4 / 36

TF6746_A_NOT_DXA230_REFERENCE Aereco S.A.

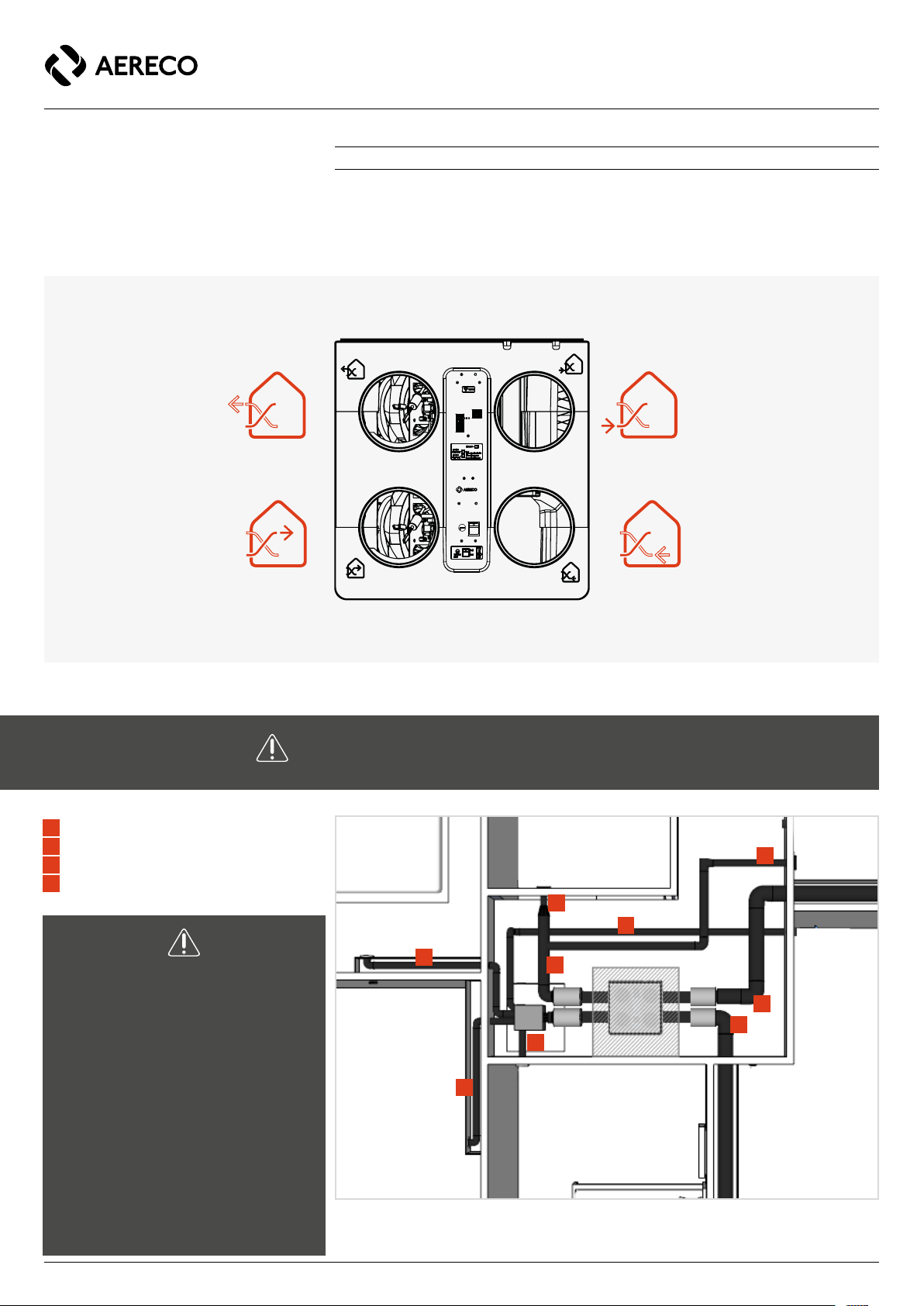

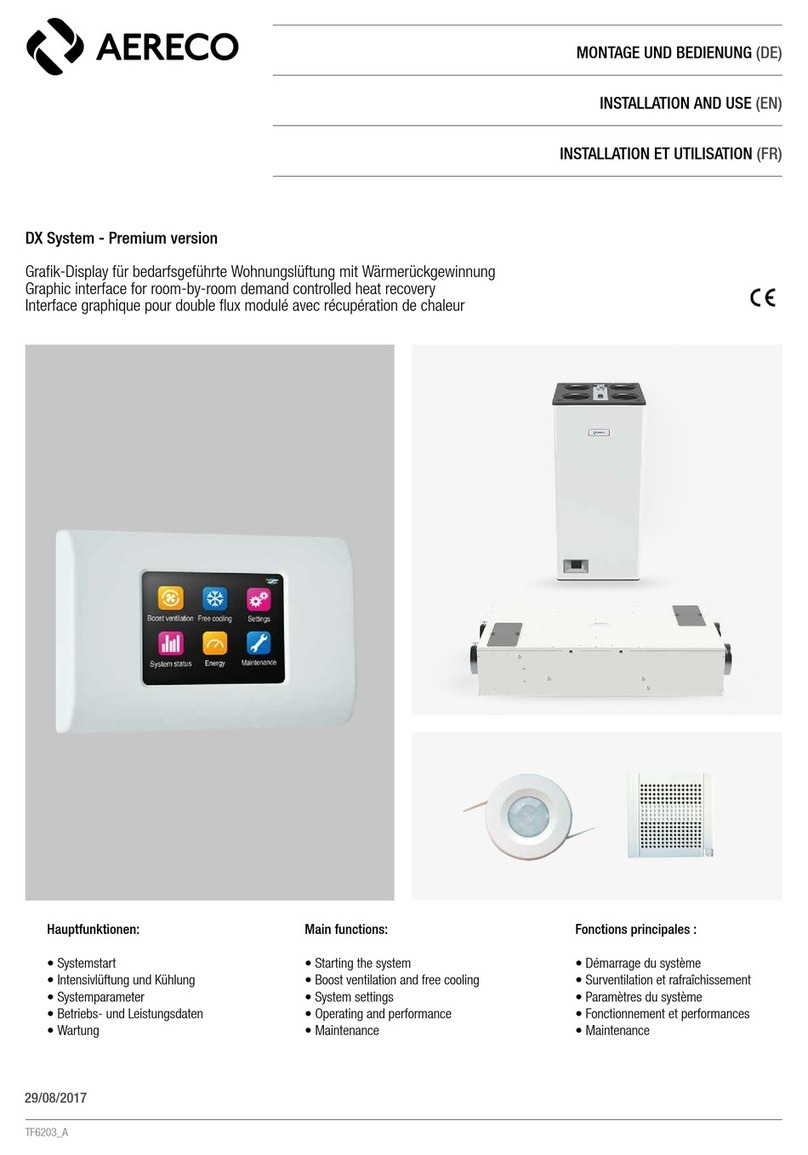

The Heat Recovery Unit : DXA Unit

The DXA has been specifically designed for wall or cupboards installation. Thanks to its wellfitted dimensions, the DXA can be installed in technical

rooms, wallmounte.

2. DESCRIPTION

2.1. GENERAL INFORMATION

The DX System is a range of smart heat recovery ventilation systems that continually supply pollen-free and dust-free preheated fresh air to living areas,

ensuring a comfortable feel-good climate.

The DXA REFERENCE is a heat recovery unit with constant airflows for vertical installation (on the wall) in the apartment or in the house, from 2to 6 main

rooms, and from 1 to 5 technical rooms (kitchen, bathroom, others wet rooms). The dwelling has to be limited to 2 floors (1 ground floor and 1 floor

maximum), and has a maximum surface of 210m². This HRV (Heat Recovery Ventilation)system can also be used in oces, hostels, etc., if the required

airflow is in accordance with the one oered by the system.

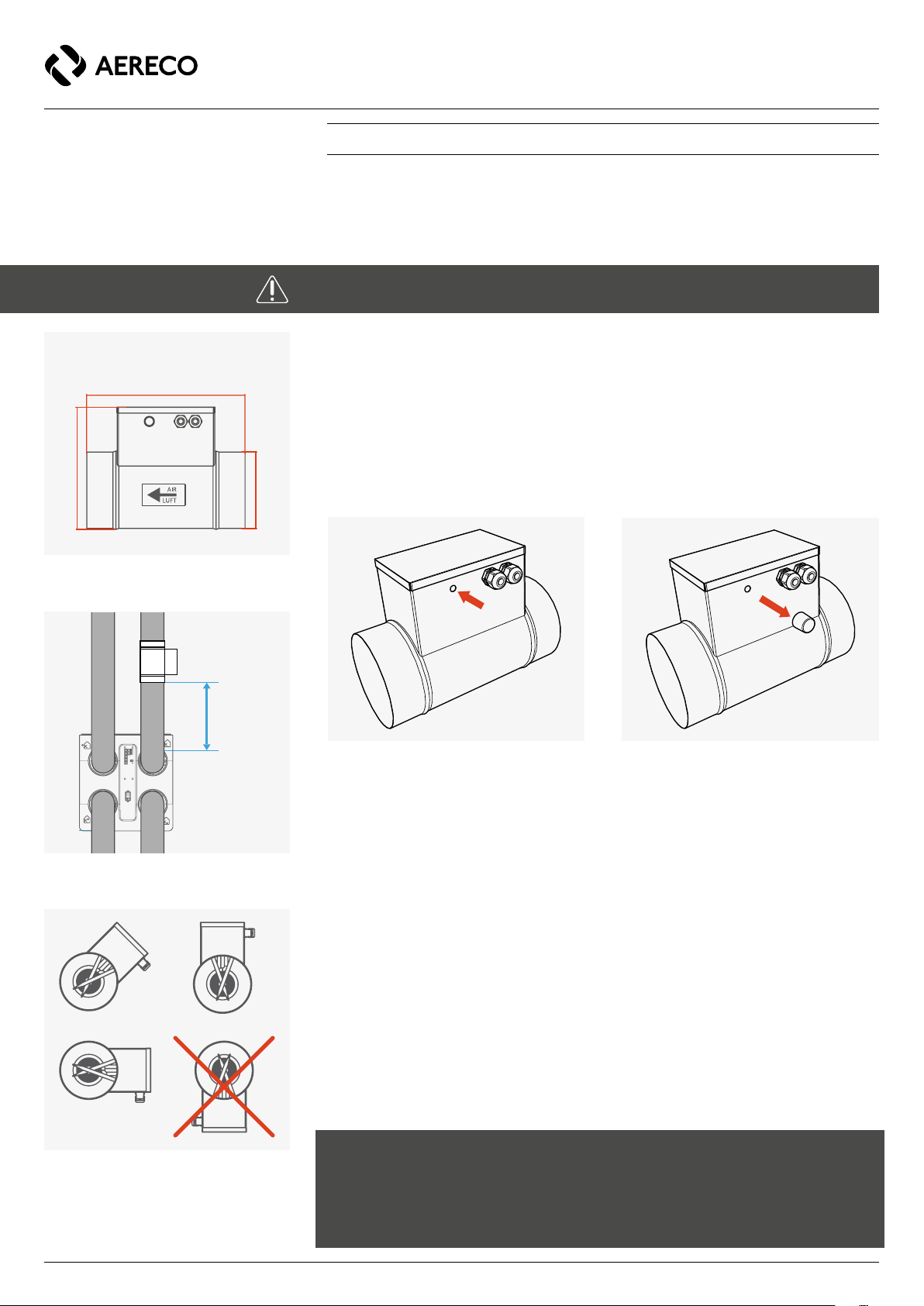

General working of the DXA System, REFERENCE Version

The DXA System is comprised of a heat recovery unit (DXA Unit 1 )

connected to exhaust and supply ductworks. The counter-flow heat

exchanger, integrated into the main unit, ensures the recovery and transfer

of most of the energy from the exhaust air to the supply air, thus limiting

the energy required to heat the fresh air.

According to the size of the dwelling and the number of occupants,

supply and exhaust airflows can easily be set from the interface (80 m3/h,

140 m3/h, 200 m3/h or 230 m3/h). Outdoor filtered air is supplied 3in

the bedrooms and in the living room. Stale air is extracted 7from the

kitchen, bathroom and WC.

At all times, total supply airflows and total exhaust airflows are measured

through pressure sensors placed in the DXA unit. The use of electronic

pressure sensors allows to calculate with a very high accuracy supply and

exhaust airflows without influence of clogging filters or ductwork pressure

drops. So, a dedicated micro-controller drives the two fan motors in such

a way that supply and exhaust massflows are balanced according to the

desired airflow setting point (80 m3/h, 140 m3/h, 200 m3/h or 230 m3/h).

The DXA Reference allows 4 specific regulation modes :

- Absence mode. This mode runs a 40 m3/h airflow ventilation for a

duration the customer may choose within a list of 1, 2, 3, 6, 14 or 30

days.

- Overventilation mode. This mode increase ventilation airflows staying

on the bypass rules. The customer may choose the over ventilation

airflows within a list of 140, 200, 230 or 250 m3/h for a duration he can

also choose (1, 2, 3, 6, 12 or 24 hours).

- Free cooling mode or Free warming mode. This mode is an over

ventilation mode enable only if temperature conditions allow to refresh or

to warm the dwelling.

- Stop mode. This mode allows to stop the fan motors. This mode may be

useful, for example not to clog the filters in case of works in the dwelling.