1. INTRODUCTION

The new data logger ALMEMO®2290-8

Version 5

is an instrument from the

unique product range of measuring devices that are all equipped with the

ALMEMO®connector system, which has been patented by Ahlborn GmbH. The

intelligent ALMEMO®connector provides important advantages with regard to

the connection of sensors and peripherals as all parameters are stored in an

EEPROM within the connector. As a result, the programming that usually has

to be performed for the connection is not required.

All sensors and output modules can be connected to all ALMEMO®measuring

devices in the same way. The operation and programming is identical with all

units. Therefore, all of the ALMEMO®measuring system items listed below are

described, in detail, in a separate ALMEMO®manual that is supplied with every

device:

Detailed description of the ALMEMO®system (manual section 1)

Overview of the device functions and measuring ranges (manual section 2)

All sensors with basic principles, operation, technical data (man. section 3)

The options for connecting existing sensors (manual section 4)

All analogue and digital output modules (manual section 5.1)

The interface module RS232, fiber optics, Centronics (manual section 5.2)

The entire ALMEMO®networking system (manual section 5.3)

All functions and their control via the interface (manual section 6)

A complete interface command list with all print outputs (manual section 7)

These operating instructions only cover features and controls that are specific

for a certain device. As a result, the sections dealing with the system control

via keyboard will only often provide a note referring to a more detailed

description within the manual (manual section x.x.x).

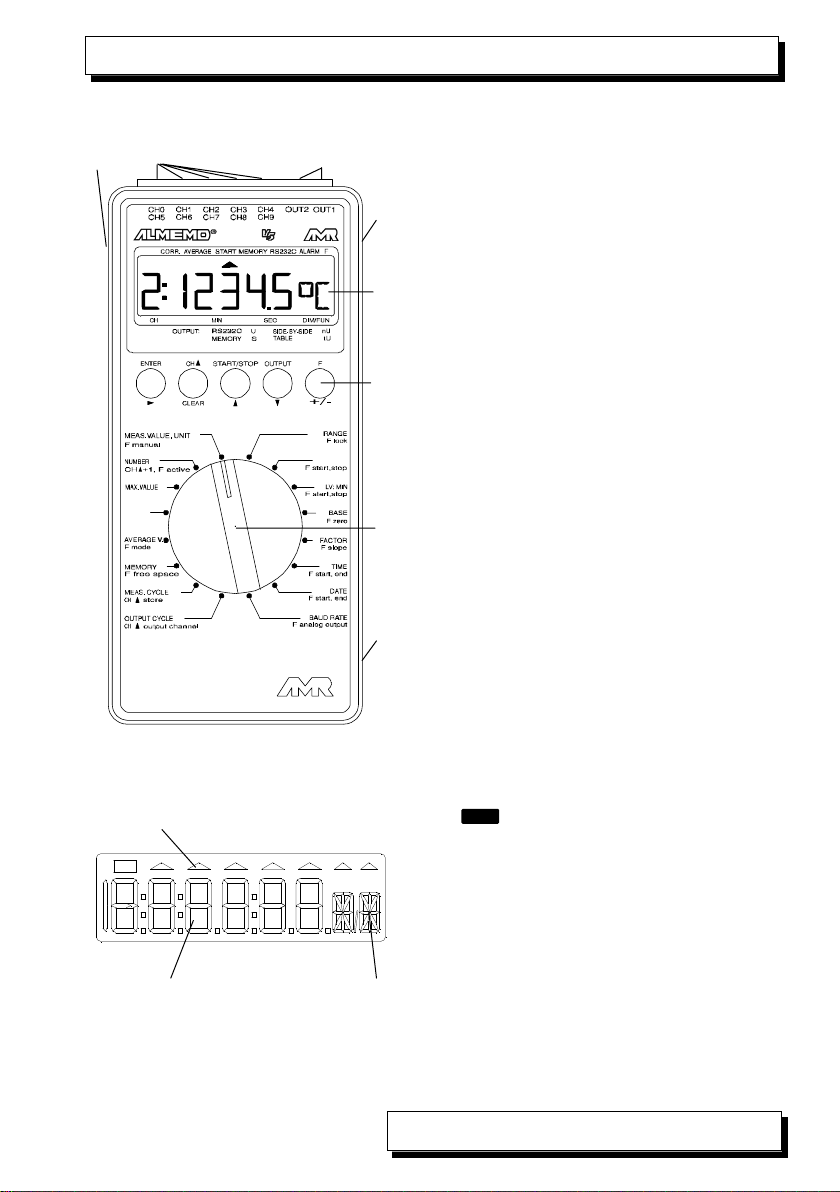

1.1 Function Range

The ALMEMO®2290-8 data logger has five electrically isolated measuring

inputs with up to 20 measuring channels for more than 70 measuring ranges, a

real time clock and a 500kB memory for approximately 100,000 measured

values. Two output sockets allow for connecting any ALMEMO®output

modules, for example, the analogue output, digital interface, trigger input or

alarm contacts. Several devices can be networked by a simple connection

between the devices. For easy operation it is equipped with a rotary switch,

keyboard and an 8½ digit LCD display.

SENSOR PROGRAMMING

The measuring channels are automatically programmed by the ALMEMO®

connectors of the sensors. However, the user can easily complete or modify

the programming via keyboard or via interface.

4 ALMEMO®2290-8

Introduction