Stober K38-03 User manual

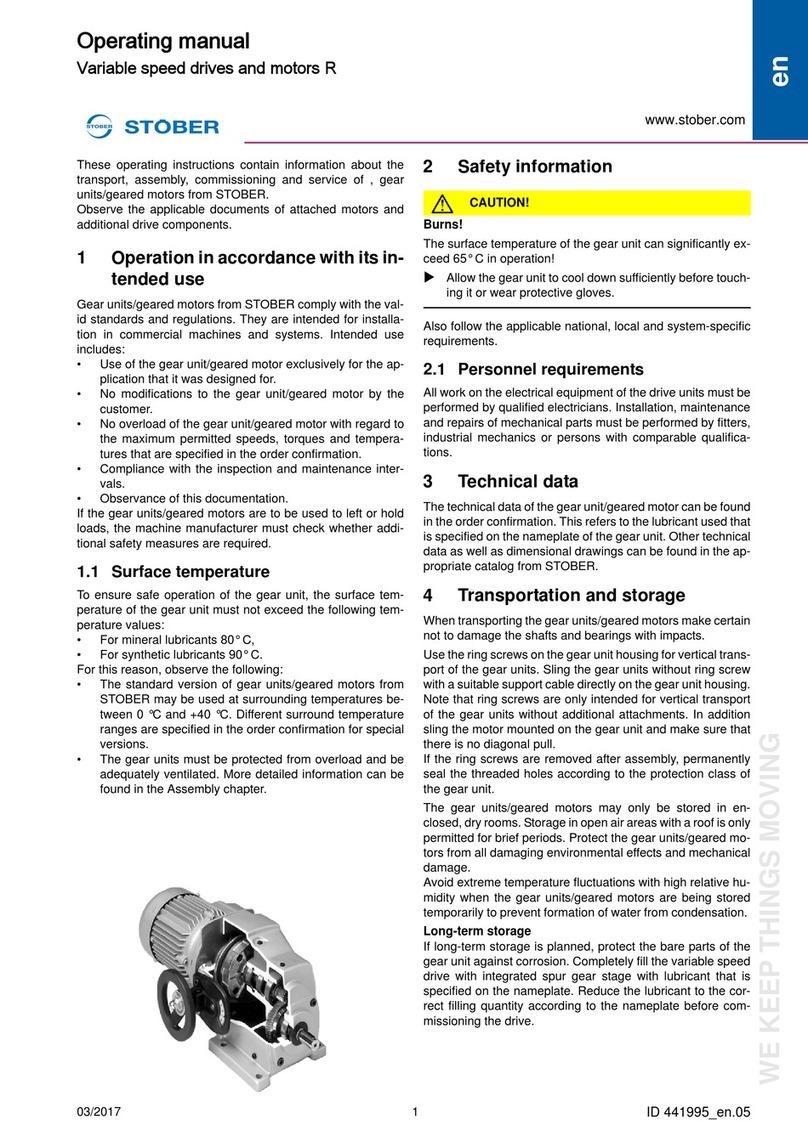

Operating manual

Brakes for Asynchronous Motors / Asynchronous Motors IE2

107/2014

WE KEEP THINGS MOVING

ID 442015_en.04

en

This operating instructions is a supplement to the operating

instructions "System Motors / Asynchronous Motors".

The electromagnetically operated, twin-surface spring

pressure brake is applied by spring force when not energised

and is released by an electromagnetic DC coil (Fig. 1, pos. 2)

or, when stationary, by an optionally installed manual valve

(Fig 1, pos. 3). The DC coil can be supplied either directly with

direct current or with an alternating current via a brake

rectifier (bridge, single-phase or Powerbox, see information

on the specification plate). When a direct DC supply is

provided (without a rectifier), a varistor must be installed as

protection against switching surges.Observe the information

in the STÖBER catalogue, on the braked motor specification

plate, in the operating instructions, wiring diagrams and

safety instructions.

If in doubt or when documents are lacking, obtain the

necessary information from the pertaining STÖBER sales

office or service workshops.

1 Technical data

Technical data for brake see appendix.

1.1 Electrical features Powerbox

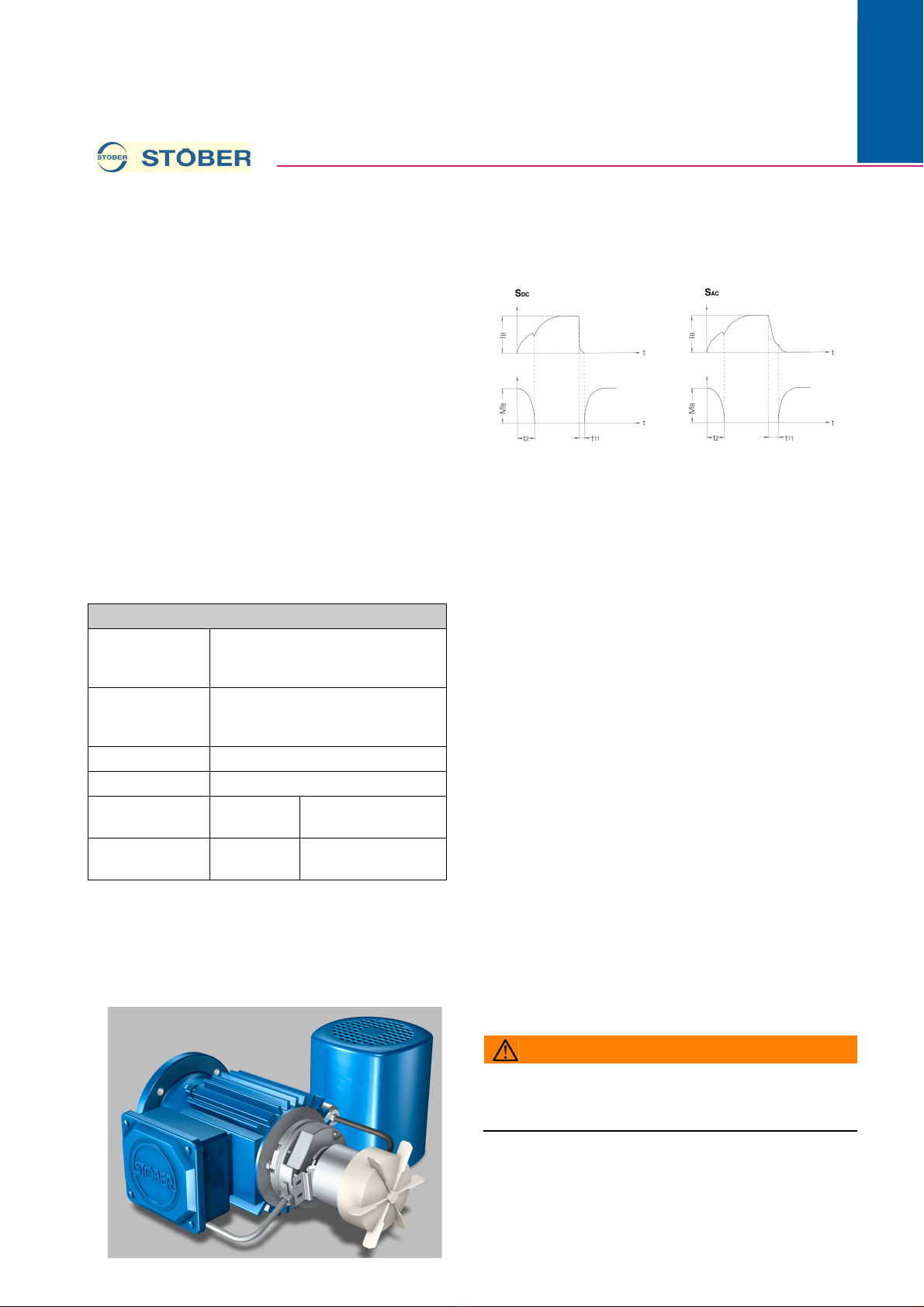

1.2 Current and torque-time diagram in

dependency on the circuit

arrangement

It is appropriate to switch on the brakes by the respective

switch-on time t2 before the motor.

See also Item 3, Electrical connection.

1.3 Formula brake

MB[Nm] - Braking torque

P20 [W] - Power input in continuous operation at 20° C

WNR [106·J] - Friction work until next adjustment,

amplification factor for Powerbox see below!

(WNR=10·W01·(Lmax-LN))

W01 [106·J] - Friction work per 0.1 mm of wear

LN[mm] - Rated air gap

Lmax [mm] - Maximum air gap

gmin [mm] - Min. permissible lining thickness

t2[ms] - Switch-on time (brake release time) up to M = 0 Nm

t11 DC [ms] - Switch-off time (delay) at S DC

t11 AC [ms] - Switch-off time (delay) at S AC

JB[10-4kgm2] - Mass moment of inertia

UDC [VDC] - Brake voltage

UAC [V] - Brake rectifier voltage

t2P [ms] - Powerbox switch-on time (brake release time) up to

M = 0 Nm

t11DCP [ms] - (delay) at S DC with Powerbox

t11ACP [ms] - (delay) at S AC with Powerbox

WNRP/WNR - Friction work until next adjustment, Powerbox

(amplification factor)

IB- Brake current

ZS[1/min] - Permitted switching cycles per minute (a

switching cycle consists of switching on and off once)

2 Installation, adjustment /

readjustment of the air gap (Fig. 1)

WARNING!

For work on the brake:

XSecure machine against unintentional movement

(vertical load, etc.).

The brakes are installed on the drive upon delivery and the

braking torque and air gap are adjusted to their rated values.

Air gap setting:

Adjust the air gap “L” to the rated value (LN) when the

maximum air gap (Lmax) is reached due to wear:

- Remove fan guard (1).

Powerbox electrical properties

Powerbox for use

with Frame size 63 - 132: Terminal box or

switch cabinet;

Size 160 - 225: only in switch cabinet

Input voltage 180 - 300 VAC +/- 0%

can be used for a wide range

220 - 275 V +/- 5% 50 or 60 Hz

Excitation time 350 ms +/- 10%

Cable length max. 100 m of brake coil

Current IN45°C 1,2 A stable;

2,4 A for 350 ms

Current IN75°C 0,7 A stable;

1,4 A for 350 ms

Operating manual

Brakes for Asynchronous Motors / Asynchronous Motors IE2

2

ID 442015_en.04

WE KEEP THINGS MOVING

07/2014

en

- Loosen cheese-head screws (5).

- Adjust the air gap to the rated value by applying an open-

jawed spanner to the adjusting nuts (4). Two calliper gauges

are necessary to measure the air gap; the deviations at the

three measuring points should not exceed ±0.05 mm.

- Tighten cheese-head screws (5).

- Replace fan guard (1).

Replace brake:

When the minimum lining thickness gmin is reached, replace

brake disc (6). During the replacement, inspect the anchor

disc (7), lining (motor B bearing bracket), friction disc (8) and

brass foil (if installed). Replace if excessively worn. Anchor

disc (7) available only complete with brake coil (2).

Fig. 1

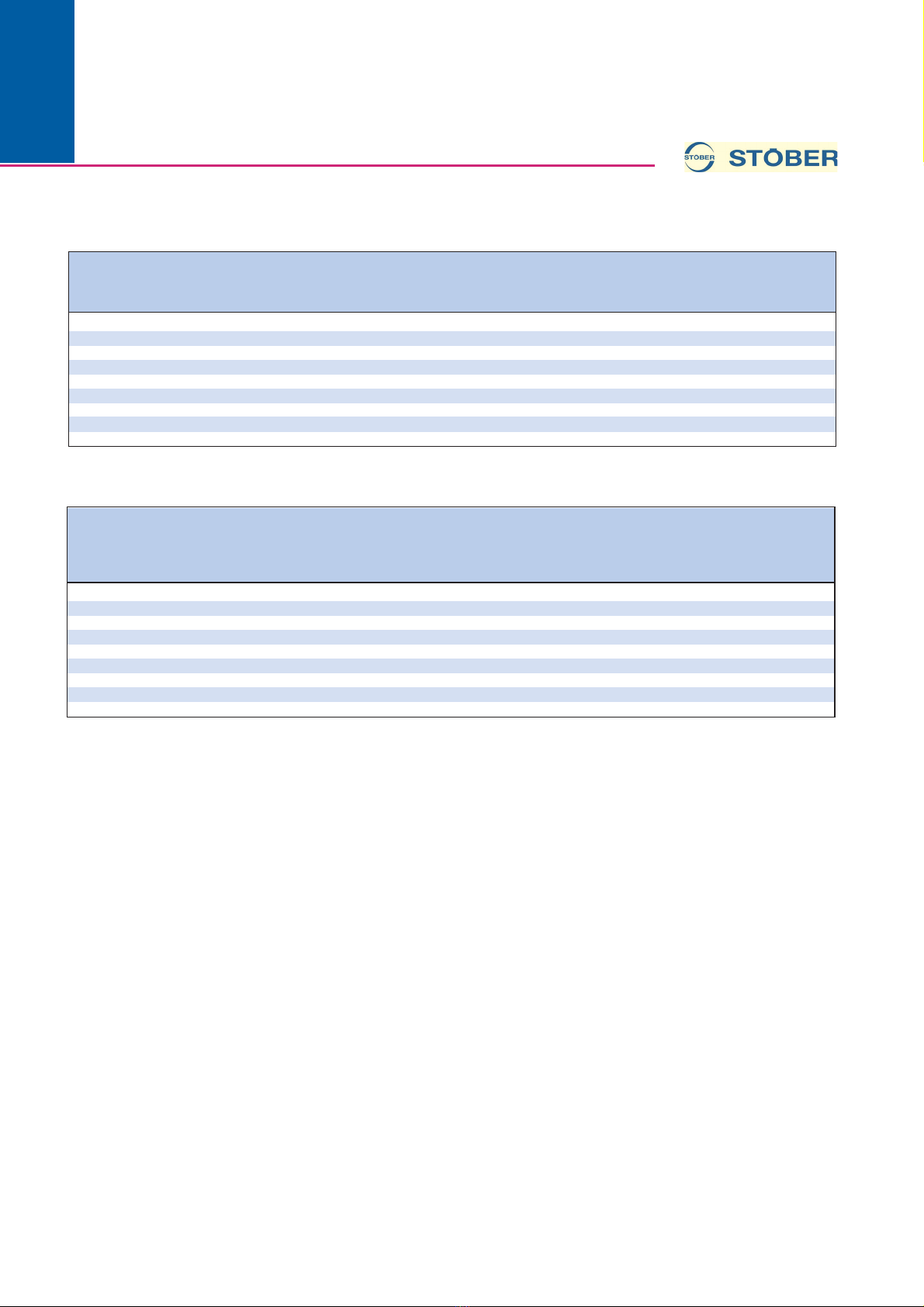

3 Electrical connection

- Without rectifier, connected voltage UDC see specification

plate (Fig. 3)

- With rectifier and external supply UAC (Fig. 2, Fig. 4) fast

rectfier (Powerbox) also included.

See specification plate for connected voltage UAC.

AC switching (with bridge B).

DC switching (fast application of the brake).

Remove bridge B in Fig. 2, replace with switch contacts and

employ additional AC switching.

- With rectifier and direct UAC supply from the motor

terminals.

Install the enclosed connecting bridges as shown in Fig. 5 and

Fig. 6.

The following applies for connected voltage of the brake

(UAC) according to specification plate and supply voltage

(U3AC):UAC = U3AC x 0.58 (Fig. 5), UAC = U3AC (Fig. 6).

Connection of the brake to motor terminals possible only

when the voltages are equal.

Permissible only for direct starting with supply.

Connected voltage with Powerbox rectifier 220 - 277 VAC, coil

voltage 115 (or 127) VDC.

Observe terminal designations on the component.

For other designs or other installed equipment, see separate

circuit diagram.

While making the motor connection, observe and comply with

the attached safety instructions and the respective operating

instructions. Observe connection designation and connection

plan!

To be observed while using rectifiers:

If the full nominal power is used, or if the motor is driven only

with its own ventilation in the lower speed range (at drive

controller), then it is possible for the temperature of the motor

housing surface to exceed the maximum permissible

ambient temperature for Powerbox fast rectifier (75° C) or

for one-way or bridge rectifier (80° C). In this case, installation

in the terminal box is not advisable, as the higher

temperatures can lead to the premature failure of the rectifier.

Instead, the rectifier should be installed in the control cabinet.

Of course, here too, a position should be selected at which

the temperature is always lower than the permissible ambient

temperature! For use under increased temperature

conditions, or operation through drive controllers, we request

you to please discuss the matter with our sales engineers.

Operating manual

Brakes for Asynchronous Motors / Asynchronous Motors IE2

307/2014

WE KEEP THINGS MOVING

ID 442015_en.04

en

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 6:

4 Troubleshooting

In the event of a malfunction of the drive unit, call the

STÖBER service department at 07231 582-1190 (-1191, -

1224, -1225) in order to locate the nearest STÖBER service

partner for further action.

In urgent cases outside of normal business hours, you

can call the STÖBER 24-hour service hotline at 01805

786323 / 01805 STOEBER

5 Spare parts

Include the following when ordering replacement parts:

– item no. of the part according to the replacement parts lis

– model designation according to the rating plate

– serial number according to rating plate

You can reach the STÖBER replacement parts service by

phone: 07231 582-1190 (-1191, -1224, -1225), or fax: 07231

582-1010.

Important notice: The replacement parts lists are not

assembly instructions! They are not binding for assembly of

the gear unit. Use only original replacement parts from

Stöber. Otherwise we will provide no guarantee and will

assume no liability for resulting damages!

6 Disposal

This product contains recyclable materials. Observe local

applicable regulations for disposal.

Operating manual

Brakes for Asynchronous Motors / Asynchronous Motors IE2

4

ID 442015_en.04

WE KEEP THINGS MOVING

07/2014

en

7 Appendix

Technical data:

Technical data for standard wide-range brakes with high-

speed rectifier:

Typ Mot. M

B

P

20

W

NR

W

01

L

N

L

max

g

min

t

2

t

11DC

t

11 A C

J

B

m

B

[Nm] [W] [10

6

J] [10

6

J] [mm] [mm] [mm] [ms] [ms] [ms] [10

-4

[kg]

kgm

2

]

K38-03 80K,80L 10 30 37,5 12,5 0,2 0,5 6,5 55 15 100 0,79 1,7

K38-04 90L,90S 20 30 76,0 19,0 0,2 0,6 8,0 90 25 180 1,50 3,3

K38-05 100K,100L 36 48 112,0 28,0 0,2 0,6 10,0 110 25 220 3,85 5,0

L48-14 112M 60 50 215,0 43,0 0,3 0,8 6,0 150 65 390 6,93 5,7

L48-16 132M,132S 80 55 434,0 62,0 0,3 1,0 7,5 180 90 540 16,5 8,7

L48-18 160K,160L,160M 150 85 540,0 90,0 0,4 1,0 8,0 300 110 660 31,9 13,2

L48-20 180L,180M 260 100 612,0 76,5 0,4 1,2 9,6 400 200 1200 80,3 21,2

L48-25 200L,200M,225M,225S 400 110 792,0 88,0 0,5 1,4 12,5 500 270 1620 220 32,0

Typ Mot. M

B

U

DC

U

AC

L

N

L

max

t

2P

t

11DCP

t

11 A C P

W

NRP

/Z

S

W

NR

[Nm] [V] [V] [mm] [mm] [ms] [ms] [ms] [1/min]

50-60 [Hz]

K38-03 80K,80L 10 115 220–275 0,2 1.36 - 1.75 31 - 26 13 - 16 78 - 85 3.9 - 5.2 40

K38-04 90L,90S 20 115 220–275 0,2 1.6 - 2.1 50 - 44 17 - 21 126 - 139 3.5 - 5.3 40

K38-05 100K,100L 36 115 220–275 0,2 2.1 - 2.8 55 - 48 35 - 42 186 - 198 4.8 - 6.5 25

L48-14 112M 60 127 220–275 0,3 2.5 - 3.4 89 - 76 54 - 65 359 - 390 4.6 - 6.2 5

L48-16 132M,132S 80 127 220–275 0,3 2.5 - 3.4 107 - 91 75 - 90 497 - 540 4.1 - 5.6 5

L48-18 160K,160L,160M 150 127 220–275 0,4 2.5 - 3.4 179 - 152 91 - 110 608 - 660 4.7 - 6.3 5

L48-20 180L,180M 260 127 220–275 0,4 2.5 - 3.4 238 - 203 166 - 200 1105 - 1200 3.5 - 5.9 2

L48-25 200L,200M,225M,225S 400 127 220–275 0,5 2.5 - 3.4 286 - 244 224 - 270 1492 - 1620 4.3 - 6.0 1

This manual suits for next models

7

Other Stober Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Jäger

Jäger Z62-K360.12 S4AG1IP manual

DH

DH RGI-30 Short manual

Sentry

Sentry Saf-T-Vise STV-LP1 Installation, operation & maintenance manual

Orca

Orca UVpro EKB 100 manual

Max-Air Systems

Max-Air Systems Max Electric ME C 004 Series Installation, operation and maintenance instructions

Miller

Miller 74 Series owner's manual