8

ACCESSORIES

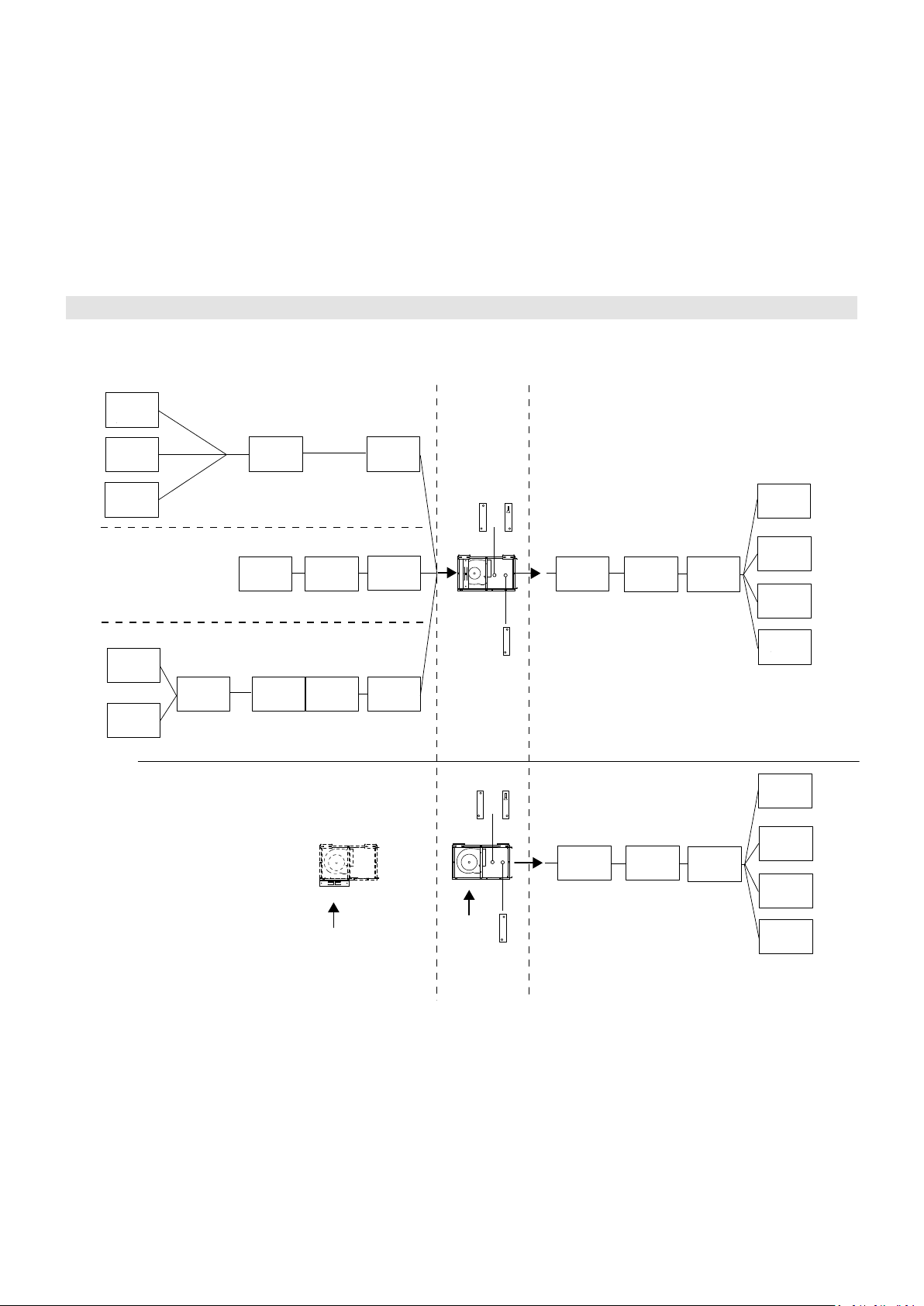

M2S Mixing chamber 2 dampers

Section made of galvanised steel sheet with two air calibration

dampers and louvers made of galvanised sheet steel. 50 mm louver

pitch; 8 mm motorised regulation pin made of galvanised steel.

M3S Mixing chamber 3 dampers

Section made of galvanised steel sheet with three air calibration

dampers and louvers made of galvanised sheet steel. 50 mm louver

pitch; 8 mm motorised regulation pins made of galvanised steel. It

must be coupled with the VRF accessory

FTF Soft bag lter section

Section made of galvanised steel sheet with F6 degree of ltration

soft bag lters. For dierent ltering degrees, please contact the

Aermec Sales Technical Dept.

B1R 1-row water coil

For 4-pipe systems, positioned internally, downstream of the main

coil. The threaded sleeves for the hydraulic connections and the air

vent valve are supplied.

B2R 2 row water coil

For 4-pipe systems, positioned internally, downstream of the main

coil. The threaded sleeves for the hydraulic connections and the air

vent valve are supplied.

VCT Two or three-way valve (actuator excluded)

They are 2 and 3-way globe bronze valves with female/female

connections that can be servo-activated by servo controls. The VCT

valves do not have ttings and pipes for hydraulic connections,

which must be provided by the installer.

They can be controlled from the control panels (accessories),

enabled at the valves control function. Before selection, consult

the features of the control panels.

VCTA Two or three-way valve actuator

the VCT series valves can be combined with one of the two actuators,

VCTA230 on/o 230V or 24V modulating VCTA24M. The actuator

must be selected according to the type of system/adjustment

provided.

PBE Section with post-heating coil

The electric coil consists of armoured resistances tted with a twin

safety thermostat.

SSL Module with silencer baes

Section made of galvanised steel sheet with mineral wool silencer

baes covered in a polyethylene lm in order to prevent aking.

S2Z 2-area damper (70-30%)

Damper made of galvanised steel sheet with opposite louvers for the

external air ow to blend with the recirculating air ow. 50 mm louver

pitch; 8 mm motorised regulation pin made of galvanised steel.

VRF Return ventilating section with a G4 lter

Ventilation unit equipped with an electronic rev shifter, contained in

a galvanised steel sheet section with at lters having a G4 eciency

(EN779).

PMM Plenum with multiple circular ow attachments

Plenum with 15 mm thick galvanised steel sandwich panel with

polyurethane insulation. The plenum has multi-diameter circular

plastic ttings (200 mm, 180 mm and 150 mm) for circular pipes to be

connected.

PMC Closed ow plenum

Closed plenum with 15 mm thick galvanised steel sandwich panel

with polyurethane insulation. The plenum allows the ow to turn

by 90°. The installer must make the ow aperture.

SAS Intake damper

Air calibration damper with louvers made of galvanised sheet

steel. 50 mm louver pitch; 8 mm motorised regulation pin made of

galvanised steel.

GMD Flow grid with adjustable louvers

Grid with double row adjustable louvers for air to be introduced in

the relative room. It can be installed directly on the appliance by

removing the anges or on the wall.

GAP Intake grid

With louvers tilted at 45°; it can be installed directly on the

appliance by removing the anges or on the wall.

FPI G4 lter ange for lower intake

PX Control panel with only the switch-over

WMT 05 Electro-mechanical thermostat

For fan coils installed in 2-pipe systems. The panel must be

installed on the wall and protected electrically with an internal

fuse. It has the following functions:

- on / o switch;

- cursor to select the heating / cooling modes (manual season

change);

- cursor to select the fan speed (high, medium and low);

- temperature selector (+5°C÷30°C)

WMT10 Control panel

For fan coils installed on the wall. Controls the fan coil operation

according to the set mode. The panel must be wall mounted; it

is to be used in 4-pipe and 2-pipe systems and 2-pipe systems

with resistance, with the possibility of connecting two ON - OFF

type valves to cut o the coil supply water. The panel is protected

electrically by an internal fuse. The control has the following

functions:

- cursor to select cooling or heating functioning mode;

- manual season change;

- manual selection of the fan speed;

- selection of the desired room temperature (+10°C÷30°C);

- 2-pipe system management;

- 4-pipe system management;

- 2-pipe system management (cooling) + electrical resistance

(heating);

- thermostated ventilation;

- continuous ventilation;

- continuous ventilation in cooling mode and thermostatic in

heating mode.