AFM LX-100 User manual

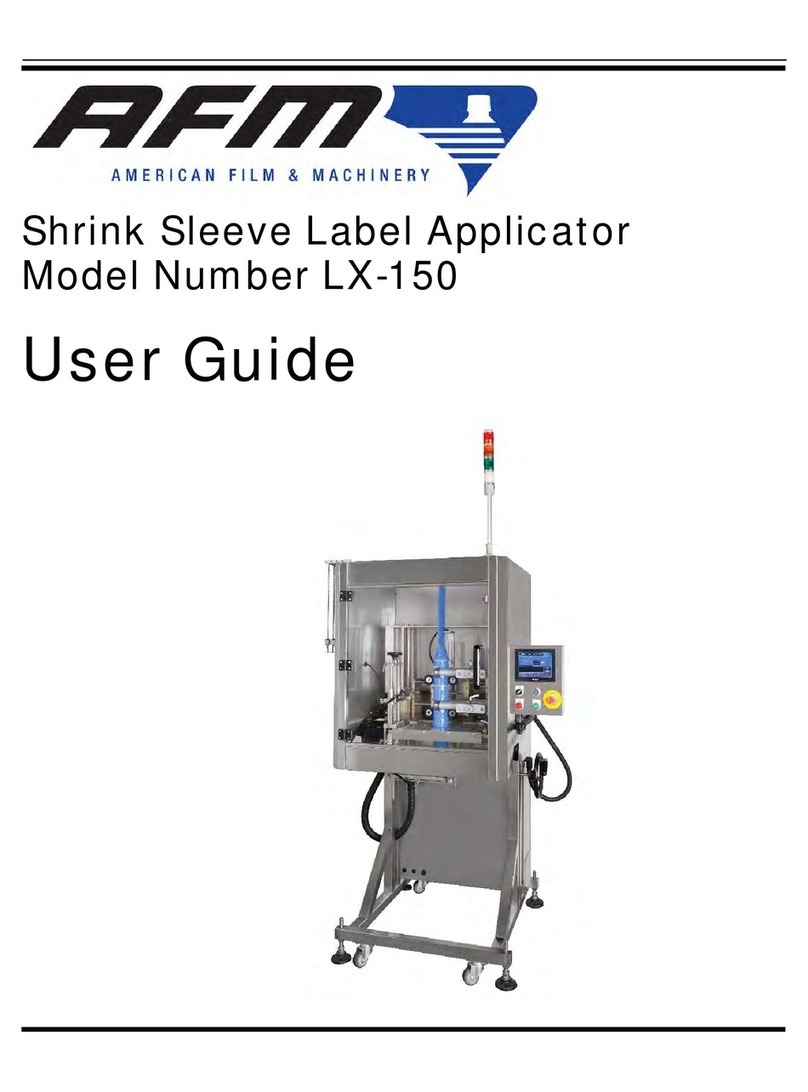

Shrink Sleeve Label Applicator

Model Number LX-100

User Guide

AFM

Shrink Sleeve Label Applicator

Model Number LX-100

User Guide

Revised 4/20/2018

P/N 4510004 Rev Beta

Copyright and Trademarks

Copyright ©2018 American Film and Manufacturing.

All rights reserved. All trademarks and brand names

are the property of their respective owners.

AFM

7041 Boone Avenue North

Brooklyn Park, MN 55428

Phone: (714) 974-9008; Fax (763) 795-8867

www.afmsleeves.com

Contents:

Safety .......................................................................................................8

Introduction............................................................................................11

System Components ................................................................................................... 11

System Dimensions .................................................................................................... 12

System Specifications ................................................................................................. 13

Description and Main components .............................................................................. 14

Installation and Setup............................................................................16

Location Requirements ............................................................................................... 17

Data Cable and Power Connections ........................................................................... 18

Operation................................................................................................19

Before Running Product .............................................................................................. 19

Location of Switches ................................................................................................... 19

Loading a Film Roll ............................................................................................................... 20

Threading Film ...................................................................................................................... 21

Sub-Assemblies .................................................................................................................... 22

Changing/Installing/Adjusting Mandrels ...................................................................... 24

Conveyor ............................................................................................................................... 31

Motion Detector Sensor (product trigger) .............................................................................. 31

Adjustment locations ............................................................................................................. 34

Typical setup ......................................................................................................................... 35

Testing ...................................................................................................36

Touch Panel Screens (H.M.I.) ................................................................43

Screens ....................................................................................................................... 43

Screen 10 .............................................................................................................................. 43

Screen 15 .............................................................................................................................. 43

Screen 12 .............................................................................................................................. 44

Screen 30 .............................................................................................................................. 44

Screen 13 .............................................................................................................................. 45

Screen 14 .............................................................................................................................. 46

Screen 31 .............................................................................................................................. 46

Screen 33 .............................................................................................................................. 47

Screen 11 .............................................................................................................................. 47

Maintenance...........................................................................................48

Changing Cutter Blades .............................................................................................. 48

LX-100 ........................................................................................................................ 50

Weekly .................................................................................................................................. 50

Every three weeks ................................................................................................................. 50

Every six months ................................................................................................................... 50

Annually ................................................................................................................................ 51

Every two to three years ....................................................................................................... 51

Unwind System ........................................................................................................... 52

Daily ...................................................................................................................................... 52

Table of contents

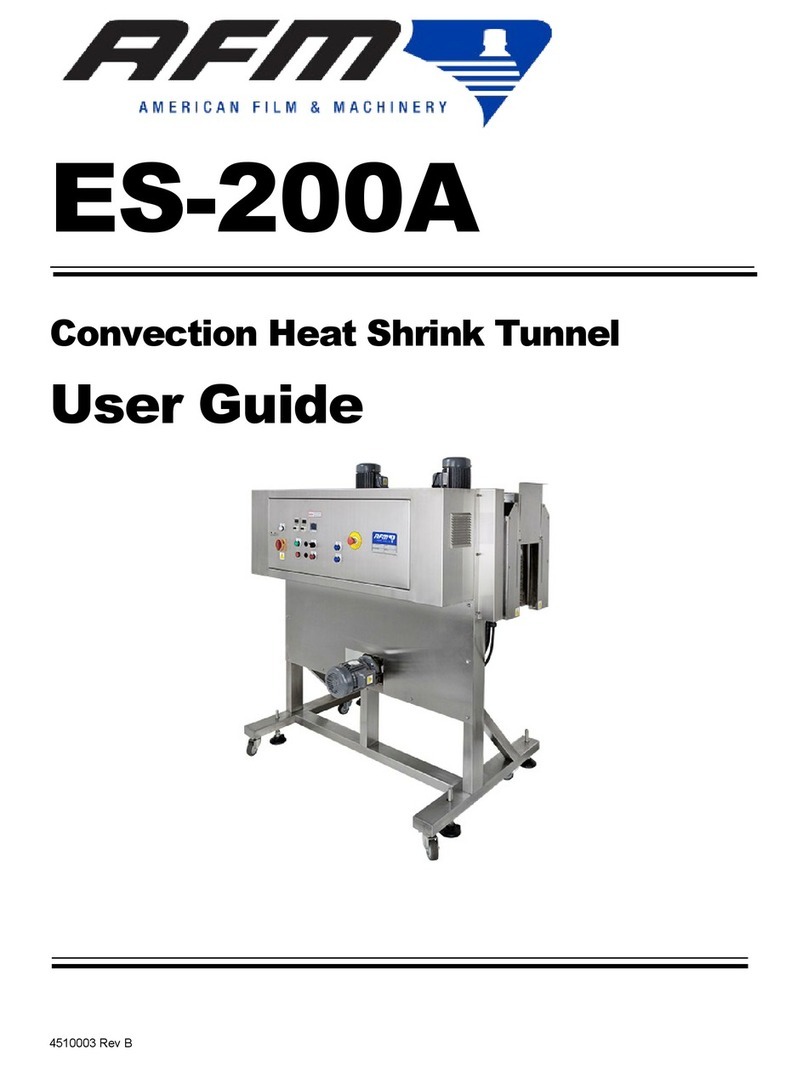

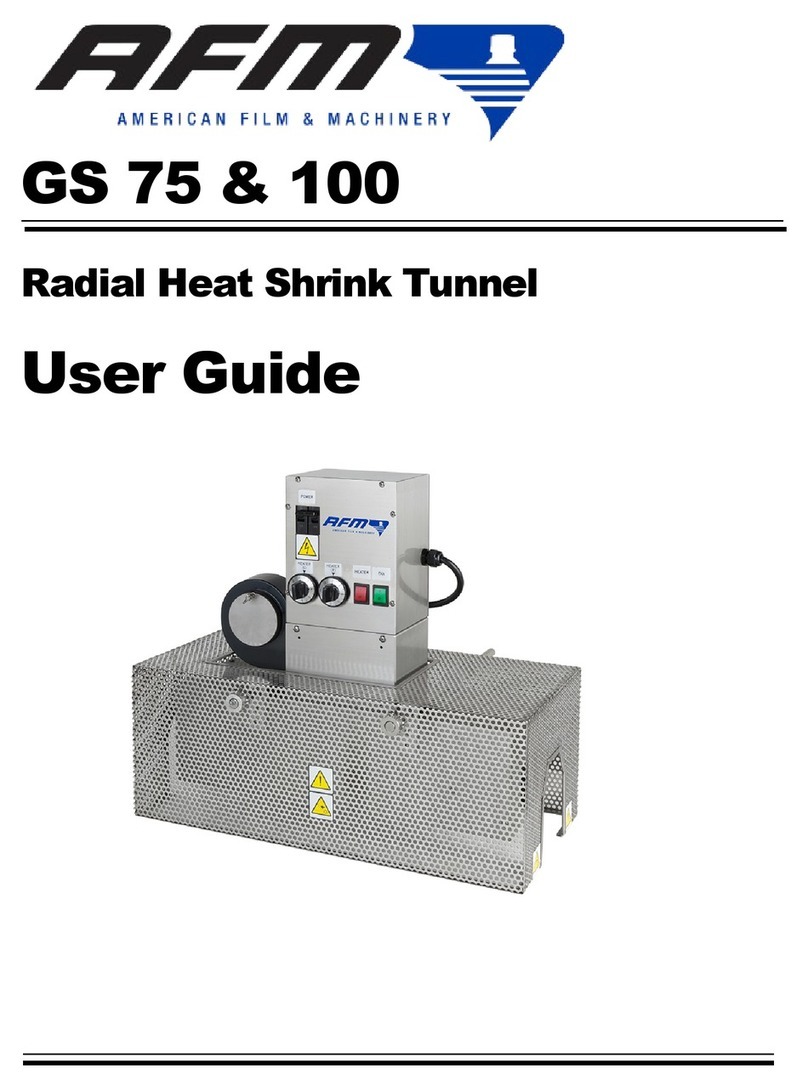

Other AFM Industrial Equipment manuals