Aerservice Equipments ARMOTECH Instruction manual

ARMOTECH

Rev 02.00

Pag. 1 di 24

©| Aerservice Equipments S.r.l. | 2021 all rights reserved è vietata la riproduzione del presente manuale, anche parziale.

INSTRUCTION MANUAL

FOR USE

AND MAINTENANCE

ARMOTECH

Rev 02.00

Pag. 2 di 24

©| Aerservice Equipments S.r.l. | 2021 all rights reserved è vietata la riproduzione del presente manuale, anche parziale.

CONTENTS

Par

Descrizione

0

Analytical index of the operating and maintenance manual

CONTENTS.........................................................................................................................2

Analytical index of the operating and maintenance manual ..................................................2

GENERAL INFORMATION.................................................................................................3

Manufacturer’s identification data ...........................................................................................3

Machine identification and data plates (if they are present) ..................................................4

Declarations...............................................................................................................................4

UK Declaration of Conformity (UKCA).....................................................................................6

THE SUCTION ARM ARMOTECH......................................................................................7

Description of the arm ..............................................................................................................7

Technical data ...........................................................................................................................9

ASSEMBLY OF THE ARM ARMOTECH..........................................................................11

Assembly.................................................................................................................................11

TYPES OF WALL BRACKET ...........................................................................................14

Description types of wallbracket:...........................................................................................14

FIRST START ...................................................................................................................18

Recommendations ..................................................................................................................18

Normal use...............................................................................................................................19

MAINTENANCE ................................................................................................................20

Ordinary and extra-ordinary maintenance.............................................................................20

DISASSEMBLY AND DISPOSAL.....................................................................................21

Disassembly and disposal......................................................................................................21

OPERATOR’S NOTES......................................................................................................22

Details of maintenance operations ........................................................................................22

ARMOTECH

Rev 02.00

Pag. 3 di 24

©| Aerservice Equipments S.r.l. | 2021 all rights reserved è vietata la riproduzione del presente manuale, anche parziale.

GENERAL INFORMATION

Par

Description

1

Manufacturer’s identification data

MANUFACTURER

Aerservice Equipments S.r.l.

REGISTERED OFFICE –ADMINISTRATIVE OFFICE

Viale dell’industria 24 –35020 –Legnaro –(PD) –Italy

CONTACTS

Tel. +39 049 641 200

E-mail: info@aerservice.com

ARMOTECH

Rev 02.00

Pag. 4 di 24

©| Aerservice Equipments S.r.l. | 2021 all rights reserved è vietata la riproduzione del presente manuale, anche parziale.

GENERAL INFORMATION

Par

Description

2

Machine identification and data plates (if they are present)

Each machine is fitted with a CE plate with indelible identification data. All communications with the

manufacturer or technical assistance centres must refer to the said data.

The position of the plate on the machine may vary.

GENERAL INFORMATION

Par

Description

3

Declarations

The machine is manufactured in conformity with relevant EC Directives applicable when the machine is put

on the market.

ANNEX IV Directive 2006/42/EC

The machine does not belong to the category of machines mentioned in Annex IV to directive 2006/42/EC.

ARMOTECH

Rev 02.00

Pag. 5 di 24

©| Aerservice Equipments S.r.l. | 2021 all rights reserved è vietata la riproduzione del presente manuale, anche parziale.

EC DECLARATION OF CONFORMITY

(Annex IIA DIR. 2006/42/EC)

THE MANUFACTURER

Aerservice Equipments S.r.l.

Company

Viale dell’Industria, 24

35020

Padova

Address

Postal code

Province

Legnaro

Italy

City

Country

DECLARES THAT THE PRODUCT

Articulated suction arm with external structure and rigid tubes

Description

Serial number

Year of manufacture

ARMOTECH

Commercial name

Extraction of welding fumes and microparticles from industrial processes

Intended use

IS IN COMPLIANCE WITH THE FOLLOWING DIRECTIVES

Directive 2006/42/EC of the European Parliament and Council, May 17th 2016, on machinery amending directive 95/16/EC.

Directive 2014/30/EU of the European Parliament and Council, February 26th 2014, on the approximation of the laws of the member States relating

to electromagnetic compatibility.

Directive 2014/35/EU of the European Parliament and Council, February 26th 2014, on the approximation of the laws of the member States relating

to electrical equipment destined to be used within certain voltage limits.

Directive 2011/65/EU of the European Parliament and Council, June 8th 2011, on the restriction of the utilization of certain substances in the electric

and electronic devices. The following harmonized standards have been applied

UNI EN ISO 12100:2010: Safety of machinery - General principles for design - Risk assessment and risk reduction.

UNI EN ISO 13849-1:2016: Safety of machinery - Safety-related parts of control systems - Part 1: General principles for design.

UNI EN ISO 13849-2:2013: Safety of machinery - Safety-related parts of control systems - Part 2: Validation.

UNI EN ISO 13857:2020: Safety of machinery - Safety distances to prevent hazard zones being reached by upper and lower limbs.

CEI EN 60204-1:2018: Safety of machinery - Electrical equipment of machines - Part 1: General requirements.

The complete list of applied standards, guidelines and specifications are available at the manufacturer.

Additional information: The declaration of conformity decays in case of non-compliant use and in the event of

non-confirmed construction changes approved by the manufacturer.

DECLARES THAT THE TECHNICAL FILE

Has been compiled, and is kept and available at the registered office of the company.

Place and date of the document

The manufacturer

Legnaro,

Marco Gallerino

ARMOTECH

Rev 02.00

Pag. 6 di 24

©| Aerservice Equipments S.r.l. | 2021 all rights reserved è vietata la riproduzione del presente manuale, anche parziale.

UK Declaration of Conformity (UKCA)

THE MANUFACTURER

Aerservice Equipments S.r.l.

Company

Viale dell’Industria, 24

35020

Padova

Address

Postal code

Province

Legnaro

Italy

City

Country

DECLARES THAT THE PRODUCT

Articulated suction arm with external structure and rigid tubes

Description

Serial number

Year of manufacture

ARMOTECH

Commercial name

Extraction of welding fumes and microparticles from industrial processes

Intended use

IS IN COMPLIANCE WITH THE FOLLOWING DIRECTIVES

Machinery: The Supply of Machinery (Safety) Regulations 2008.

EMC: Electromagnetic Compatibility Regulations 2016.

LVD: The Electrical Equipment (Safety) Regulations 2016.

RoHS: Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment Regulations 2012.

The following harmonized standards have been applied

S.I. 2008 No. 1597: Safety of machinery - General principles for design - Risk assessment and risk reduction (ISO 12100:2010)

S.I. 2008 No. 1597: Safety of machinery - Safety-related parts of control systems - Part 1: General principles for design (ISO 13849-1:2015)

S.I. 2008 No. 1597: Safety of machinery - Safety-related parts of control systems - Part 2: Validation (ISO 13849-2:2012)

S.I. 2008 No. 1597: Safety of machinery - Safety distances to prevent hazard zones being reached by upper and lower limbs (ISO 13857:2008)

S.I. 2008 No. 1597: Safety of machinery - Electrical equipment of machines - Part 1: General requirements.

The complete list of applied standards, guidelines and specifications are available at the manufacturer.

Additional information: The declaration of conformity decays in case of non-compliant use and in the event of

non-confirmed construction changes approved by the manufacturer.

DECLARES THAT THE TECHNICAL FILE

Has been compiled, and is kept and available at the registered office of the company.

Place and date of the document

The manufacturer

Legnaro,

Marco Gallerino

ARMOTECH

Rev 02.00

Pag. 7 di 24

©| Aerservice Equipments S.r.l. | 2021 all rights reserved è vietata la riproduzione del presente manuale, anche parziale.

THE SUCTION ARM ARMOTECH

Par

Description

1

Description of the arm

The new ARMOTECH series, thanks to the materials used and the innovative design, allows the operator to

count on high maneuverability, stable positioning and exceptional robustness, guaranteed by a pantograph

structure that supports the arm.

ARMOTECH arm represents the ideal solution for extracting the fumes produced by the various work

operations, in the metalworking, chemical industry, goldsmith laboratories, electronics industry etc. sectors,

capturing fumes as close as possible to the source of pollutant as required by EU regulations and in line with

international standards.

The reduced air flow rates, optimized by the possibility of choosing the type of ARMOTECH most appropriate

to the customer's needs, ease of installation and reduced maintenance, mean that this product increasingly

meets the favor of operators in the sector.

ARMOTECH

Rev 02.00

Pag. 8 di 24

©| Aerservice Equipments S.r.l. | 2021 all rights reserved è vietata la riproduzione del presente manuale, anche parziale.

CAUTION:

During the removal of the packaging, all resulting residues must be disposed of in accordance with

the provisions of the laws in force.

For greater simplicity and better comprehensibility of this manual, some images have been rendered

not exactly in conformity with reality (e.g. dismantled protections).

The installation operations (lifting, fixing, etc.) must be carried out through the use of appropriate

devices and means and in accordance with the Legislative Decree 626/94.

At the end of the installation, it should be checked that there are no exhaust gas leaks in the work

environment. Follow the provisions in force regarding emissions into the atmosphere.

Aerservice Equipments SRL declines all responsibility for damage to persons or things, which could

derive either from an improper use of the appliance or from failure to observe what is prescribed in

this manual.

ARMOTECH

Rev 02.00

Pag. 9 di 24

©| Aerservice Equipments S.r.l. | 2021 all rights reserved è vietata la riproduzione del presente manuale, anche parziale.

THE SUCTION ARM ARMOTECH

Par

Description

2

Technical data

AVAILABLE VERSIONS:

IBSA

Ø

LENGTH

AIR FLOW

HEAD LOSS

WEIGHT

TOT.

mm

mm

m³/h

Pa

Kg

100/2

100

2000

600 - 750

average 700

15

100/3

3000

23

125/2

125

2000

800 - 900

average 700

16

125/3

3000

24

125/4

4000

28

160/2

160

2000

1000 - 1200

average 700

18

160/3

3000

26

160/4

4000

30

IBSAV

Ø

LENGTH

FAN

POWER

EXTRACTION

CAPACITY

ERSIDUAL

PRESSURE

NOISE

WEIGHT

TOT.

mm

mm

mod.

kW

m³/h

Pa

dBA

Kg

100/2

100

2000

EV 15

1,1

750

520

74

31

100/3

3000

39

125/2

125

2000

EV 15

1,1

900

520

74

32

125/3

3000

40

125/4

4000

44

160/2

160

2000

EV 18

1,5

1200

520

74

34

160/3

3000

42

160/4

4000

46

IBSAC

Ø

LENGTH

AIR FLOW

HEAD LOSS

WEIGHT

TOT.

mm

mm

m³/h

Pa

Kg

100/2

100

2000

600 - 750

average 700

15

100/3

3000

23

125/2

125

2000

800 - 900

average 700

16

125/3

3000

24

125/4

4000

28

160/2

160

2000

1000 - 1200

average 700

18

160/3

3000

26

160/4

4000

30

ARMOTECH

Rev 02.00

Pag. 10 di 24

©| Aerservice Equipments S.r.l. | 2021 all rights reserved è vietata la riproduzione del presente manuale, anche parziale.

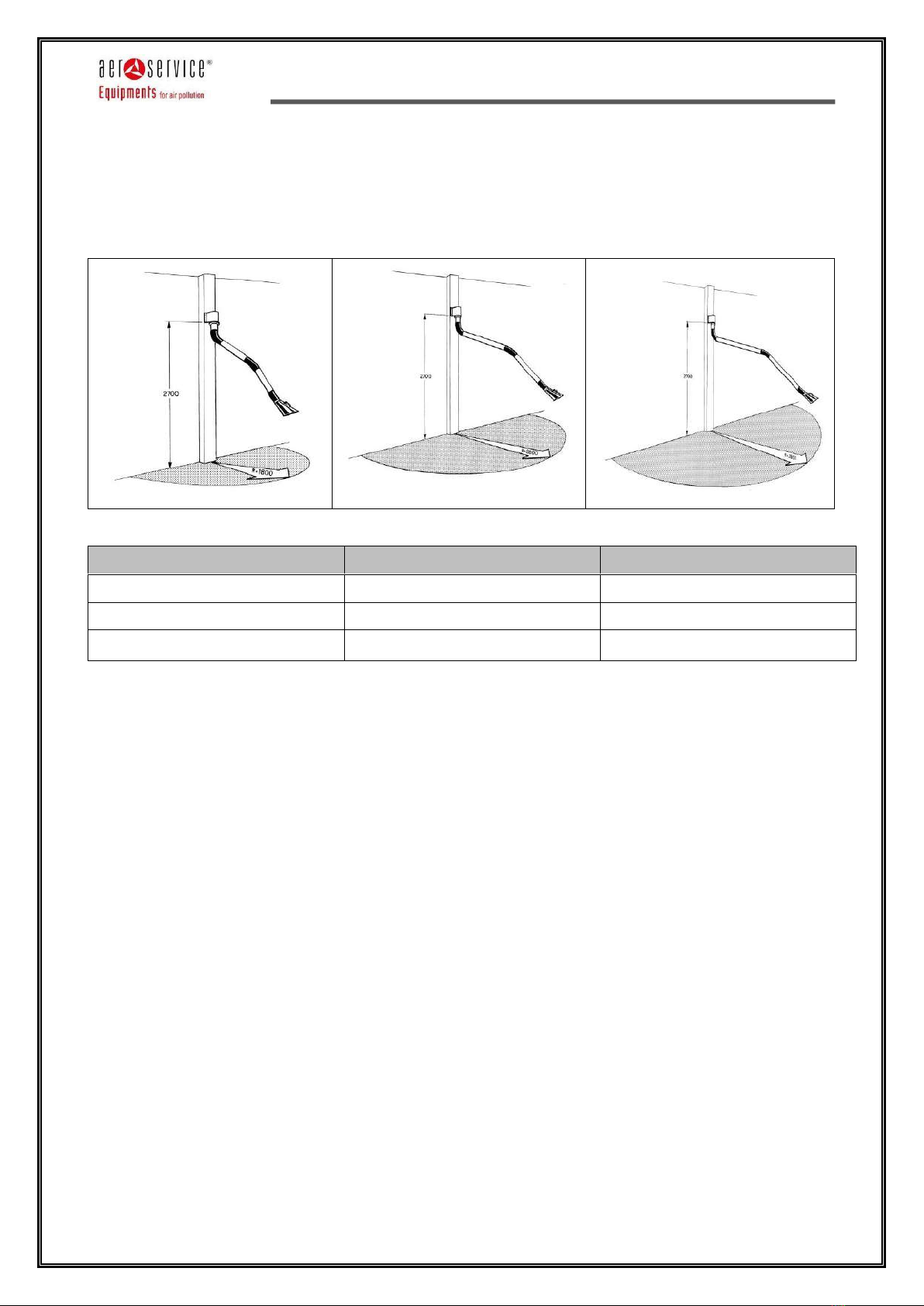

For arms with a length of 2, 3, 4 m, the table shows the range of action (corresponding to the maximum

extension of the arm), installation height, figure and diagram.

Mod.

Height of installation (m)

Radius of action (m)

ARMOTECH L = 2000

2,40

2,25

ARMOTECH L = 3000

2,40

3,25

ARMOTECH L = 4000

2,70 - 3,80

4,25

ARMOTECH

Rev 02.00

Pag. 11 di 24

©| Aerservice Equipments S.r.l. | 2021 all rights reserved è vietata la riproduzione del presente manuale, anche parziale.

ASSEMBLY OF THE ARM ARMOTECH

Par

Description

1

Assembly

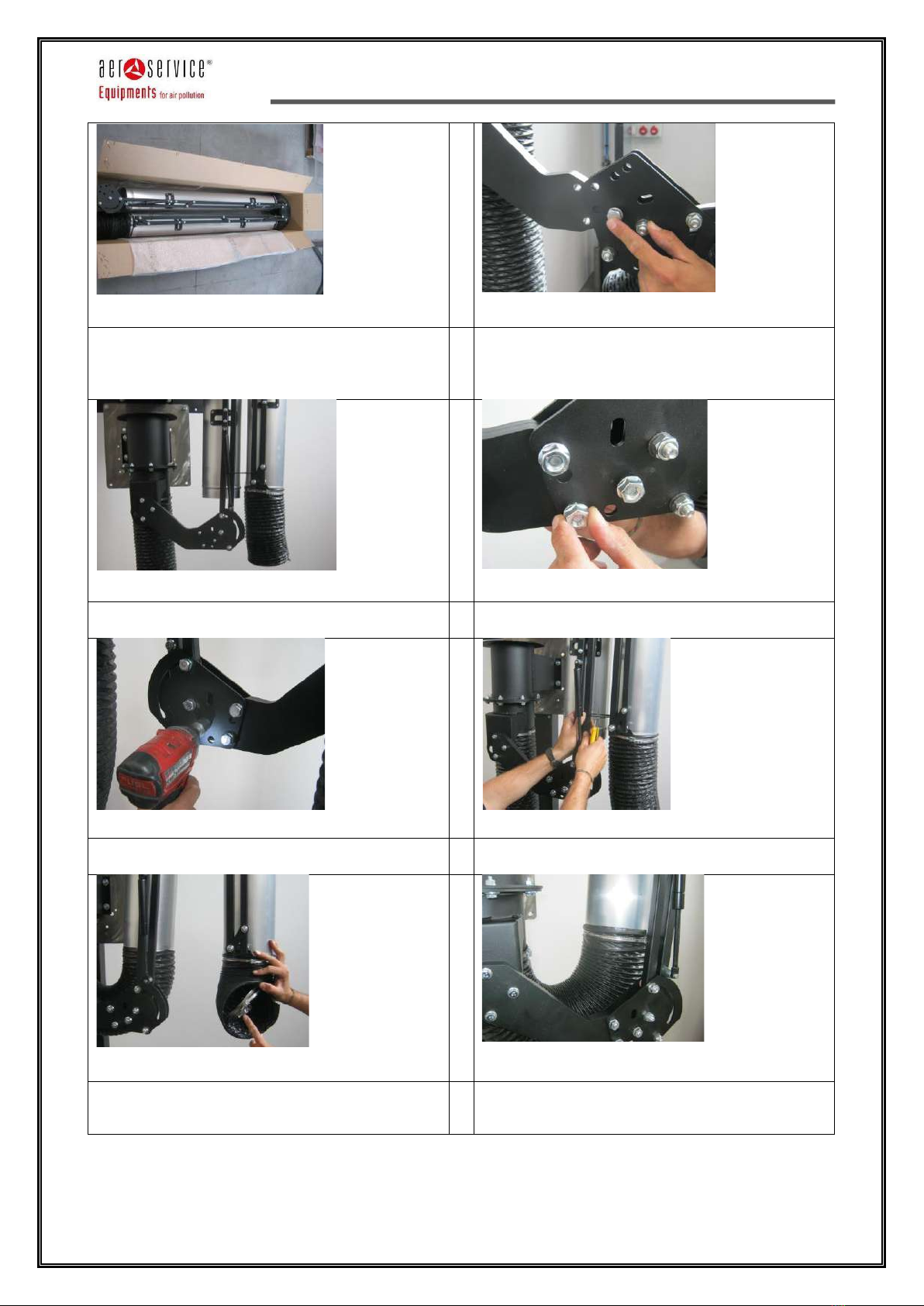

The arm is packed inside n ° 4 cardboard boxes:

1. Rotating base unit

2. Lever (for wall arm version)

3. Articulated arm assembly incl. aluminium tubes and PVC sleeves

4. Suction hood incl. bolts

1

2 –open the box with the rotating base and check

that the hardware kit, the rotating base unit, the

flexible hose and the 3 pre-assembled screws are

present.

3 –use the screws of the bag to connect the

rotating flange of the rotating base unit to the

lower flange of the wall bracket.

In this phase, lubricate the internal part of the r

rotating base unit with grease.

4 –ensure that all M8 screws are tightened fix.

5 –open the box of the lever and check that the

hardware kit and the lever are present.

6 –use the pre-assembled screws on the rotating

base unit to secure the lever on it.

Be sure to tighten all three screws.

1

4

3

2

ARMOTECH

Rev 02.00

Pag. 12 di 24

©| Aerservice Equipments S.r.l. | 2021 all rights reserved è vietata la riproduzione del presente manuale, anche parziale.

7 –open the box of the articulated arm assembly

and check its integrity.

8 –use one of the screws of kit supplied to fix the

structure to the lever.

Use the hole indicated first, to make assembly

easier.

9 –lift the structure until the remaining holes

match and insert the appropriate screws.

10 –screw the flanged nuts to the screws.

11 –be sure to tighten all three M10 screws.

12 –carefully remove the plastic band that keeps

the pantograph system closed.

13 –remove the two hose clamps from inside the

hose.

14 –use a clamp to secure the flexible sleeve to

the aluminum tube.

ARMOTECH

Rev 02.00

Pag. 13 di 24

©| Aerservice Equipments S.r.l. | 2021 all rights reserved è vietata la riproduzione del presente manuale, anche parziale.

15 –open the suction hood box and check the

integrity of the hood and the presence of the

protective band called "clamp cover".

16 -

17 –remove the screw and nut. The red bakelite

washers must remain attached to the joint

structure.

18 –insert the clamp cover into the hood

19 –screw the suction hood to the joint using the

screws removed previously, making sure to insert

the belleville washers (dished washers) in the

correct direction.

Make all the adjustments of the joint by screwing

or unscrewing the system.

20 –use the second hose clamp to fix the flexible

sleeve and finally use the clamp cover to hide

everything.

21 –move and check correct maneuverability and, if necessary, review the adjustments made previously.

ARMOTECH

Rev 02.00

Pag. 14 di 24

©| Aerservice Equipments S.r.l. | 2021 all rights reserved è vietata la riproduzione del presente manuale, anche parziale.

TYPES OF WALL BRACKET

Par

Descrption

1

Description types of wallbracket:

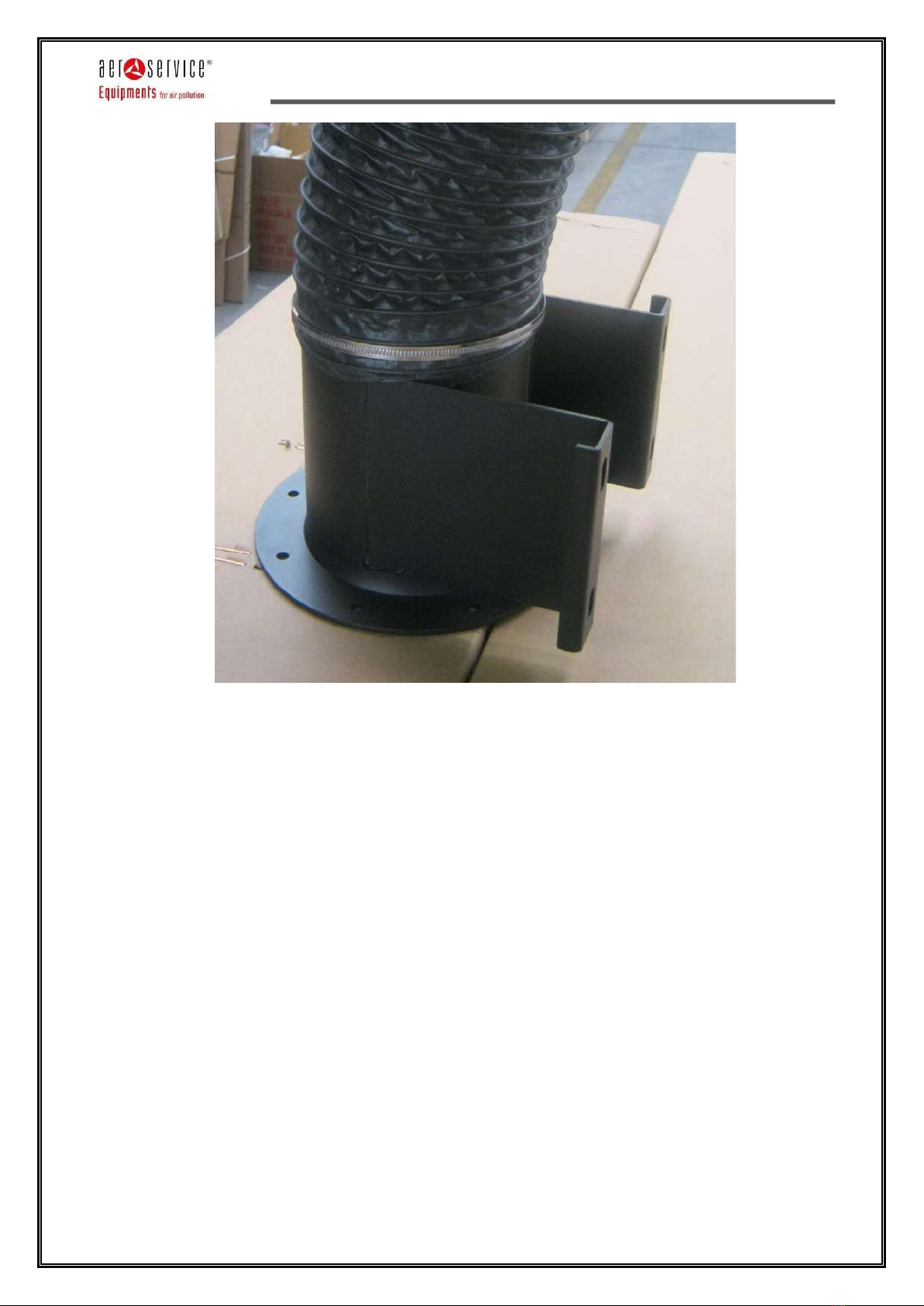

1) Bracket for central ventilation plants;

2) Bracket for fan;

3) Bracket with RF1 adapter.

Bracket for central ventilation plants, without hose.

ARMOTECH

Rev 02.00

Pag. 15 di 24

©| Aerservice Equipments S.r.l. | 2021 all rights reserved è vietata la riproduzione del presente manuale, anche parziale.

Bracket for central ventilation plants, with hose

ARMOTECH

Rev 02.00

Pag. 16 di 24

©| Aerservice Equipments S.r.l. | 2021 all rights reserved è vietata la riproduzione del presente manuale, anche parziale.

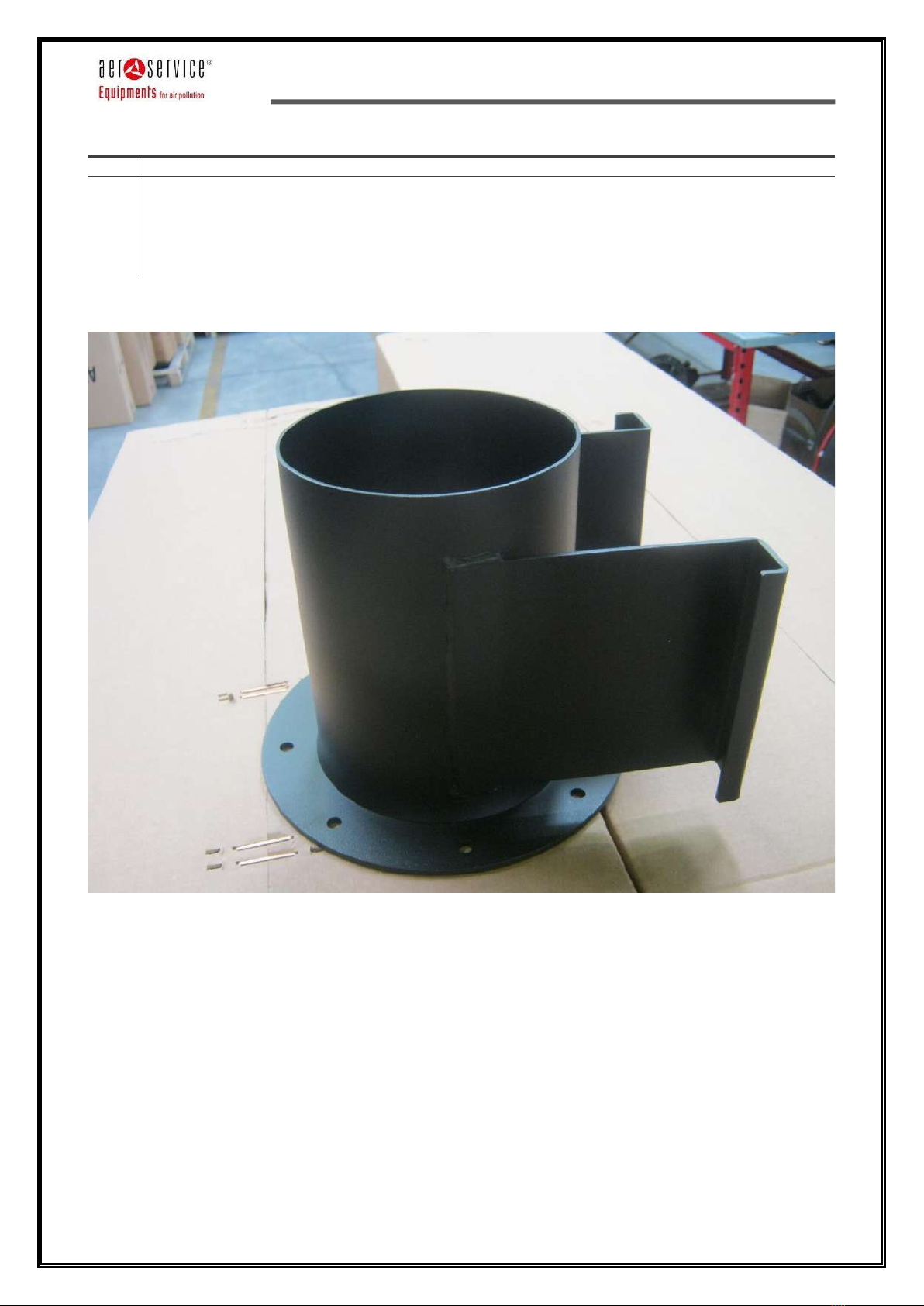

Bracket for extractor fan

FLANGE WITH HOLES FOR

FIXING OF FAN

MOD. EV 15 / EV 18

FLANGE WITH HOLES FOR

FIXING OF ROTATING

BASE UNIT OF THE

SUCTION ARM

ARMOTECH

Rev 02.00

Pag. 17 di 24

©| Aerservice Equipments S.r.l. | 2021 all rights reserved è vietata la riproduzione del presente manuale, anche parziale.

Bracket with RF1 adapter

ARMOTECH

Rev 02.00

Pag. 18 di 24

©| Aerservice Equipments S.r.l. | 2021 all rights reserved è vietata la riproduzione del presente manuale, anche parziale.

FIRST START

Par

Description

1

Recommendations

Permitted environmental conditions

-The ambient operating temperature of the machine is between -10 ° C and 60 ° C.

-The humidity of the internal environment in which the work is carried out must be between 0% and

90%.

-THE EQUIPMENT CANNOT BE USED IN AN EXPLOSIVE ATMOSPHERE!

Indications relating to the removal / elimination of waste materials

The elimination of this material must be carried out according to current regulations.

Recommendations on the prevention measures that must be adopted by the user

For the replacement operations of any damaged parts, consult the manufacturer.

Testing the machine

It is carried out by the manufacturer at its headquarters before shipment.

After carrying out the checks described above, turn on the suction arm with the switch on the panel and

adjust the position of the suction arm.

ARMOTECH

Rev 02.00

Pag. 19 di 24

©| Aerservice Equipments S.r.l. | 2021 all rights reserved è vietata la riproduzione del presente manuale, anche parziale.

FIRST START

Par

Description

2

Normal use

The equipment must only be used to suck in semi-dusty air of low and medium grain size deriving from

industrial processes through the suction arm or the flexible hose whose ends are inserted one into the

special attachment on the suction arm, the other near the position where the fumes are generated (e.g.

welding fumes).

For any other use, other than that described, the manufacturer is not liable.

Usage rules

- In general, do not disassemble or remove any part of the suction arm when it is in operation or connected

to the power supply.

- Do not insert the electric cable into the joints of the arm.

- Do not tamper with the components of the electrical panel.

- Do not operate the vacuum cleaner for a long time with the arm nozzle closed.

- Do not suck up liquids.

IMPORTANT NOTE!

THE EQUIPMENT CANNOT BE USED IN AN EXPLOSIVE ATMOSPHERE!

Most frequent faults: causes and remedies

Given that most of the malfunctions occur due to incorrect use of the system, some possible malfunctions

that may occur and the measures to be taken to remedy them are indicated in the following table.

FAULT

POSSIBLE CAUSE

REMEDY

The suction arm does not support itself,

maneuverability and positioning of the

hood is compromised.

•The clutches are loose :

• new clutches that must grip

the support material

• consumption of the same

Tighten the fixing bolts gradually and not

too much so as not to compromise

maneuverability.

The sleeves break near the grip

The clutch bolts are tightened too much,

overcoming the resistance of the joints

•Loosen the clutch bolts, and

replace the hoses:

• hood connection forearm tube

(replacement can be carried out

by the customer)

• spring part tube (must be

replaced by the manufacturer

for safety reasons)

Breakage of flexible fittings.

Wear, abrasion, puncture etc. caused by

incandescent material sucked in by the

arm.

Remove and replace the hose clamps

The fan over the suction arm stops

suddenly.

Power failure.

Restore the power supply

The fuse has blown

Replace the fuse.

The thermal switch has tripped.

Open the switchboard and reset the

switch.

Check the reasons why the thermic

tripped.

The engine burned out.

Repair where possible or replace. See

related manual.

Turn off

To turn off the arm, turn OFF the switch on the electric switch box.

ARMOTECH

Rev 02.00

Pag. 20 di 24

©| Aerservice Equipments S.r.l. | 2021 all rights reserved è vietata la riproduzione del presente manuale, anche parziale.

Description of dangers and specific protections

However, the manufacturer has taken steps to reduce the dangers that may arise due to incorrect use of the

machine by installing protective devices on the machine itself.

Description of hazards that cannot be eliminated from the security measures adopted

The dangers that cannot be eliminated from the safety measures adopted by the manufacturer are caused

by incorrect use of the machine or by a failure by the user to comply with the safety standards described in

this manual.

INSTRUCTIONS FOR EMERGENCY SITUATIONS

In case of fire, use powder fire extinguishers complying with current regulations.

Never use liquid fire extinguishers.

In case of fire, pay attention to the combustion gases (plastic system).

MAINTENANCE

Par

Description

1

Ordinary and extra-ordinary maintenance

CLEANING AND ROUTINE MAINTENANCE

Adequate cleaning is recommended for optimal operation. Regular checks and cleaning of the fan impeller

should be provided.

For normal cleaning operations, commercially available cleaners can be used.

Regular maintenance of the system increases its duration and operating safety, the hood internal joint must

be periodically greased.

EXTRAORDINARY MAINTENANCE, REPLACEMENTS AND REPAIRS

Extraordinary operations are those for the repair and replacement of one or more components of the

the system that normally becomes necessary only after years of good operation, which do not alter the

characteristics of the machine.

The device does not require any particular replacements except in cases where there is a possible filtering of

the fluid downstream of the system.

The parts most subject to wear and which need to be replaced over time can be the flexible hose, the nozzle

and the centrifugal impeller of the fan.

In the event of substantial changes, the manufacturer cannot be held responsible for any dangers that may

arise.

Table of contents

Other Aerservice Equipments Welding Accessories manuals