2.2.2 Disadvantages of Catalytic Bead technology

The Catalytic sensor can be “poisoned”: Certain chemicals will damage the internal

elements and cause the sensor to lose sensitivity. Common poisons are chemicals

which contain silicon (found in hand lotions and industrial lubricants) and Sulfur

compounds, which can be released with gases. Chlorine (found in many cleaning

products) and heavy metals can also poison a catalytic sensor. This list is by no means

comprehensive.

The Catalytic Bead sensors require oxygen to detect gases: Because a Catalytic Bead

sensor burns the sample of gas, oxygen is required for the monitor to detect the

presence of combustible gases.

The Catalytic Bead sensor can burn out:Exposure to high concentrations of gas can

completely disable the sensor. See section 2.1 Over Range Alert Function

The Catalytic Bead sensor is more prone to sensor drift: These sensors typically

require more frequent calibration. See section 8. Calibration

The Catalytic sensor requires more power: Due to the sensor design, the Catalytic

Bead sensor requires more power to operate, thus shortening the runtime of the

monitor.

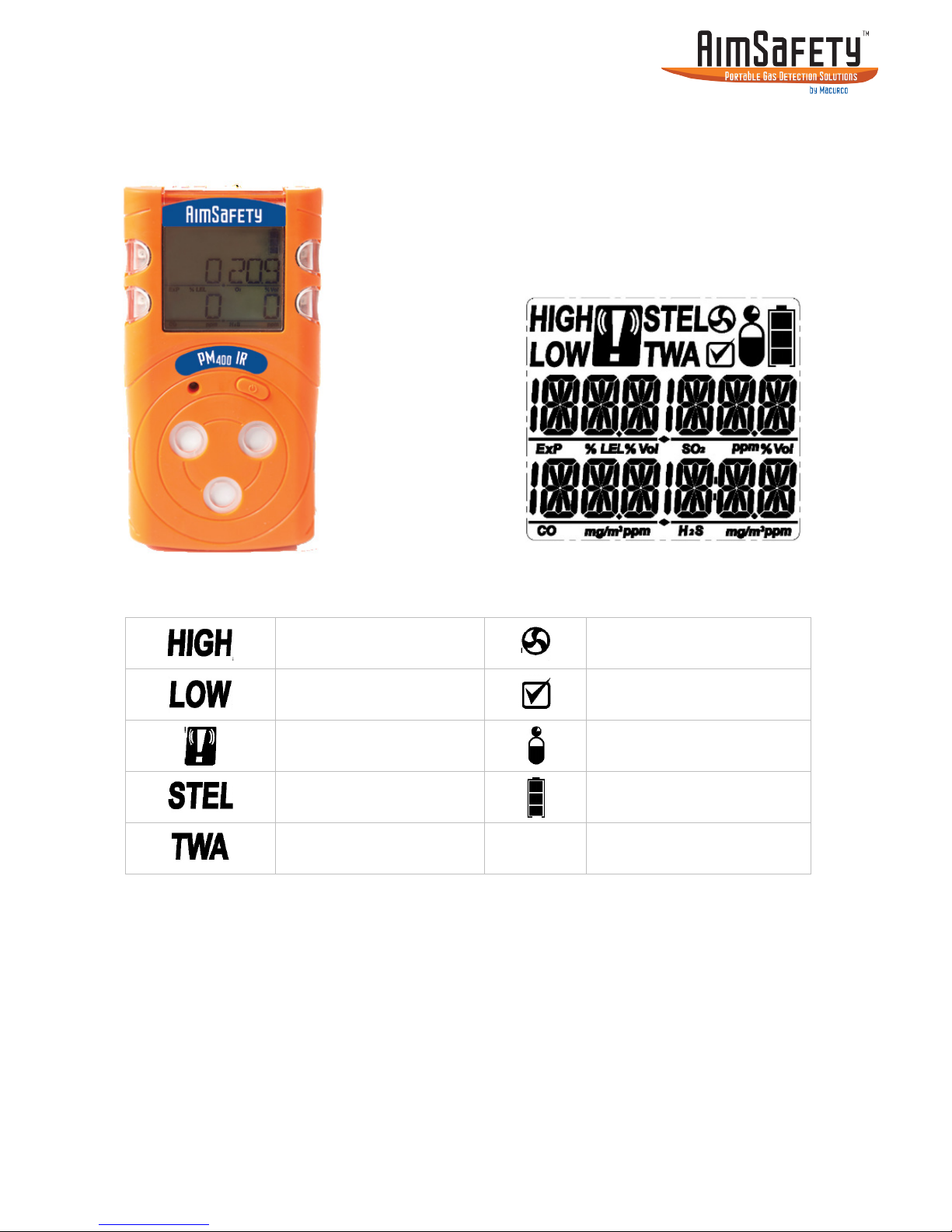

2.3 Non-Dispersive Infra-Red (NDIR) technology (PM400 IR)

Overview

2.3.1 Disadvantages of NDIR technology

Doesn’t detect certain combustible (LEL) gasses: Gases such as hydrogen and

acetylene go undetected by NDIR sensors.

Be sure the safety of your users isn’t dependent on detecting hydrogen

and/or acetylene. The PM400 IR does NOT detect these gases.

2.3.2 Advantages of NDIR technology

The NDIR sensor does not require oxygen to detect gases: Because the NDIR sensor

uses absorbed light spectrum technology to detect combustible gases, the sensor does

not require oxygen to operate, making it ideal for inert and oxygen deficiency

applications.

The NDIR is more durable:Cannot be inhibited, poisoned by external chemicals and

gases.

The NDIR sensor is more stable: Requires minimal recalibration and is typically stable

even after extended storage.

The NDIR sensor has a longer lifespan: The sensor has a life expectancy of up to 10

years.

The NDIR sensor requires less power: Due to the sensor design the NDIR sensor

requires less power to operate, thus allowing for extended runtimes compared to the

Catalytic Bead sensor.