Installation-, Operating-, Maintenance-Manual, Spare part List MAK10

AGT-PSG GmbH & Co.KG

Errors and printing mistakes excepted

Page 7

Translation - Manual MAK10 Rev. 11/2017

Assembly and Installation

Installation Site

The main dimensions are shown at the dimensioned drawing of the sample gas cooler. The weight is

mentioned on the model identification plate.

Failure to install the sample gas cooler in the proper ambient conditions will affect the sample gas coolers

ability to condense refrigerant gas. This can cause higher loads on the compressor, loss of cooler

efficiency and performance, electrical component failure and cooler failure due to the following:

Compressor loss and electrical component failure. Failures of this type will affect warranty considerations.

The layout of the compact sample gas conditioner guarantees a problem-free integration into the analysis

systems.

Minimum installation requirements:

Select a clean dry area, free from dust, and protected from atmospheric disturbances. Avoid

direct solar radiation.

Minimum ambient temperature +5°C, maximum ambient temperature +40°C.

Specific humidity: 20-70%, non-condensing.

For the wall mounting, the wall has to be perfect vertical. The brackets must hold 4 times the

given weights. Only use the existing fastening points of the housing. The dryer has to be

mounted in perfect upright position.

Ensure unhindered cooling air circulation while installing the sample gas cooler. Do not install the

sample gas cooler directly over, under or beneath possible sources of heat.

CAUTION! Ambient conditions! Do not install the cooler in areas of extreme dust and dirt or

in corrosive environment.

CAUTION! Min. 80mm free space for ventilation and bleeding! The required free space at

front- and side-plates for ventilation and bleeding the sample gas conditioner must be

maintained for smooth functioning.

We recommend a wall mounting of the device. For an operation in enclosed housings, such as

analytic cabinets, we recommend a suitable ventilation or air conditioning.

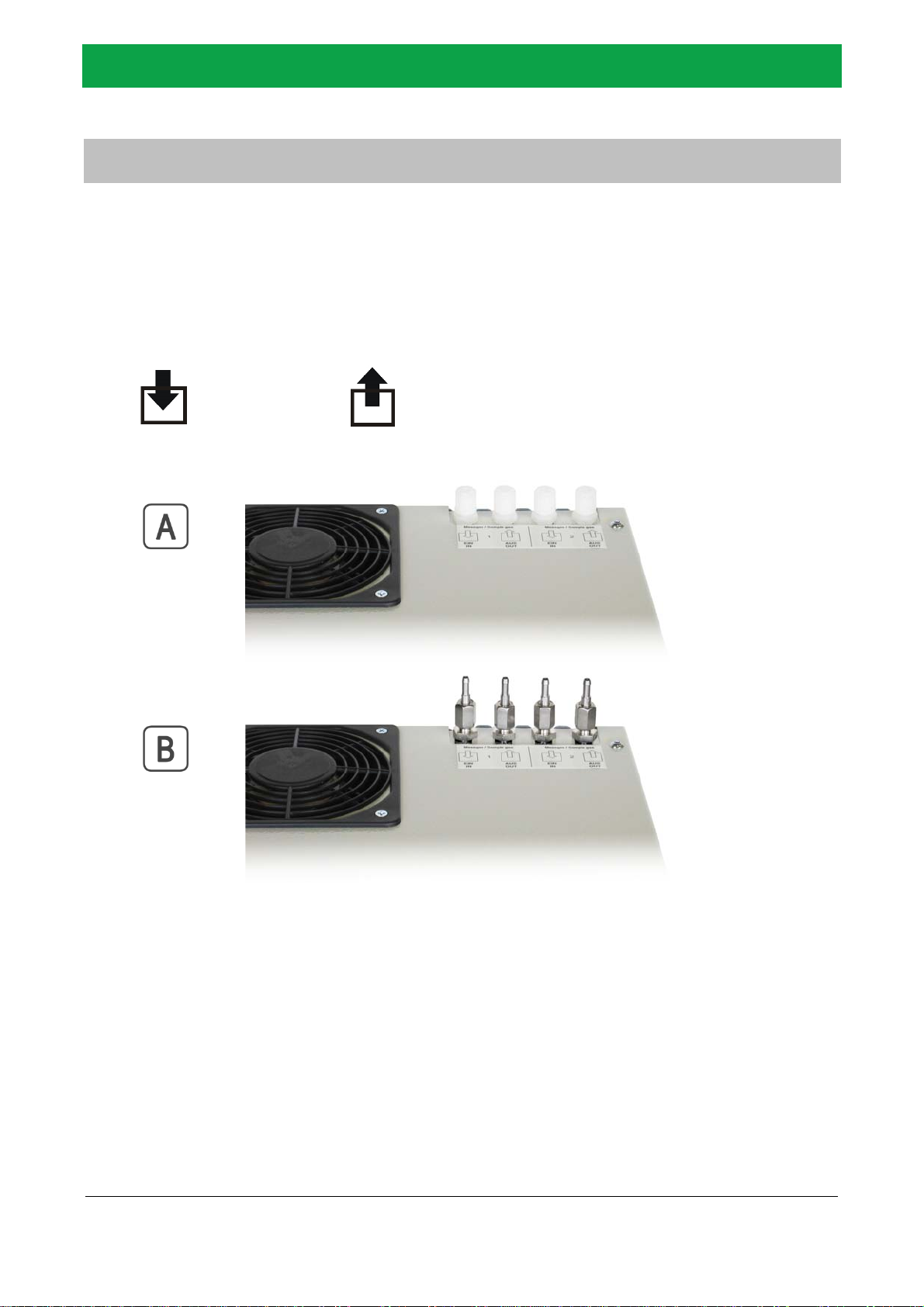

If your sample gas cooler is equipped with handles (mobile version), please use exclusively

these handles to lift or move the cooler. Otherwise the cooler is only to lift or move at its

bottom panel (1-2 persons needed).

WARNING! Possible damage! Handle with care. Heavy blows could cause irreparable

damage.

WARNING! Possible damage! Protect the display during installation of the cooler or during

mounting work. The display is very fragile.

If your sample gas cooler is equipped with condensate connectors at the bottom, always put the

housing on ca. 5cm high rails when mounting or moving the cooler. Otherwise protruding

condensate connectors at the bottom of the housing can be damaged.