Ahlborn ALMEMO 4490-2 User manual

Operating Instructions

Switchboard Instrument

ALMEMO®4490-2

V1.2

04.12.2003

ALMEMO4490-2 1

Operating Instructions

Switchboard Instrument

ALMEMO®4490-2

For Reference with the ALMEMO®Manual

Table of Contents

Page

1. INTRODUCTION 4

1.1 Function Range 4

1.2 Front Operating Controls 9

1.3 Rear Operating Controls 10

2. INITIAL OPERATION 11

3. POWER SUPPLY 11

3.1 Mains Operation 11

3.2 DC Voltage Supply 11

3.3 Data Storage, Reinitialisation 11

4. CONNECTION OF THE TRANSDUCERS 12

4.1 Transducers 12

4.2 Measuring Inputs and Additional Channels 13

5. DISPLAY AND KEYPAD 14

5.1 Display 14

5.2 Selection and Activation of Functions 15

5.3 Keypad 16

5.4 Data Input 16

2 ALMEMO4490-2

Table of Contents

6. SENSOR PROGRAMMING 17

6.1 Selecting the Measuring Channel 17

6.2 Selecting the Measuring Range 17

6.3 Changing the Dimension 20

6.4 Limit Values 21

6.5 Correction Values 22

6.6 Scaling, Decimal Point Setting 23

6.7 Locking of the Sensor Programming 24

7. MEASUREMENT 25

7.1 Continuous Measurement of a Measuring Point 25

7.1.1 Selecting the Measured Value and Measuring Point 25

7.1.2 Conversion Rate, Continuous Measuring Point Scan 26

7.1.3 Memory for Peak Values 26

7.1.4 Setting Measured Values to Zero, Zero Point Correction 27

7.1.5 Atmospheric Pressure Compensation 29

7.1.6 Temperature Compensation 29

7.2 Measuring Point Scans 30

8. ANALOGUE OUTPUT 30

8.1 Scaling 31

9. DIGITAL DATA OUTPUT 31

9.1 Baud Rate, Data Format 31

9.2 Device Address and Networking 32

9.3 Manual Data Output 33

10. TROUBLESHOOTING 34

11. ELECTROMAGNETIC COMPATIBILITY 35

APPENDIX 36

Technical Data 36

Product Overview 36

ALMEMO4490-2 3

Table of Contents

1. INTRODUCTION

The switchboard instruments ALMEMO®4490-2

Version 5

are instruments

from the unique product range of measuring devices that are all equipped with

the ALMEMO®connector system, which has been patented by Ahlborn GmbH.

The intelligent ALMEMO®connector provides important advantages with

regard to the connection of sensors and peripherals as all parameters are

stored in an EEPROM within the connector. As a result, the programming that

usually has to be performed for the connection is not required.

All sensors and output modules can be connected to all ALMEMO®instruments

in the same way. The operation and programming is identical with all units.

Therefore, all ALMEMO®measuring system items listed below are described,

in detail, in a separate ALMEMO®manual that is supplied with every device:

Detailed description of the ALMEMO®system (manual section 1)

Overview of the device functions and measuring ranges (manual section 2)

All sensors with basic principles, operation, technical data (man. section 3)

The options for connecting existing sensors (manual section 4)

All analogue and digital output modules (manual section 5.1)

The interface module RS232, fiber optics, Centronics (manual section 5.2)

The entire ALMEMO®networking system (manual section 5.3)

All functions and their control via the interface (manual section 6)

A complete interface command list with all print outputs (manual section 7)

These operating instructions only cover features and controls that are specific

for a certain device. As a result, the sections dealing with the system control

via keypad will only often provide a note referring to a more detailed description

within the manual (manual section x.x.x).

1.1 Function Range

The switchboard instrument ALMEMO®4490-2 has an ALMEMO®measuring

input with 4 channels or a measuring channel for a direct connection of

sensors. Two output sockets allow for connecting any ALMEMO®output

modules, for example, the analogue output, digital interface, trigger input or

alarm contacts. As an option, an electrically isolated analogue output and

relays can also be integrated into the instrument. Several devices can be

networked by simply connecting them with network cables.

For an easy operation a keypad and a 6-digit LED display are integrated. The

instruments have many functions for an optimal evaluation of all sensors. To

avoid a difficult operation resulting from functions that are not required, the

functions can be activated and deactivated automatically or by selecting the

display mode or individually via the interface. A range of special functions can

only be accessed via the interface.

4 ALMEMO4490-2

Functions

SENSOR PROGRAMMING

The measuring channels are automatically programmed by the ALMEMO®

connectors of the sensors. However, the user can easily complete or modify

the programming via keypad or interface.

Measuring Ranges

There are corresponding measuring ranges for sensors with a non-linear

characteristic such as 10 thermocouple types, Ntc and Pt100 sensors, infrared

sensors, and flow sensors (rotating vanes, thermoanemometers, pitot tubes).

Humidity sensors are available with additional function channels that also

calculate humidity data such as dew point, mixture ratio, vapour pressure and

enthalpy. Even complex chemical sensors can be used. The acquisition of

measured data from other sensors is easily possible by using voltage, current

and resistance ranges with individual scaling in the connector. Existing sensors

can be used without problems. Only the corresponding ALMEMO®connector

has to be connected using its terminals. Furthermore, there are adapter

connectors with an own microcontroller for digital signals and for measuring

frequencies and pulses. This way, nearly all sensors can be connected to any

ALMEMO®measuring instrument and are interchangeable without requiring

any settings.

Function Channels

Maximum, minimum, average values and differences of two measuring

channels can be programmed as function channels and can be processed and

printed like normal measuring points.

Dimension

The 2-digit dimension can be altered for each measuring channel so that the

display and the printout will always indicate the correct dimension, for example

when a transmitter is connected. The conversion from °C to °F is automatically

performed according to the dimension.

Name of Measured Values

Sensors can be identified by a 10-digit alphanumeric designation. It is entered

via the interface and appears on the printout or display if the evaluation is done

via PC.

Correction of Measured Values

For correcting measured values a zero point and slope (gain) correction can be

applied to the measured value of each measuring channel. This also allows for

sensors to be interchanged that usually, at first, require an adjustment

(expansion, force, pH). The zero point and the slope (gain) correction can be

performed by the push of a button.

ALMEMO4490-2 5

Functions

Scaling

The base value and the factor allow for a further scaling of the corrected

measured value of each measuring channel for zero point and slope (gain).

The decimal point position can be set by the exponent.

Limit Values and Alarm

Two limit values (optionally Max and/or Min) can be set for each measuring

channel. An alarm value printout can be performed if a limit value is exceeded

and, by means of the limit value relay option, alarm contacts are available that

can be individually allocated to limit values. As a standard, the hysteresis is set

to 10 digits, however, it can also be set between 0 and 99 digits. Furthermore,

limit value exceeding can also be used to start or stop a measuring point scan.

Sensor Locking

All sensor data stored in the EEPROM of the connector can be protected

against undesired access by means of a graded locking function.

MEASUREMENT

A total of up to 4 measuring channels are available for each transducer, i.e. it is

also possible to evaluate double sensors, individually scaled sensors, or

sensors with function channels. The measuring channels can be successively

selected forwards or backwards via keypad. The selected measuring point can

be scanned with a conversion rate of 2.5 or 10 measurements/second. The

measured value is calculated and indicated on the display or, if available,

provided on the analogue output. Standard sensors without an ALMEMO®

connector can be directly connected by means of a special multipoint

connector. The programming of the corresponding channel must be performed

each time the sensor is changed.

Measured Value

A continuous presentation of measuring data from the selected measuring

point is provided and also includes automatic zero point correction and optional

correction of the measured value or new scaling.

A sensor breakage condition is, with most sensors, automatically detected

(exception: connectors with shunts, dividers or additional electronics).

Measuring Functions

Special measuring functions are required for some sensors in order to achieve

an optimal acquisition of measuring data. The cold junction compensation is

available for thermocouples, a temperature compensation for dynamic

pressure and pH and conductivity probes, and an atmospheric air pressure

compensation for humidity sensors, dynamic pressure sensors and O2

sensors. With infrared sensors the parameters zero point and slope correction

are used for background temperature and emissivity factor.

6 ALMEMO4490-2

Functions

Analogue Output and Scaling

By means of analogue start and analogue end the indicated measured value

can be scaled so that the resulting measuring range covers the full analogue

output range (0-2V, 0-10V or 0/4-20mA).

Max and Min Value

Each measurement involves an acquisition and storing of the maximum and

minimum value. These values can be displayed, printed and cleared.

PROCESS FLOW PROGRAMMING

A cyclic measuring point scan with a time-based process flow control is

required to register measuring data of all measuring channels via the interface.

For this purpose, a clock, the print cycle and the measuring cycle are available

and, if fast processing is required, the conversion rate is available. The

measurement can be started and stopped by using the interface, an external

trigger signal or an exceeding of limit values.

Time and Date

Time and date or the pure measuring time is used for the recording of any

measurement.

Print Cycle

The print cycle is programmable between 1s and 59h/59min/59s. It allows a

cyclic output of measured values to the interfaces as well as a cyclic averaging.

Measuring Cycle

The measuring cycle, also programmable between 1s and 59h/59min/59s, is

for a cyclic scanning with limit value monitoring, alarm message and output of

alarm values and averaging.

Average Value over Measuring Point Scans

The measured values that result from measuring point scans can be averaged

as desired either over the total measuring time or over the print cycle. Function

channels are provided for a cyclic output of average values.

Conversion Rate

With ALMEMO®

V5

devices, all measuring points can be continuously

scanned with the conversion rate (2.5 or 10 meas./s). It is also possible to

provide all measured values as an output via the interface.

Control Outputs

The interface allows to individually trigger the 2 internal or up to 4 external

output relays and one analogue output.

ALMEMO4490-2 7

Functions

Output

All measuring and programming data is, firstly, accessible via keypad and LED

display. RS232, RS422 and a Centronics interface are available by using

different interface cables. All data logs, stored measured values and

programmed parameters can be provided as output to any peripheral

equipment. The output of measuring data can be selected in list format,

columns or spreadsheet format. Files in spreadsheet format can be processed

by each spreadsheet software. The print header can be programmed

specifically to the company or application.

Networking

All ALMEMO®devices can be addressed and can be easily networked by a

simple connection with network cables or network junctions for longer

distances.

Software

The AMR-Control software, which allows for the entire programming of the

sensors and the configuration of the measuring instrument, is supplied with

each ALMEMO®manual. The integrated terminal also allows for online

measurements. The WINDOWS®software packages, Win-Control and

DATA-Control, are available for data acquisition of networked devices,

graphical presentation and complex data processing.

8 ALMEMO4490-2

Functions

1.2 Front Operating Controls

(1) LED DISPLAY 4-digit 7-segment and minus f. meas. and progr. values

2-digit 14-segment for dimension or function

(2) MEAS. CHAN. M1, M2, M3 (M0 clamp. conn. or ALMEMO®without display)

(3) ALARM LAMPS A1 and A2 for limit value 1 and limit value 2

(4) FUNCTION KEYS

ENTER, ▲▼, entering programming values

▲

ENTER, CLR clear data, set measured value to zero

MEAS.VAL. ▲ selection of meas. value and meas. point

F1 selection of measuring functions

max value (Hi) MH

min value (Lo) ML

conversion rate CR

~for humidity, dyn. press. a. O2sensors atmospheric pressure mb ~

" for pH and dyn. pressure probes temperature compensation TC "

F2 selection of programming functions

range R

limit value 1 max/min (Hi/Lo) H1/L1

limit value 2 min/max (Lo/Hi) L2/H2

hysteresis HY

base value BA

factor FA

exponent EX

zero point correction ZC

slope (gain) correction SC

^ for IR sensors ambient temperature AT ^

emissivity factor EF ^

locking mode LM

* with interface module baud rate BR *

device address A*

analogue output - start AS

analogue output - end AE

analogue output type 0/4-20 mA

ALMEMO4490-2 9

Operating Controls

1.4 Rear Operating Controls

(5) Power Supply N-L 230 V AC, 50/60 Hz

Option U -+ 10..36 V DC

(6) Relay Contacts S1-C1-Ö1 lim. value 1 (make and break)

S2-C2-Ö2 lim. value 2 (make and break)

(7) Analogue Output Out -+ electrically isolated

Option R1 -1.25 V to 2 V (0.1mV/digit)

Option R2 -6.00 V to 10 V (0.5mV/digit)

Option R3 0/4 mA to 20mA (1µA/digit)

Meas. Inputs

(8) Clamp. Connector A-B-C-D meas. chan. M0, internal for exist. sensors

Sensor Volt. Supply -+ ca. 7V DC, 50 mA not electrically isolated

Option V1 12V DC, 30 mA electrically isolated

Option V2 12V AC, 50 mA electrically isolated

(9) ALMEMO®socket M meas. chan. M0 to M3 for all ALMEMO®sensors

Output Sockets

(10) ALMEMO®socket A2 network cable ZA1999-NK5

trigger input with cable ZA 1000-ET

relay outputs ZA 1000-EGK

analogue output 2 ZA 1601-RK

(11) ALMEMO®socket A1 V24 interface with cable ZA 1909-DK5

V24 interface with fiber optics ZA1909-DKL

RS 422 (ZA 5099-NVB / L)

analogue output 1 with cable ZA 1601-RK

AHLBORN

C1 C2S2S1 O1 O2

ABCD

OUT

20mA

-+-+

M1

AMR

NL

230V~

A1A2

5

6

78

91011

10 ALMEMO4490-2

Operating Controls

2. INITIAL OPERATION

1. For power supply, depending on the version (see type plate), connect

mains supply 230 V AC or 10-36 V DC to terminals (5), see 3.1 and 3.2.

2. Connect transducer with ALMEMO®connector to socket M1 or

connect a sensor with bare ends to the clamping connector (8),see 4.2.

Program the measuring range in function ´ R´ (F2), see 6.2.

3. Displaying the measured values

Select function MEAS. VALUE and meas. channel

with key MEAS.VAL.▲(4), read measured value, see 7.1.

4. Limit value monitoring

Enter limit values using key F2 in function ´H1´ or ´L2´, see 6.4.

Connect alarm device to clamping connector (6).

5. Display max and min values using key F1 in function ´MH´ or ´ML´, s. 7.1.3.

6. Data transfer to a computer

Connect peripheral device via interface cable to socket A1, see man. 5.2.

Set 9600 bd, 8 data bits, 1 stop bit, no parity, at peripheral device, see 9.1.

Enter commands by using the terminal of AMR-Control, see man. 6.

3. POWER SUPPLY

Before connecting any supply voltage refer to the type plate to

ensure the correct type of power supply!

3.1 Mains Operation

For mains operation the power supply 230V +-10% / 50-60Hz must be

established via the terminal screw connector at socket (5) on the rear side of

the unit.

Please note that connection to the 230V mains supply network

must only be performed by a qualified electrician.

3.2 DC Voltage Supply

The option U is required for a 10...36 V DC voltage supply with an electrical

isolation. The voltage must be connected via a terminal screw connector to

socket (5) on the rear side of the unit.

3.3 Data Storage, Reinitialisation

The measured data, time and date will be lost when the device is switched off.

However, all programmed values and the calibration in the EEPROMs will be

maintained.

ALMEMO4490-2 11

Initial Operation

If the device is not functioning properly due to disturbances (e.g. electrostatic

charging) or if incorrect programming must be avoided, the instrument can be

reinitialised.

The reset can be achieved if the key CLR is pressed during switch-on. During

this process the measuring data, time and date, as well as all internal data

such as cycles, conversion rate, atmospheric pressure and function key

assignment, will be cleared or set to their default values. However, the device

configuration and the sensor programming within the ALMEMO®connectors

will not be affected by the reset.

4. CONNECTION OF THE TRANSDUCERS

Any ALMEMO®sensors can be connected to the ALMEMO®input socket M (9).

Existing sensors with bare ends can be connected directly to the terminal block

(8) or to a corresponding ALMEMO®connector.

The connection of the sensors should be performed very thoroughly as it can

have large effects on the electromagnetic compatibility. Although the

measuring input is electrically isolated from the outputs, it is advisable to

isolate the transducer when installing because the protective earth connection

and the housing can often provide high voltage transients in industrial

environments. When performing the cabling it must be considered that the

leads are not wired near magnetic valves, contactors and motors and that they

are not guided together with leads for such devices. The leads should be as

short as possible and should have a cross section of 0.5 mm² at minimum (1.0

mm² at max.). Furthermore, electromagnetic influences can be reduced by

twisting the lines or by guiding cables in steel tubes. Electrostatic disturbances

can be avoided by using shielded cables. The metal braid shield is then

connected to the ´-´ terminal of the connector.

4.1 Transducers

A detailed description of the comprehensive ALMEMO®sensor range (see

manual section 3) and the connection of existing sensors (see manual section

4) to the ALMEMO®instruments are provided in the ALMEMO®manual. All

standard sensors with ALMEMO®connector usually have the measuring range

and dimension already programmed and can be immediately connected to any

input socket. A mechanical coding ensures that sensor and output modules

can only be connected to the correct sockets. Furthermore, each ALMEMO®

connector has two locking levers that snap in when the insertion into the socket

is established and that prevent a disconnection caused by pulling the cable.

Both levers must be pressed on the sides for disconnecting the connector.

12 ALMEMO4490-2

Connection of the Transducers

4.2 Measuring Inputs and Additional Channels

Either the ALMEMO®socket M (9) or the clamping connector (8) can be used

as measuring input for the ALMEMO®4490-2. When using the clamping

connector only one measuring channel is available and must be programmed

via the instrument. When an ALMEMO®sensor is connected to socket M the

programming can cover up to four measuring channels (M0 to M3) and will be

automatically loaded from the connector. The additional channels can be

especially used for humidity sensors with 4 measuring variables

(temperature/humidity/dew point/mixture ratio) or for function channels. A

sensor can, if required, also be programmed with several ranges or scalings

or, depending on the pin assignment, 2 or 3 sensors can be combined in one

connector (e.g. rH/Ntc, mV/V, mA/V etc.).

The measuring input, outputs and power supply are electrically

isolated from each other and a potential difference of 50V at

maximum is permissible between them. However, sensors

combined within one connector and sensors with an own

power supply are electrically connected to each other and

must, therefore, be operated in isolation. The voltage applied

to the measuring inputs must not exceed ±5V (between B,C,D

and A or - respectively).

As only one input but two options for a connection are

available, an ALMEMO®connector and a sensor with a

clamping connector must not be plugged in at the same time!

The cold junction compensation for thermocouple measurement is integrated

in socket M of the device. Therefore, thermocouples should always be

connected with an ALMEMO®connector.

0

1

2

3

chann.1

chann.2

chann.3

chann.4

MA2 A1

4490-2

ALMEMO4490-2 13

Connection of the Transducers

5. DISPLAY AND KEYPAD

5.1 Display

The display (1) of the instrument ALMEMO®4490-2 consists of a 6-digit LED

display plus a minus sign. The first four digits indicate the measuring or

programming value including the sign. The following two alphanumeric digits

indicate the dimension in case of a measured value, or the selected function

(see 6.1). In case of values exceeding 9999 an automatic decimal point switch

is performed, so the last digit will disappear.

Special Operating Conditions

Segment test of the display automatically after switching on.

Sensors that are not connected,

de-activated measuring points,

cleared programming values.

Alarm Conditions

are displayed as follows and cause an alarm (see man. 6.3.9):

Sensor breakage:

NiCr° C

abbrev. flashes

Exceeding of limit value: A1 or A2 is illuminated

Overshooting of measuring range: A1 illuminated, max value flashes

Undershooting of measuring range: A2 illuminated, min value flashes

Undershoot. of meas. range CJ compens. (cold junction)

Meas. without ext. CJC or CJC breakage: flashes

Exceeding of range of values (>65000): flashes

6500!° C

----

C J!° C

14 ALMEMO4490-2

Display and Keypad

5.2 Selection and Activation of Functions

The keys MEAS.VAL.▲, F1 and F2 can be used to successively select the

measured values of all channels as well as the following measuring and

programming functions. For switching back to the previous channel or function

the key must be pressed and held (approx. 1s). The measured value will be

automatically indicated again when the keypad has not been used for approx. 1

minute. The functions can be identified by a 2-digit abbreviation, which is

displayed instead of the dimension. Some functions will only be activated when

they are required by ALMEMO®sensors or modules.

MEAS.V.▲F1 F2

Meas.Val, Dim Meas. Functions Ab DM Programming Values Abbr. DM

Display Mode DM 0

Meas. Ch. M0 Max Value (Hi) MH 0Range R 0

Meas. Ch. M1 Min Value (Lo) ML 0 Limit Value 1 Max/Min H1/L1 1

Meas. Ch. M2 Conversion Rate CR 7 Limit Value 2 Min/Max L2/H2 1

Meas. Ch. M3 ~Atmosph. Pressure mb 0Hysteresis HY 2

° Temp. Compens. TC 0 Base Value BA 3

Factor FA 3

Exponent EX 3

Zero Point Correction ZC 4

Slope (Gain) Correction SC 4

^ Ambient Temperature AT 4

^ Emissivity Factor EF 4

Locking Mode LM 5

* Baud Rate BR 6

* Device Address A 6

Analogue Output Start AS 8

Analogue Output End AE 8

0-20/4-20 mA 9

Automatic activation of the functions by:

*interface modules ^ infrared sensors

° dyn. pressure and pH probes ~humidity, dyn. press and O2sensors

Limitation of Function Range in Display Mode

The last digit in the display mode allows to limit the number of selectable

functions, up to a certain level. The disabled functions can then not be selected

any more and, therefore, are protected against accidental changes. The

display mode ´DM´ can be accessed by selecting the function ´ R´ and by

pressing and holding the key F2 once. Entering the digit 1 (see 5.4) limits the

functions to range, lim.val.1 and lim.val.2. The locking mode ´LM´ (see 6.7) can

be used to lock the sensor parameters.

By setting up the key functions via interface (AMR-Control) the devices can be

individually configured for any application (man. 6.10.13.3). The original setting

can always be re-established by pressing the key CLR during switching on.

ALMEMO4490-2 15

Display and Keypad

5.3 Keypad

The keypad (4) has the following functions that are displayed below the keys:

Function Normal Input

Data Entry ENTER

▲

Selection Meas. Value, Measuring Point MEAS.VAL.▲CLR

Selection of Measuring Functions F1 ▲

Selection of Programming Functions F2 ▼

The key ENTER is used for programming the parameters. After operating this

key a digit or an abbreviation will flash in the display, i.e. the instrument is in

edit mode and the red designations on the keys are valid (s. 5.4). Then, the

keys ▲, ▼are available for changing the input digit, the key operates as

▲

cursor key and CLR is available for clearing the parameters The data input is

finished when the last digit has been confirmed by operating the key .

▲

5.4 Data Input

The programming of numeric parameters is performed as follows:

Selection of the function by using the keys F1 or F2... or

F1 F2

The programming is started by pressing the key ENTER.

The first programmable digit flashes and can be altered.

If 5-digit values are entered the upper 4 digits will be indicated

at first and then, after switching, the lower 4 digits.

The digit can be increased using the key ▲.

After exceeding the maximum value the cycle restarts from zero.

The digit can be decreased using the key ▼.

At the 1st digit, negative values follow after falling below zero.

Aswitch to the next digit is performed using the key .

▲

▲

Switch back to previous digit by pressing and holding the key .

▲

▲

1s

The programming process is complete

after setting the last digit and again operating the key .

▲

Programming and meas. values can be cleared by using ,

ENTER

CLR

ENTER

▲

▼

▲

16 ALMEMO4490-2

Display and Keypad

6. SENSOR PROGRAMMING

As all ALMEMO®instruments contain the whole sensor programming stored in

the ALMEMO®connector plug, the user does not usually need to perform any

programming. Only if, for example, sensor errors must be corrected or existing

sensors must be scaled or limit values need to be specified, the

comprehensive programming options have to be used. It must be considered

that standard sensors are, by a locking mode, protected against unintentional

modification and that the locking level must first be reduced before desired

changes can be performed (see 6.7). All parameters can easily be entered or

changed via keypad if the corresponding sensor connector is connected.

6.1 Selecting the Measuring Channel

If no ALMEMO®connector has been connected, measuring channel M0 will

only be available. When an ALMEMO®connector is used the function

MEAS.VAL. allows, depending on the programming, to select up to four channels

by using the key MEAS.VAL.▲. For switching back to the previous channel the

key must be pressed and held for approx. 1 sec. If the channels are locked,

only the activated channels will be considered. Therefore, the selection of a, so

far, not programmed channel is only possible if the locking of the 1st channel is

cleared.

The channel number will be indicated by illuminated symbols M1, M2 and M3

(2). There is no symbol for the 1st channel.

Increase measuring channel by using: (programmed chann. only)

MEAS.VAL.

Decrease measuring channel with key: press and hold (ca. 1s)

1s

MEAS.VAL.

6.2 Selecting the Measuring Range

If sensors are connected using the terminal block or if the user wants to

program the ALMEMO®connectors on his own, it must be considered that the

locking of the connectors is cleared (see 6.7) and that a special connector is

required for some transducers (e.g. thermo, shunt, divider etc., see table).

After selecting the corresponding channel (see 6.1), the function RANGE ´ R´

must be selected by using the key F2. For activating a channel that has not yet

been programmed the locking of the first channel of the corresponding

connector must be cleared. After operating the key ENTER the abbreviation of

the measuring range will flash in the display:

ALMEMO4490-2 17

Sensor Programming

The keys ▲and ▼can be used to select all possible ranges in the sequence

given below. When the desired range is indicated in the display it can, by

pressing the key again, be transferred including the correct dimension to the

▲

connector and the programming can be finished. All other programming values

of the channel will be cleared by this.

Function RANGE ´R´

Selection with key F2... ...

F2

NiCrR

Example :

range NiCr-Ni

Change meas. range: , ... or ... ,

ENTER

▲▼

▲

Transducer Conn. / Cable /

Sensor

Meas. Range Dim Display

Pt100-1 ZA 9000-FS -200.0... +850.0 °C P104

Pt100-2 ZA 9000-FS -200.00...+200.00 °C P204

Ni100 ZA 9000-FS -60.0... +240.0 °C N104

NiCr-Ni (K) ZA 9020-FS -200.0...+1370.0 °C NiCr

NiCroSil-NiSil (N) ZA 9020-FS -200.0...+1300.0 °C NiSi

Fe-CuNi (L) ZA 9000-FS -200.0... +900.0 °C FECO

Fe-CuNi (J) ZA 9000-FS -200.0...+1000.0 °C IrCo

Cu-CuNi (U) ZA 9000-FS -200.0... +600.0 °C CUCO

Cu-CuNi (T) ZA 9000-FS -200.0... +400.0 °C CoCo

PtRh10-Pt (S) ZA 9000-FS 0.0...+1760.0 °C Pt10

PtRh13-Pt (R) ZA 9000-FS 0.0...+1760.0 °C Pt13

PtRh30-PtRh6 (B) ZA 9000-FS +400.0...+1800.0 °C EL18

Au-FeCr ZA 9000-FS -270.0... +60.0 °C AUFE

Ntc type N ZA 9000-FS -30.00...+125.00 °C Ntc

Millivolt 1 ZA 9000-FS -26.000...+26.000 mV U 26

Millivolt ZA 9000-FS -10.000...+55.000 mV U 55

Millivolt 2 ZA 9000-FS -260.00...+260.00 mV U260

Volt ZA 9000-FS -2.6000...+2.6000 V U2.60

Differential Millivolt 1 ZA 9050-FS -26.000...+26.000 mV d 26

Differential Millivolt ZA 9050-FS -10.000...+55.000 mV d 55

Differential Millivolt 2 ZA 9050-FS -260.00...+260.00 mV d260

Differential Volt ZA 9050-FS -2.6000...+2.6000 V d2.60

Sensor voltage ZA 9000-FS 0.00...20.00 V UbAt

Milliampere ZA 9601-FS -32.000...+32.000 mA I032

Percent (4-20mA) ZA 9000-FS 0.00... 100.00 % P420

Ohm ZA 9000-FS 0.00... 400.00 ΩOhn

Frequency ZA 9909-AK 0... 25000 Hz FrEq

Pulses ZA 9909-AK 0... 65000 PULS

18 ALMEMO4490-2

Sensor Programming

Transducer Conn. / Cable Meas. Range Dim Display

Digital input ZA 9000-EK2 0.0... 100.0 % Inp

Digital interface ZA 9919-AKxx -65000... +65000 diGi

Infrared 1 ZA 9000-FS 0.0... +200.0 °C Ir 1

Infrared 2 ZA 9000-FS 0.0... +800.0 °C Ir 2

Infrared 3 ZA 9000-FS -30.0... +70.0 °C Ir 3

Infrared 4 ZA 9000-FS -30.0... +100.0 °C Ir 4

Infrared 6 ZA 9000-FS 0.0... +500.0 °C Ir 6

Snap-on head Normal 20 FV A915-S120 0.30... 20.00 m/s S120

Snap-on head Normal 40 FV A915-S140 0.40... 40.00 m/s S140

Snap-on head Micro 20 FV A915-S220 0.50... 20.00 m/s S220

Snap-on head Micro 40 FV A915-S240 0.60... 40.00 m/s S240

Macro FV A915-MA1 0.10... 20.00 m/s L420

Water-Micro FV A915-WM1 0.00... 5.00 m/s L605

Dyn.press. 40m/s w. TC a. PC FD A612-M1 0.50... 40.00 m/s L840

Dyn.press. 90m/s w. TC a. PC FD A612-M6 1.00... 90.00 m/s L890

Rel. humidity cap. FH A646 0.0... 100.0 %H °orH

Rel. humidity cap. w. TC FH A646-R 0.0... 100.0 %H H rH

Mixture ratio w. PC FH A646 0.0 ... 500.0 g/kg H AH

Dew point temperature FH A646 -25.0... 100.0 °C H dt

Partial vapour pressure FH A646 0.0 ...1050.0 mbar H UP

Enthalpy w. PC FH A646 0.0 ... 400.0 kJ/kg H En

Humid temperature ZA 9000-FS -30.00 ... +125.00 °C P Ht

Rel. humidity psychr. w. PC ZA 9000-FS 0.0 ... 100.0 %H P RH

Mixture ratio w. PC ZA 9000-FS 0.0 ... 500.0 g/kg P AH

Dew point temperature w. PC ZA 9000-FS -25.0 ... +100.0 °C P dt

Partial vapour pressure w. PC ZA 9000-FS 0.0 ...1050.0 mbar P UP

Enthalpy w. PC ZA 9000-FS 0.0 ... 400.0 kJ/kg P En

Conductivity probe w. TC FY A641-LF 0.0 ... 20.000 mS LF

CO2sensor FY A600-CO2 0.0 ... 2.500 % CO2

O2saturation w. TC and PC FY A640-O2 0 ... 260 % O2-S

O2concentration with TC FY A640-O2 0 ... 40.0 mg/l O2-C

Function Channels:

Difference any diFF

Maximum value any Hi

Minimum value any Lo

Average value over time any A[t]

Average value over junctions any A[n]

Sum over junctions any S[n]

Total number of pulses ZA 9909-AK2 0... 65000 S[t]

Pulses/print cycle ZA 9909-AK2 0... 65000 S[P]

Alarm value any Alrm

TC=Temperature Compensation, PC=Atmospheric Pressure Compensation

ALMEMO4490-2 19

Sensor Programming

The use of the function channels for the output of measuring and calculated

variables with the corresponding reference channels is described in the manual

section 6.3.4.

Switch-off, i.e. deactivation of a programmed measuring channel

Function: RANGE ´R´ Keys: ,

ENTER

CLR

After switch-off the measured value is no longer indicated, queried or provided

as output. However, the programming is still maintained.

Re-activation of the measuring channel:

Function: RANGE ´R´Keys: ,

ENTER

▲

If the channel was previously deactivated, it will be re-activated with all

programmed values. However, if the channel is already active then all

programming values will be cleared by operating the above key combination

(corresponds to selecting a measuring range).

6.3 Changing the Dimension

Each measuring channel allows replacing the standard dimension of the

measuring range by any other dimension that has two digits (see manual

6.3.5). In addition to all capital and normal letters, the characters , Ω, %, [,

,

], *, -, =, ~ and spaces (_) are available. The dimension is indicated by two

14-segment characters that are indicated following the measuring and

programming values.

The change of the dimension can be performed within the function MEAS.

VALUE by pressing the key ENTER. The first character of the dimension will

flash in the display. It can then be changed by using the keys ▲and ▼. When

the first character is set the key can be operated again and the same

▲

procedure can be performed for the second character. When the desired

dimension has been set the programming can be completed using the key .

▲

Function: MEAS.VAL. , ... , , ... ,

ENTER

▲

▲

▲

▲

1st dim change 2nd dim change end

When the dimension °F is entered a temperature value in degrees

Celsius will be converted into degrees Fahrenheit.

The cold junction compensation can be switched off by using the

characters Cor F.

20 ALMEMO4490-2

Sensor Programming

Table of contents

Popular Switch manuals by other brands

Coherent Solutions

Coherent Solutions SwitchPXIe 1000 Series user manual

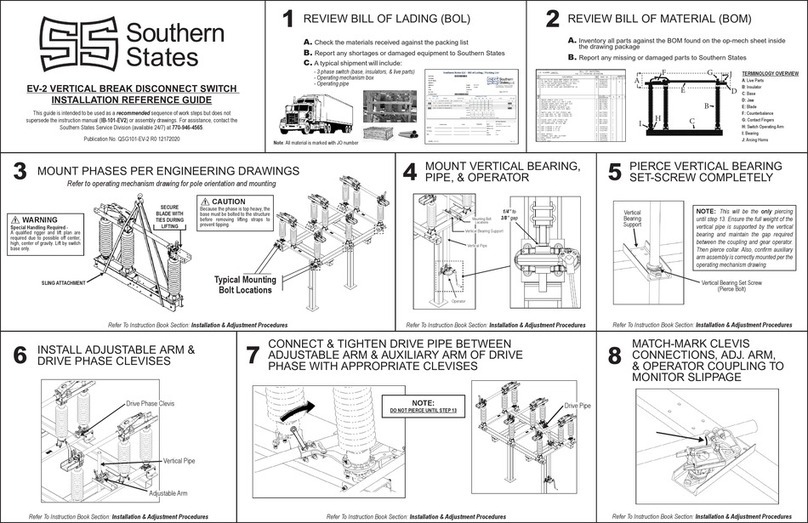

Southern States

Southern States EV-2 Installation reference guide

Splash

Splash Bootloader Domestic Installation

Hama

Hama USB 2.0 / Fire Wire Combo Operating instruction

Magnetrol

Magnetrol ECHOTEL 940 Installation and operating manual

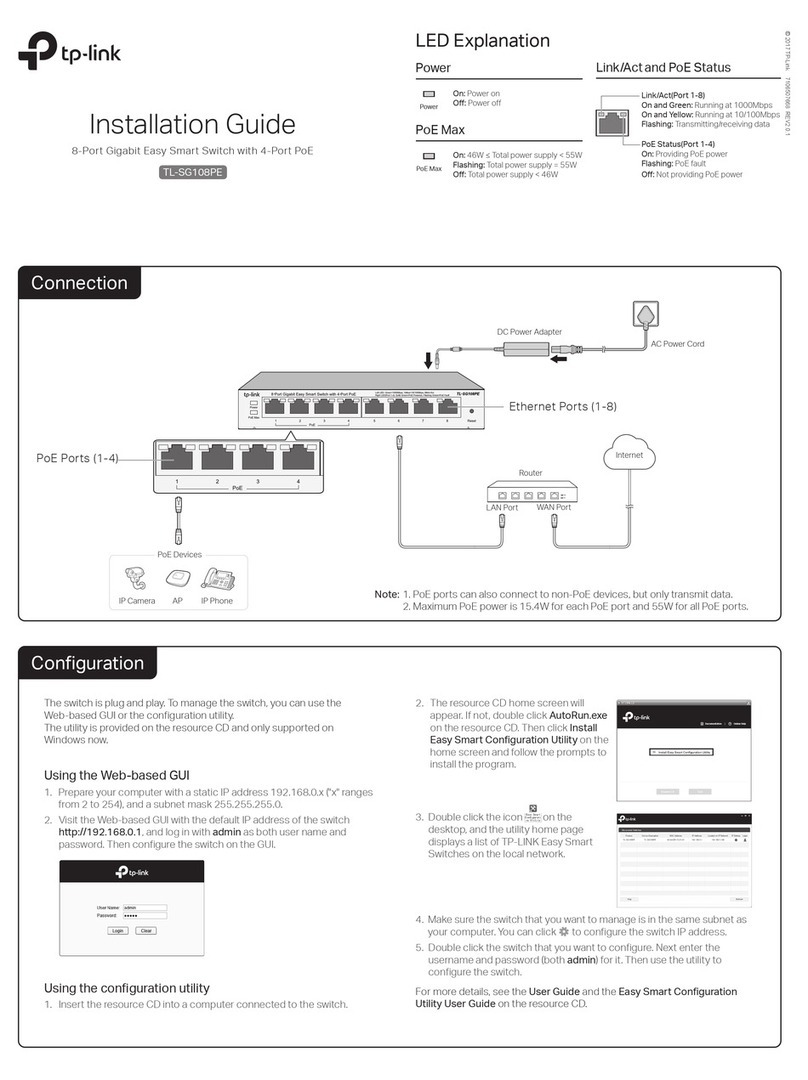

TP-Link

TP-Link TL-SG108PE installation guide