AfiMilk AfiAct II User manual

Heat Detection TieStall™– Test Group Guide

s

Preface

Preface

AfiAct II™ Installation Manual

Page i

AfiAct II™

Installation

Product: Reader 2.0

Manual P/N 9440311

Version 2.8

Date Completed –Jan 2020

Afimilk Ltd., Kibbutz Afikim, 15148 Israel

Tel: 972-4-6754812 | Fax: 972-4-6751862

Federal Communications

Commission, USA

Conformité Européenne

(European Conformity)

Standards Institute

of Israel

Ministry of Internal

Affairs and

Communications, Japan

Industry Canada

Preface

Preface

AfiAct II™ Installation Manual

Page ii

Preface Material

About this Manual and Scope

This manual describes the installation of AfiAct II, either as a standalone system or as

part of the larger Afimilk system. For a description of the features and usage of the

AfiAct II system, refer to AfiAct II UM.

Intended Users

This manual is intended forAfimilk authorized technicians, experienced in installing

electrical systems in non-protected environments, for dealers-technicians and farm

technicians.

Contacting Technical Support HelpDesk

Afimilk technical support contact information:

email: [email protected]o.il

Tel: +972-4-675-4824.

Preface

Preface

AfiAct II™ Installation Manual

Page iii

Notes and Certifications

This device complies with FCC Rules Part 15 and with Industry Canada license-

exempt RSS standard(s). Operation is subject to two conditions: (1) This device may

not cause harmful interference, and (2) this device must accept any interference that

may be received or that may cause undesired operation.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux

appareils radio exempts de licence. L'exploitation est autorisée aux deux conditions

suivantes :

(1) l'appareil ne doit pas produire de brouillage, et

(2) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même

si le brouillage est susceptible d'en compromettre le fonctionnement.

NOTE: The digital circuit of this device has been tested and found to comply with the

limits for a Class B digital device, pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to

try to correct the interference by one or more of the following measures:

•Reorient or relocate the receiving antenna.

•Increase the separation between the equipment and receiver.

•Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

•Consult the dealer or an experienced radio/TV technician for help.

Changes or modifications to this equipment not expressly approved by the party

responsible for compliance (Afimilk Ltd.) could void the user’s authority to operate

the equipment.

To comply with FCC RF exposure compliance requirements, the antenna used for

this transmitter must be installed to provide a separation distance of at least 20 cm

from all persons and must not be co-located or operating in conjunction with any

other antenna or transmitter.

Preface

Preface

AfiAct II™ Installation Manual

Page vii

Legal Notice

Copyright

Copyright © 2016 Afimilk Ltd., All Rights Reserved

Disclaimer

This document contains proprietary information of Afimilk Ltd. and may not be

reproduced in any form without the prior written consent of Afimilk Ltd.

No part of this document may be reproduced, translated, stored in a retrieval system

or transmitted in any form and by any means, electronic, mechanical, photographic,

photocopying, recording, or otherwise, without the prior written permission of

Afimilk Ltd.

Information provided in this document is subject to change without notice and does

not represent a commitment on the part of Afimilk Ltd.

All products and company names are trademarks or registered trademarks of their

respective holders.

Software License Terms

The software and the system design is the property of Afimilk Ltd.

It is supplied to the user to be used solely for its stated purposes. It is strictly

forbidden to make copies of the software or transfer it in any way, for any purpose,

to any third party.

In addition to application software specifically developed by Afimilk Ltd., the system

makes use of certain third party utilities and system software. These are licensed for

a single user. They must not be copied in any way, for any purpose, by the user, its

employees, or anybody else.

The license to use the software is granted to the user only for the specific system it is

installed on by Afimilk Ltd., or its authorized distributors and representatives.

The purchaser shall not modify the software in any way.

It is strictly forbidden to usethis product for any purpose other than originally

designated for or stipulated by Afimilk Ltd.

Preface

Preface

AfiAct II™ Installation Manual

Page viii

Conventions

Important information is highlighted in a frame, as explained below:

Environment notice

Hints and recommendations for working efficiently

Actions requiring special attention, to avoid possible damage to equipment

or livestock

Actions requiring special attention to avoid serious bodily injury;

For example, working with high voltage components

Preface

Preface

AfiAct II™ Installation Manual

Page ix

Safety Instructions and Notice

Before installing and operating any equipment, review the safety instructions for any

hazards associated with installation and use of the device. Also, review standard and

local practices for preventing accidents.

The system and its components are powered by electricity from main power supply.

This power supply is sufficient to cause serious personal injury or even death.

Only a (local state) licensed electrician should install power cables and power supply

units.

Use only a correctly rated power cable that is certified, as appropriate, for the

country of operation.

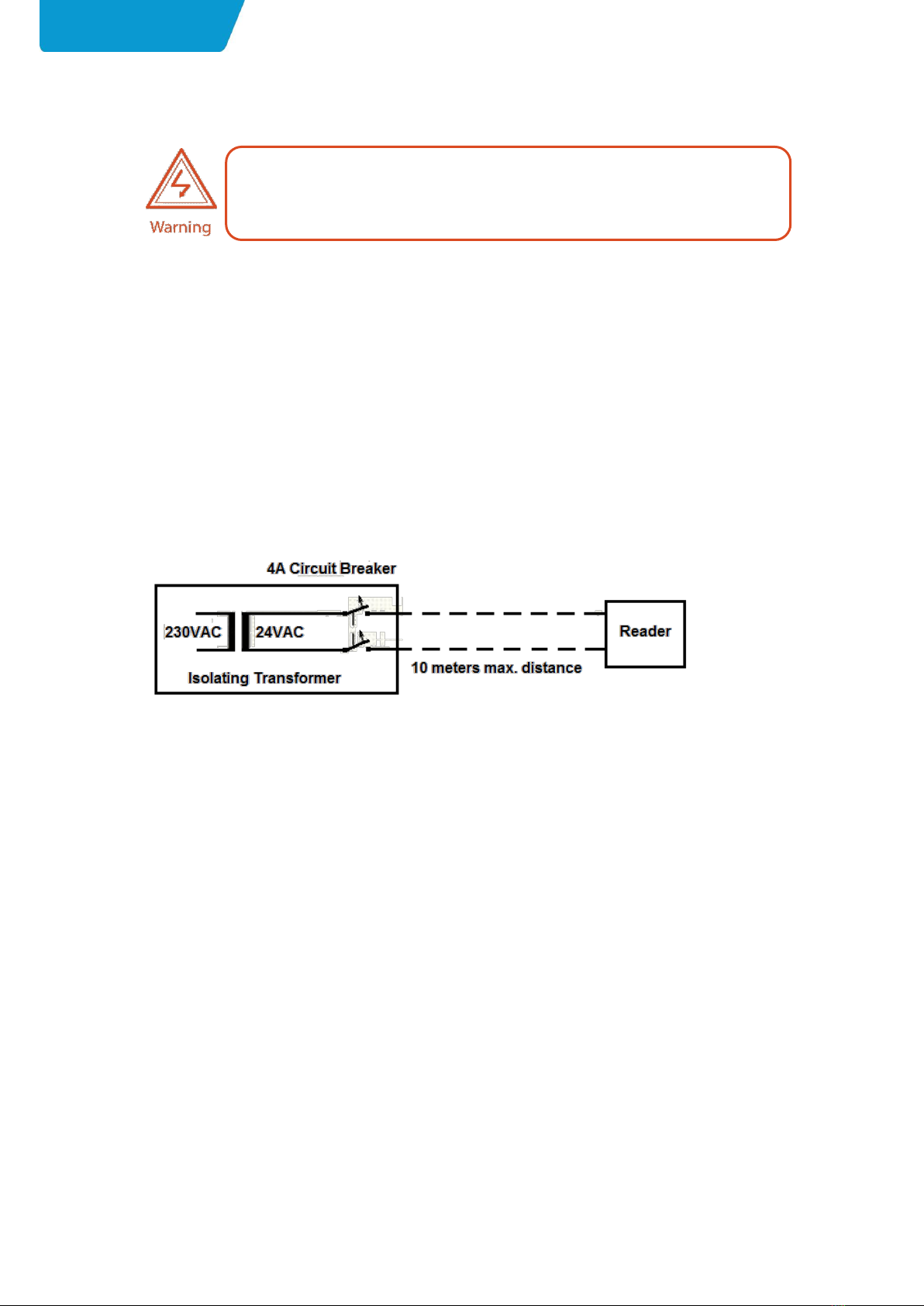

The AfiAct II must be powered by an external isolating transformer (output 21.6 -

27.5Vac, 75 VA maximum, certified as LPS according IEC 60950-1 clause 2.5) with an

accessible circuit breaker and double isolated from mains.

•Read this manual carefully. Proper handling of the equipment is the basis for

correct functioning.

•Only technicians who are skilled and authorized by Afimilk, dealer

technicianstogether with the farm staff may carry out installation of the

equipment.

•The customer is fully responsible for any changes made, either in the system

configuration or in the software application data, by the customer or by the

customer’s agent.

•Afimilk will not be held responsible directly or indirectly for any damage caused

to the customer and/or to a third party and/or to the animals, by an action

and/or change and/or omission performed in the AfiAct II™ system, either by the

customer or by the customer’s agent, directly and/or indirectly.

Electrical connections must only be performed by a certified electrician.

The installation must be performed in accordance with current norms and

regulations as well as local and national rules.

Preface

Preface

AfiAct II™ Installation Manual

Page x

•Afimilk recommends that the customer call for a full system inspection by a

qualified technician authorized by Afimilk every six months.

•It is the responsibility of the operator to install, operate, and maintain the system

in accordance with all applicable laws, codes and regulations.

•The equipment must be used only for the described purpose.

•This system has been checked for viruses prior to supply.If in the course of a

service call, a virus is detected, removal of the virus, and any software or

hardware repairs resulting from it, will be charged to the purchaser.

The system and its components are powered by electricity from a main power

supply. To avoid personal injury, danger of fire, and possible damage to equipment

and materials, all work on electrical and electronic circuits should be done following

these basic safety procedures:

•Power to all Afimilk devices must be supplied through an accessible, well-marked

circuit breaker (usually placed on the power transformer).

•Before conducting work on any Afimilk device, make sure power to devices is

switched off at the circuit breaker (usually placed on the power transformer).

•Remove power from the circuit or equipment prior to working on it. Never

assume the circuit is off; check it with a multimeter.

•In case of electrical fire, switch off the circuit and report it immediately to

appropriate authority.

•Stay away from live circuits. Do not work on or make adjustments when the

power switch is on.

•Never switch on equipment in the presence of water leakage.

•Work in clean, dry areas. Avoid working in damp or wet locations because this

increases the chance of electrical shock.

•Wear only nonconductive shoes to lessen the possibility of electrical shock.

•Remove all rings, wristwatches, bracelets, and similar metal items. Avoid working

in clothing that contains exposed metal zippers, buttons, or other types of metal

fasteners. The metal can act as a conductor, heat up, and cause a bad burn.

•High voltage surges and other power irregularities can cause extensive damage

to a system. It is the responsibility of the operator to provide a power protection

system.

Do not dispose of WEEE as unsorted municipal waste!

Preface

Preface

AfiAct II™ Installation Manual

Page xi

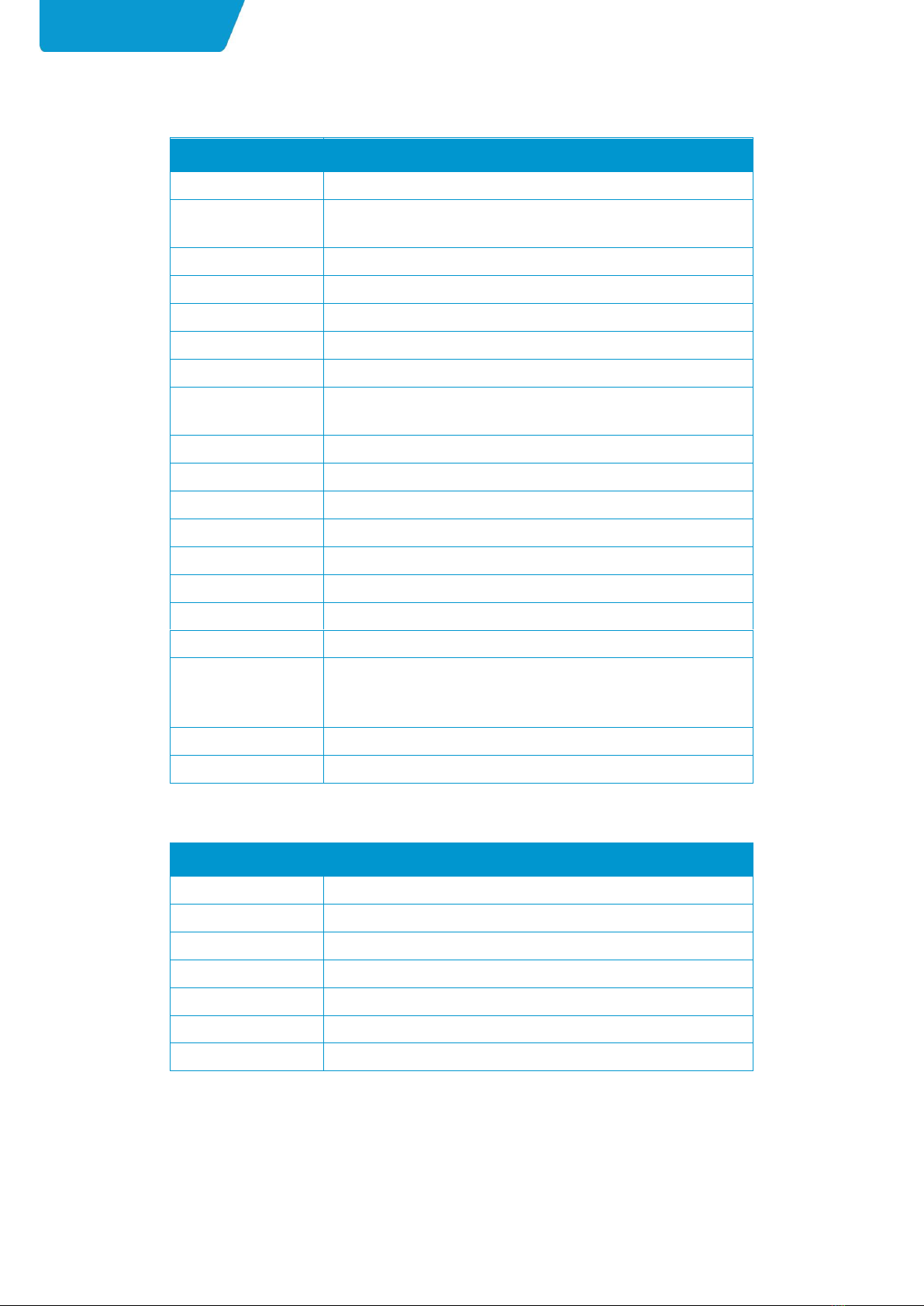

List of Terms and Abbreviations

Term/Abbreviation

Description

RPU

Tag Reading/Programming Unit

AfiAct II

AfiFarm module for generating cow database and

providing general fertility reports.

DIM

Days in Milk

ID

Identification

PC

Personal Computer

PD

Pregnancy Diagnosis

RF

Radio Frequency

LR

Long Range radio i.e. 916/868 MHz, communication

between Reader and tags

SR

Short Range radio i.e. 200/80 KHz

RT

Real Time system

RTMS

Real Time Setup module

RTG

Real Time GUI module - AfiControl

RTC

Real Time Station Controller module

RPM

Revolutions per Minute

Opcode

Operation Code

AP

WiFi Access Point (antenna)

WLAN

Wireless Local Area Network - links two or more devices

using wireless distribution, providing a connection through

an access point to the Internet.

Tx

Transmit

IM

Installation Manual

Referred Documents

PN

Document Name

9140233

Tag Reader& Tag RPU user guide

9040946

SR Opcodes (for RPU programming)

9040953

AfiFarm Installation Manual

5096003

AfiFarm Configuration Manual

9040954

AfiFarm Integration and Prerequisites

9440312

AfiAct II User Manual

9040952

AfiAct II Software Upgrade Instructions (R1 →R2)

Preface

Preface

AfiAct II™ Installation Manual

Page xii

Revision History

Version

Date

Description

1.00

Oct 2013

Revision one.

1.2

Oct 2013

Add FCC Approvals

2.0

Feb 2014

Update WIFI spec 2.2

PC requirements 2.3.1

re-locate RT quick-start (after RT installation) 4.2

add tag-activation runtine 6.1

correct troubleshooting flow for disconnection, 7.1

Update antenna names 1.3.1

update location of RID label,

correct wifi setings 4.4,

remove tag survey section (covered by other sections),

add backup settup,

add db backup and restore.

2.1

Mar 2014

Correct supported Windows version, section 2.4.1

2.2

Mar 2014

Add Japan radio regulation certification (preface).

2.3

Sep 2014

Add Circuit Breaker warning, see Safety instructions on page ix

Replace reader mounting plate and rod

2.4

May 2015

Installation and configuration - screens and process updated.

RPU flow updated

New template implemented

2.5

Sep 2015

Comply with safety regulations (updates in section 1.5)

2.6

Dec 2015

Replace Reader’s blue wire + extension by the new white wire

Correct names (RT Studio→AfiControl)

Update screens and flow

Update safety instructions to suit new regulations

Update AfiTag arrow pictures

2.7

May 2016

New Reader version 2.0, with internal antennas

2.8

Dec 2019

Updated to support AfiCollar.

Updated to work with Windows 10.

Preface

Preface

AfiAct II™ Installation Manual

Page xiii

Table of Contents

Preface Material ......................................................................................................................................ii

Table of Contents .................................................................................................................................xiii

1Introduction ................................................................................................................................ 1

1.1 Principle of Operation ......................................................................................................... 1

1.2 Supported Scenarios ........................................................................................................... 2

1.3 AfiAct II Components .......................................................................................................... 2

1.3.1 Reader Box Components .................................................................................................. 3

1.3.2 Electricity Box Components .............................................................................................. 4

1.3.3 Tag Types ......................................................................................................................... 4

1.4 AfiAct II

Reader –Indicators and I/Os................................................................................. 5

1.4.1 Front Panel - LED Indications ........................................................................................... 5

1.4.2 Back Panel –Inputs and Outputs ..................................................................................... 7

1.4.3 Reader box - Attributes Label ........................................................................................... 8

1.5 AfiAct II Reader Power Specifications ................................................................................. 8

1.6 System Installation Overview.............................................................................................. 9

2Prerequisites and Site Planning................................................................................................. 10

2.1 Determine Reader Mounting Location.............................................................................. 10

2.2 Setup Network and Power Coverage ................................................................................ 12

2.3 Prepare the PC Environment ............................................................................................. 13

2.3.1 Verify Operating System, Processor & Memory ............................................................. 14

2.3.2 Network Connections ..................................................................................................... 19

2.3.3 Additional Windows OS Preparations ............................................................................ 21

2.3.4 Verify System is Prepared ............................................................................................... 28

3Install and Set AfiAct II Software............................................................................................... 29

3.1 General Notes ................................................................................................................... 29

3.2 Set & Initiate the Installation Wizard................................................................................ 30

4Initial Reader Communication................................................................................................... 34

4.1 Connect the Reader to the Wired Network....................................................................... 35

4.2 Set AfiControl (Quick Start)............................................................................................... 37

4.2.1 Navigating AfiControl Tool ............................................................................................. 38

4.2.2 Determine the Required Sampling Sessions ................................................................... 40

4.2.3 Set Mandatory System Parameters ............................................................................... 42

4.2.4 Faulty Tag Check ............................................................................................................ 57

4.3 Verify Reader & AfiControl Communication ..................................................................... 59

4.4 If Needed: Set Wi-Fi Communication ................................................................................ 59

4.4.1 Set Reader to use Wi-Fi settings different than Default ................................................. 60

5Mount the Reader..................................................................................................................... 64

5.1 Mount the Power and Electricity Boxes ............................................................................ 65

5.2 Mount the Reader on the Pole.......................................................................................... 68

5.3 Connect the Reader to Power ........................................................................................... 71

Preface

Preface

AfiAct II™ Installation Manual

Page xiv

6Tag Management ...................................................................................................................... 72

6.1 AfiAct II Tags’ Transmission Test....................................................................................... 73

6.1.1 Activating and Validating AfiTag Transmission ............................................................. 73

6.1.2 Activating and Validating AfiCollar Transmission .......................................................... 75

6.2 Perimeter Coverage Validation......................................................................................... 77

6.2.1 Perimeter Coverage Validation for AfiTags .................................................................... 77

6.2.2 Perimeter Coverage Validation for AfiCollars ................................................................ 77

6.3 Attach Tags ....................................................................................................................... 78

6.3.1 Attach AfiTags to the Cows ............................................................................................ 78

6.3.2 Attach AfiCollars to the Cows ......................................................................................... 81

6.4 Replace and Re-Use Tags.................................................................................................. 82

6.4.1 Remove AfiTag II from the Cow ...................................................................................... 83

6.5 Store Tags ......................................................................................................................... 85

6.5.1 Storage Location ............................................................................................................ 85

6.5.2 Storage Position ............................................................................................................. 85

7Fault Identification and Troubleshooting.................................................................................. 86

7.1 Reader Connection to AfiControl or Network Fault .......................................................... 87

7.2 Tag Problems .................................................................................................................... 88

7.3 Reader and Tag Communication Faults ............................................................................ 89

7.4 Reader’s Luci Cannot be Accessed .................................................................................... 89

7.5 Back-to-Back Connection .................................................................................................. 90

7.6 Region Transmission Setup ............................................................................................... 90

7.7 AfiFarm Installation Problems .......................................................................................... 91

Appendix A: Set Laptop’s Static IP........................................................................................................ 92

Appendix B: RPU Tool for Tag Management ........................................................................................ 97

Appendix C: AfiControl Summary....................................................................................................... 102

Appendix D: TieStall............................................................................................................................ 109

Appendix E: Enter Herd’s Data ........................................................................................................... 111

Introduction

Chapter 1

AfiAct II™ Installation Manual

Page 1

1Introduction

AfiAct II is an estrus and fertility monitoring system that provides at a glance full

picture of cows and heifers in estrus. The monitoring system provides thorough

tracking of the fertility-related data for the dairy farm herd. It can be implemented

either as a standalone system or as part of a comprehensive Afimilk system.

This is done by collecting cows’ physical behavior and aggregating them with

events information to generate heat lists, fertility reports, and fertility disorder

alerts.

1.1 Principle of Operation

The following diagram shows the data flow in the AfiAct II system.

Figure 1: AfiAct II system data flow

AfiAct II uses Long Range (LR) communication to collect data from cow tags (AfiTag

II sensors or AfiCollar sensors) and transfers the information via a standard

network (IP based Wi-Fi or wired communication) to a PC based analysis.

Tags are placed on the cows. Each tag contains the unique ID of each cow, and

records different aspects of its activities, as follows:

•AfiTag II leg tags –records the cow's number of steps, standing time, rest time

and bout.

•AfiCollar neck tags –records the cow's eating and rumination times.

The tags use LR (Long Range) RF (Radio Frequency) communication to send this

data periodically (every pre-defined time-interval, default is 15 minutes) to an

antenna located inside the AfiAct II Reader device (two antennas that provide

optimal coverage).

AfiAct II Reader collects data from the cows’tags which are within its receiving

range. The Reader uses either wired or Wi-Fi communication to send the data to

the PC for analysis (2 internal antennas are for Wi-Fi, when used).

Introduction

Chapter 1

AfiAct II™ Installation Manual

Page 2

The AfiAct II software, located on the PC, uses the collected activity data of each

cow to calculate when the cow is in estrus and find the best time for breeding. The

application generates reports and alerts the farmer.

The communication used by the entire system complies with local regulations and

safety tests, corresponding with the ‘home appliance’category.

1.2 Supported Scenarios

This document describes the following scenarios:

•Installation

•Upgrade from R1 –see AfiAct II software upgrade instructions

Both scenarios use a single computer (no custom installation)

1.3 AfiAct II Components

The following table provides a list of the basic AfiAct II system elements. For

specific part numbers, refer to the detailed tables of each element.

Table 1-1. System Components

Picture

Name

Description

PNs –see:

AfiAct II Reader 2.0

(including nounting

brackets)

TheReader is the interface

between the tags and the

AfiAct II Software. Internal

antennas allow Reader-tag

communication, & Reader-

PC Wi-Fi communication.

1.3.1

AfiAct II software

program (AfiFarm 5.4 +

AfiControl module)

CD with PC software to

control the system:

AfiFarm 5.4 for user

interface;

AfiControl module for

data collection from the

Reader.

4196000A2

Introduction

Chapter 1

AfiAct II™ Installation Manual

Page 3

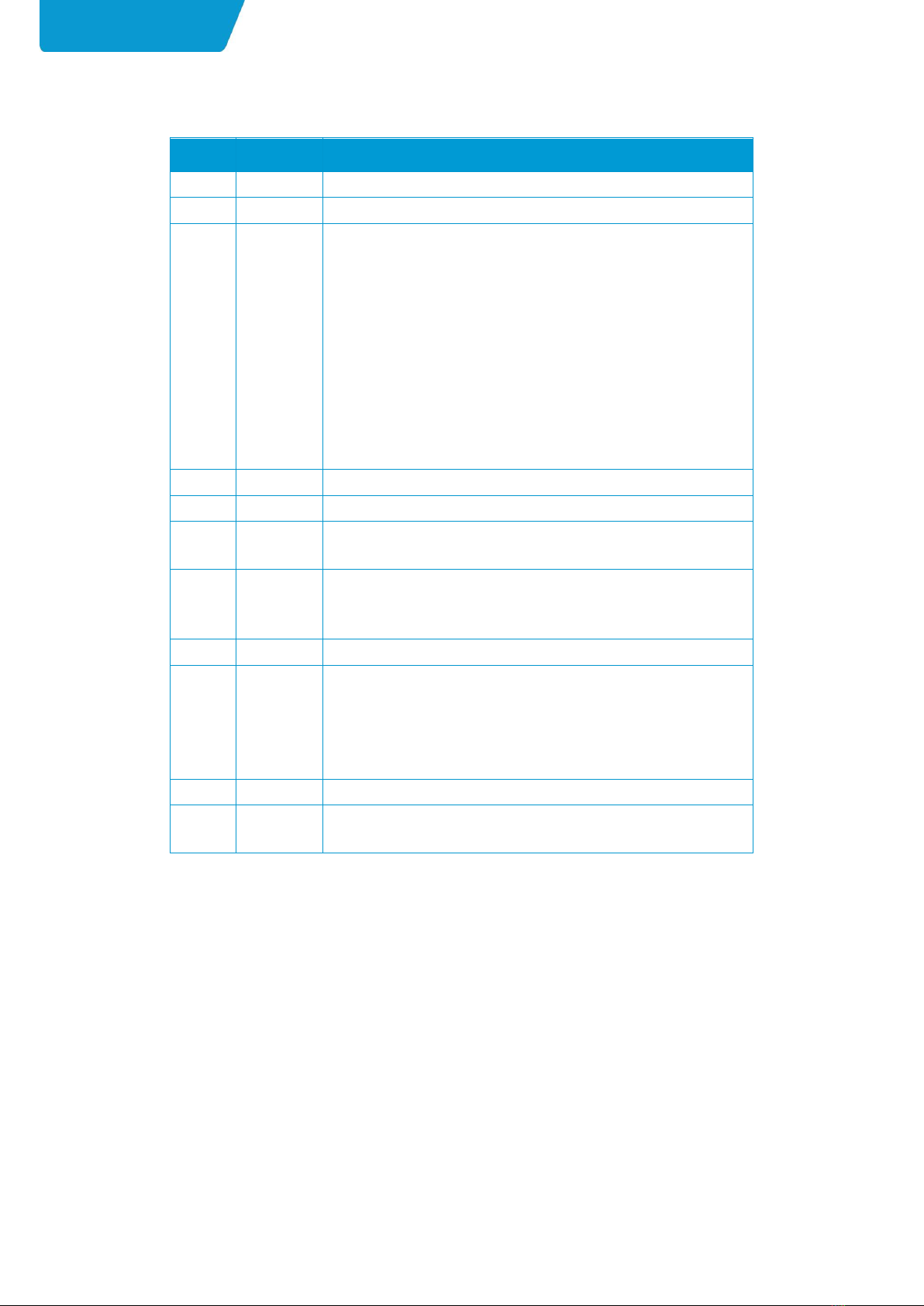

Table 1-2. AfiTag II Components

Picture

Name

Description

PNs –see:

AfiTag II

(40096xx)

Afimilk’s leg-tag, including the

attachment strap.

A tag should be attached to

every cow participating in the

AfiAct II group.

1.3.3

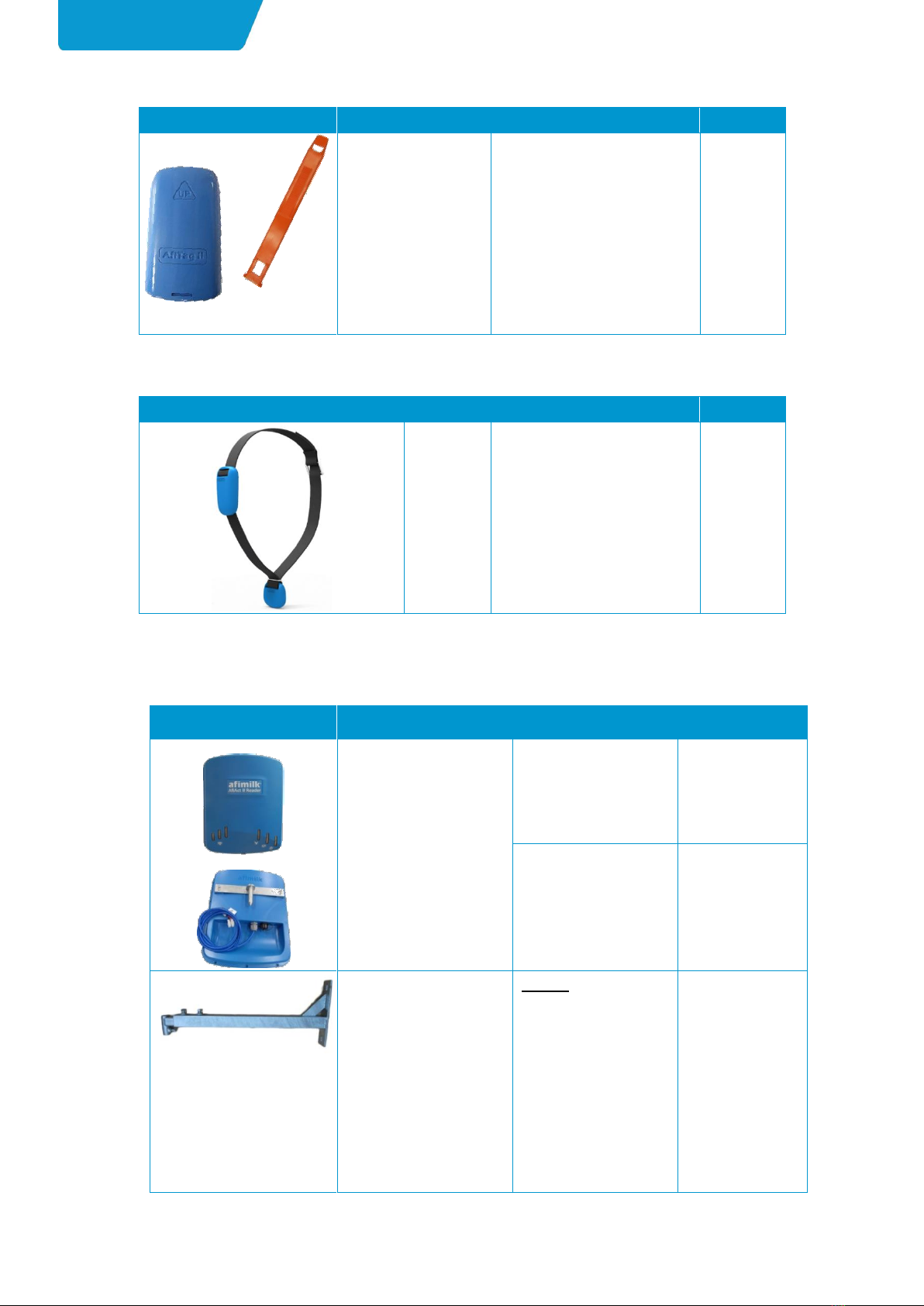

Table 1-3. AfiCollar Components

Picture

Name

Description

PNs –see:

AfiCollar

Afimilk's neck-tag, including

attachment strap and weight.

A tag should be attached to

every cow participating in the

AfiAct II group.

1.3.3

1.3.1 Reader Box Components

Table 1-4.Reader Box Components

Picture

Name

Description

PN

AfiAct II Reader 2.0

International (907-928

MHz)

4256200;

Backward

compatibility

Reader 4256000

Europe (868 MHz):

4256201;

Backward

compatibility

Reader 4256001

Bracket arm

Bracket

(screws for wall

connection –not

supplied. The fasteners

must be determined by

the installer, according

to conditions: surface

(e.g. concrete vs wood

vs steel, etc.) and other

specific variables.

9030050

Introduction

Chapter 1

AfiAct II™ Installation Manual

Page 4

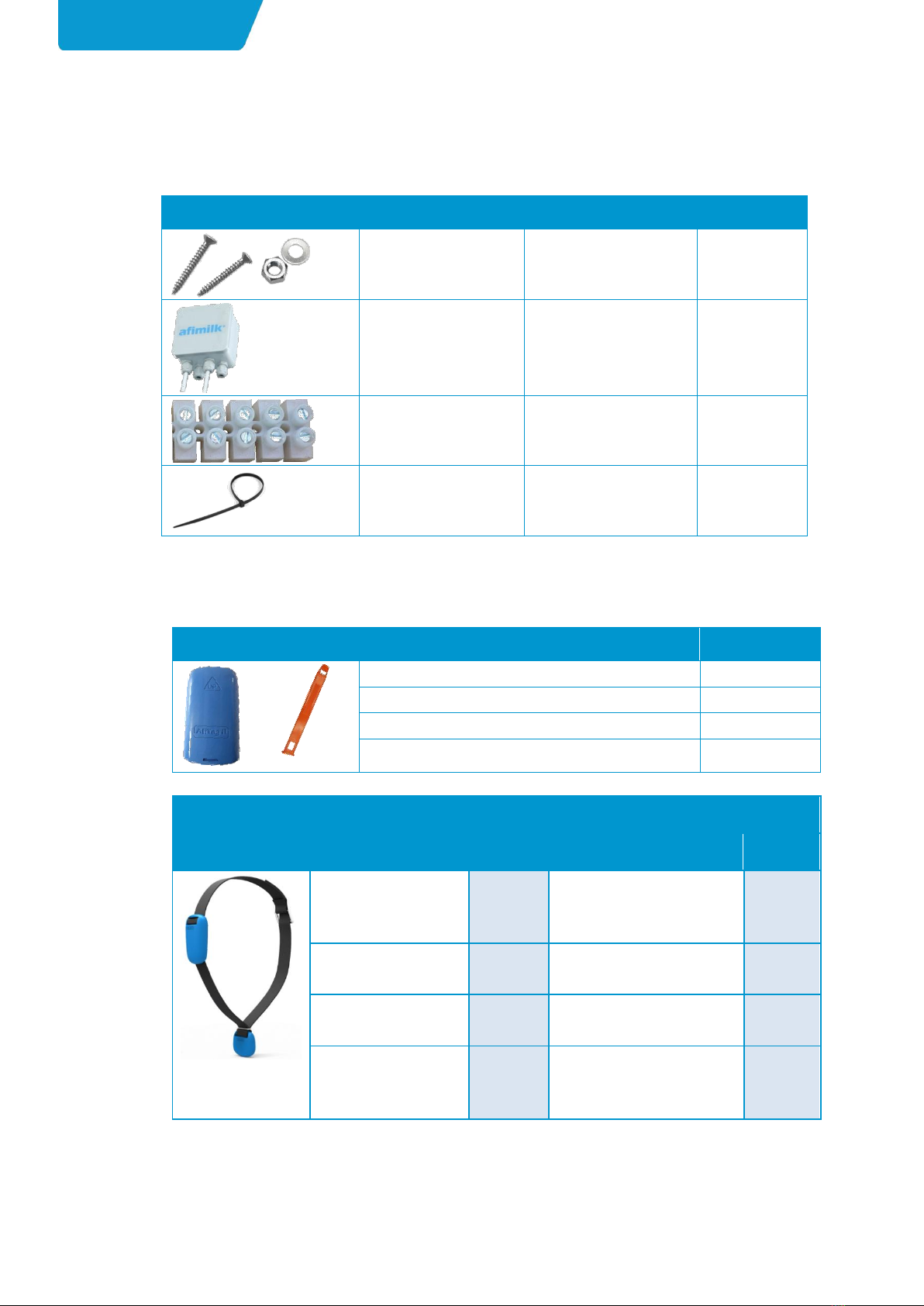

1.3.2 Electricity Box Components

Table 1-5.Electricity Box Components

Picture

Name

Description

PN

Screws and nuts

Not provided!

To be supplied by

installation technician.

Electrical connection

box for AfiAct II Reader

Not provided!

To be supplied by

installation technician.

4085851

Electrical terminal

block

Arrives connected to

Reader’s blue cable.

9020201

Cable ties

Not provided!

To be brought with

technician kit.

1.3.3 Tag Types

Table 1-6.Tag Types

Picture

Description

PN

AfiTag II, Type A, 200 KHz SR, 916 MHz LR

4009600

AfiTag II, Type A, 200 KHz SR, 916 MHz LR, Israel

4009680

AfiTag II, Type B, 80 KHz SR,868 MHz LR

4009610

AfiTag II, Type E, 200 KHz SR, Japan 922.4 MHz LR

4009650

Image

Primary P/Ns

Secondary P/Ns

Description

PN

Description

PN

AfiCollar

907MHz_200KHz -

ASSY.*

8002020*

AfiCollar 908.1MHz_200KHz -

ASSY

8002070

AfiCollar 868.1MHz _

80KHz - ASSY.*

8002030*

AfiCollar 868.3MHz _ 80KHz -

ASSY

8002040

AfiCollar 868.1MHz _

200KHz –ASSY*

8002050*

AfiCollar 868.3MHz _ 200KHz

–ASSY

8002060

AfiCollar

915.5MHz_80KHz –

ASSY*

8002080*

AfiCollar 915.7MHz_80KHz -

ASSY

8002090

By default, dealers should order the primary P/Ns; however, if there is a problem

with the primary sub-g frequency (such as a nearby farm/s, known RF noises, etc.),

then dealers should order their secondary sub-g frequency.

Other manuals for AfiAct II

1

Table of contents

Other AfiMilk Farm Equipment manuals