ShopBot SBG00140 User manual

© Copyright 2018 ShopBot Tools, Inc.

page 1

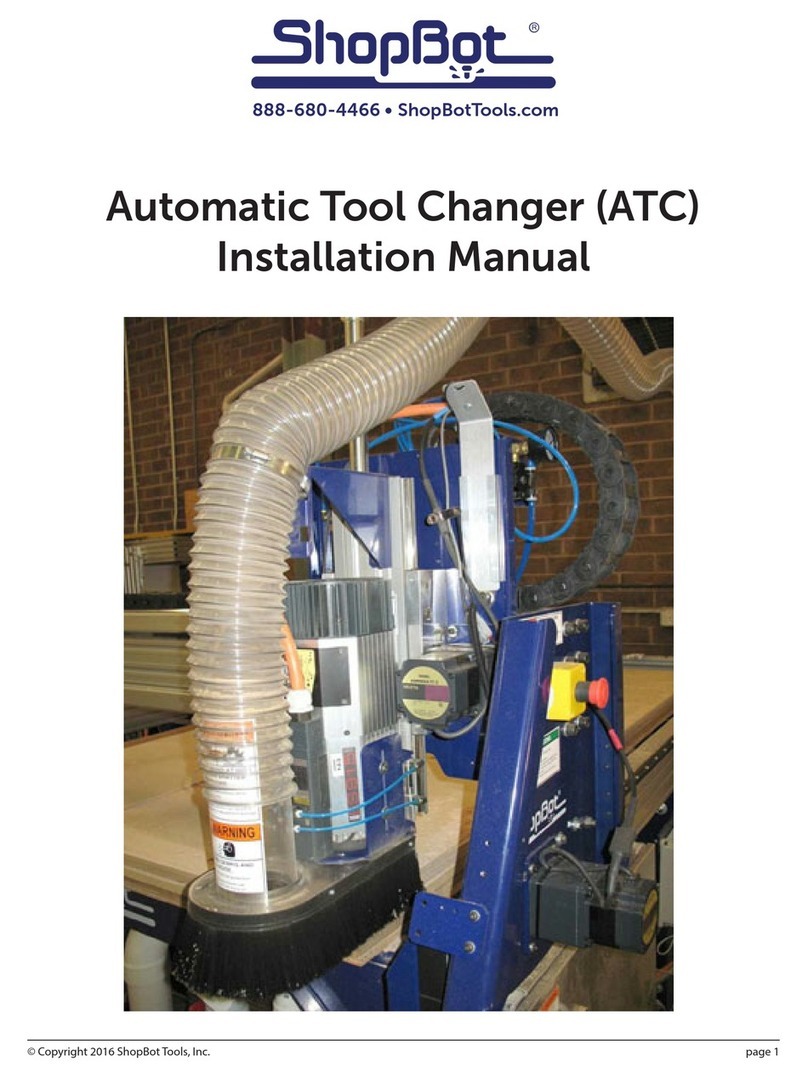

Automatic Tool Changer (ATC)

Installation Manual

SBG00140

Automatic Tool Changer (ATC) Installation Manual ●July 23, 2018

© Copyright 2018 ShopBot Tools, Inc.

page 2

Table of Contents

Introduction..................................................................................................................................................... 3

ATC Installation (Mechanical) ......................................................................................................................... 4

ATC Table and Spoil Board............................................................................................................................ 4

Mounting the Spindle ..................................................................................................................................... 5

Install Pneumatic Assist Line ...................................................................................................................... 5

Mount Tool Bar ........................................................................................................................................... 6

Mount Tool Chuck ...................................................................................................................................... 7

ATC Installation (Spindle) ............................................................................................................................... 8

Connecting the Pressure Switch ................................................................................................................ 8

Connecting the Spindle .............................................................................................................................. 8

ATC Installation (Pneumatic) ........................................................................................................................ 10

ATC Software Setup and Tool Calibration ................................................................................................... 12

Install the ATC Software ........................................................................................................................... 12

ShopBot Setup (TS)...................................................................................................................................... 13

Software Inputs and Outputs Check ............................................................................................................ 16

Inputs ........................................................................................................................................................ 16

Outputs ..................................................................................................................................................... 17

Basic Function Check............................................................................................................................... 17

Additional function checks ....................................................................................................................... 18

Calibration Cables ................................................................................................................................ 18

Z Zero Plate .......................................................................................................................................... 18

Fixed Z Zero Plate ................................................................................................................................ 18

Tool Draw Bar ....................................................................................................................................... 18

Calibrating the ATC ...................................................................................................................................... 19

Home Machine (C3) .................................................................................................................................. 19

Calibration Routine (CN74) ....................................................................................................................... 19

Step 1: Determine Z Height for Calibration .......................................................................................... 20

Step 2: Determine XY Position of Tool Clips........................................................................................ 21

Step 3: Set Fixed Z-Zero Plate Location.............................................................................................. 22

Step 4: Setup Tool Holders .................................................................................................................. 23

Step 5: Zero Tools in Rack (CN72) (Daily Operation) ........................................................................... 25

Step 6: Change Tools (C1) ................................................................................................................... 25

Step 7: Get Plate Offset (CN73)............................................................................................................ 26

Step 8: Zero to Various Z Heights (C2) (Daily Operation)..................................................................... 27

Regularly Used ATC Files............................................................................................................................. 27

Create a Tool Change File............................................................................................................................ 28

Spindle Warmup Routine (C5) ...................................................................................................................... 29

Run the File................................................................................................................................................... 29

If Something Goes Wrong ............................................................................................................................ 29

Automatic Tool Changer (ATC) Installation Manual ●July 23, 2018

© Copyright 2018 ShopBot Tools, Inc.

page 3

Introduction

The ShopBot Automatic Tool Changer (ATC) automates the bit changing process during projects that

require multiple tool changes. The ATC system includes a 5HP HSD spindle, a pneumatically-assisted Z-

axis, six-position tool bank standard, up to ten tool positions for our four-foot-wide tool (12 for a five-foot

and 14 for a six-foot), fixed-position Z-zero plate, chuck holder, magnetically removable dust skirt, and ATC

interface board.

The ATC reduces the time a project must remain on the machine by automatically changing bits between

cuts, thus eliminating the need to change and calibrate tools by hand. The ATC allows the PRSalpha to cut

complete projects where tool changes are required without additional inputs.

The 5HP HSD spindle assembly is fan-cooled. The ATC requires 7 scfm at 100 psi of clean, dry, un-oiled

compressed air. PORTABLE AIR COMPRESSORS ARE NOT RECOMMENDED, as they can have trouble

maintainaing this pressure reliably and have a reduced service life.

The ShopBot ATC is available in the following voltages:

(#22520) HSD ATC 5HP 220V 1PH PRS4

(#22521) HSD ATC 5HP 380/460V 3PH PRS4

(#22540) HSD ATC 5HP 230V 3PH PRS4

Automatic Tool Changer (ATC) Installation Manual ●July 23, 2018

© Copyright 2018 ShopBot Tools, Inc.

page 4

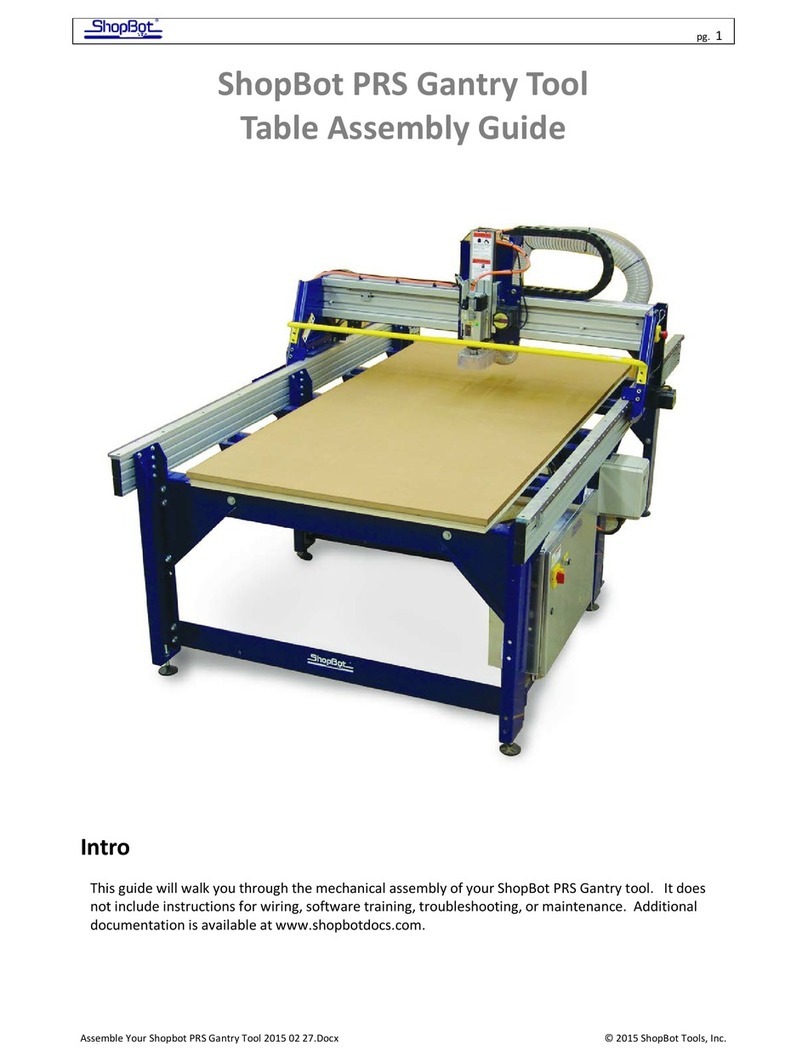

ATC Installation (Mechanical)

This section assumes that the ShopBot has been assembled using the instructions provided in the ShopBot

assembly manual. This means that the ShopBot is at a point in which it is able to connect and move under

the control of a computer. Wire/cable management may be left until the ATC installation has been

completed.

When naming sections, as in all writing, you should strive for consistency in tense. If the first section is

entitled Preparing the Workspace, the second section should be called Unpacking the Materials rather

than Unpack the Materials. Finally, make sure to use AP Style title case for your headlines.

VERY IMPORTANT!

For New Table Setups

The location of the table bed is extremely critical for an ATC tool. Excess overages in the X

dimension could mean tooling collisions, insufficient cutting area, and dropped tooling. At

the end of this section there is a table drawing that shows how the table should be set up.

Pay close attention to the relationship between table sides and the table surface.

For Previously Assembled Tables

Loosen the bolts that are attached to the table side extrusions and slide table sides in the

positive X direction until the table is in the position called out in the table drawings at the end

of this section.

ATC Table and Spoil Board

As noted in the provided table drawings, ATC tools deck mounting should be 2.75” from the front cross

support. Verify that the deck has been constructed properly at this time, or wait to complete this document

before continuing with deck assembly. Additionally ATC tools that are not equipped with Vacuum tables

require a double layer of MDF spoilboard to ensure proper clearance over the ATC toolbar.

Automatic Tool Changer (ATC) Installation Manual ●July 23, 2018

© Copyright 2018 ShopBot Tools, Inc.

page 5

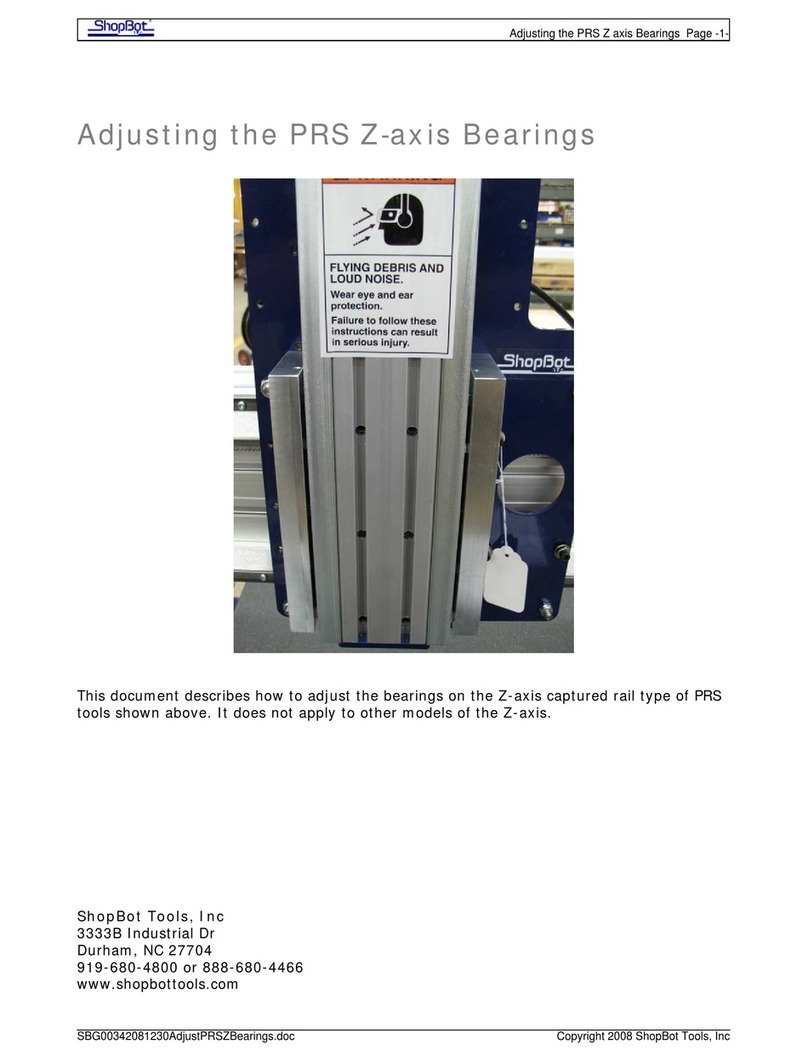

Mounting the Spindle

The ShopBot ATC is equipped with a 5HP fan cooled HSD spindle. An ATC system requires a minimum of 7

scfm at 100 psi of clean, dry, un-oiled compressed air which will be internally regulated to the following

pressures:

Pressure

Purpose

60 psi (4 bar)

Maintain Positive Pressure in spindle body, prevent contamination

90-100 psi (6-7 bar)

Internal drawbar that holds tool holders in place

60-90 psi (4-6 bar)

Pneumatic assist cylinder on Z-axis that balances the weight of the spindle

Power up the ShopBot and position the YZ car so that it is in a location where

the front and back of the Z-axis may be reached.

Use the keypad mode (K) on the computer to move the Z-axis to a height close

to the table’s surface.

Position the ATC Spindle as shown (resting on the red cap) and move the Z-

axis up or down using the keypad mode until the holes in the Z-axis align with

the 4 mounting screws in the spindle plate. If the table has not yet been

assembled, temporarily place a piece of plywood across the cross supports.

Gradually tighten spindle securely to Z-axis with four pre-mounted M6 x 25

socket head screws, and four more loosely packaged M6 x 25 socket head

screws. Depending on the height you are mounting the spindle at, only 6 of the

8 screws may be able to be used.

Install Pneumatic Assist Line

The pneumatic assist line should be installed as per document SBG 00275-

PRS4 Pneumatic Assist Install at this time. Turn off the main air supply switch

and verify that the gauge reads 0 psi.

Automatic Tool Changer (ATC) Installation Manual ●July 23, 2018

© Copyright 2018 ShopBot Tools, Inc.

page 6

Mount Tool Bar

ATC toolbars are shipped pre-assembled. There are three different toolbar lengths, corresponding to 48”,

60”, and 72” wide tools. The toolbar is installed at the rear of the tool, and provides a mounting location for

tool holder clips and fixed Z-zero plate. Toolbars include six tool holders standard. Bit diameter should not

exceed 1.25” and total bit length should not exceed 5”.

To mount the toolbar, use a 1/2” wrench to loosen the 4 hex cap screws connecting each of the two toolbar

brackets such that they can be adjusted to span between the table sides. Slide T-nuts into the 4 inner slots

of the table side. Toolbar brackets should be mounted 12.5” from the table end, as per the drawing on page

7. Before tightening, level the tool bar by placing a level on top of the extrusion in both directions (along X-

axis and Y-axis of table) to ensure that the tool bar and table sides are aligned.

Note: Before fully tightening the mounting bolts, turn on the machine and move the gantry to the positive x

extreme to ensure that the spindle will reach the toolbar without hitting the mechanical stops. Mechanical

stops should be positioned such that the center of the rear gantry v-wheel’s center reaches a minimum of

0.125” from the end of the rail.

The Fixed Z-zero plate can now be wired directly

into the control box using the attached 2

conductor cable. Connect the cable to the plate

with the attached WAGO connector and wire the

black and red wires into ground and input 1 (ZZ)

respectively on the control board.

Automatic Tool Changer (ATC) Installation Manual ●July 23, 2018

© Copyright 2018 ShopBot Tools, Inc.

page 7

Mount Tool Chuck

The tool chuck is used to hold the tool holder cone while changing

collets and bits. Use 5/16”x3/4” button head screws and T-nuts to

mount the tool chuck in the second slot from the bottom of the table

extrusion. If this location is not optimal, mount the chuck where it is most

convenient, taking care not to interfere with the movement of the gantry.

Automatic Tool Changer (ATC) Installation Manual ●July 23, 2018

© Copyright 2018 ShopBot Tools, Inc.

page 8

ATC Installation (Spindle)

This portion of the installation covers spindle power and control box cabling as well as pneumatic lines.

Connecting the Pressure Switch

Locate the pressure switch on the primary air

regulator. Attach the threaded pressure switch cable

to the wire coming out of the pressure switch. Route

the two pin terminal block end into the control box.

Inside the control box, route the pressure switch

cable to the ATC interface board. Connect the blue

two pin terminal block to the location marked

“pressure switch.”

Connecting the Spindle

Using a 4mm hex wrench, remove the small socket

head screw from the front face of the spindle plug.

PRESSURE SWITCH

CONNECTOR

PRIMARY AIR

REGULATOR

Automatic Tool Changer (ATC) Installation Manual ●July 23, 2018

© Copyright 2018 ShopBot Tools, Inc.

page 9

Plug the cables into the mating plug of the HSD spindle and

secure the socket head screw to lock the plugs in place.

Route the cabling from the spindle through the Y-axis E-

chain into the control box and over to the left side of the ATC

interface board.

Before locking cables into the Y-axis E-chain, manually

move the Z-axis to both of its extents of travel to make sure

there is enough slack in the cables for the Z-axis to move

freely.

Connect the small blue terminal block to the location marked

“VFD Logic”. Ensure the wires are attached with red

connected to S4, black connected to S1, and green

connected to SC.

The spindle sensor cable has a 12 pin male Wago connector

and will connect into the corresponding female piece on the

ATC board.

Find the female Wago connector on the board identified as

“spindle sensor cable.” Connect the male Wago connector

into the ATC interface board.

Automatic Tool Changer (ATC) Installation Manual ●July 23, 2018

© Copyright 2018 ShopBot Tools, Inc.

page 10

ATC Installation (Pneumatic)

Using a 4mm hex wrench and adjustable wrench, connect the ATC manifold to the Y-Echain Bracket on the rear of

the YZ car using the pair of pre-mounted hardware as shown above.

Run the ferruled side of the 3-conductor 30’ ATC cable from

the pneumatic manifold through the Y and X cable carriers

and into the control box and to the ATC interface board as

shown in the picture to the right.

Black to +24V

Green to GND

Red to TR + under Tool Release

Automatic Tool Changer (ATC) Installation Manual ●July 23, 2018

© Copyright 2018 ShopBot Tools, Inc.

page 11

The 3/8” hose with a T-fitting on the end can now be run to

the regulator. The T-fitting should be inserted into the

regulator stem first as shown in the picture at right.

Run the 2 1/4” blue tubes included with the pneumatics

manifold from push-in connectors on the manifold to the

push-in connectors marked 5 and 2on the spindle.

The spindle’s push-in connector marked 5 should connect to

the lower of the 2 push-in connectors on the manifold (this is

the spindle’s drawbar which will actuate tool pickup and

release).

The spindle’s push in connector marked 2 should run to the

upper of the 2 push in connectors on the manifold with a

regulator (this is supply for positive pressure air to the

spindle which will remain open when the tool is on).

Turn on the pneumatics switch at the filter regulator manifold and verify that the pressure here is between

90 and 100 psi.

The small regulator for the spindle’s positive pressure should be set to 60 psi (note that the gauge reads

in 1/10ths). The red LED on the positive pressure solenoid should be on.

UPPER (2)

LOWER (5)

Automatic Tool Changer (ATC) Installation Manual ●July 23, 2018

© Copyright 2018 ShopBot Tools, Inc.

page 12

ATC Software Setup and Tool Calibration

This portion of the installation covers the software setup and tool calibration.

Install the ATC Software

Download the latest ShopBot control software from the ShopBot website:

http://www.shopbottools.com/mSupport/controlsoftware.htm

If an earlier version of the ShopBot control software is present, uninstall the software and install the most

recent version. Refer to “Uninstall/Reinstall ShopBot and VCarve Software”

at http://www.shopbottools.com/ShopBotDocs/software.htm

Note: If there are personal files within the “SbParts” folder, be sure to rename or move this folder so the

files are not lost.

Automatic Tool Changer (ATC) Installation Manual ●July 23, 2018

© Copyright 2018 ShopBot Tools, Inc.

page 13

ShopBot Setup (TS)

Type in “UR” or go to “Utilities” pull-down menu and select “Reset default Settings”. Select the file name

that correctly describes the table size, making sure it ends with ATC.

Move the cutter to the location that is to be “0, 0” (the reference point for programming) on the

table. Open the ShopBot control software and open the “ShopBot Setup” file in the “Tools” drop-

down (TS). Read through the window and click “Next”. The second window is the “Tool Settings”.

Go step-by-step through this window while verifying information about the machine. Make sure

that the check boxes for the Z zero plate and proximity switches are checked at the bottom of the

window. Select the radio button marked ATC4. (If your ATC tool has a pneumatically actuated

dust foot please call ShopBot for support and an alternate document).

MOVE TOOL HERE

Automatic Tool Changer (ATC) Installation Manual ●July 23, 2018

© Copyright 2018 ShopBot Tools, Inc.

page 14

In the “ShopBot Setup (Z Zero Plate)” screen, measure the

thickness of the plate and enter that value. Make sure the input

switch is set to “1”. DO NOT check the “Yes, I want to always

zero my Z axis at the same place on my table”. Click “Next”

.

At the “ShopBot Setup (Prox Switches)” screen, select

“Make it easy on me…” and click the “Click Here To Make It

Easy On Me” button to start the zeroing routine.

The next screen is “X and Y axis zeroing setup”. Read this screen and click

“Run the prox switch setup routine”.

Automatic Tool Changer (ATC) Installation Manual ●July 23, 2018

© Copyright 2018 ShopBot Tools, Inc.

page 15

Follow the prompts from the pop-up screens. Select “Yes”

to open the keypad for any adjustment to the “0, 0” home

position, then click “OK”.

Move the machine to the zero point, and hit “ESC” to exit the keypad

mode.

Click “Yes” to zero out the X and Y axes and click “OK”.

Read through the “ShopBot Setup (Finished)” window and click

“I’m done.”

Automatic Tool Changer (ATC) Installation Manual ●July 23, 2018

© Copyright 2018 ShopBot Tools, Inc.

page 16

Software Inputs and Outputs Check

Ensure that all of the inputs and outputs are being recognized by the automatic tool changer (ATC) by

checking for each of the cases outlined in this section.

Inputs

Inputs are signals that the software receives from devices that cause the tool to have a specific reaction.

Input 1 –The Z zero plate and the fixed Z zero are connected to this input. When either of these

plates are connected to a ground, the circuit is closed and input “1” on the ShopBot position

screen lights up. The tool’s fixed z-zero plate does not require a grounding clip, however use of

the standard z-zero plate does.

Input 2 –The X-axis proximity switch is connected to this input. During normal operation, the input

“2” light will be off in the ShopBot position screen. If the X-axis proximity switch passes the

proximity targets, the light will turn on. Among other things, this feature will be used for homing

the X and Y positions and for limiting the safe table cutting boundaries.

Input 3 –The Y-axis proximity switch is connected to this input. During normal operation, the input

“3” light will be off in the ShopBot position screen. If the Y-axis proximity switch passes the

proximity targets, the light will turn on. Among other things, this feature will be used for homing

the X and Y positions and for limiting the safe table cutting boundaries.

Input 4 –This input is connected to the stop switch. When active, the switch allows for use of the

tool and when inactive, the connection is severed and the tool comes to a stop.

Input 5 –The Z-axis proximity switch is connected to this input. During normal operation, the input

“5” light will be ON in the ShopBot position screen. When the Z-axis proximity switch passes the

proximity targets, the light will be turned OFF. This switch will be used most often for a reference

location in zeroing the bits in the tool rack and for limiting the safe Z cutting boundary.

Input 6 –NA

Input 7 –Drawbar closed. Lights when tool holder is properly inserted into spindle and clamped.

Input 8 –Drawbar open. Lights when tool holder is ejected.

Automatic Tool Changer (ATC) Installation Manual ●July 23, 2018

© Copyright 2018 ShopBot Tools, Inc.

page 17

Outputs

Outputs are signals that ShopBot software is sending to cause a desired action. Unused outputs can be

programed to activate other peripherals using an optional relay board.

Output 1 –Runs the spindle.

Output 2 –NA

Output 3 –Toggles the ATC dust skirt gate open.

Output 4 –Turns on during machine operation (safety flashing screen). Required for spindle “on” signal.

Output 5 –NA

Output 6 -NA

Output 7 –NA

Output 8 -Toggles the spindle drawbar open /close (releases tool holders from spindle).

Caution: When the spindle is not spinning it is possible to drop the tools from the spindle if Output 8

is activated.

Basic Function Check

Check that all systems involved are working properly, starting with the proximity switches.

In keypad mode (K) move the X-axis into the proximity target

using the left arrow on the keypad. The proximity switch will

have a red LED lit until it comes across the proximity target,

when it will turn off. Moving off the top of the target should

cause the LED to come back on. This should also be evident in

the ShopBot position screen when looking at input “2”, the light

will turn from black (normally closed) to green (open).

In keypad mode (K), move the Y-axis into the proximity target

using the down arrow on the keypad. The proximity switch

will have a red LED lit until it comes across the proximity

target, when it will turn off. Moving off of the target should

cause the LED to come back on. This should also be evident

in the ShopBot position screen when looking at input “3”.

In keypad mode (K), move the Z-axis into the proximity target using “Page Up” on the keypad. The

proximity switch will have a red LED lit until it comes across the proximity target, when it will turn off.

Moving off the top of the target should cause the LED to come back on. This should also be evident in the

ShopBot position screen when looking at input “5”. Input “5” will appear green until the target is hit then the

input goes black.

Automatic Tool Changer (ATC) Installation Manual ●July 23, 2018

© Copyright 2018 ShopBot Tools, Inc.

page 18

Additional function checks

Calibration Cables

To check calibration cables, insert plug end of the calibration and grounding clip into socket

located on the YZ car. If the Z zero plate is connected to this socket, you will have to unplug it to

connect the calibration cables. The calibration clip will be designated by the red grips and the

grounding clip by the black grips.

Touch the calibration clip (red) to the grounding clip (black) and make sure that input “1” lights up

green on the ShopBot position screen.

Z Zero Plate

To check the Z zero plate, insert the plug end of the Z zero plate cable into the socket locate on

the YZ car. If the calibration cables are connected to this socket, you will have to unplug them to

connect the Z Zero plate.

Touch the Z zero plate grounding clip to the Z zero plate and make sure that input “1” lights up

green on the position screen.

Fixed Z Zero Plate

To check the fixed Z zero plate, simply press down firmly on the

plate. Input “1” should light up green on the position screen while

the plate is pressed. The light should go off again when the plate is

released.

Tool Draw Bar

Make sure your compressed air supply is on for the following checks.

Press the green button on the side of the spindle. While the button is

depressed the internal draw bar will open, allowing the spindle to accept

Automatic Tool Changer (ATC) Installation Manual ●July 23, 2018

© Copyright 2018 ShopBot Tools, Inc.

page 19

tools. While the draw bar is open, a rish of air will be heard, and input “8” will be lit.

With the green button still

depressed, insert a tool holder into

the spindle and hold it there.

Release the green button. The

drawbar will close, capturing the

tool holder. Input “7” should light

up, and input “8” should turn off.

Calibrating the ATC

Home Machine (C3)

Type C3 in the ShopBot 3 software or use the XY home icon in the position window. The tool should end up

at the home location previously set in the ShopBot Setup routine.

Calibration Routine (CN74)

The ATC calibration routine (CN74) is programmed to find

and record the clip locations. This document will walk

through the process.

Take out the calibration clip and drill rod that came with

the ATC. Connect the Wago plug to the mating socket on

the YZ car. The grounding clip is also attached to this

same plug.

The red calibration clip will be clipped to the bottom of

an empty tool holder as it is moved through all of the clip positions.

The black clip is will be clipped to the tool holder that is in the spindle.

Type “CN74” into the ShopBot 3 software to begin the routine. Enter the number of tool clips that are

mounted on the ATC.

Click yes if X and Y were zeroed. Otherwise, click “No” and return to the Homing the Machine (C3)

step.

Automatic Tool Changer (ATC) Installation Manual ●July 23, 2018

© Copyright 2018 ShopBot Tools, Inc.

page 20

Step 1: Determine Z Height for Calibration

Press the green button located on the side of the spindle, and

insert an empty tool holder.

Place a second, empty tool holder, inverted in clip position #1.

Use the keypad to move the spindle over the inverted tool

holder in clip position #1. Position the two faces about 1 inch

apart and visually center the top tool holder over the inverted

one as closely as possible. Hit “ESC”.

Place the black grounding clip on the tool holder in the spindle.

Table of contents

Other ShopBot Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Siemens

Siemens SIRIUS ACT 3SU19 operating instructions

Tenco

Tenco ENOL MASTER Technical handbook

Bell

Bell VSD 42/12 Manual for use and maintenance

Endress+Hauser

Endress+Hauser Flexdip CYA112 operating instructions

Stahl

Stahl SolConeX 8573/14 Series operating instructions

Festo

Festo 152962 operating instructions