Corn Crusher

5

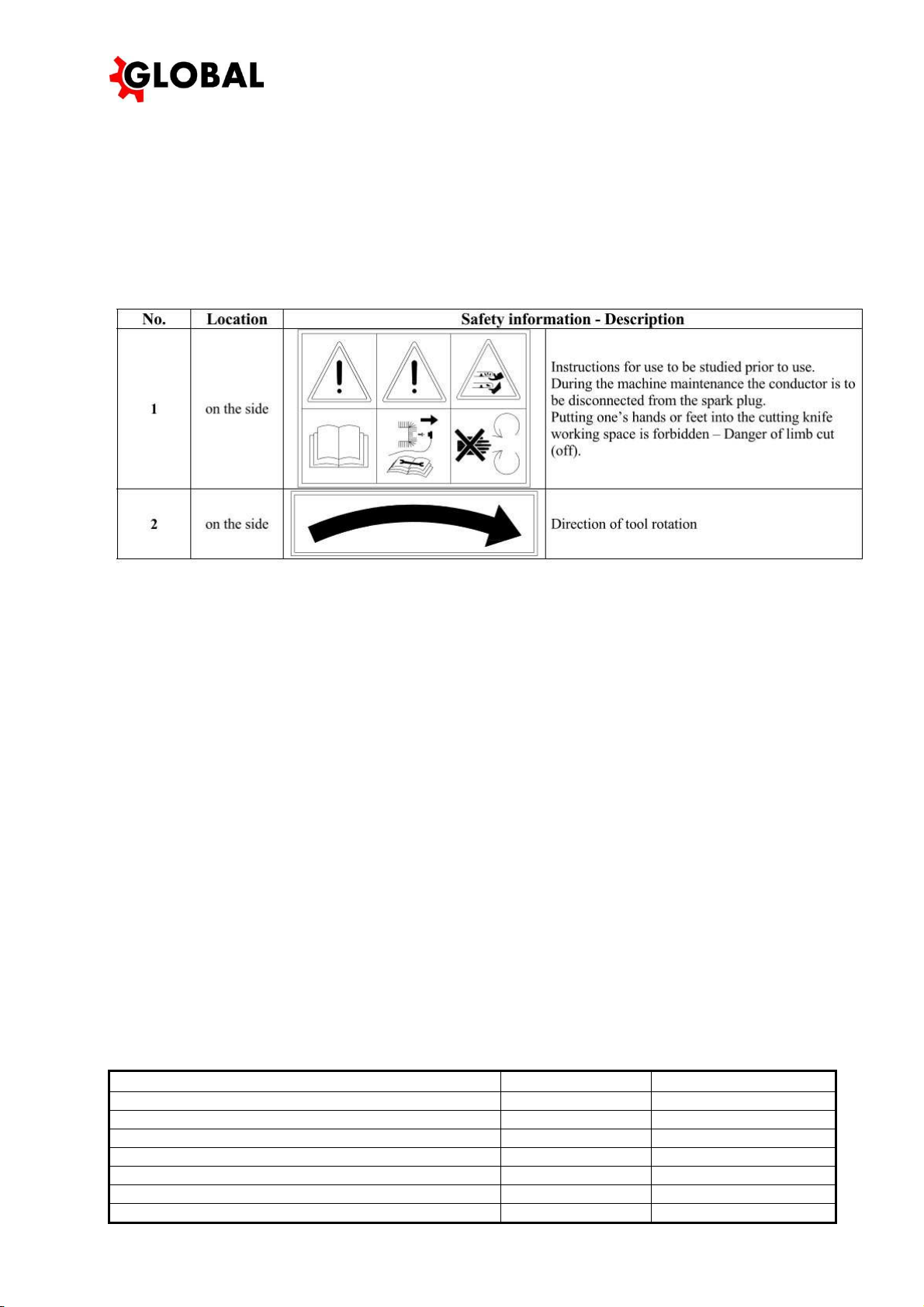

3Operation safety.

3.1 Safety regulations.

* This international symbol indicates important messages concerning safety. When you see

the symbol, be aware of a possible injury threatening to yourself or to other persons and

read the attached instruction carefully.

* The machine operator must be over 18 years of age. He/she is obliged to get acquainted

with the instructions for the machine use and is supposed to have awareness about the

general principles of work safety.

* Prior to starting work with the machine, check the safety engine switch on the left handle

of handlebars of the power unit for its correct function. The function of the switch is

described in the instructions for use of the driving unit.

* Materials such as stones, earth, glass, metal or plastic articles must never get into the

crusher as they might cause damage to its working parts.

* The crusher operator bears a full responsibility for the safety of persons dwelling in the

immediate vicinity of the machine. When the machine is in operation, all other persons

and animals have to be outside the machine’s working space. The machine operator can

continue working only after they will have been shown to a safe distance.

* Never leave the crusher unattended in the presence of children.

* The crusher must be always placed on a flat, stable and firm base.

* Prior to each employment of the machine check all machine parts (namely working

mechanisms and machine casing) for a possible damage or loosening. Defects must be

rectified without any delay. Repairs are to be made only with the use of original spare

parts.

* With respect to the exceeded recommended values of noise and vibrations, you are

warned to adhere to the following instructions while working with the machine:

a) Protect your hearing by using suitable protective aids specified in ČSN EN

352-1 (shell ear protectors) or in ČSN EN 352-2 (plug ear protectors). Require

the aids from your dealer.

b) Working with the machine should be interrupted after max. 20 minutes for a

minimum break of 10 minutes. During these breaks, the machine operator must

not be exposed to the impact of another source of noise or vibrations.

* Machine operators are warned to use working aids authorized to ČSN EN 166 or ČSN

EN 1731 (tight-fitting garments, sturdy shoes, working gloves and protective glasses).

Keep a safe distance given by the handle.

* After the engine is switched off, the cutting knives are still running out. Before leaving the

machine or prior to dismounting the sieve, you are warned to wait until the knives stop

turning!

* Don’t start the engine if not connected to a working implement. If the engine is still

running, don’t remove it. Don’t start the engine in enclosed spaces! Be very careful when

handling the machine since the exhaust silencer remains hot after the engine has been

switched off. Make sure there are no leakages or spills on engine parts when refuelling. If

they happen to occur, dry out the stained parts or wait until the petrol evaporates.