AFM ES-200A User manual

4510003 Rev B

ES-200A

Convection Heat Shrink Tunnel

User Guide

4510003 Rev B

4510003 Rev B

ES-200A

Convection Heat Shrink Tunnel

User Guide

V2 (240V)

V6 (480V)

Revised 6/12/2019

P/N 4510003 Rev B

Copyright and Trademarks

Copyright ©2019 American Film and Manufacturing

All rights reserved. All trademarks and brand names

are the property of their respective owners.

AFM

7041 Boone Avenue North

Brooklyn Park, Minnesota 55428

Phone: 714-974-9006

Fax: 763-795-8867

www.afmsleeves.com

4510003 Rev B

4510003 Rev B

Contents

Safety.........................................................................................................7

Warnings

...................................................................................................................... 7

Cautions........................................................................................................................ 8

Introduction ...............................................................................................9

General System Description ......................................................................................... 9

System Components..................................................................................................... 9

System Specifications ................................................................................................. 10

Optional Equipment..................................................................................................... 10

Installation and Setup.............................................................................11

AC Power.................................................................................................................... 11

Work Area ................................................................................................................... 11

Maintenance Access................................................................................................... 11

Unpacking and Placement .......................................................................................... 11

ES-200A Heat Tunnel Major Components .................................................................. 12

Tunnel Placement ....................................................................................................... 13

Connecting Power....................................................................................................... 14

Operation .................................................................................................15

Startup ........................................................................................................................ 15

Control Cabinet Overview ........................................................................................... 16

ES-200A V2 Control Cabinet...............................................................................................16

ES-200A V2 with Conveyor Controls...................................................................................16

Running Product ......................................................................................................... 17

Fan Control Module..................................................................................................... 18

Fan Control Keypad ............................................................................................................18

Temperature Control Module ...................................................................................... 20

Current Transformer Input...................................................................................................21

Interior Vents............................................................................................................... 22

Maintenance ............................................................................................23

Mounting Hardware and Connections......................................................................... 23

External Cleaning........................................................................................................ 23

Schematics..............................................................................................24

ES-200 V2 Wiring Diagram .................................................................................................24

4510003 Rev B

Fan Inverter Setting.............................................................................................................25

ES-200A Wiring Diagram ....................................................................................................26

Troubleshooting ......................................................................................29

ES-200A Parts Lists.................................................................................30

ES-200A V2 (240V) Parts List..................................................................................... 30

ES-200A Recommended Replacement Parts List....................................................... 32

ES-200A V6 (480V) Parts List..................................................................................... 32

Component Dimensions ..........................................................................35

Warranty Statement ................................................................................36

Limitations................................................................................................................... 36

Repairs........................................................................................................................ 36

Shrinking Quality......................................................................................................... 36

Shipping Policy............................................................................................................ 36

Exclusions................................................................................................................... 36

Warranty Verification................................................................................................... 37

Warranty Eligibility....................................................................................................... 37

Limited Warranty......................................................................................................... 37

Disclaimer of Damages ............................................................................................... 38

AFM Technical Support...........................................................................39

7 Safety

4510003 Rev B

Safety

When installing, operating, and maintaining the ES-200A Convection Heat Tunnel,

follow these safety practices.

•All operators should study this User Guide thoroughly before operating the machine.

•Always follow GMP (Good Manufacturing Practices) when operating this machinery.

•The machine is heavy. While unpacking and setting up the unit, always take care to

use proper lifting techniques. Avoid overreaching and leaning over while handling

the machine and accessories. Use more than two or more persons to lift and move

the tunnel.

•Wear safety shoes and work gloves when moving the machine.

•Beware of uneven spots on the factory floor; the machine could tip over.

•Make sure the electrical power source is properly wired and grounded. The power

source should comply with all safety regulations and codes applicable to the

installation location.

•Before attempting any service or repair, make sure that the power is turned off and

power cable is disconnected from the power source.

•The equipment generates heat, so make sure that the area is properly ventilated.

•Do not place any body parts or tools into a running machine.

•Turn off and unplug the machine while servicing and performing maintenance

procedures.

Warnings

Before operating the machine, inform all personnel of the following warnings:

•

Do not tamper with electrical wiring. Use only licensed electricians for

maintenance. Always disconnect electrical power before attempting

maintenance to any electrical or moving parts.

•

To prevent damage to machinery and injury to personnel, do not increase

settings on either electrical or mechanical overload safety devices.

•

Keep hands away from moving conveyors and assemblies. Conveyor belts that

have become worn or frayed can be hazardous and should be replaced

promptly.

•

Never operate this or any moving equipment without all covers

and guards in

place. The internal mechanism of most packaging machinery contains numerous

pinch, shear, and in-running nip points, many of which are capable of causing

severe injury and permanent

disfiguration.

•

To minimize potential for personal injury, always be sure that machine

operators and others working on machinery are properly

trained in the correct

usage of the equipment and properly instructed

regarding the safety

procedures for operation.

8Safety

4510003 Rev B

•

Do not make any modifications to either the electrical circuitry or the

mechanical assemblies of this machinery. Such modifications may

introduce

hazards that would not otherwise be associated with this machinery. American

Film & Machinery will not be responsible for the consequences of such

unauthorized modification.

•

The use of certain types of plastic films in sealing and shrinking equipment may

result in the

release of hazardous fumes due to the degradation of the film at

high temperatures. Before using

any plastic film in this equipment, the

manufacturer or supplier of the film should be contacted for specific

information

concerning the potential release of hazardous fumes. Always provide

adequate ventilation.

•

Keep combustible and explosive materials away from this equipment. The

equipment may be a source of ignition.

•

Do not use with pressurized containers. Exposure to high temperatures can

cause pressurized containers to burst, and could cause injury to operators

and other personnel nearby.

•

Take care when clearing product jams inside the heat tunnel. Do not use

anything that could potentially puncture a container. Use an electric lift to

raise the tunnel from the conveyor before clearing product from inside the

heat tunnel. If containers remain in the heat chamber, turn off power and

allow the temperature to drop below 100

°

F before clearing. Temperature

inside the tunnel can easily cause burns.

Cautions

ELECTRICAL HAZARD: Do not open cover. No user-serviceable parts inside.

ELECTRICAL HAZARD: Ensure that unit is properly grounded.

FIRE HAZARD: Do not tamper with electrical equipment.

WATER HAZARD: Keep the equipment dry and indoors.

FUME HAZARD: Some fumes may be a health hazard with prolonged exposure.

Ensure that the area has adequate ventilation.

Introduction 9

4510003 Rev B

Introduction

General System Description

The AFM ES-200A heat shrink tunnel is designed for the shrinking of heat shrink film

(labels, tamper bands, multi-pack), on containers over which they have been applied.

AFM shrink tunnels are intended for industrial use only.

System Components

•Stainless Steel Stand with Motorized Adjustment Height Control

•Electric Heat Tunnel

•Digital Time Proportional Controls

•Operator Controls

Control Panel

Heat Tunnel

Stand

Digital Time

Proportional

Controls

10 Introduction

4510003 Rev B

System Specifications

Power: 3-Phase, AC, 240/480 Volt, 50/60 Hz

Motor: 2-230 VAC, 3-Phase,12 KW ½ HP

Tunnel Opening Dimensions: 200 mm W (7.875”) x 350 mm H (13.75”)

Machine Dimensions: 1000 mm W (39.375”) x 1650 mm H (65.00”) x 1500 mm L

(59.00”)

Film Thickness: 0.035 mm to 0.07 mm

Temperature: 400 °F

Optional Equipment

Conveyor:The conveyor is customer-supplied. For conveyor options, consider an

Eastey conveyor system. Call AFM Customer Service for more information.

External Controls: Call AFM Customer Service for more information.

Installation and Setup 11

4510003 Rev B

Installation and Setup

AC Power

In many locations where the heat tunnel is installed, AC power may be subject to line

noise, brownouts, and blackouts. If any of these occur on a regular basis, a good-

quality line conditioner or Uninterruptible Power Supply (UPS) should be installed to

ensure data integrity. In many cases, these devices may not be necessary. If system

lockups occur, the first corrective measure should be to isolate and clean up the AC

power.

Work Area

The ES-200A may require occasional cleaning due to environmental contaminants.

Maintenance Access

When planning the installation, allow for easy access to the tunnel for convenient

cleanup, maintenance, and repair.

IMPORTANT: Turn off power and allow the heat tunnel to cool before cleanup,

maintenance, and repair.

Unpacking and Placement

1. Open the box.

2. Roll the tunnel assembly out of the box on its casters.

3. Examine the tunnel exterior for damage.

12 Installation and Setup

4510003 Rev B

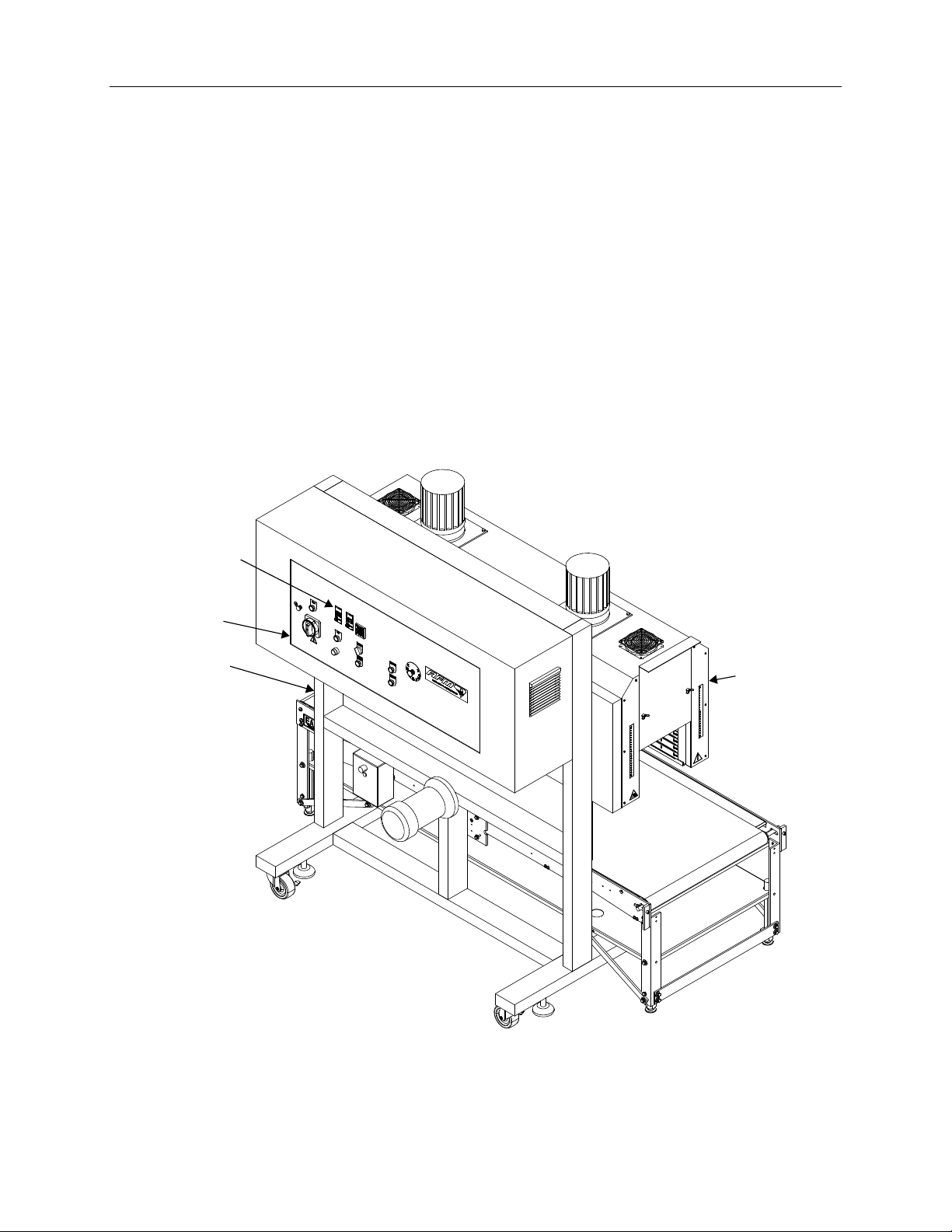

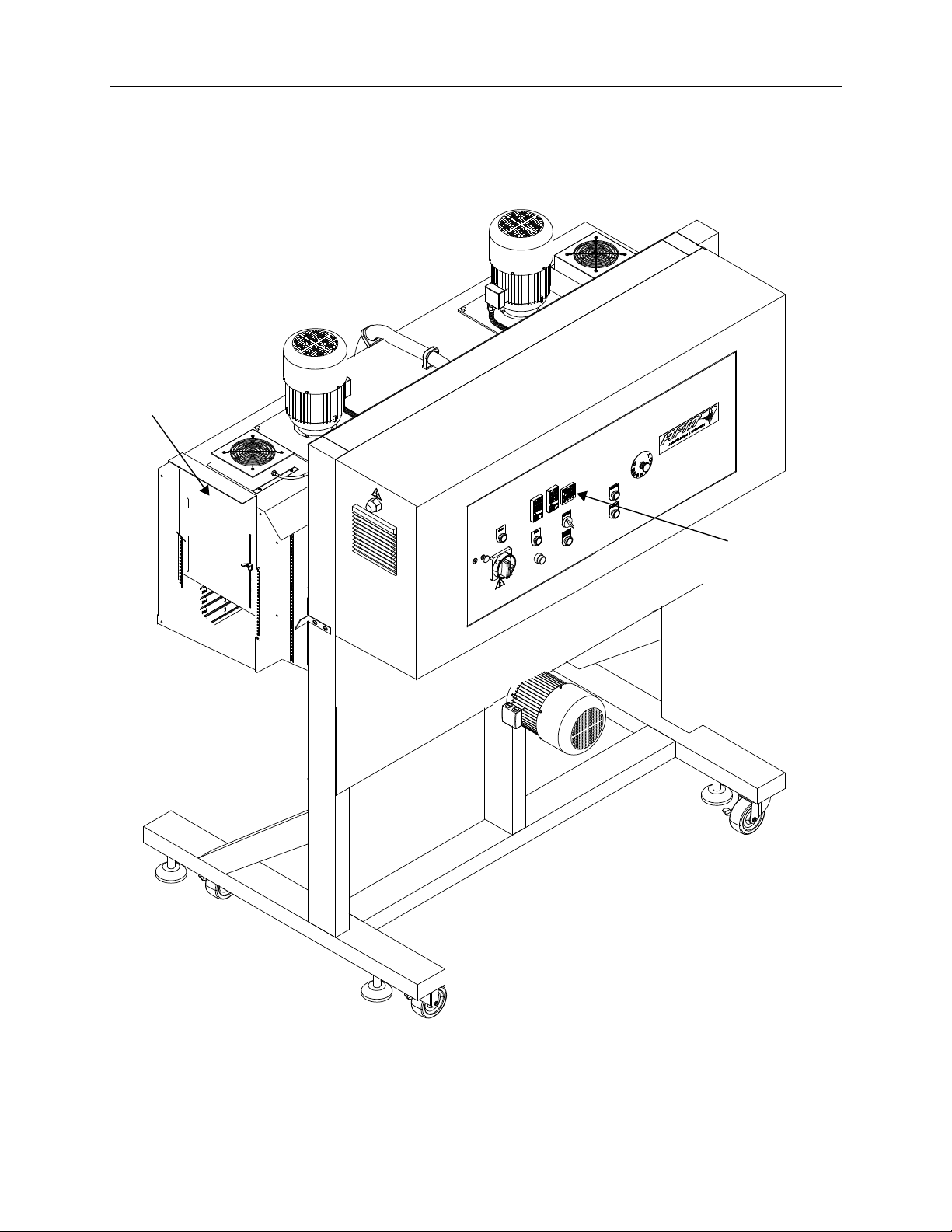

ES-200A Heat Tunnel Major Components

Control Cabinet

Heater Fan Motors

Recirculating Fans

Tunnel Exit

Height Adjustment Motor

Stand

Installation and Setup 13

4510003 Rev B

Tunnel Placement

A conveyor must be used with the tunnel to move the product while it is being sleeved.

1. Position the tunnel next to the conveyor, considering product size and location on

conveyor.

2. Ensure that all controls on both control panels are easily accessible.

3. Set the conveyor height.

4. If the tunnel height needs adjustment, connect the heat tunnel to AC power. Refer

to the “Connecting Power” section on page 14.

5. Press the Ascend or Descendbuttons as required to raise and lower the heat

tunnel.

6. When the tunnel and conveyor have been properly positioned, unscrew the leveling

feet to keep the tunnel from moving.

Tunnel Controls

Conveyor Controls

Tunnel

Feet

14 Installation and Setup

4510003 Rev B

Connecting Power

CAUTION: Before connecting power, verify that the power switches are in the OFF

position.

Connect an appropriate electrical plug to the end of the cord.

Plug the power cords from the conveyor and tunnel into properly wired and grounded

electrical outlets.

Heat Tunnel Power Cord

Conveyor Power Cord

Conveyor Power Switch

Tunnel Power Switch

Operation 15

4510003 Rev B

Operation

Startup

1. Before starting the ES-200A Heat Tunnel, double-check the installation.

2. Verity that all power cables are properly connected.

3. Turn the Heat Tunnel Power Switch located on the front of the Control Cabinet to the

ON position.

4. Turn the conveyor power switch to the ON position.

Heat Tunnel

Power Switch

Conveyor Power Switch

16 Operation

4510003 Rev B

Control Cabinet Overview

CAUTION: The control cabinet is not a watertight enclosure. Do not splash the

cabinet with liquid.

The front panel of the control cabinet includes the following:

ES-200A V2 Control Cabinet

ES-200A V2 with Conveyor Controls

Power Indicator Light

Tunnel Power Switch

Emergency

Stop Button

Heater Power Switch

Height

Adjustment

Buttons

Temperature

Control

Module

Fan Power Button

Alarm

Reset

Button

Fan Speed

Controls

Power Indicator Light

Tunnel Power Switch

Emergency

Stop Button

Heater Power Switch

Height

Adjustment

Buttons

Temperature

Control

Module

Fan Power Button

Alarm Reset Button

Fan Speed

Controls

Conveyor

Controls

Conveyor

Power

Button

Operation 17

4510003 Rev B

Running Product

1. Turn the Tunnel Power Switch to the ON position.

2. Press the ASCEND and DESCEND height adjustment buttons on the tunnel to set

the correct height for the product.

NOTE: In Manual Mode, press the ASCEND button to raise the tunnel. Press the

DESCEND button to lower the tunnel. In Auto Mode, the tunnel rises when the

conveyor has stopped. To use Auto Mode, the Conveyor Input wire must be

connected.

3. Turn on the Conveyor.

4. Turn on the Fan power button.

5. Turn on the HEATER power switch.

Fan Power Button

Heater Power Switch Ascend Button

Descend Button

Tunnel

Power

Switch

18 Operation

4510003 Rev B

Fan Control Module

Fan Control Keypad

Right Heater Fan

Left Heater Fan

Left Fan Controls Right Fan Controls

Operation 19

4510003 Rev B

The VFD-M fan control modules control each large fan motor speed. The smaller fans

on the top outer edges of the tunnel begin running automatically when the Tunnel power

Switch is turned to the ON position.

The tunnel is shipped with the fan controls set at F60.0, which equals 60 Hz or full

power of the fans.

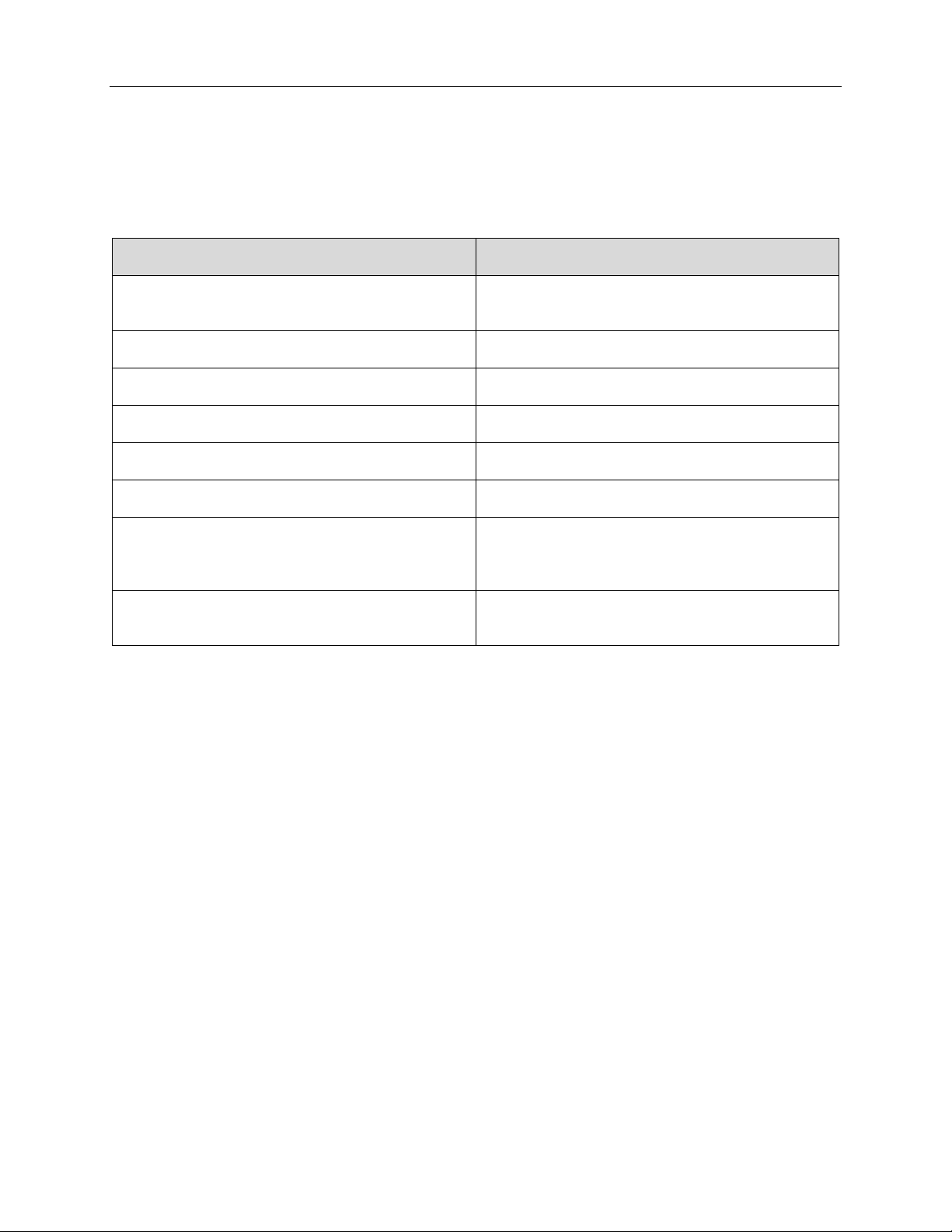

Control Function

Program/Function key Used to change parameters and display

amperage, hertz, frequency, and counter.

LED Display key Displays settings.

LED Indicators Lamps light up for each operation.

RUN key Not used

STOP/RESET key Not used

ENTER key Saves settings and changes to settings.

UP and DOWN keys Used to raise fan speed (no higher than 60) and

to lower fan speed to slow down airflow through

the inside vents of the tunnel.

Potentiometer Refer to the VFD-M Digital Keypad Manual for

more information.

20 Operation

4510003 Rev B

Temperature Control Module

The SDC15 (Temperature Control) controls the chamber temperature in the heat zone.

Heating elements are inside the top of the tunnel and run the length of the tunnel.

After a temperature setpoint has been selected, run some product and observe the

results. To adjust the temperature, set the control to the new desired temperature.

Always wait for tunnel heat to stabilize before making changes.

Heating

Elements

Temperature

Control

Table of contents

Other AFM Industrial Equipment manuals