9

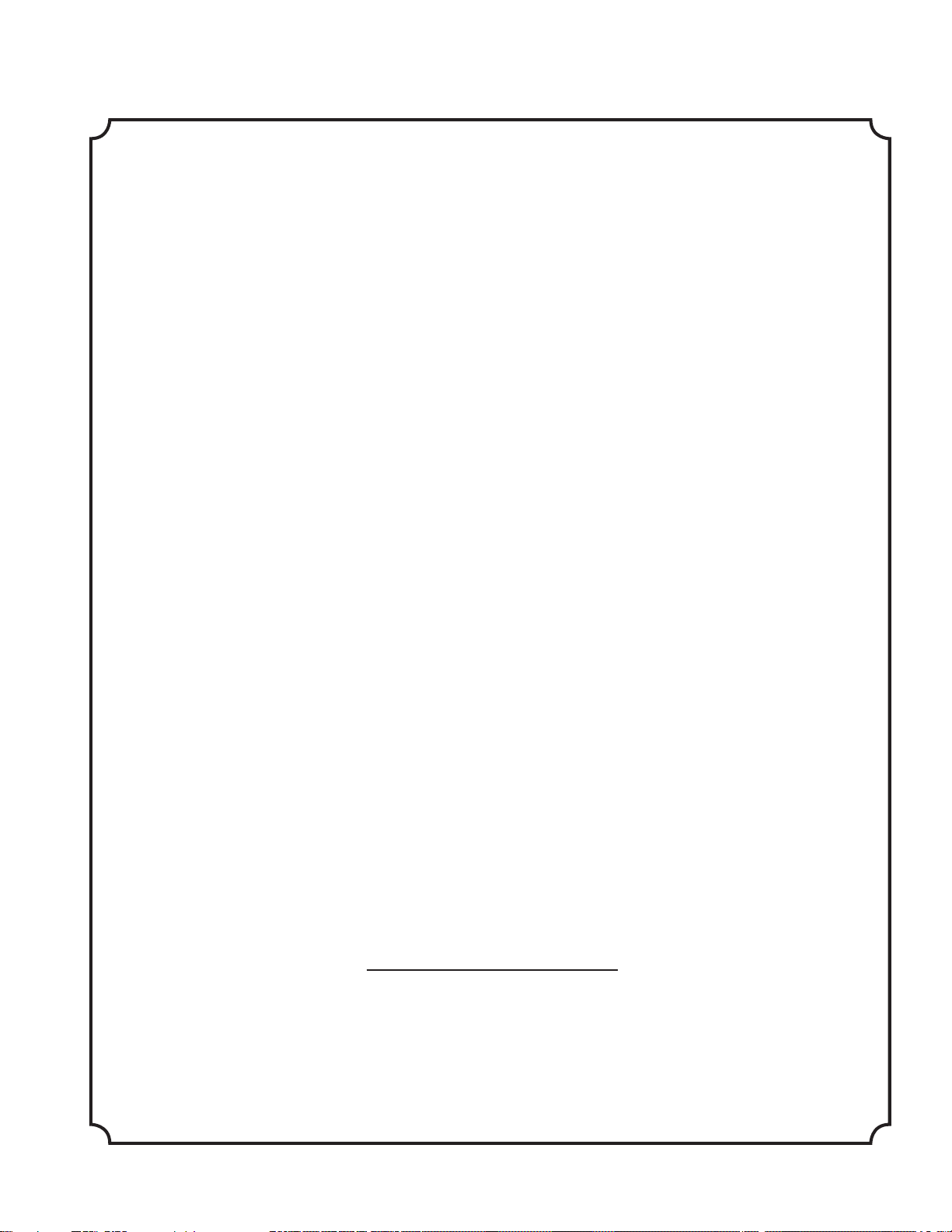

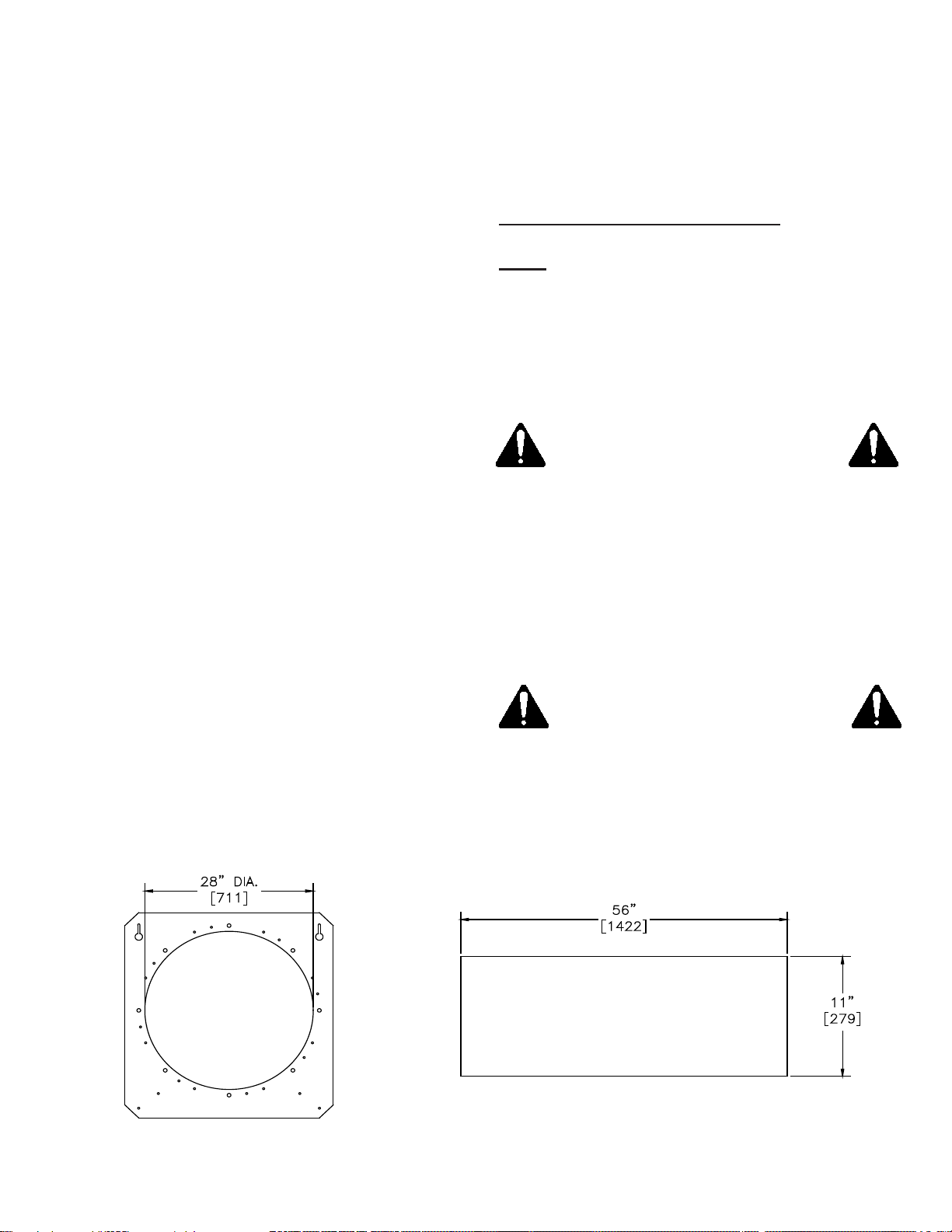

Figure 3.

INSTALLATION

AREA= 56 X 11 = 616 SQ IN.

[3974 sq. cm.]

TRANSITION DISCHARGE OPENING

FAN DISCHARGE

AREA = 616 SQ. IN.

[3974 sq. cm.]

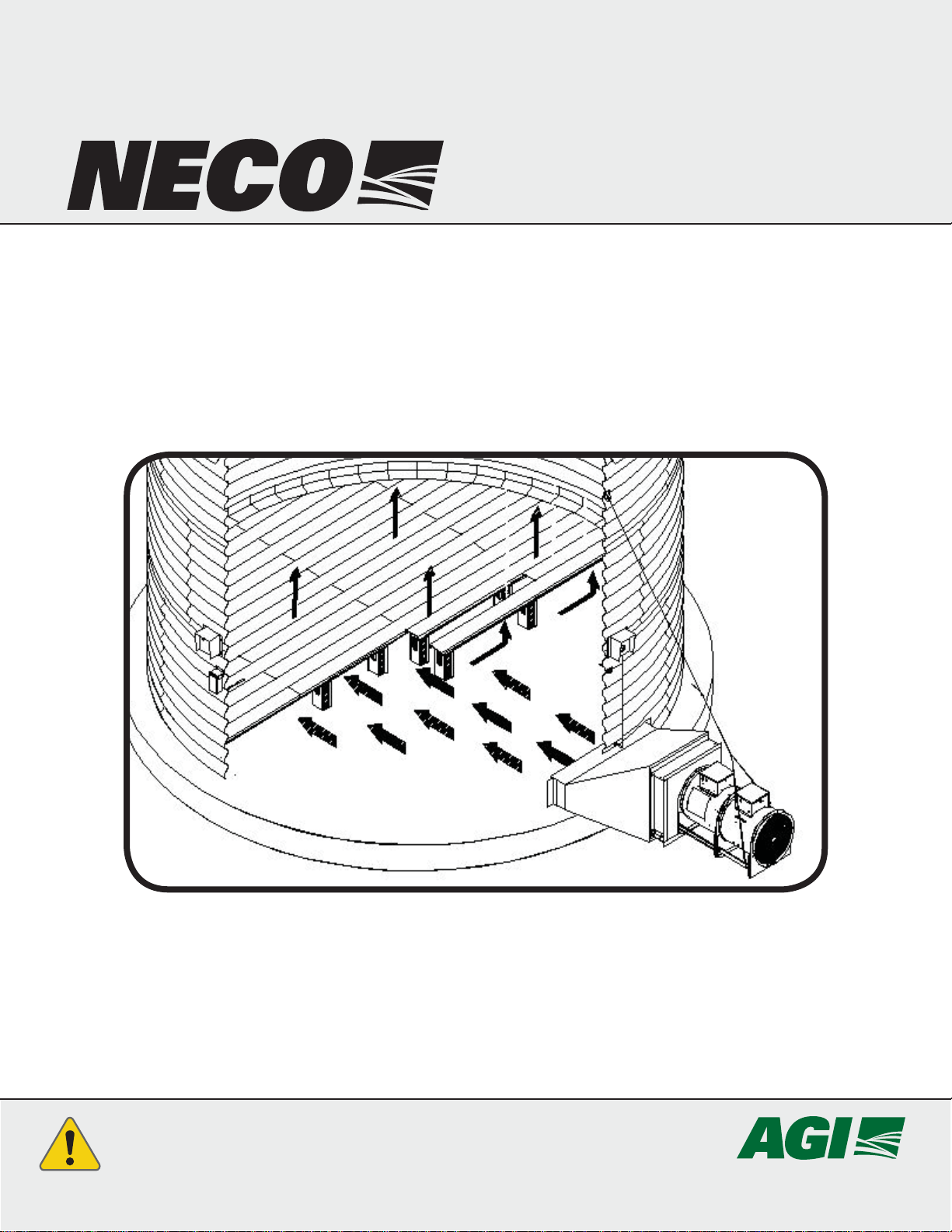

4. Fan and add-on heater mounting plane is

the same as your grain bin.*

*On MFS corrugated grain bins with a rolled in

base angle, the fan and heater mounting needs

to be 1½" lower.

Place the fan and heater on a mounting pad

or hang them off the side of the grain bin with

cables. Hanging installations can prevent the

costs and maintenance issues associated

with poured concrete pads. NECO premium

axial fans and axial heaters 24" and greater

are equipped with cable attachment brackets

(located at the handles). Use at a minimum a

3/16" galvanized steel (or stainless steel) wire

rope with appropriate ttings. Make certain the

units are secured to prevent any wind-induced

sideways motion. Centrifugal fans and heaters

can also be hung by cables, but due to their

weight and size the installations usually require

angle brackets and heavier wire rope. Speak to

your dealer or local millwright before attempting

cable installations.

It's very important that the unit is securely

mounted. If you choose a poured concrete slab

to mount your fan and heater on, it is recom-

mended that the slab be approximately 6 inches

thick [152] and 12" [305] wider on each side of

the fan/heater.

TIP: In order to reduce the chances of frost

heave, the pad can be poured on top of several

metal or concrete pilings which extend lower

than average frost depth.

5. Make sure the bin transition discharge is of

an equal area to your fan outlet. (See Figure 3.)

1. Using the appropriate caulk (caulking rated

at 200°F) caulk the Fan/Heater anges. Con-

nect the fan to the heater using nuts, bolts etc.

Hand tighten these fasteners only.

Note: use the appropriate adapter plates to

connect Fans/Heaters and transitions. Do not

weld onto transitions! Welding will cause

distortions which could lead to vibrations

during operation.

2. Place fan and heater on mounting pad.

Make sure the units sit level.

Any bending of the units will twist

the housing and cause future

problems.

Note: Frost heave can cause Fan/Transition

distortion and even vibration.

3. Wrench tighten the fan mounting bolts/nuts,

followed by wrench tightening of the heater

mounting nuts/bolts.

Make sure heater/fan mountings

are secure. A loose fan mounting

will cause the fan to vibrate. Vi-

bration can cause excessive wear

on the fan motor bearings.

4. Wrench tighten all ange fasteners.