Smaller deciduous trees start to sway, white

crests are formed on lakes.

Velocity 28 – 37 km/h = 7.5 – 10.4 m/s

Your awning cannot be protected from sudden gusts of wind by a wireless

wind sensor. In the event of a meteorological hazard, ensure that the

awning remains run in.

Installation Instructions and Instructions for Use

10 Subject to technical modifications – Date of issue January/2023

Designated use

Sun protection

Thermal protection

Sight screen

Anti-glare blind

Rain protection (only partly!)

The inclination of the awning in the drawn-out position must be at least 14° to

prevent water pockets when it is raining.

Also with a sufficient inclination, a complete denseness of the seams cannot be

guaranteed when it is raining!

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 11

Servicing, maintenance and repair

With the purchase of your awning you have opted for a high-quality product. To enjoy your

awning for as long as possible, please observe the following information:

Notes to awning covers made of brand acrylic fibres

Brand acrylic fibres, as used for awnings, are materials of the highest quality for awnings.

As they are dope-dyed, these materials show the highest light- and color-fastness. In

addition, their resistance to tearing and resistance to weather, rotting and environmental

effects is unsurpassed. Furthermore, a special textile finishing makes them dirt-, water-, oil-

and grease resistant. The awning cover is heavily tested. At the weaving plant, at the

awning manufacturer and during awning fabrication. As with other covers, differences in

the surface uniformity can also occur with the awning cover. When viewing from the top or

seeing through, you will perhaps find small knots, spots of color, irregular runs of threads

or minimal differences and displacements in the design and rapport, as well as differences

in the color. Please note, that the awning will cause a different color effect in sunlight and

in shade. Naturally, the optical color perception depends on the composition and the

intensity of the emerging light. With increasing depth of color, more light will be absorbed

and less will be reflected. Therefore dark coloured covers let through a small amount of

light, while light colors let a lot of light through. Due to the part-absorption, the composition

of the light shining through will be modified, which results in other color perceptions.

Due to the coloured pigments embedded in the cover and the impregnation, shadings

caused by crinkles or crumple folds can appear, that, especially with light colors, become

visible as strips of shade.

The function, strength or density of the cover will not be reduced by that. Minor differences

in colors between the different cover strips or differences in colors with regard to the

collection of samples cannot be ruled out. The fabrication of several strips also with varying

widths depends on the overall width of the awning.

Ripples in the cover and wrinkling at the seams can arise, because the cover is double

rolled up at the seams.

The highest strain is on the seams of the cover. When rolling up the cover, the seams and

hems lie on top of each other, intensifying the strain. Hems and seams will be pressed flat,

increasing in length. As a result, the lateral seams of the cover can hang down slightly.

Sagging as a result of the own weight of the cover is possible. These specified

phenomenons are not faults in the awning cover, which have been overseen in the testing;

they are unavoidable due to technical, material and physical regularities. They therefore do

not entitle the customer to any refusal or reduction of the purchase price.

Correspondingly, the guidelines for the assessment of ready-made awning covers,

summarized by the German Federal Association "Manufacture of technical textile

registered association" (Bundesverband Konfektion Technischer Textilien e. V.), are also

an integral part of our conditions of sale and delivery.

Installation Instructions and Instructions for Use

12 Subject to technical modifications – Date of issue January/2023

Servicing, maintenance and repair

Cleaning

Cleaning

As a sun protection device fixed outside, the unit can get dirty in the

course of time. This will not reduce the usability of your unit. The powder-

coated parts of your unit will remain presentable for longer, if they are

cleaned regularly with a soft woollen cloth.

Do not use solvents, alcohol (rubbing alcohol) or scouring cleansing

agents!

Leaves or other foreign material lying on the awning cover and in the

awning cassette must be removed immediately. There is danger of

damage or crashing to the awning.

Preventive measures

If you have to draw in the cover in a wet condition, please draw it out for

drying when the next opportunity arises, to prevent marks caused by mould

or mildew.

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 13

Servicing, maintenance and repair

Maintenance

All inspection and maintenance works must be carried out by a

specialised company from HELLA or a HELLA partner. Regularly check

the electrical wires of motor driven units for damage. Check the

mechanical parts of your unit for visible damage. After exceptional events

such as storm, hail, sleet, maloperation or the like, the unit must be

checked for noticeable damage prior to operating it. If the unit is

damaged, it must not be used; consult authorized specialist staff

immediately. It is recommended to have the unit maintained by specialist

staff on an annual basis. This way wear is detected at an early stage and

damage to the unit is prevented.

An unintentional switching on of electrically driven awnings is possible.

Make sure, that the awning is switched dead during cleaning or

maintenance work (e.g. building cleaner).

The automatic control device must be switched dead when working in the

operating range of the awning. There is danger of squashing and danger

of fall hazards.

In addition, it has to be ensured, that an unintentional manual operation

of the awning is prevented. This may be done by disconnecting the

power supply or by unplugging the plug-in coupling from the motor.

If the awning is operated manually, the operating crank handle must be

hooked out and kept in a safe place.

Repair:

Improper repair works may cause both risk of injury to persons or

damage to the units.

Repair works must be carried out by a HELLA specialist company or a

partner company of HELLA.

Only use original spare parts from HELLA.

Installation Instructions and Instructions for Use

14 Subject to technical modifications – Date of issue January/2023

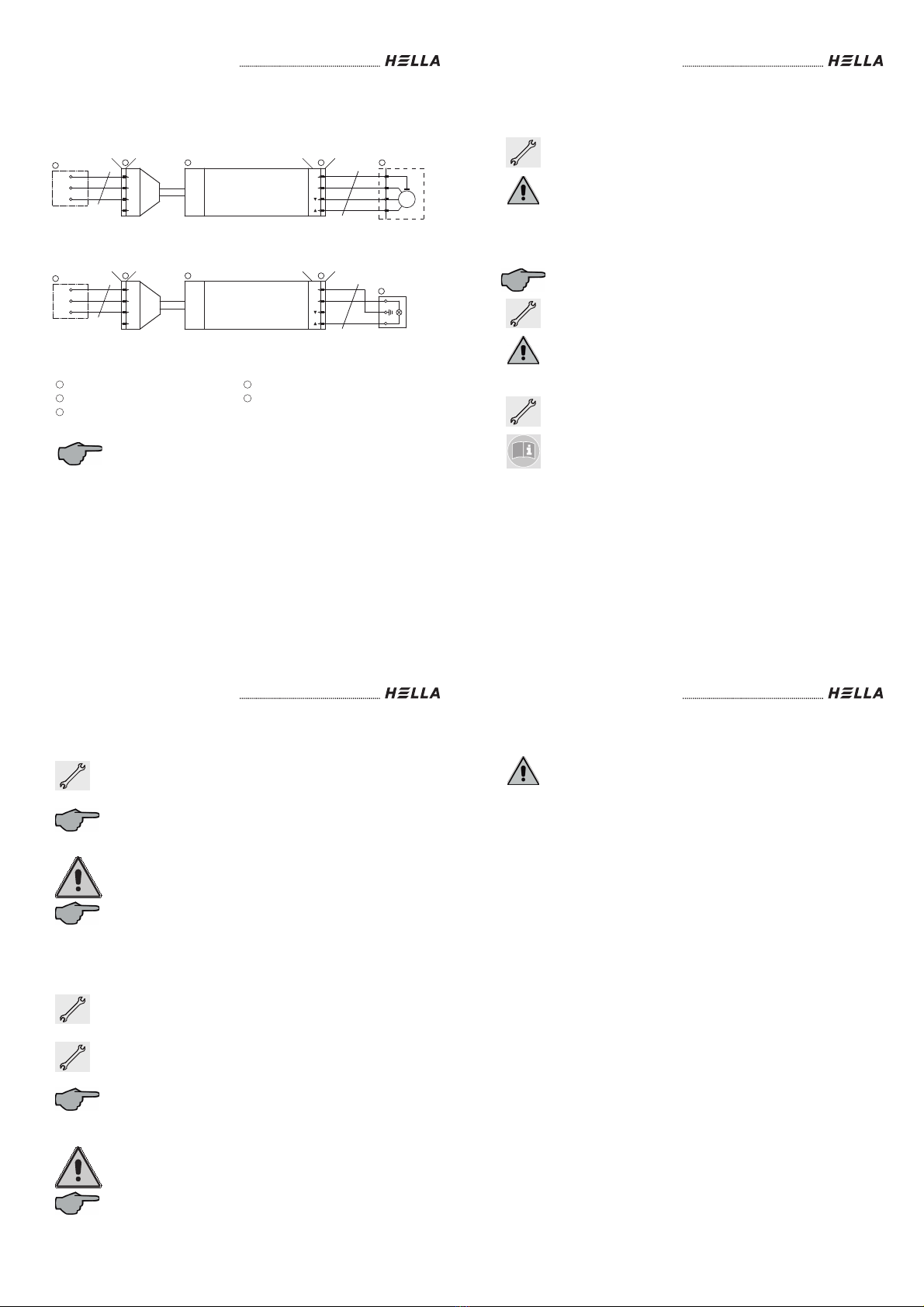

Operating guidelines

Legend

Eyelet

Crank handle hook

Crank rod

Crank handle drive

Stick the crank handle hook

together with the crank rod into

the eyelet.

The awning is extended or

retracted by turning the crank

rod.

The respective direction of

rotation depends on the drive

side.

In the direction of extending

the stop position of the gear is

limited by an override.

In this position you hear a

click, when turning the crank

handle beyond this stop.

Do not use force when

turning towards the upper

stop.

1

2

3

1

2

3

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 15

Operating guidelines

Motor drive

The awning can be extended

or retracted by activating a

switch, a hand-held radio

transmitter or an automatic

device.

The end points of the drive are

adjusted ex works. Please

observe the enclosed

instructions of the

manufacturer of the drive, if

any modification is required.

Thermal protection:

The drives used are not suitable for a non-stop operation. The integrated

thermal protection switches the drive off after approx. 4 minutes. After

approx. 10 to 15 minutes, the drive is ready for use again.

Installation Instructions and Instructions for Use

16 Subject to technical modifications – Date of issue January/2023

Operating guidelines

Legend

Varioplus roller blind

Eyelet

Crank handle hook

Crank rod

Varioplus roller blind with crank handle

drive

Stick the crank handle hook of

the crank rod into the eyelet of

the Varioplus drive situated at

the front rail.

The blind is raised or lowered

by turning the crank handle.

The respective direction of

rotation depends on the drive

side.

Do not use force when

turning towards the upper

stop.

1

2

3

4

1

2

3

4

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 17

Operating guidelines

Varioplus roller blind with motor drive

The roller blind can be raised

or lowered by activating a

remote control or a switch.

The end points of the drive are

set in the factory; should any

modifications be necessary,

please observe the

instructions in Chapter

"Alignment of the awnings –

Adjusting the end positions".

Installation Instructions and Instructions for Use

18 Subject to technical modifications – Date of issue January/2023

Before installation

Check the product immediately for possible shipping damage and for

compliance with the delivery receipt.

If parts are missing or damaged, please consult your supplier immediately.

Check the mounting base and ensure that the mounting material to be used

complies with the given conditions to guarantee proper installation. In case

of doubt, please seek advice from a specialist enterprise for fixing

techniques.

The packaging cardboard box should not be exposed to humidity. To

protect it from rain during transport, it should be covered by a foil.

Carry larger units by two persons. Transport and store the units carefully to

prevent injury of persons and damage to the product.

Remove the packaging material carefully. When using a knife, be careful

not to damage the packaging content and to avoid cuts!

Dispose of the packaging material via recycling.

Caution!

A wrong installation can endanger the user seriously. Please strictly

observe the installation instructions. Close off the place of installation.

When working at higher heights, there is risk of falling. Suitable ascent

supports, scaffoldings and fall protection devices are to be used. Please

make sure that the ascent supports stand solidly and provide a firm grip.

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 19

Overview Cassette awning C2

Legend

End cap cassette profile Front rail Varioplus

Front rail Folding arm

End cap front rail Covering end cap cassette profile

End cap cassette profile Varioplus Arm bearing

Cassette profile Varioplus Cover

Varioplus roller blind Cassette profile

1 7

2 8

3 9

4

10

5

11

6

12

1

2

3

4

5

6

7

8

9

10

1

11

12

10

Installation Instructions and Instructions for Use

20 Subject to technical modifications – Date of issue January/2023

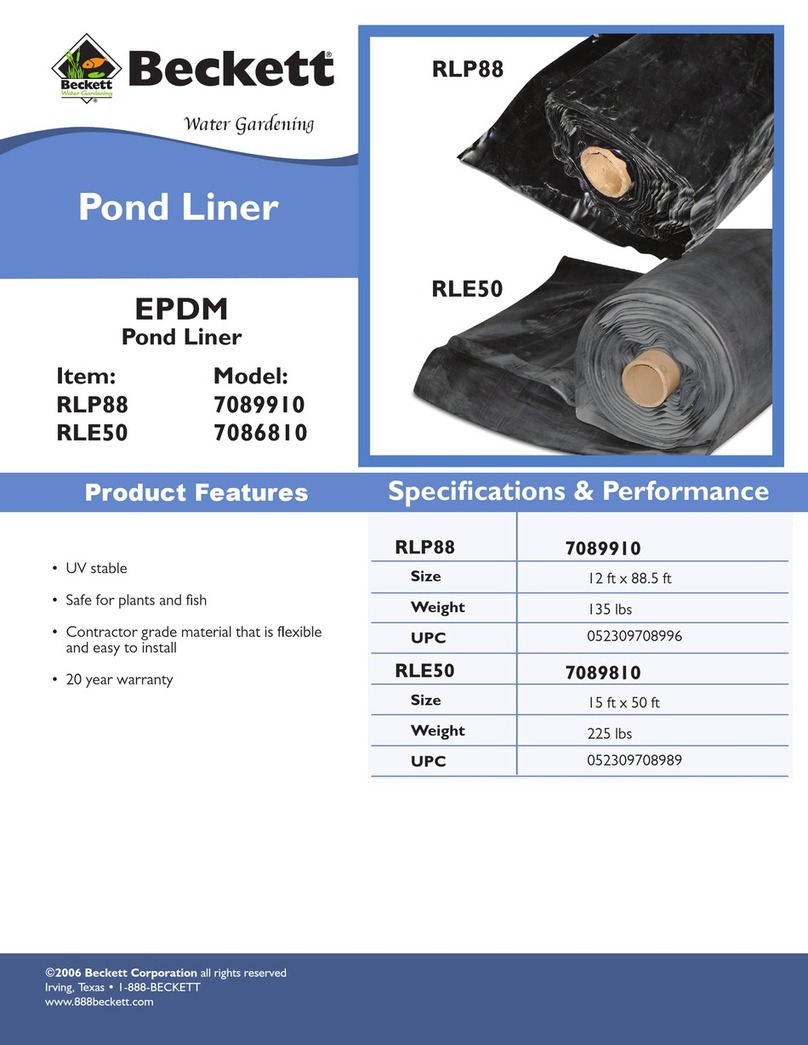

Overview tensioning bracket types

Legend

Wall bracket Type A (034905E1)

Wall bracket Type B (034905E2)

Wall bracket Type C (034905E3)

Wall bracket Type D (034905E4)

1

2

3

4

12

3

4

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 21

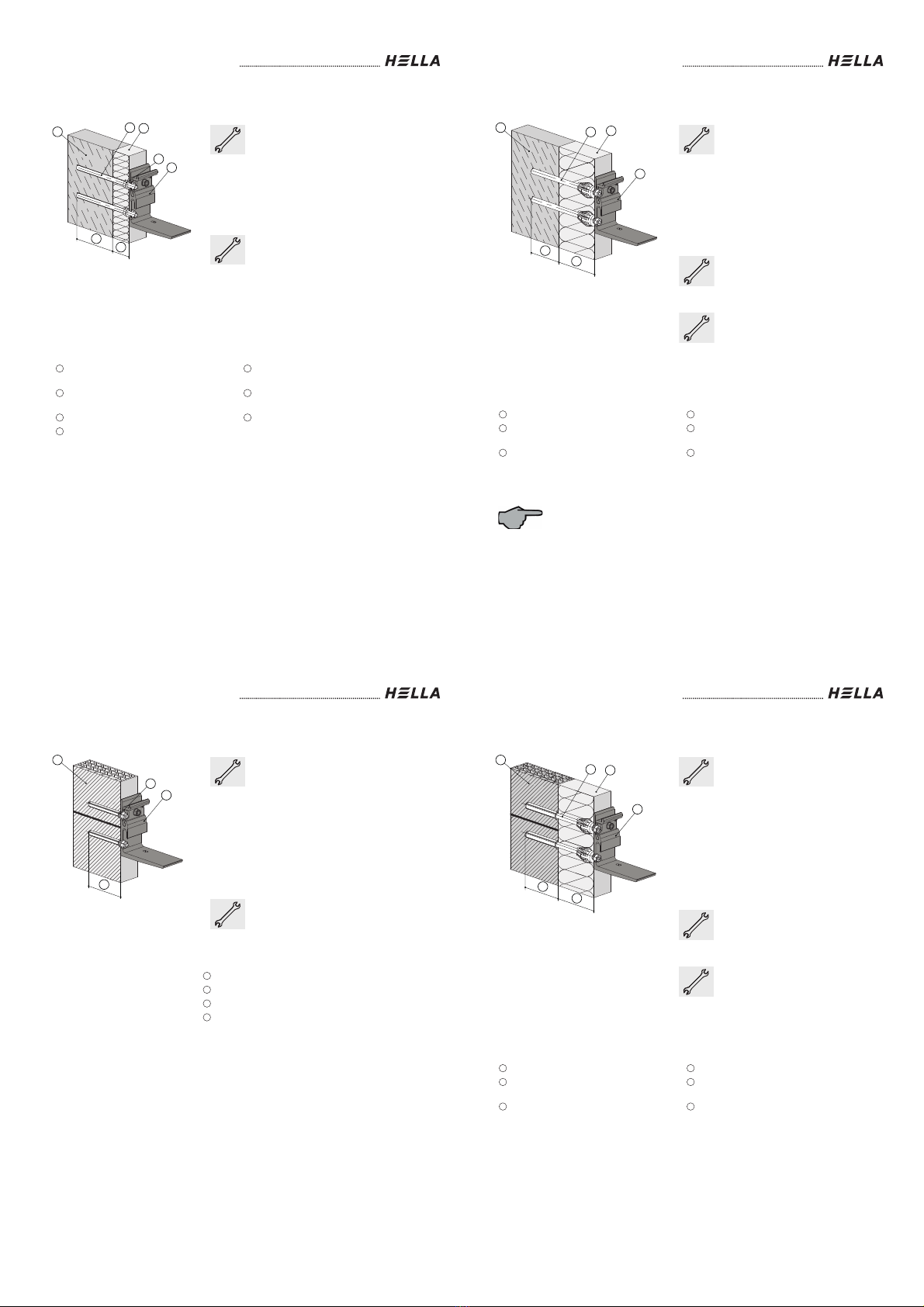

Overview tensioning bracket types

Legend

Ceiling bracket Type E (034905E5)

Ceiling bracket Type F (034905E6)

Ceiling bracket Type G (034905E7)

Ceiling bracket Type H (034905E8)

1

2

3

4

1

2

34

Installation Instructions and Instructions for Use

22 Subject to technical modifications – Date of issue January/2023

Overview tensioning bracket types

Legend

Rafter bracket Type K (034905E9)

1

1

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 23

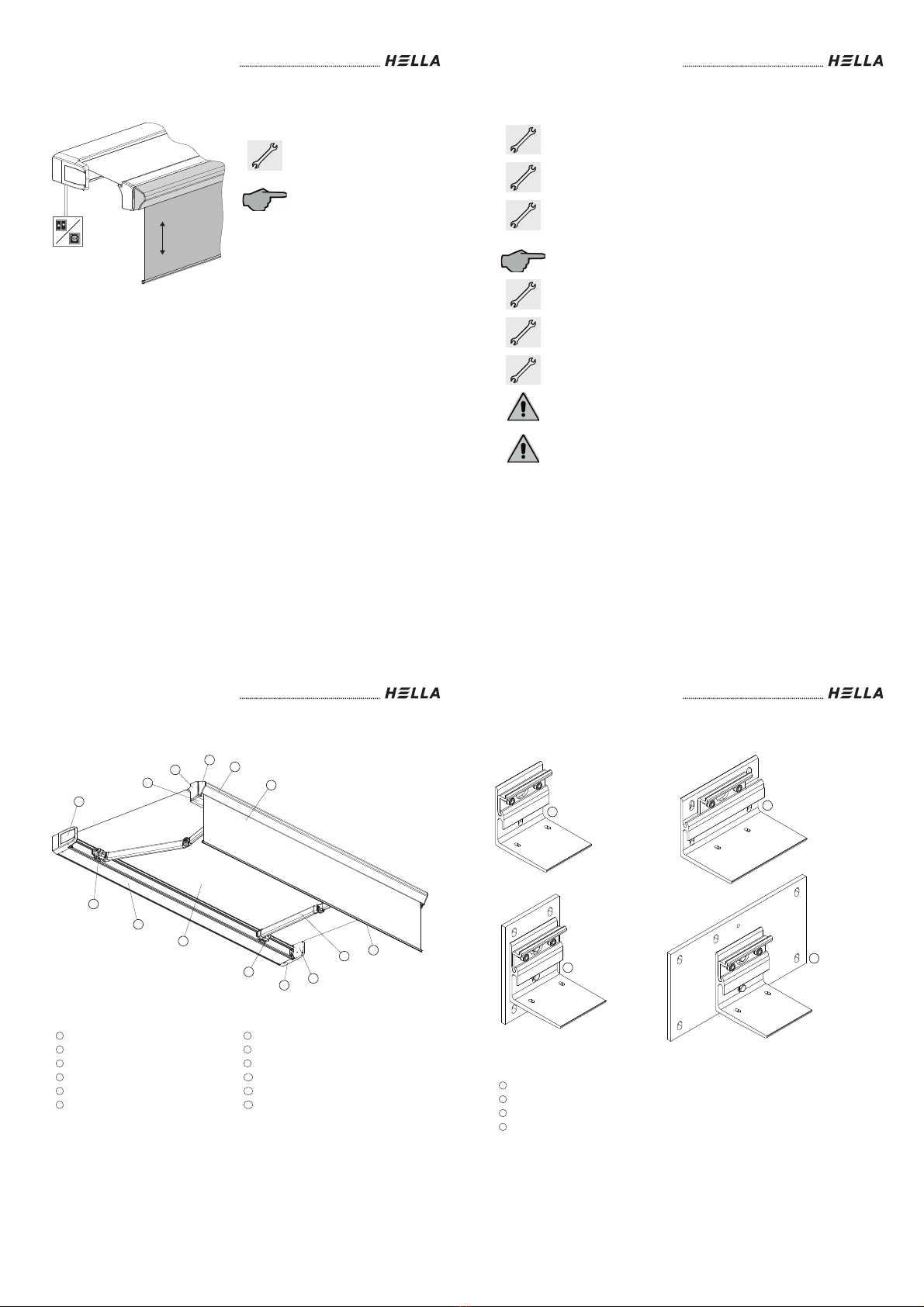

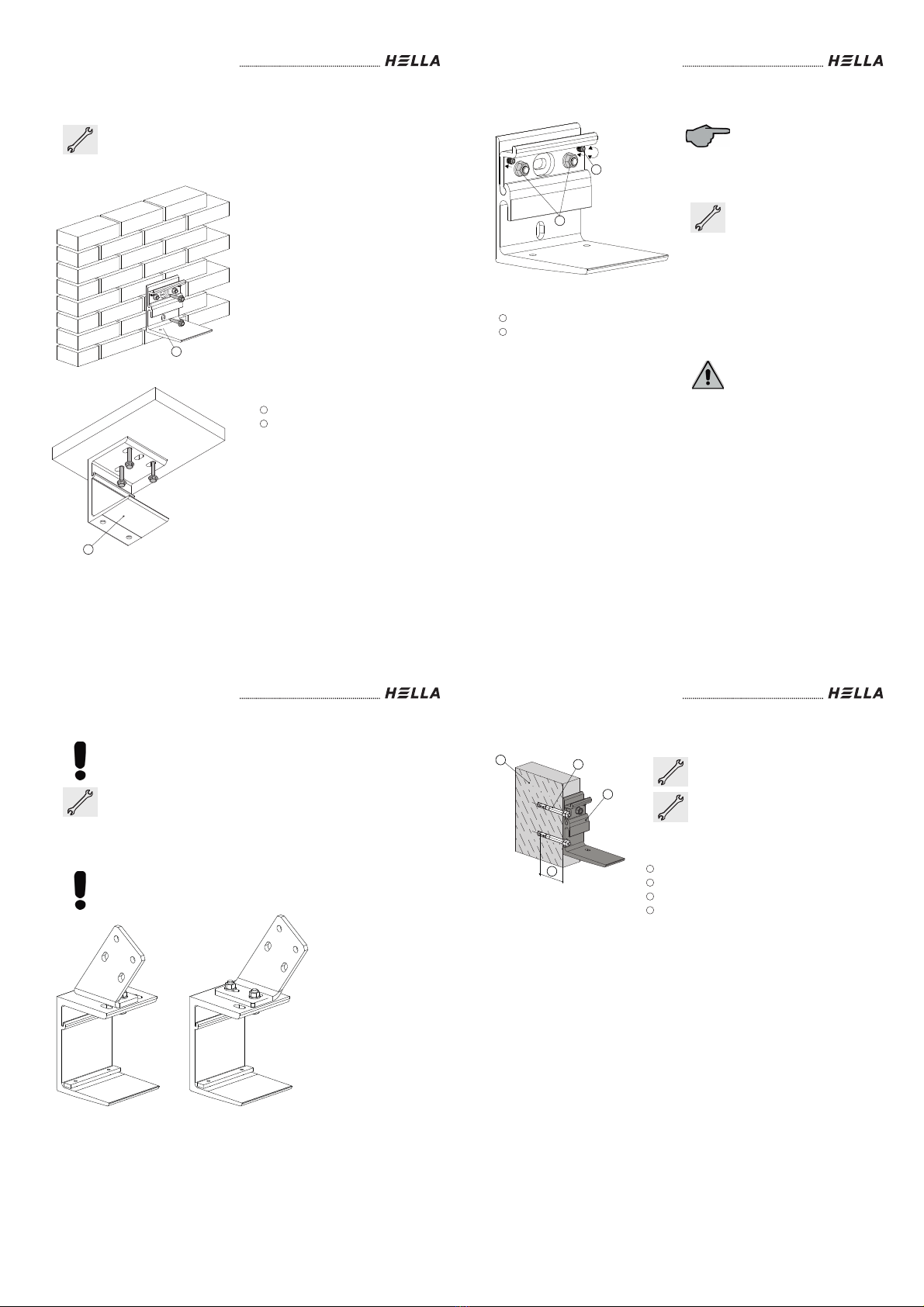

Installation of wall / ceiling brackets

You specified the number, form and type of brackets on purchasing the awning in

accordance with the size, the mounting base, the screw pull-out forces, the mounting

material and the wind resistance classes. Recommendations can be found in our awnings

price list and the product-related calculation tables.

Before starting the installation, please check whether the details you gave in

your order concerning the mounting base comply with the given mounting

base. In case of doubt, please obtain information from a specialist shop or a

structural engineer.

If there are any discrepancies that could jeopardise the safety, the

installation must not be carried out. The wind class given may need to be

reduced.

Mark the position of the brackets (2) correspondingly:

- Determine the position for the holes of the fastening screws

(measure, adjust, mark).

- Drill holes, align and affix brackets.

Please observe the maximum allowable offset (± cm)

- Check the alignment of the brackets by means of a level or a plumb line.

The brackets must be situated on one level both horizontally and

vertically!

Irregularities in the mounting base must be equalised accordingly.

- Observe the torque indications of the anchor manufacturer when

tightening the screws. Please note, that the bore hole geometry is

decisive for the load-bearing capacity of an anchor.

- All elongated holes defined in the bracket must be used for fastening.

Installation Instructions and Instructions for Use

24 Subject to technical modifications – Date of issue January/2023

Installation of wall / ceiling brackets

The maximum admissible lateral difference from the given installation

points may not exceed 50 mm!

The tensioning bracket distance A is shown on the rear side of the awning

via labels in the form of arrows.

Attention:

*...Observe the minimum space for the different brackets:

min. 155 mm with bracket Type A, C, K, E, G min. 190 mm with bracket Type B

min. 205 mm with bracket Type F min. 225 mm with bracket Type D, H

Note:

If mounting brackets with the large mounting plate (450 x 250 mm) are used, consider the

minimum widths to avoid that the mounting plate projects beyond the awning!

50 50

50505050

min. 155

min. 190

min. 205

min. 225

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 25

Installation of wall / ceiling brackets

Check the mounting base and determine the appropriate mounting material

taking into account the mounting base and the fixing devices. Information

on the pull-out forces can be found in the documents in force.

Fix the brackets to the mounting base in accordance with the working

guidelines.

Wall installation

Ceiling

installation

Legend

Wall bracket

Ceiling bracket

1

2

1

2

Installation Instructions and Instructions for Use

26 Subject to technical modifications – Date of issue January/2023

Installation of wall / ceiling brackets

Legend

Threaded pin M8

Hexagon nut M10

If, after the levelling out of

irregularities on the mounting

base, the fixing brackets are

not situated on one level, it is

possible to level out smaller

differences via the wall

brackets.

Loosen the hexagon nuts.

Screw down the threaded pin

to the desired depth till the

position of the wall bracket is

in alignment with the other

brackets.

Check the adjustment of the

wall brackets by using a spirit

level or a chalk line.

Clamp the wall bracket again

by tightening the hexagon

nuts.

The hexagon nuts must be

screwed down completely.

1

2

1

2

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 27

Rafter bracket installation

With rafter installation, an appropriate distance of the rafter bracket towards

the leading edge of the rafter should be kept to avoid shakes in the rafter.

Check the rafters (1) for their material condition or for sufficient stability.

Align the rafter holder (2) and fix it to the rafter.

Based on the holes of the rafter holder, create the relevant through holes

(3) and attach the holder. Check if the holding device fits well.

Connect the rafter holder and the ceiling bracket (4) by means of the

enclosed threaded screws and nuts and align them.

The brackets must be situated on one level both horizontally and vertically.

It may be necessary to level out irregularities on the mounting base.

Installation Instructions and Instructions for Use

28 Subject to technical modifications – Date of issue January/2023

Installation on concrete

Installation of the anchor bolts as per

approval ETA-05/0069:

- Drilled hole preparation ø12 mm

Installation of the attachment:

- Tightening torque as per ETA-

05/0069

Legend

Concrete

Installation set 1; anchor bolt FAZ II M12

Bracket

Minimum anchoring depth - 70 mm

1

2

3

4

12

3

4

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 29

Installation on concrete up to 60 mm ETICS

Installation of the anchor rod as per

approval ETA-12/0258:

- Drilled hole preparation ø14 mm

- Observe the anchoring depth and

the minimum edge distance!

- Drilled hole cleaning

- Fill drilled hole with mortar

- Slide the anchoring element into the

drilled hole

- Wait for the curing time

Installation of the attachment:

- Cut free lock nut in the ETICS

- Align lock nuts

(1 mm before the plaster level) and

then seal the expansion joint

- Cut the threaded rod to the correct

length

- Screw down the bracket

Legend

Concrete Thickness of the non-bearing layer

<60 mm

Installation set 8; anchor rod M12 Anchoring depth 140 mm = drilled hole

depth

ETICS Lock nut + washer

Bracket

1 5

2 6

3 7

4

23

4

7

1

5

6

Installation Instructions and Instructions for Use

30 Subject to technical modifications – Date of issue January/2023

Installation on concrete 60-200 mm ETICS

Installation of the anchor rod as

per approval ETA-02/0024:

- Drilled hole preparation ø18

mm

- Observe the anchoring depth

and the minimum edge

distance!

- Drilled hole cleaning

- Fill drilled hole with mortar

- Slide the anchoring element

into the drilled hole

- Wait for the curing time

Installation of the Thermax as per

approval Z-21.8-1837:

- Mill open the thermal insulation

prior to injection

- Sealing of the expansion joint

Installation of the attachment:

- Tightening torque as per Z-

21.8-1837

- Sealing of the free elongated

hole parts

Legend

Concrete Bracket

Installation set 3; Thermax 16/170 M12 Thickness of the non-bearing layer up

to 200 mm

ETICS Anchoring depth 140 mm = drilled hole

depth

Depending on the thickness of the non-bearing layer, different brackets

must be used (60-170 mm; 170-200 mm).

1 4

2 5

3 6

5

6

4

123

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 31

Installation on brickwork

Installation of the anchor rod as per

approval ETA-10/0383:

Depending on the type of stone, the

injection anchor sleeve must be used!

- Drilled hole preparation

ø12 mm without sleeve

ø16 mm with sleeve (16x130)

- Drilled hole cleaning

- Fill drilled hole (anchor sleeve) with

mortar

- Slide the anchoring element into the

drilled hole

- Wait for the curing time

Installation of the attachment:

- Tightening torque as per ETA-

10/0383

Legend

Brickwork

Installation set 2; anchor rod M10

Bracket

Anchoring depth 130 mm

drilled hole depth

1

2

3

4

2

3

1

4

Installation Instructions and Instructions for Use

32 Subject to technical modifications – Date of issue January/2023

Installation on brickwork 60-170 mm ETICS

Installation of the anchor rod as

per approval ETA-10/0383:

Depending on the type of stone,

the injection anchor sleeve must

be used!

- Drilled hole preparation

ø18 mm without sleeve

ø20 mm with sleeve (20x200)

- Drilled hole cleaning

- Fill drilled hole (anchor sleeve)

with mortar

- Slide the anchoring element

into the drilled hole

- Wait for the curing time

Installation of the Thermax as per

approval Z-21.8-1837:

- Mill open the thermal insulation

prior to injection

- Sealing of the expansion joint

Installation of the attachment:

- Tightening torque as per Z-

21.8-1837

- Sealing of the free elongated

hole parts

Legend

Brickwork Bracket

Installation set 3; Thermax 16/170 M12 Thickness of the non-bearing layer up

to 170 mm

ETICS Anchoring depth 200 mm = drilled hole

depth

1 4

2 5

3 6

5

6

1

23

4

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 33

Installation on wood

Installation of the attachment:

- Drilled hole preparation ø9 mm

- Secure bracket with wood screw and

washer

Legend

Wood

Installation set 5; wood screw ø12x120

Bracket

Drilled hole depth 125 mm

No wind protection class can be given in case of installation on wood due to

the variance of the building material.

1

2

3

4

12

3

4

Installation Instructions and Instructions for Use

34 Subject to technical modifications – Date of issue January/2023

Installation on wood 60-170 mm ETICS

Installation of the anchor rods:

- Drilled hole preparation ø14

mm

- Observe the anchoring depth

and the minimum edge distance

of 100 mm!

- Drilled hole cleaning

- Lubricate threaded rod

- Screw threaded rod into the

wood

Installation of the Thermax

following approval Z-21.8-1837:

- Milling open the thermal

insulation

- Sealing of the expansion joint

Installation of the attachment:

- Sealing of the free elongated

hole parts

Legend

Wood Bracket

Installation set 3; Thermax 16/170 M12 Thickness of the non-bearing layer up

to 170 mm

ETICS Anchoring depth 140 mm = drilled hole

depth

Required wood quality is C24, P30, GL24, F40/30 or equivalent with a wood

PRLVWXUHRI

1 4

2 5

3 6

5

6

4

23

1

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 35

Installation of the awning

Installation dimensions for the

installation

on the wall

Installation dimensions for the installation

on the ceiling

Observe the installation

dimensions as shown

opposite.

289

168

276

212

Installation Instructions and Instructions for Use

36 Subject to technical modifications – Date of issue January/2023

Installation of the awning

Legend

Rafter

Rafter Bracket

1

2

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 37

Installation of the awning

Wall installation

Legend

Cassette profile

Wall bracket

Hook-in groove

As shown opposite, hook the

awning into the fixing brackets

mounted and adjust it equally

towards the sides.

It is not allowed to lift the

awning by using the

Varioplus profile.

The profile may tear causing

the collapsing of the awning.

The ceiling installation will be

carried out analogously to the

wall installation.

Risk of injury and danger to

life due to a crash of the

awning!

Do not extend the awning,

before it is appropriately

clamped.

1

2

3

1

2

3

1

2

Installation Instructions and Instructions for Use

38 Subject to technical modifications – Date of issue January/2023

Installation of the awning

Wall installation

Legend

Cassette profile

Slot nut

Cylinder head screw M8x16

The sliding blocks (2) are

already inserted into the

cassette, but it is still

necessary to place these

above the fixing brackets.

Then fix the awning via the

fixing brackets by using the

cylinder head screws M8x16.

Risk of injury and danger to

life due to a crash of the

awning!

Do not extend the awning,

before it is appropriately

clamped.

1

2

3

1

2

3

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 39

Installation of the awning

Ceiling installation

Legend

Ceiling bracket

Cassette profile

Slot nut

Cylinder head screw M8x16

Lock the awning with the

cylinder head screws M8x16.

1

2

3

4

1

2

3

4

4

Installation Instructions and Instructions for Use

40 Subject to technical modifications – Date of issue January/2023

Installation of the awning

Awning with a sloping projection of 4 m

With a sloping projection of

4m, the cassette profile and

the tensioning bracket are

screwed together to get an

additional stability.

This installation step applies

for the wall and ceiling

installation as well as for the

rafter installation.

Fix the awning as described

previously.

Make the necessary boreholes

in the cassette profile (1) by

using a drill ø5 mm.

Screw the fixing bracket and

the cassette profile together by

using the self-tapping screws

M6x25.

Legend

Cassette profile

Wall bracket

Self-tapping screw M6x25

1

2

3

ø 5

1

2

3

3

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 41

Adjusting the awning

Adjusting the height of the front rail

During manufacturing, your awning has been adjusted optimally and gone

for a test run. To level out possible irregularities of the mounting base, the

following adjusting options are available.

Legend

Front rail

Rating nut

Counter nut

In the height the front rail is not

flush with the awning cassette.

Extend the awning for approx.

30 to 50 cm.

Loosen the upper counter nut

(3) at the height adjustment of

the front bar holding device.

By turning the rating nut (2)

the front rail (1) is positioned in

the desired height.

Tighten the nut (3) again to

secure the position adjusted.

Retract the awning and check

the adjustment.

Repeat this action if

necessary.

1

2

3

1

2

3

Installation Instructions and Instructions for Use

42 Subject to technical modifications – Date of issue January/2023

Adjusting the awning

Adjusting the roller tube

Legend

Front rail

Cover

Offset of the angular bracket

Cassette profile

If the awning does not close

correctly or if the cover does

not roll up symmetrically, you

can adjust the roller tube as

follows:

1

2

3

4

2

3

4

1

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 43

Adjusting the awning

Adjusting the roller tube

Legend

End cap cassette profile

Threaded pin M8x8 with square

nut

Extend the awning for approx.

50 cm.

Loosen the 4 threaded pins of

the square nuts, which clamp

the respective end cap.

Remove the end cap from the

cassette profile.

Legend

Cylinder head screw M6x12

Loosen the cylinder head

screws M6x12 with an Allen

key AF 5.

1

2

1

1

2

1

Installation Instructions and Instructions for Use

44 Subject to technical modifications – Date of issue January/2023

Adjusting the awning

Adjusting the roller tube

Legend

Cover

Cassette profile

End cap cassette profile

Move the roller tube.

Then clamp the roller tube

bearing with the cylinder head

screws again.

Check the closing

characteristics of the awning

by retracting.

Fastening the end cap of the

cassette profile is not required.

If the front rail is flush with the

cassette profile, extend the

awning for approx. 50 cm and

place and fix the end cap.

If the front rail is not flush with

the cassette profile, extend the

awning for approx. 50 cm and

repeat the adjusting

procedure.

Please respect a distance of

22.5 mm between the cover

and the end cap of the

cassette profile.

1

2

3

22,5

123

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 45

Adjusting the awning

Arm adjustment

Legend

Adjusting screw

The angle of inclination and

the horizontal position of the

front rail are adjusted ex

works.

If, nevertheless, a

readjustment is required,

please proceed as follows:

Extend the awning completely.

To adjust the angle of

inclination it is necessary to

relieve the arm bearings by

slightly lifting the front rail

during the adjusting

procedure.

The profile lowers by turning

the adjusting screw to the left,

the profile raises by turning the

adjusting screw to the right.

Check the alignment of the

profile by means of the bubble

level built into the front rail.

Retract the awning and check

the adjustment.

Repeat the adjusting

procedure if required.

No final safety measures are

required after the adjustment.

Adjusting the inclination angle

of the cover is possible by

adjusting all arm bearings.

1

1

Installation Instructions and Instructions for Use

46 Subject to technical modifications – Date of issue January/2023

Adjusting the awning

Levelling out an unequal arm position

Legend

Eccentric screw with hexagon

socket M12 SW8

Hexagon nut M12

Marking on the eccentric screw

Extend the awning for approx.

50 cm.

The position of the arm is

adjusted with the eccentric

screw.

Loosen the hexagon nut by

using a spanner SW19.

Lift the front rail slightly to

relieve it. Turn the eccentric

screw into the corresponding

direction by using an Allen key

SW8.

The folding arm raises or

lowers by turning the eccentric

screw. The marking on the

eccentric screw must be within

the specified adjustment

range. (opposite side in mirror

image)

Again secure the eccentric

screw with the hexagon nut.

Retract the awning and check

the position of the arm.

Repeat the adjusting

procedure if required.

1

2

3

1

2

PD[

PLQ

3

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 47

Adjusting the awning

Adjusting the end positions

Legend

Opening of the shaft holder

Changing gear points with awnings with

crank handle operation:

The end points of the crank

handle gear can be adjusted. If

the adjustment ex works is to

be changed, please proceed

as follows:

Extend the awning for approx.

50 cm. Remove the end cap of

the cassette profile as

described in the chapter

"Adjusting the awning -

adjusting the roller tube".

Extend the awning until the

stop position is reached (you

hear a click).

Loosen the fixing screw

through the opening of the

shaft holder.

Move the awning to the

desired position using the

crank rod.

Tighten the locking screw.

Place the end cap of the

cassette profile again after the

successful adjustment.

1

1

Installation Instructions and Instructions for Use

48 Subject to technical modifications – Date of issue January/2023

Adjusting the awning

Adjusting the end positions

Legend

Fixing screw

1

1

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 49

Overview Linking Elements

Legend

Roller tube Plastic receptacle

Cassette profile Front rail

Star profile for linkage Round tube for linkage

Slot nut Clamping piece

1 5

2 6

3 7

4 8

1

2

3

4

5

6

6

7

5

1

2

4

8

Installation Instructions and Instructions for Use

50 Subject to technical modifications – Date of issue January/2023

Installation linked units

Legend

Star profile Threaded pin M8

Slot nut Round tube

Clamping piece

Attention:

The awning elements are under high mechanical stress. Exercise

highest caution when hooking-in or opening the elements!!

The linked awning C2 is supplied with a continuous cover. Cover with

clamping keder, cover keder, valance and valance keder are enclosed

loosely.

Fix the brackets for the driven and the linked element.

Hook both awnings into the already pre-installed mounting brackets.

Do not yet push the awnings together.

Extend the driven and the linked awning for approx. 50 cm.

1 4

2 5

3

2

3

4

5

2

1

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 51

Installation linked units

The folding arms of the awning are protected with sufficiently

dimensioned tapes; do not remove these tapes, there is highest

danger of accident!

Legend

Countersunk blind rivet

Star profile

Roller tube

Push the roller tube of the

awning to be linked onto the

star profile. In doing so, the

roller tube falls out of the roller

tube bearing.

Please pay attention to the

alignment of the roller tube

grooves (I) to each other.

Fix the roller tube, which is

already pre-drilled, to the star

profile by using two

countersunk blind rivets.

1

2

3

1

2

3

I

Installation Instructions and Instructions for Use

52 Subject to technical modifications – Date of issue January/2023

Installation linked units

Legend

Pan-head tapping screw ø4.2x19 mm

Before inserting the cover, it is necessary to link the front rails.

For this purpose, mark the 2 boreholes required (ø 3.5 mm).

Place the profile of the element to be linked onto the round tube for the

linkage (ø 45 mm). Adjust the front rails in true alignment, and provide the

boreholes.

1

90 30

2x ø3,5

1

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 53

Installation linked units

Exploded view: Roller tube bearing

Legend

Cassette profile

Roller tube

Cap for tubes

Shaft bearing

Shaft holder

Afterwards push the awnings

together.

The pre-assembled cylinder

bolts placed in the driven

awning serve for the correct

positioning of the cassette

profiles.

In doing so, insert the roller

tube of the unit to be linked

into the roller tube bearing

again.

1

2

3

4

5

1235

4

Installation Instructions and Instructions for Use

54 Subject to technical modifications – Date of issue January/2023

Installation linked units

Legend

Threaded pin M8

Pan-head tapping screw ø4.2x19 mm

Clamping piece

Adjust the clamping piece and the sliding blocks concentrically. Then fix the

clamping piece, the sliding blocks as well as the round tube to the awning to

be linked by using the appropriate screws.

Risk of injury and danger to life due to a crash of the awning!

Do not extend the awning, before it is appropriately clamped.

The correct clamping is described in the chapter "Installation of the awning".

1

2

3

1

3

1

2

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 55

Installation linked units

Legend

Bale of cloth

Folding arm

Legend

Cover

Cassette profile

End cap cassette profile

Place the ball of cloth (1) onto

the folding arms (2) and adjust

it centrically.

Starting from one side push

the clip keder into the groove

of the roller tube (e.g. by using

a large slotted screwdriver).

Please respect a distance of

22.5 mm between the cover

and the end cap of the

cassette profile.

Please try to avoid damage to

the cover or the awning.

After clipping-in the keder and

a final check, it is possible to

roll the cover onto the roller

tube by using the motor.

After rolling-up the other end

of the cover must protrude the

awning cassette for approx.

150 mm.

1

2

1

2

3

1

2

22,5

123

Installation Instructions and Instructions for Use

56 Subject to technical modifications – Date of issue January/2023

Installation linked units

Legend

Groove insertion

Insert the cover into the

groove insertion; then push the

keder up to the middle of each

unit into the cover loop.

To simplify the insertion of the

keder, a 2nd person should

keep the cover loop in the

groove insertion.

1

1

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 57

Installation of linked awnings:

Special Situation

The awning is installed in a recess, the required lateral space is not

available.

Approach:

Place the awning on a suitable support and provide the coupling

connections as described above. With the help of several persons (at least

4) hook the complete unit into the mounting brackets and fix it immediately

by using the sliding blocks and the cylinder head screws M8x16 (please

refer also to the chapter "Installation of the awning").

Installation Instructions and Instructions for Use

58 Subject to technical modifications – Date of issue January/2023

Retrofitting of the Varioplus roller blind

Design Varioplus roller blind with crank handle drive

Legend

Front rail B

Front rail A

Raised countersunk head screw

ø4.2x13 mm

Wedge-shaped hanger

Legend

Varioplus profile

Wedge-shaped hanger

Hold the wedge-shaped

hangers to the front rail A (as

per illustration). In doing so,

the lug is flush with the joint of

the front rails A and B.

Arrange the wedge-shaped

hangers equally throughout

the profile and mark the

boreholes.

Provide the boreholes, ø13

mm.

Fix the wedge-shaped hangers

with the enclosed raised

countersunk head screws

ø4.2x13.

Hook the Varioplus valance

into the wedge-shaped

hangers.

Wedge-shaped hanger

1

2

3

4

1

2

1

2

3

4

1

2

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 59

Retrofitting of the Varioplus roller blind

Design Varioplus roller blind with crank handle drive

Legend

Varioplus profile

Pan-head tapping screw ø3.9x9.5

mm

Front rail B

Mark the boreholes, which are

provided to secure the

Varioplus valance, on the

bottom side.

Provide the boreholes, ø13

mm.

Fix the Varioplus valance by

using the enclosed pan-head

tapping screws ø3.9 x 9.5 mm.

Design Varioplus roller blind with motor drive

Please contact your authorized specialist shop, if the Varioplus roller blind is

provided with a motor drive.

The installation as well as the electrical installation are only allowed to be

carried out by a qualified fitter.

1

2

3

1

2

3

Installation Instructions and Instructions for Use

60 Subject to technical modifications – Date of issue January/2023

Installation of the Wall Connection Profile

Legend

Wall connection profile

Please observe the following

steps when mounting the wall

connection profile.

Before fixing the wall

connection profile, the

cassette profile must be free of

dust and grease.

Fix the wall connection profile

as shown in the illustration,

and adjust it in the middle.

Position it against the wall as

well as against the cassette

and fix it with silicone.

1

1

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 61

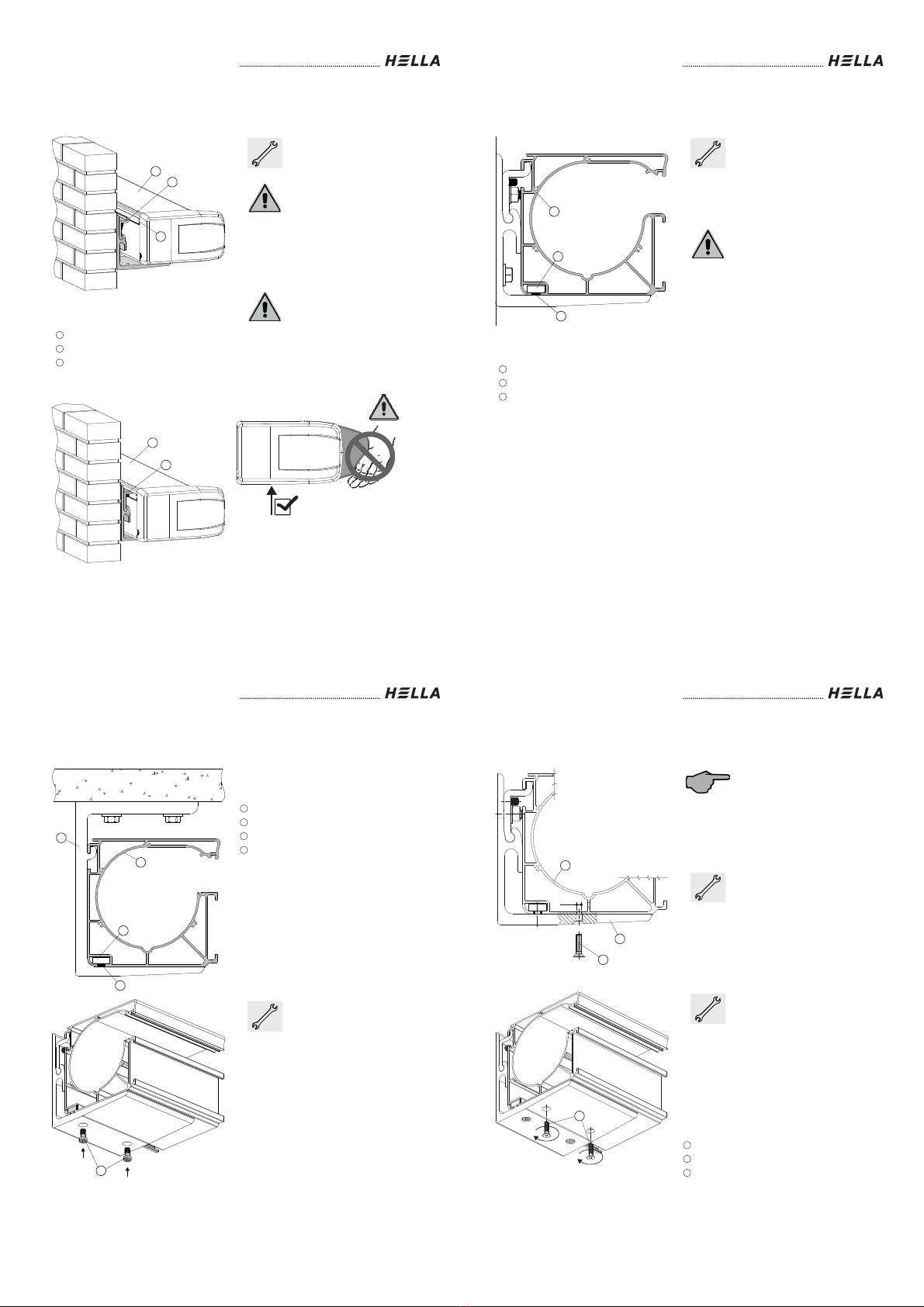

Electric commissioning and overview table power

This general overview table shows which awning designs are possible with an electric

control.

Possible types of operation

Somfy

wire-bound

Somfy radio io ONYX

Awning drive yes yes yes

V

arioplus roller blind yes yes yes

Heater yes yes no

Installation Instructions and Instructions for Use

62 Subject to technical modifications – Date of issue January/2023

Electric commissioning and overview table power

Technical data of the awning

Connection for all cables: 220-240V / 50-60Hz

Overview powers [W]

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 63

Activation guidelines for electric drives

The motors we use are drives with integrated planetary gear, brakes, limit

stops at the top and at the bottom, and thermo cut-off switches, also not

only a motor, but a complete drive system.

In some respect, the drives do NOT correspond to other household

electrical consumers. Please strictly observe the following notes and safety

instructions.

The construction, checking, commissioning and error-correcting of the

electrical system are only allowed to be carried out by an electrician (acc. to

VDE 0100). In case of improper connection, considerable danger can arise

for the user.

-Follow the wiring diagram precisely!

- We cannot accept responsibility for damage, that can result from

improper installation.

- Never simultaneously activate the drives with an UPWARDS and a

DOWNWARDS signal!

-Keep a break of approx. 0.5 seconds between the UPWARDS and

the DOWNWARDS command (is often neglected with Instabus EIB-

systems).

Radio interference suppression

The drives are provided with a radio interference suppression according to

the current VDE standards and EC Guidelines. If the drives are operated

with other devices, that include interferences, it is the fitter's duty - as part of

the obligation to suppress interference - to ensure that the entire unit

complies with the current regulations.

Operation in wet spaces

The drives are "splash-proof"; if they are operated in wet spaces, the VDE-

guidelines, inter alia VDE 0100/Parts 701, 702, the guidelines of the local

electric supply companies and of the TÜV must be observed and fulfilled.

Both the instructions and notes given in these instructions, as well as

the instructions and notes given in the respective enclosed

instructions of the manufacturers of the drive systems must be

observed.

Installation Instructions and Instructions for Use

64 Subject to technical modifications – Date of issue January/2023

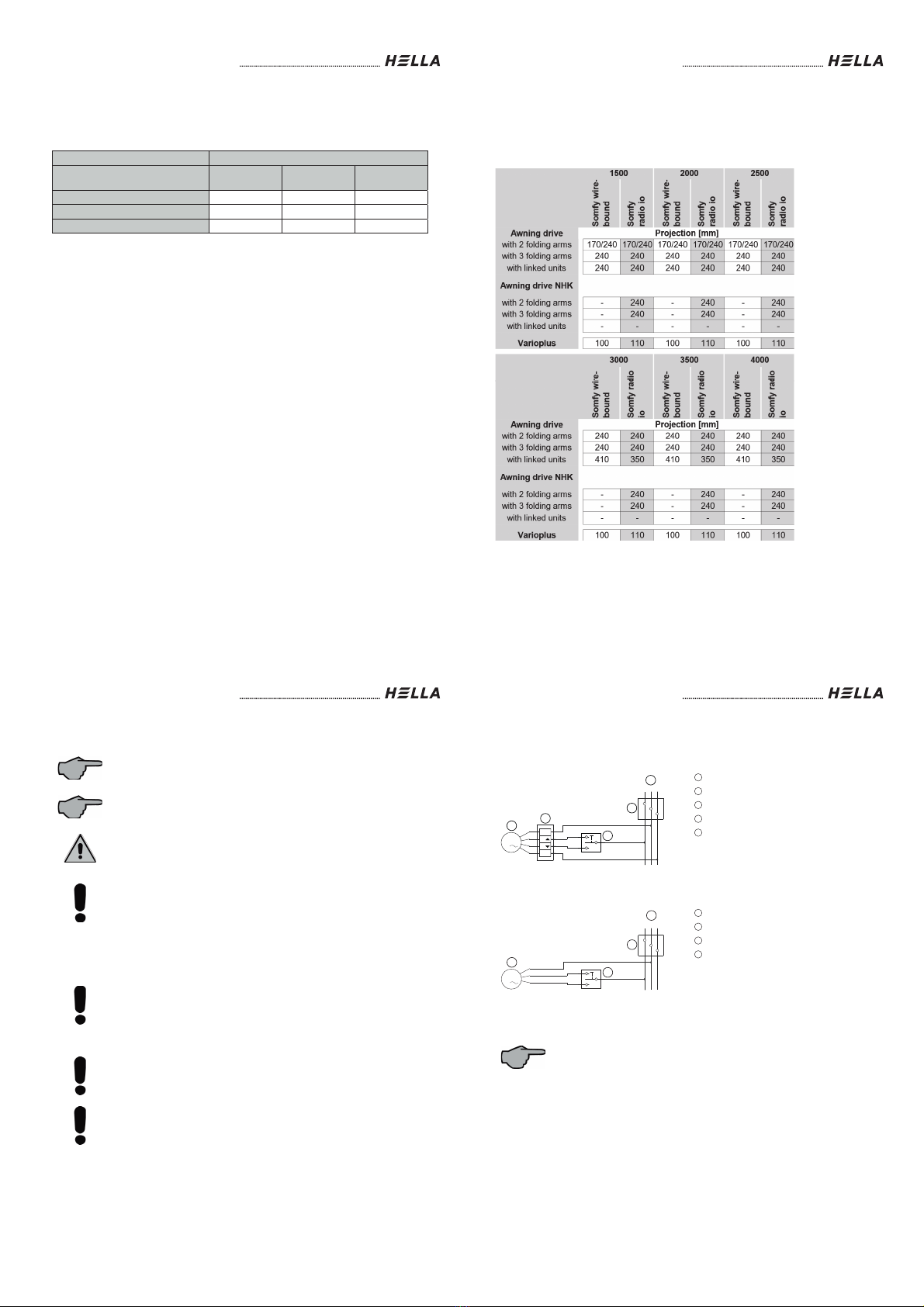

Wiring diagram for motors with switch operation

Drive system awning

Legend

Drive system awning

Hirschmann connector

Junction box

Switch

Mains

Drive system Varioplus

No PE available!

Legend

Drive system Varioplus

Junction box

Switch

Mains

For more details concerning the electrical connections, powers, operating

instructions and programming, please refer to the enclosed documents of

the manufacturer or the HELLA installation instructions.

It is essential that switches for the awning drive be electrically and

mechanically locked.

1

2

3

4

5

1

3

4

5

M

1

3

1 N

2

3

PE

2

4

1

5

L1 NPE

M

1

3

4

5

1

L1 NPE

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 65

Wiring diagram for motors with Somfy io

Drive system awning

Legend

Radio drive awning

Hirschmann connector

Junction box

Mains

Drive system Varioplus

No PE available!

Legend

Radio drive Varioplus

Junction box

Mains

For more details concerning the electrical connections, powers, operating

instructions and programming, please refer to the enclosed documents of

the manufacturer or the HELLA installation instructions.

With the radio system Somfy io all receivers must be taught one after

another (order does not matter), i.e. do not connect several receivers to the

network at the same time as the radio system does not support a

simultaneous teaching process of multiple components.

1

2

3

4

1

3

4

3

1 N

2

3

PE

2

M

1

4

1

L1 NPE

M

1

3

4

1

L1 NPE

Installation Instructions and Instructions for Use

66 Subject to technical modifications – Date of issue January/2023

Wiring diagram for motors with elero radio

Drive system awning Radio drive awning

Hirschmann connector

Junction box

Mains

For more details concerning the electrical connections, powers, operating

instructions and programming, please refer to the enclosed documents of

the manufacturer or the HELLA installation instructions.

1

2

3

4

3

1N

2

3

PE

2

M

1

4

1

L1 N PE

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 67

Wiring diagram for motors with ONYX.NODE

Drive system awning

Legend

Drive system awning

Hirschmann connector

Junction box

Mains

Button

ONYX.NODE

Drive system Varioplus

Legend

Drive system Varioplus

Junction box

Mains

Button

ONYX.NODE

For more details concerning the electrical connections, operating

instructions and programming, please refer to the enclosed documents

"ONYX".

It is essential that switches for the awning drive be electrically and

mechanically locked.

1

2

3

4

5

6

1

2

3

4

5

M

1

L1 N PE

3

1 N

2

3

PE

2

5

Local Motor

N

NNLL

Power

6

+

Typ YR 3x0,8

0,5

4

1

M

1

L1 N PE

2

4

Local Motor

N

NNLL

Power

5

+

Typ YR 3x0,8

0,5

3

1

Installation Instructions and Instructions for Use

68 Subject to technical modifications – Date of issue January/2023

Wiring diagram for motors with

ONYX.CONNECTOR

Drive system awning

Legend

Drive system awning

Hirschmann connector

Junction box

Mains

ONYX.CONNECTOR

Drive system Varioplus

Legend

Drive system Varioplus

Hirschmann connector

Junction box

Mains

ONYX.CONNECTOR

For more details concerning the electrical connections, operating

instructions and programming, please refer to the enclosed documents

"ONYX".

It is essential that switches for the awning drive be electrically and

mechanically locked.

1

2

3

4

5

1

2

3

4

5

N

PE

L

PE

N

1

2

3

44

1

3

2

LNPE

M

1

1

2

3

4

5

N

PE

L

PE

N

1

2

3

44

1

3

2

LNPE

M

1

1

2

3

4

5

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 69

Wiring diagram for motors with

ONYX.CONNECTOR

Legend

Junction box Motor

Adapter plug ONYX.CONNECTOR Lighting

Hirschmann plug connection

For more details concerning the electrical connections, operating

instructions and programming, please refer to the enclosed documents

"ONYX".

1 4

2 5

3

ONYX.CONNECTOR

22

33

11

44

Hirschmann

STAS 3

PE

N

Hirschmann

STAK 3

M

~

1,5mm²

ONYX.CONNECTOR

22

33

11

44

Hirschmann

STAS 3

PE

N

Hirschmann

STAK 3

N

L

PE

1,5mm²

1,5mm²

1

2

2

3

3

4

5

44

11

33

22

PE

N

L

Hirschmann

STAK 3

Hirschmann

STAS 3

3

N

L

PE

1,5mm²

1

44

11

33

22

PE

N

L

Hirschmann

STAK 3

Hirschmann

STAS 3

3

Installation Instructions and Instructions for Use

70 Subject to technical modifications – Date of issue January/2023

Commissioning/functional check

Extend and retract the unit in and out completely. When extending the unit

for the first time, make sure no one is in the operating radius or standing

below the unit.

Make sure that during the later operation the units can be extended freely

and without blockings. Do not extend the unit, if objects or persons are in

the operating radius of the sun protection unit. Please observe the safety

instructions.

After the first extending check the mounting material and the construction

elements for strength.

Automatic control devices or switches, that are not in the operator's field of

vision, may not be used for test runs of motor driven units.

We recommend the use of a test cable for the provisional operation of the

motor.

Check all settings.

Check all screwed connections for tightness.

The awning is a sun protection device that is only allowed to be used for the

intended use. Wrong use can put the user in danger.

Additional loadings such as objects that are sticked to the awning or cable

tensionings can damage the awning or lead to its crashing, and are

therefore not allowed.

Clean the elements (see maintenance instructions).

Pass these instructions as well as possible instructions of the motor, switch

and control manufacturer on to the user.

Brief the user, whereupon you provide comprehensive information on the

safety and user instructions of the system.

Have the correct design of the system as well as the installation and briefing

with the safety information confirmed in writing (see handover report).

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 71

Adjustment - Somfy Eolis 3D radio-controlled wind

sensor

The wind sensitivity of the optional Somfy Eolis 3D radio-controlled wind

sensor is pre-set to level 2 ex works. This level offers good functionality with

our products in most cases.

There is no systematic correlation between the set level of this sensor and the

tested wind protection class of the product! The level setting may be adjusted

if the product retracts considerably very early and thus restricts functionality.

Increase to level 3 at the most to avoid overload. For small systems up to

2.5m sloping projection maximum at level 4.

If the battery charge is too low, the awning signals pending battery change by

retracting automatically. You will find detailed information related to battery

change in the enclosed instructions of the manufacturer.

Adjustment - elero Protero 868 radio-controlled

wind sensor

The wind sensitivity of the optional elero Protero 868 radio-controlled wind

sensor is pre-set to level 6 ex works. This level offers good functionality with

our products in most cases.

The inclination sensitivity of the optional elero Protero 868 radio-controlled

wind sensor is deactivated to level 0 ex works. You will find detailed

information for adjusting the inclination sensitivity in the enclosed instructions

of the manufacturer.

There is no systematic correlation between the set level of this sensor and

the tested wind protection class of the product! The level setting may be

adjusted if the product retracts considerably very early and thus restricts

functionality.

Increase to level 7 at the most to avoid overload. For small systems up to

2.5m sloping projection maximum at level 8.

If the battery charge is too low, the awning signals pending battery change

by double interruption while extending the awning. You will find detailed

information related to battery change in the enclosed instructions of the

manufacturer.

Installation Instructions and Instructions for Use

72 Subject to technical modifications – Date of issue January/2023

Removal and Disposal

With removal or disposing of the awing, the parts that are under prestress

(e.g. articulated arms, counter draw systems) must be completely released

from tension and protected against unintentional drawing-out before

removal.

For this, please contact a specialist enterprise.

Installation Instructions and Instructions for Use

Subject to technical modifications – Date of issue January/2023 73

Handing over report (for the fitter)

Dear Customer,

We are glad that you have opted for a HELLA brand product. Our units are fabricated with

greatest care and many years of experience.

The instructions for use and the installation instructions have been handed over and must

be read before using the product.

An introduction has taken place.

The safety instructions were pointed out.

Your product

Cassette awning C2

was manufactured in accordance with EN 13561:2004+A1:2008

and was installed professionally and handed over

on the .................................................................................................................................... .

Sloping projection ...................................................................................................................

Width ......................................................................................................................................

Dealer

Name

Place

Postal code

Date

Name

Street

Customer

Place

House number

Signature

Signature

Date

First name

Installation Instructions and Instructions for Use

74 Subject to technical modifications – Date of issue January/2023

Handing over report (for the user)

Dear Customer,

We are glad that you have opted for a HELLA brand product. Our units are fabricated with

greatest care and many years of experience.

The instructions for use and the installation instructions have been handed over and must

be read before using the product.

An introduction has taken place.

The safety instructions were pointed out.

Your product

Cassette awning C2

was manufactured in accordance with EN 13561:2004+A1:2008

and was installed professionally and handed over

on the .................................................................................................................................... .

Sloping projection ...................................................................................................................

Width ......................................................................................................................................

Dealer

Name

Place

Postal code

Date

Name

Street

Customer

Place

House number

Signature

Signature

Date

First name

Installation Instructions and Instructions for Use

HELLA Interior Venetian

Blinds

regulate the lighting in a

room very comfortably,

immediately gracing it

with much more

atmosphere.

HELLA Insect screens

and you decide who is

allowed to come in and