Agria 3100 User manual

Other Agria Lawn And Garden Equipment manuals

Agria

Agria 3100 User manual

Agria

Agria 1600 farmstar compact User manual

Agria

Agria Bison 5900 Series User manual

Agria

Agria 9600-112 Quick guide

Agria

Agria 400E User manual

Agria

Agria 6000 User manual

Agria

Agria 3400 User manual

Agria

Agria 5500 GRIZZLY compact User manual

Agria

Agria 5500 KL User manual

Agria

Agria Bison 5900 Series Quick guide

Agria

Agria 2100 User manual

Agria

Agria 1400 FARMBOY User manual

Agria

Agria 8000 611 User manual

Agria

Agria 3600 925 User manual

Agria

Agria 1600 FARMSTER PREMIUM User manual

Agria

Agria Bison 5900 Series User manual

Agria

Agria Cyclone 5900 Quick guide

Agria

Agria 1000E User manual

Agria

Agria 3900 User manual

Agria

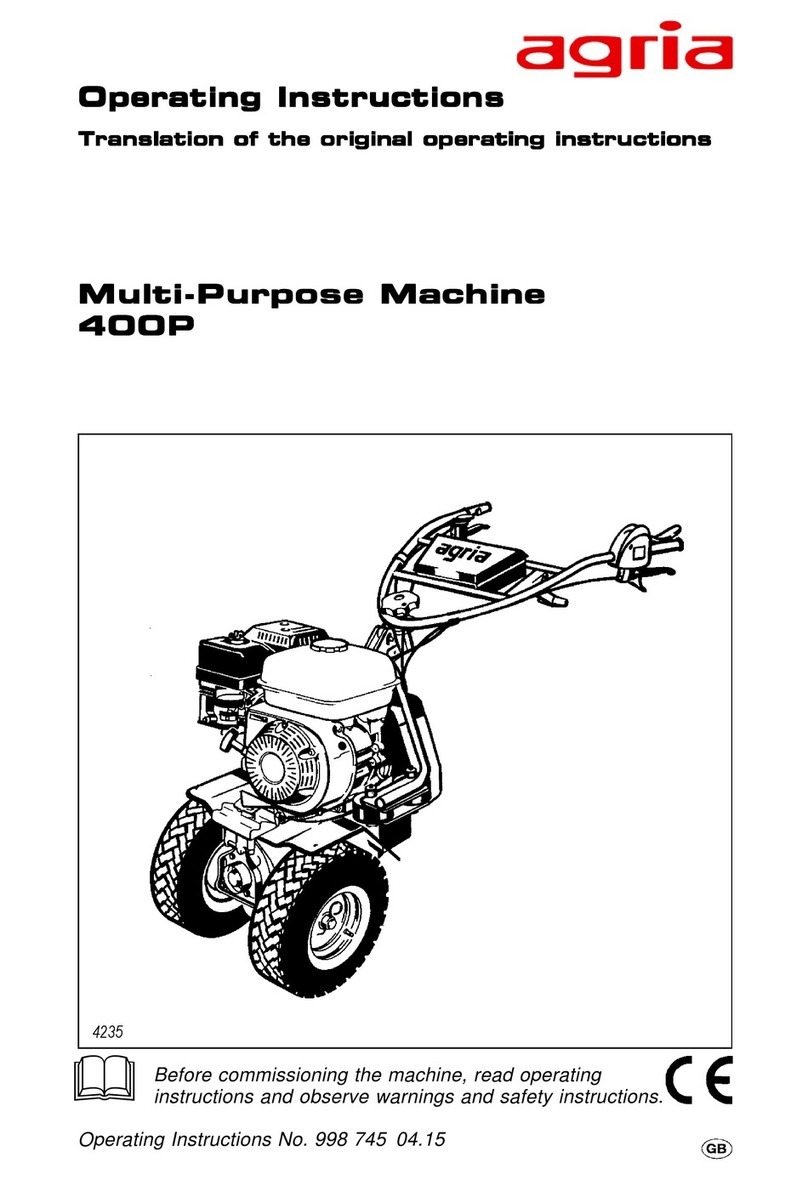

Agria 400P User manual

Popular Lawn And Garden Equipment manuals by other brands

Sunforce

Sunforce SOLAR user manual

GARDEN OF EDEN

GARDEN OF EDEN 55627 user manual

Goizper Group

Goizper Group MATABI POLMINOR instruction manual

Rain Bird

Rain Bird 11000 Series Operation & maintenance manual

Cub Cadet

Cub Cadet BB 230 brochure

EXTOL PREMIUM

EXTOL PREMIUM 8891590 Translation of the original user manual

Vertex

Vertex 1/3 HP Maintenance instructions

GHE

GHE AeroFlo 80 manual

Land Pride

Land Pride Post Hole Diggers HD25 Operator's manual

Yazoo/Kees

Yazoo/Kees Z9 Commercial Collection System Z9A Operator's & parts manual

Premier designs

Premier designs WindGarden 26829 Assembly instructions

Snapper

Snapper 1691351 installation instructions