Operator Instructions

Operator Instructions 9

3 Operator Instructions

Startup the System

The Medalist 5DX is operated through the use of a user interface

running on the system controller. Before starting the system

software, verify that the X-ray has been enabled.

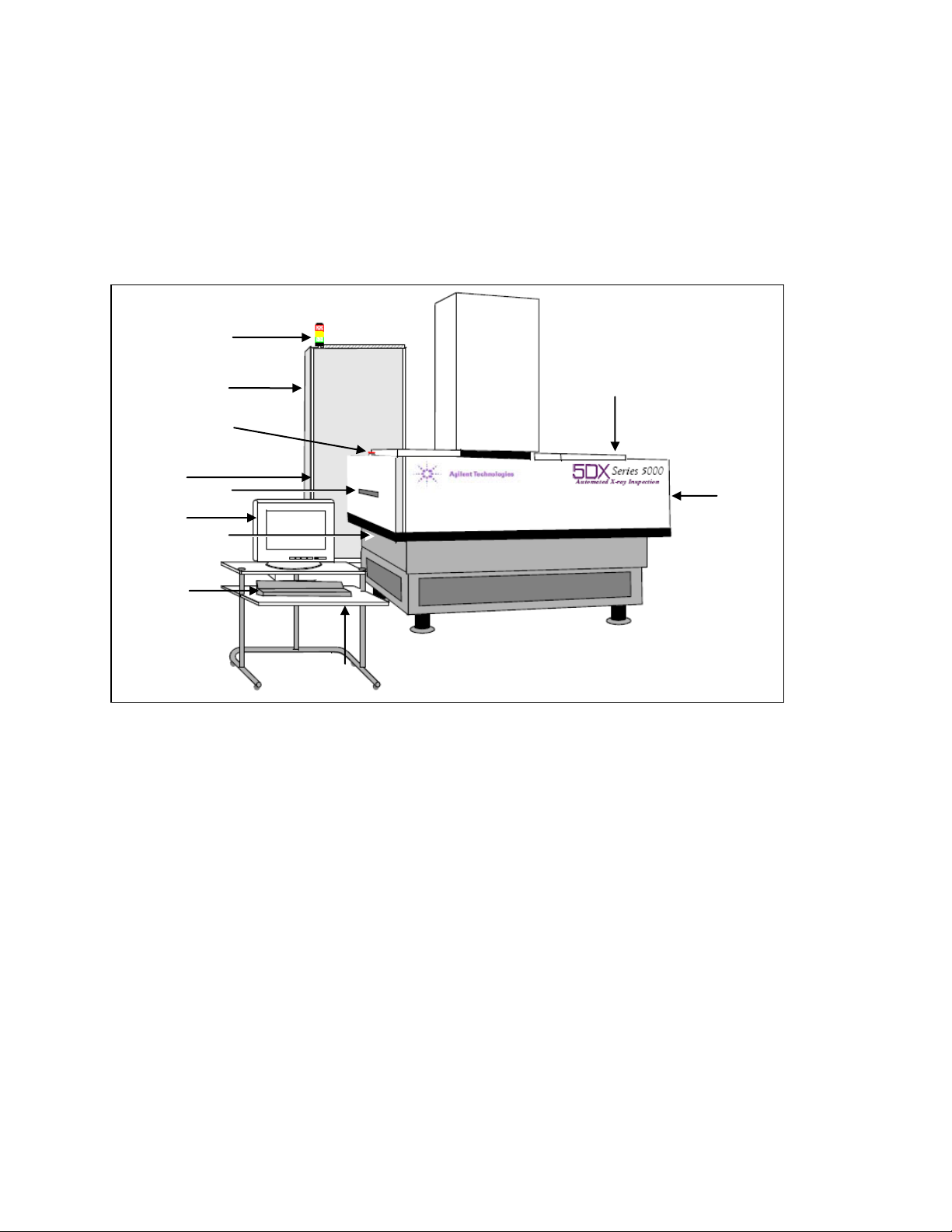

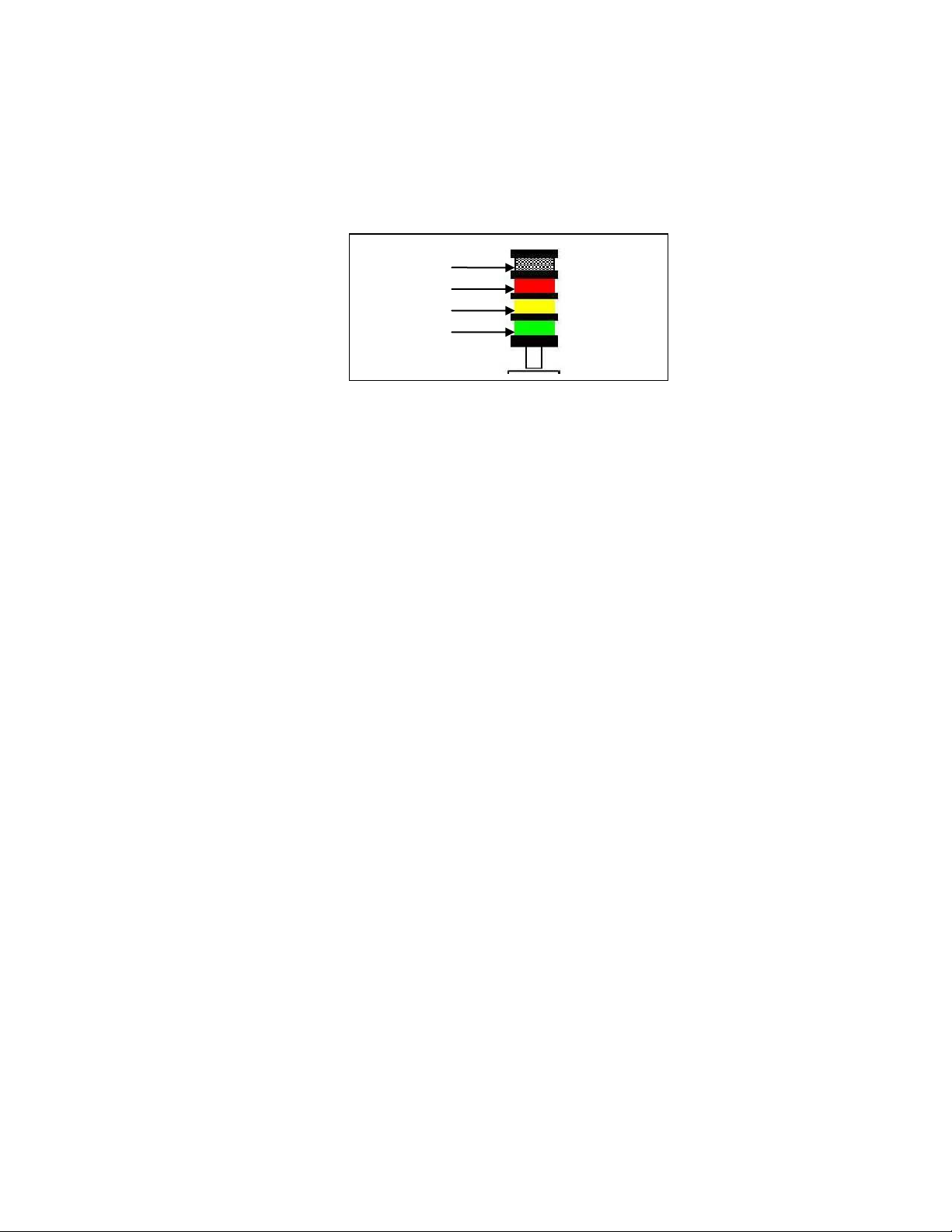

Verify the Safety Interlocks are Closed

On the operator control panel (see Figure 3) verify that the Safety

Interlocks green LED is lit. If it is not, call a service technician to

resolve the problem.

Verify the X-Ray Has Been Enabled

On the operator control panel (see Figure 3) verify that the X-ray

Control key is in the enabled position (1) and press the X-ray Control

enable button (1). Verify that the X-rays red LED is lit.

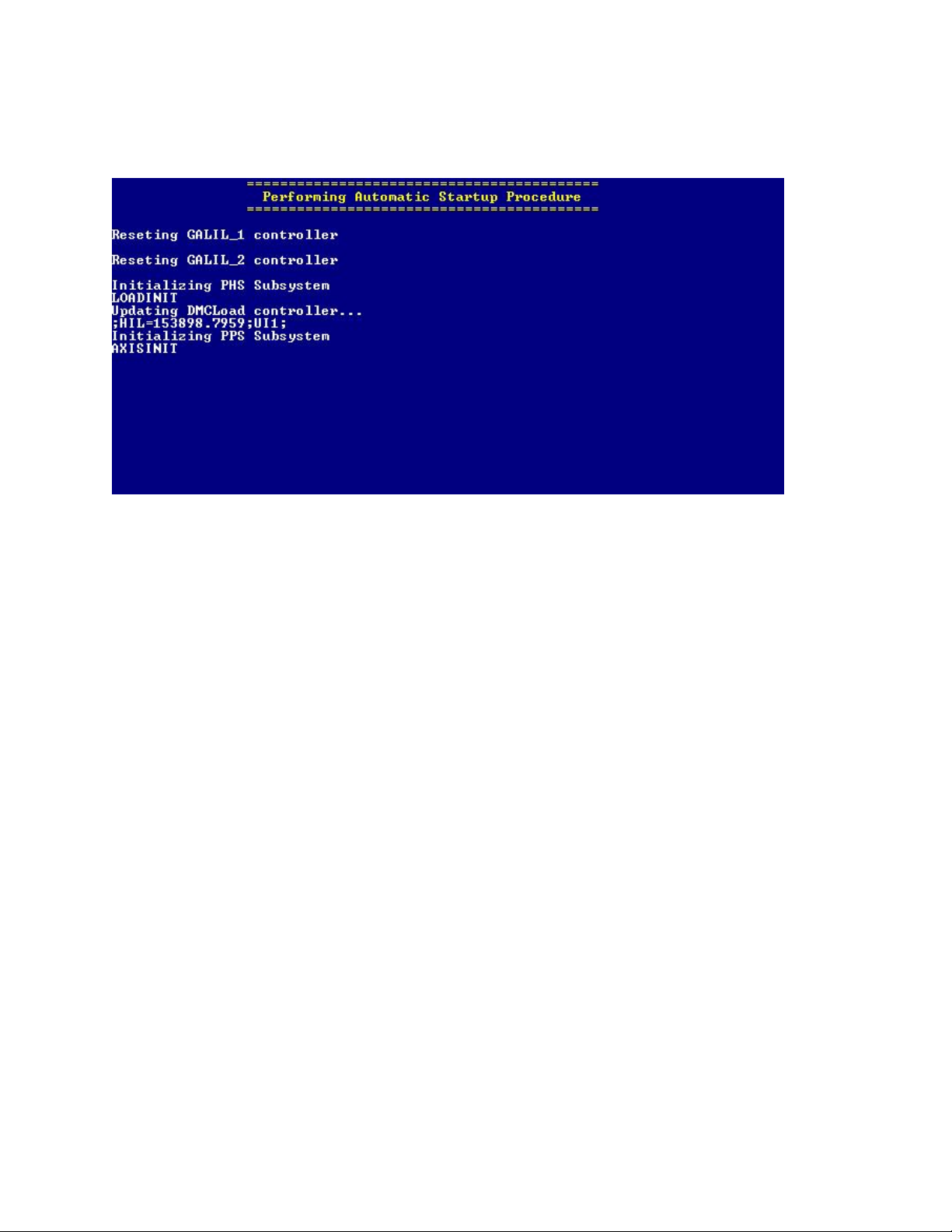

Log on to Microsoft Windows XP

Log on to Microsoft Windows using the Windows user name and

password provided by your administrator. When you log on, the

Medalist 5DX software starts automatically.

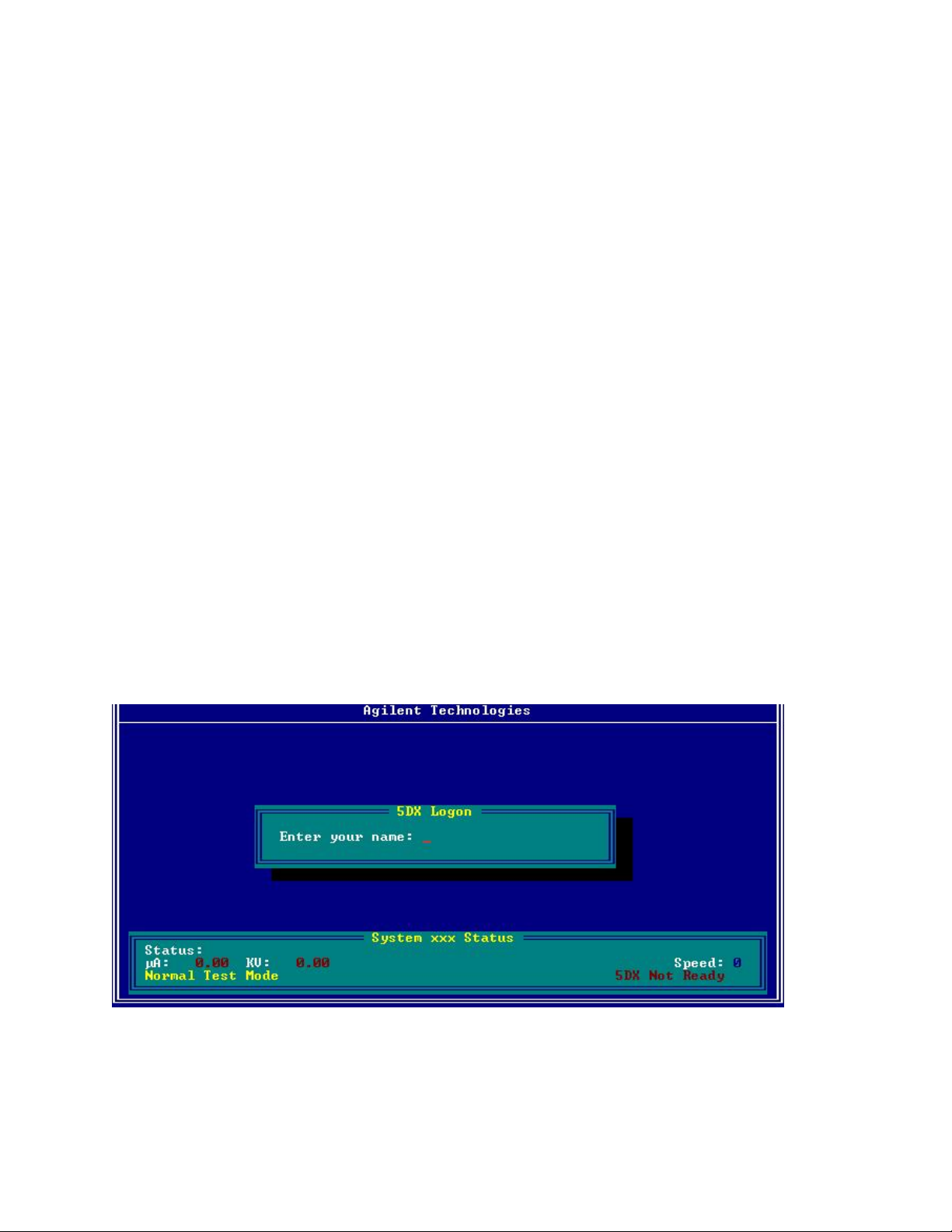

Log on to the Medalist 5DX User Interface

Log on to the Medalist 5DX user interface using the user name

provided by your administrator. Press the ‘Enter’ key to Login.

Figure 4 Login