1General Information

2020/04 993x083x-mub-en – V04 3

Contents

1General Information.....................................................................................................4

1.1 Scope of these instructions ..........................................................................................4

1.2 Designated use ............................................................................................................4

2Safety instructions .......................................................................................................5

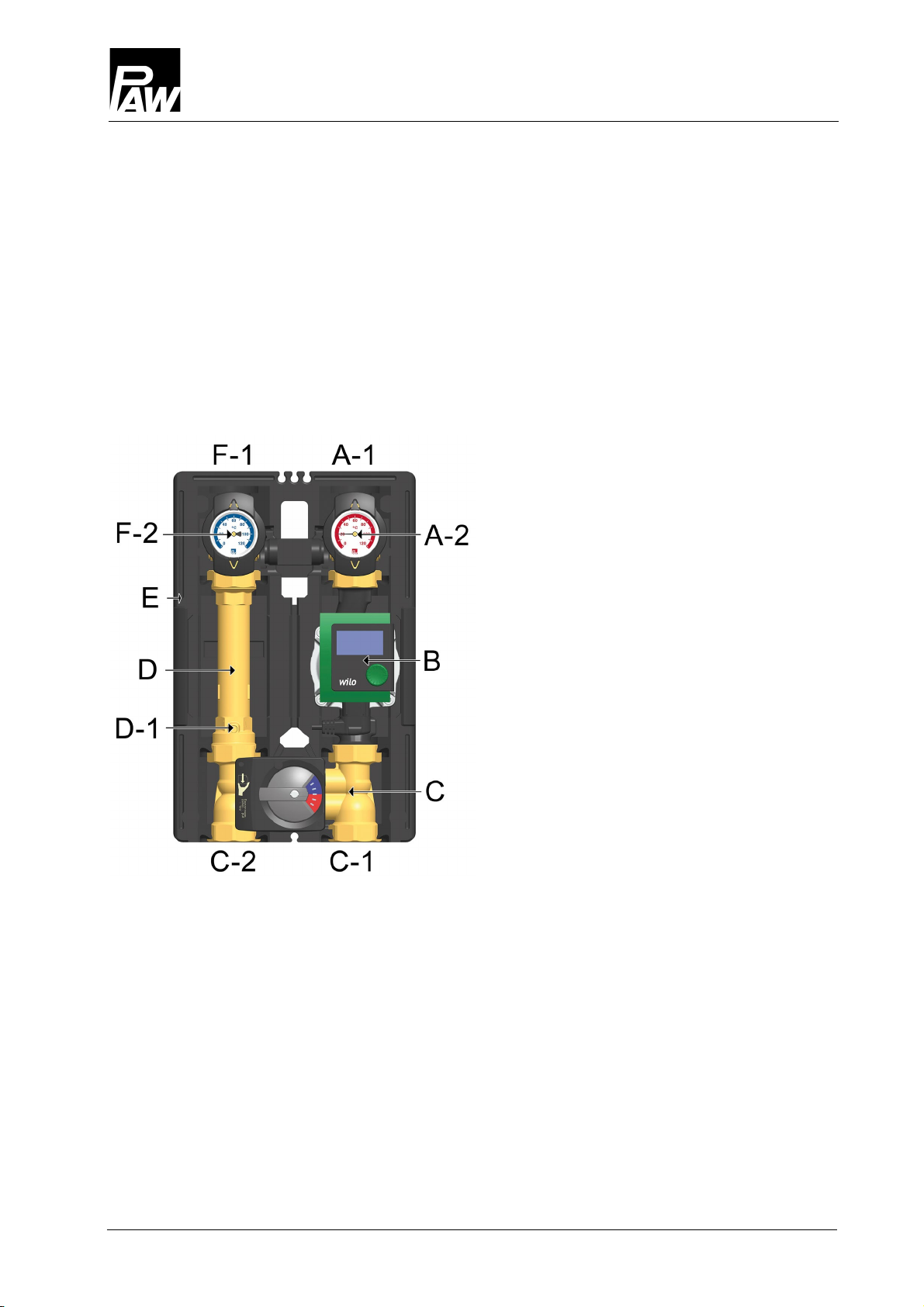

3Product description......................................................................................................6

3.1 Equipment....................................................................................................................6

3.2 Function .......................................................................................................................7

3.3 Mixing valve [specialist]................................................................................................8

3.4 Accessories: Actuator (optional)...................................................................................9

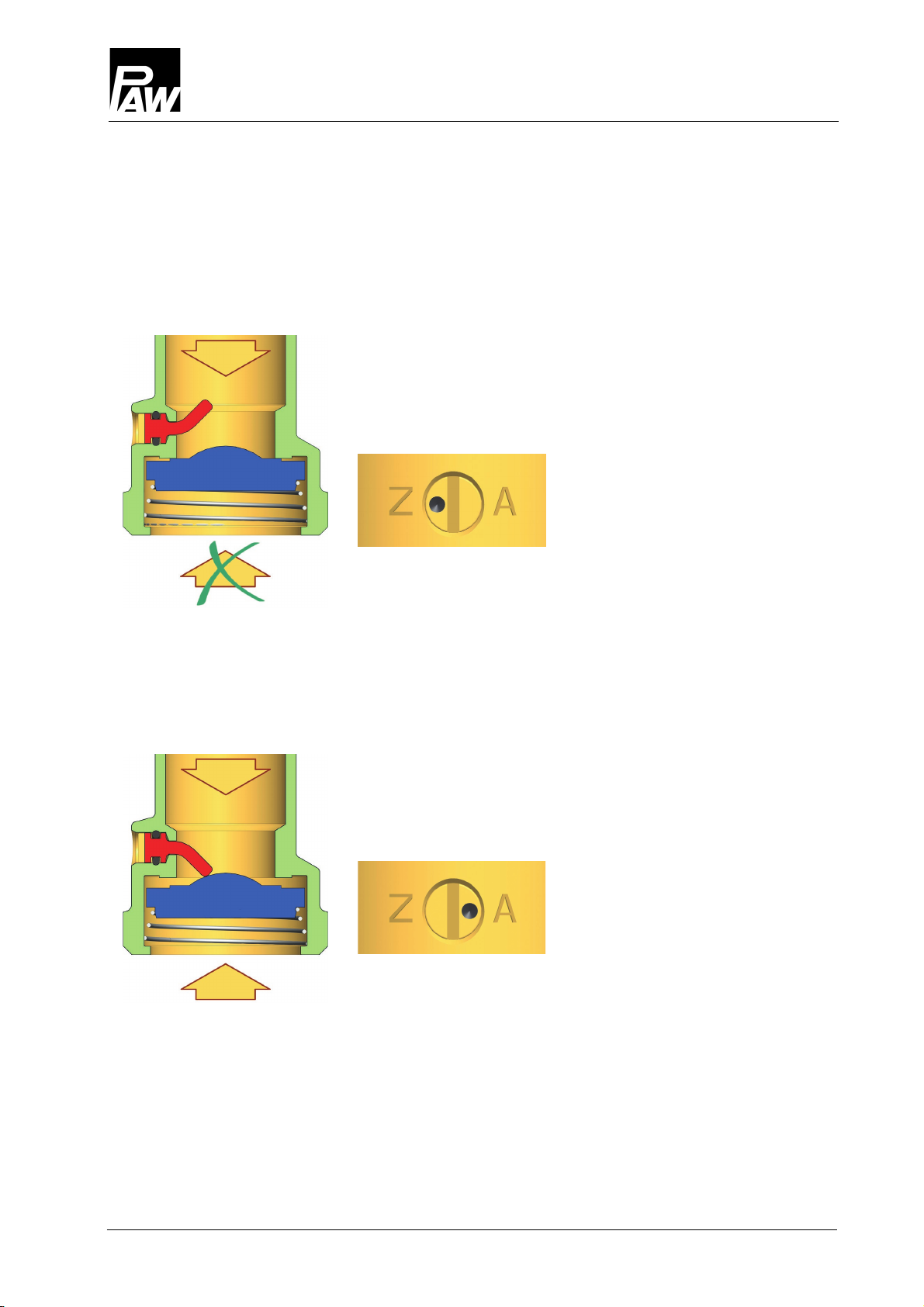

3.5 Flow check valve [specialist] ......................................................................................10

4Assembly and installation [specialist]........................................................................... 11

4.1 Installation and commissioning of the HeatBloC®.......................................................11

5Scope of delivery [specialist]....................................................................................... 13

5.1 Spare parts DN 25......................................................................................................14

5.2 Spare parts DN 32......................................................................................................16

6Technical data........................................................................................................... 18

6.1 Pressure drop and pump characteristic curves DN 25................................................ 19

6.2 Pressure drop and pump characteristic curves DN 32................................................19

7Disposal ................................................................................................................... 20