catalogue

catalogue

1.equipment description.............................................................................................................................................. 3

2.executive summary ................................................................................................................................................. 5

2.1 uesr’s manual.................................................................................................................................................5

2.2 safety orperation rules ................................................................................................................................. 5

3.transport ...................................................................................................................................................................5

4.unpacking ................................................................................................................................................................ 6

5.Installation instruction ............................................................................................................................................ 6

5.1 location requirements ...................................................................................................................................6

5.2 installation of components ...........................................................................................................................7

5.3 test run ......................................................................................................................................................... 9

6.operation .............................................................................................................................................................. 11

6.1 pressure tire .............................................................................................................................................. 11

6.2 tire dismantling .........................................................................................................................................12

6.3 tire fixing .................................................................................................................................................. 14

7.inflation ................................................................................................................................................................16

7.1 inflate the tire with the inflation nozzle ................................................................................................... 16

8.relocate ................................................................................................................................................................. 17

9.storage .................................................................................................................................................................. 17

10.scrap.................................................................................................................................................................... 17

11.Repair and maintenance .....................................................................................................................................17

11.1 warning ....................................................................................................................................................17

11.2 repairt and maintenance .......................................................................................................................... 18

12.trouble shooting-causes and solutions.................................................................................................................20

13.technical parameter ............................................................................................................................................ 20

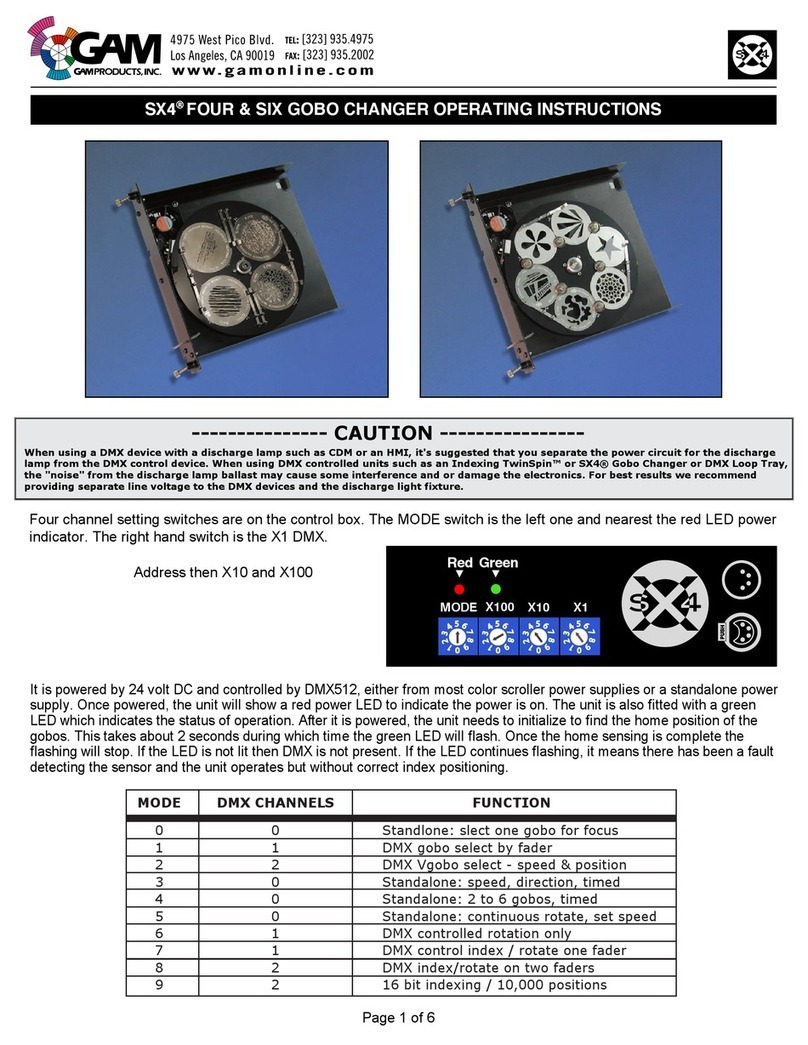

14.circuit diagram and pneumatic system diagram..................................................................................................21

14.1 circuit diagram ..................................................................................................................................... 21

14.2 pneumatic system diagram ...................................................................................................................22