Limit Values and Alarm

Two limit values (1 max and 1 min) can be set for each meas. channel. An alarm

value printout can be performed if a limit value is exceeded and, by means of relay

output modules, alarm contacts are provided that can be individually allocated to limit

values. As a standard, the hysteresis is set to 10 digits; however, it can also be

adjusted between 0 and 99 digits. Furthermore, limit value exceeding can also be

used to start or stop a data logging.

Sensor Locking

All sensor data stored in the EEPROM of the connector can be protected against

undesired access by means of a graded locking function.

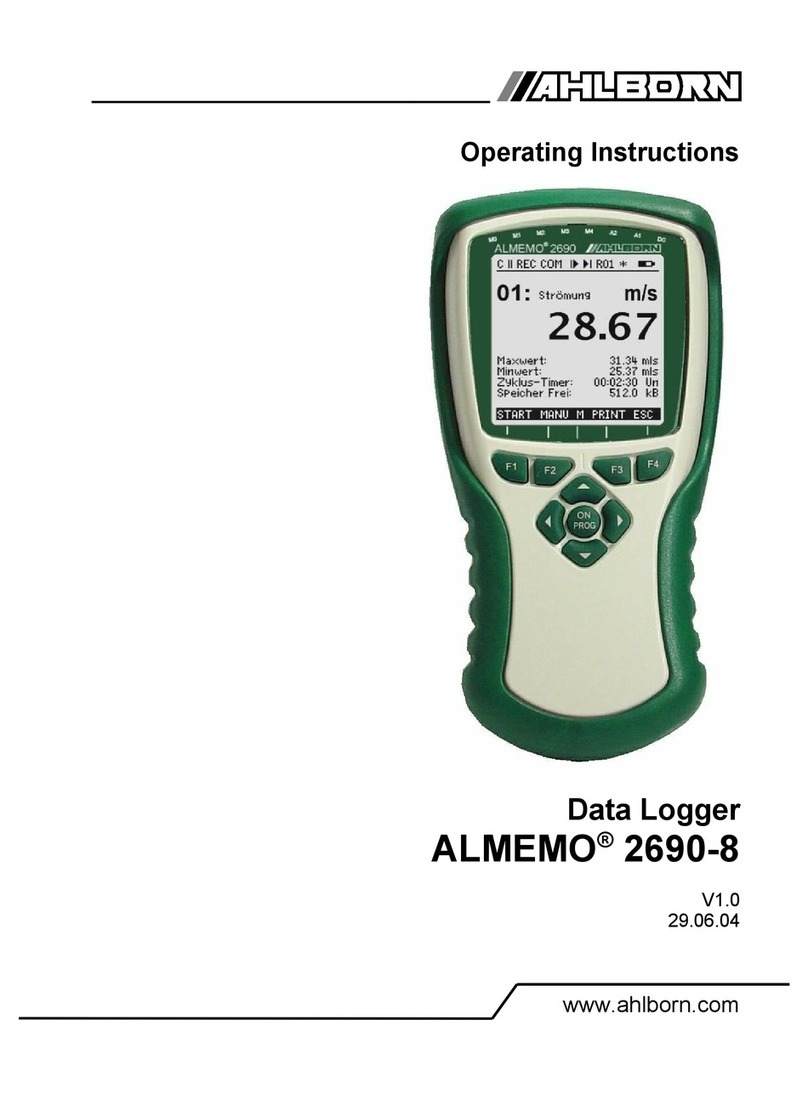

MEASUREMENT

A total of up to 36 meas. channels are available for 9 transducers, i.e. it is also

possible to evaluate double sensors, individually scaled sensors, or sensors with

function channels. The meas. channels can be successively selected forwards or

backwards via keypad or operating dial. As a standard, the meas. values of all active

meas. channels are continuously acquired at a rate of 10 meas.points/sec and

indicated on the display or, if available, provided on the analog output. In case of a

large number of meas. points the meas. point scan can be limited to one selectable

meas. point to increase the response speed.

Measured Values

The measured values of 1 to 20 measuring points can be indicated on the

display in 7 different menus (that can also be configured) in three font sizes, as

bar graph or as line chart. They are automatically acquired with auto zero and

self calibration and can also be arbitrarily corrected and scaled as required. A

sensor breakage condition is, with most sensors, automatically detected.

Analog Output and Scaling

By means of analog start and analog end any measuring point can be scaled so that

the resulting measuring range covers the full range of the bar graph or line chart or of

an analog output (2V, 10V or 20mA). The measured value of any measuring point as

well as a programmed value can be output to the analog output

Measuring Functions

Special measuring functions are required for some sensors to achieve an optimal

data acquisition. The cold junction compensation is available for thermocouples, a

temperature compensation for dynamic pressure and pH and conductivity probes,

and an atmospheric air pressure compensation for humidity sensors, dynamic

pressure sensors and O2 sensors. With infrared sensors the parameters zero point

and slope correction are used for background temperature and emissivity factor.

Max and Min Value

Each measurement involves an acquisition and storage of the Max value and the Min

value including the time and date. The values can be displayed, printed or cleared.

Average Value of a Channel

8 ALMEMO®2590-9

Function Range