3

Factory Field

Code Parameter description and choices Min Max setting setting

L2 Output logic 0 3 1

0: Alarm & pump down. = normal; 1: Alarm = inverse, pump down. = normal

2: Alarm = normal, pump down. = inverse; 3: Alarm & pump down. = inverse

b1 Battery error management, 0 3 2 *

when battery is defective, see below:

Reset possibility after

Value Alarm display Alarm relay Valve recovery/replacement

0 - - Regulating -

1 Ab - Regulating -

2 Ab Signalling Fullyclose Auto

3 Ab(blinking) Signalling Fullyclose Manual

WARNING: When setting b1 to option 0 or 1, the user must ensure appropriate

safety precautions are in place to protect the system against damage caused by a

power failure.

Factory Field

Code Parameter description and choices Min Max setting setting

/6 Show decimal point; 0=yes, 1 = no 0 1 0

A6 Maximumdischargetemperature;°F 212 284 266

A7 Discharge temp. alarm delay; sec. 0 199 30

F2 Minimumcapacity;% 10 100 10

F3 Maximumcapacity;% 10 100 100

F6 ScrollValve,PWMcycletime;sec. 10 20 20

t3 Monitor discharge temperature sensor 0 1 0

0 = no, 1 = Yes

ru 0-10Vinputltering;0=off,1=on 0 1

* Min. and Max. setting values are dependent upon selected type of refrigerant.

LIST OF PARAMETERS IN SCROLLING SEQUENCE BY PRESSING BUTTON

Factory Field

Code Parameter description and choices Min Max setting setting

H5 Password 1 199 12

u0 System refrigerant 0 7 4

0=R22;1=R134a;2=R507;3=R404A;4=R407C;

5=R410A;6=R124;7=R744(subcriticalapplication)

uP Installed pressure sensor type 0 2 0

0=PT5-07M(forR22/R134a/R507/R404A/R407C/R124)

1=PT5-18M(forR410A)

2=PT5-30M(forR744,subcritical)

ut Installed valve type 1 3 2

1 = EX4; 2 = EX5; 3 = EX6

uu Startvalveopening(%) 10 100 50

u9 Start opening duration (second) 1 30 5

uL Low superheat alarm function 0 2 1

0=disable(foroodedevaporator)

1 = enable auto reset 2 = enable manual reset

Cut-out at 0.5K (if it maintains 1 min.); Cut-in immediately at 3K

u5 Superheatset-point(°F)

If uL enabled (auto or manual) 5.4 54 10.8

If uL disabled 0.9 54 10.8

u2 MOP function 0 1 1

0 = disable 1 = enable

u3 MOPset-point(°F)

saturation temperature

* * X

Factorysettingisaccordingtoselectedrefrigerant(u0):

+55°FforR22;+59°FforR134a:+45°FforR507

+45°FforR404A;+59°FforR407C;+59°FforR410A

+122°FforR124;+23°FforR744

┌┘5 Unitsconversion 0 1 0

0=°C,K,bar;1=°F,R,psig

(Psig values are divided by 10. Example: Display 12.5 is 125 psig)

┌┘1 Valuetoshow 0 4 0

0=Measuredsuperheat(°F);1=Measuredevaporatorpressure(psig)

2=Valveopening(%);3=Measuredcoil-outtemp.(°F)

4=Calculatedevaporatingtemperature(°F)fromthepressure

5=Compressorcapacityin%

u4 Superheat control mode 0 1 0

0 = Standard, 1 = Slow

uH High superheat alarm function 0 1 0

0 = disable, 1 = enable auto reset

uA High superheat alarm setpoint 16 40 30

ud High superheat alarm delay, min. 1 15 3

P2 Freezeprotectioncut-out,°F -40 104 -32

P3 Freezeprotectioncut-in,°F -35 109 37

P4 Freezeprotectionalarmfunction 0 2 0

0 = disable, 1 = enable auto-reset,

2 = enable manual reset

P5 Freezeprotectionalarmdelay,sec. 5 199 30

P6 Pump-down function

0 = disable, 1 = enable auto-reset 0 1 0

P7 Pump-down cut-out, psig -7.3 261.1 7.2

P8 Pump-down time delay, sec. 0 199 30

P9 Low pressure alarm function 0 2 0

0 = disable, 1 = enable auto-reset, 2 = enable manual reset

PA Low pressure alarm cut-out, psig -11.6 256.7 0

Pb Low pressure alarm delay, sec. 5 199 5

Pd Low pressure alarm cut-in, psig -7.3 261.1 4.3

LIST OF PARAMETERS IN SCROLLING SEQUENCE BY PRESSING BUTTON

SPECIAL FUNCTIONS

SpecialFunctionscanbeactivatedby:

• Pressandtogetherformorethan5seconds.

Aashing0isdisplayed.

• Pressoruntilthepasswordisdisplayed(default=12).

If password was changed, select the new password.

• PressSELtoconrmpassword

A0isdisplayedandtheSpecialFunctionmodeisactivated.

• Pressortoselectthefunction.Thenumberofspecialfunctionsis

dynamic and controller dependent. See list below.

0:Resetcontrollertofactorysettings(thisactionispossibleonlywhen

digital input is 0V i.e. open)

1: Displays the current TCP/IP address

2: Assign temporary 192.168.1.101 as TCP/IP address if EC3-D72 has

different address

• PressSEL to activate the function without leaving the special function

mode.

• PressPRG to activate the function and leave the special function mode.

Control (Valve)

Start-Up Behavior

(Parameter uu and u9)

PUMP DOWN FUNCTION (IFP6=1ANDL2=1)

Cooling Alarm

DemandStatus Condition PumpDownRelay

24V (ON) NO Activate

0V(OFF) NO Deactivatewhenpressuredropsbelow

P7 and after elapsed time P8

0V or 24V YES Deactivate instantaneously

START-UP

Start the system and check the superheat and operating conditions. The

EC3-D72 is fully functional without connected PC or keypad/display unit.

ECD-002.

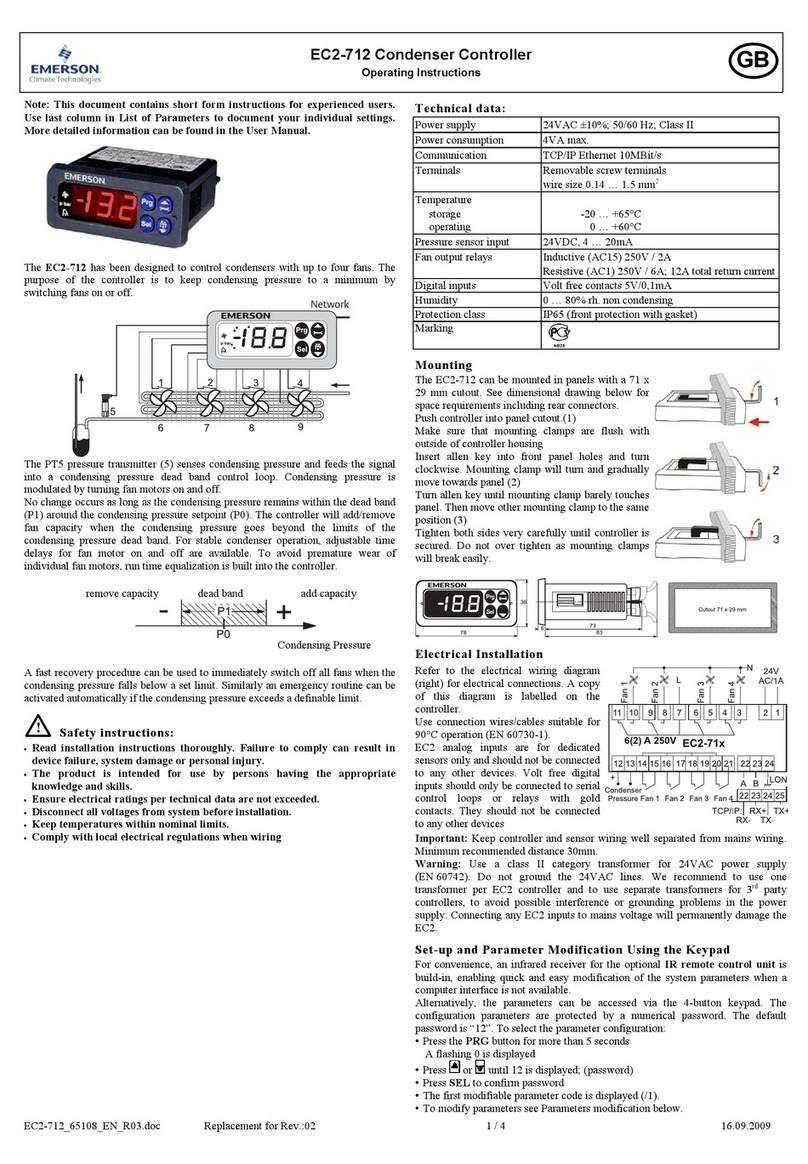

MOUNTING OF ECD-002

ECD-002 can be installed at any time also during operation.

• ECD-002canbemountedin

panels with 2.8 x 1.1 inch cutout

• Pushcontrollerintopanelcut-out.(1)

• Makesurethatmountinglugsare

ushwithoutsideofcontrollerhousing

• InsertAllenkeyintofrontpanelholesandturn

clockwise. Mounting lugs will turn and gradually

move towards panel (2)

• TurnAllenkeyuntilmountinglug

barely touches panel. Then move

other mounting lug to the same

position (3)

• Tightenbothsidesverycarefullyuntilkeypadissecured.

Do not over tighten as mounting lugs will break easily.