8

3. GENERAL

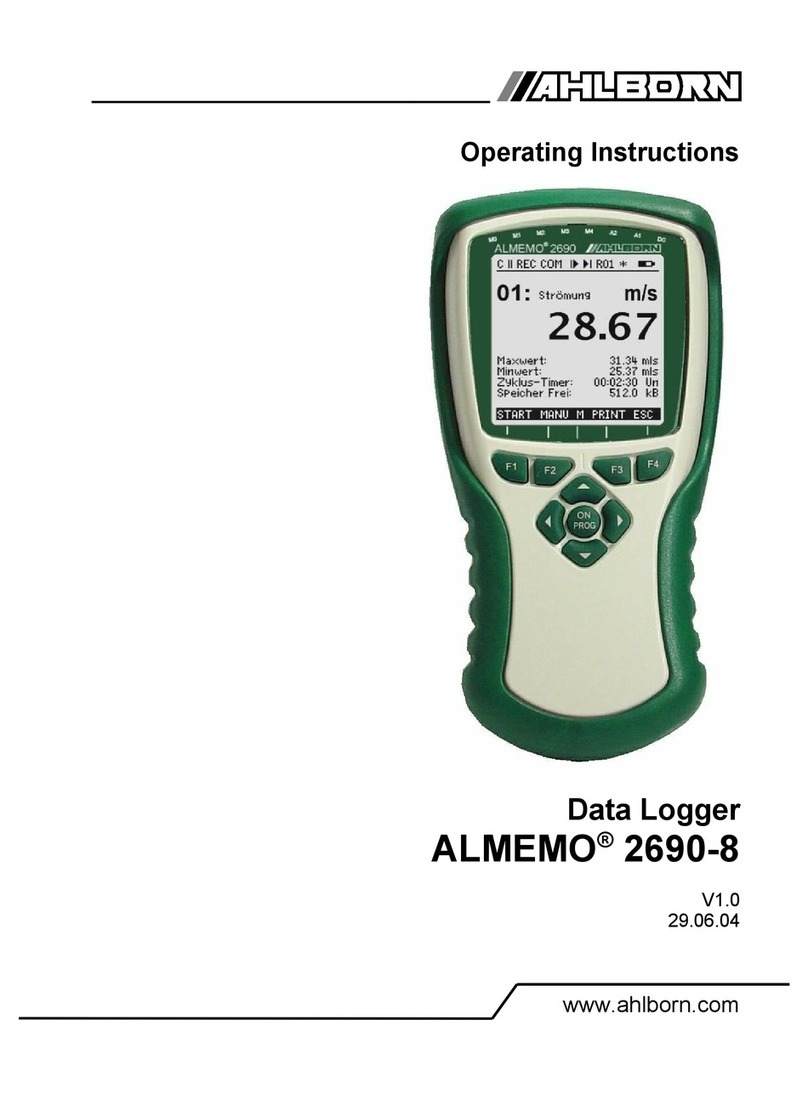

Congratulations for buying this innovative ALMEMO® data logger. By means of

the patented ALMEMO® connectors the device configures itself and with the help

of menus and help windows the operation should not be too difficult. However,

the device allows the connection of a great variety of sensors and peripherals

with many special functions. For getting to know the function range of the sen-

sors and the diverse possibilities of the device, you really should read these

operating instructions and the corresponding chapters of the ALMEMO® manual.

This is the only way to avoid operating and measuring errors as well as damages

of the device. For a quick answer to all questions, a detailed keyword index is

provided at the end of the instructions and of the manual.

3.1 Guaranteed

Every device has to pass through several quality tests before leaving the works.

For a perfect function, a guarantee of two years from the delivery date is

granted. Before sending back the device, please pay attention to the indications

in chapter 12. Troubleshooting. Should there actually be a defect, please use

the original packing material for depatch if possible and enclose an expressive

description of the trouble in connection with the corresponding circumstances.

In the following cases a guarantee benefit is excluded:

⚫After forbidden operations and changes in the device by the client

⚫Operating in surrounding conditions that are not valid for this product

⚫Using unsuitable power supply and peripherals

⚫Using the device in a way it is not determined for

⚫Damages through electrostatic discharge or flash of lightning

⚫Not paying attention to the operating instructions

Changes in the product features in favour of technical progress or due to new

components are reserved to the producer.

3.2 Extent of the Delivery

While unwrapping the delivery, pay attention to damages of the device and to

its completeness:

Measuring instrument ALMEMO® 2690-8A with 3 AA NiMH

(nickel-metal hydride) rechargeable batteries

Rubber shock absorber with a stand,

these operating instructions,

ALMEMO® Manual,

CD with Software ALMEMO® Control and useful accessories

In case of a transportation damage, the packing material is to be kept and the

supplier is to be informed immediately.