2.6 XCellSensorsOptimizedforFixedGasApplications

XCelltoxicandcombustiblecatbeadsensorsaredevelopedandmanufacturedbyMSA.Nowoptimizedforfixedgas

applications,theXCellsensorplatformisavailableintheULTIMAX5000andprovidesmultiplebenefits,includinga

standard3-yearwarrantyonallXCellsensors.

OneimportantoptimizationforfixedgaswasincorporatingtheGMcatalyticbeadintotheXCellsensor.

TheXCellOxygensensordoesnotuselead,butratheranon-consumingreactionchemistry.TheXCellOxygensensoris

expectedtolastwellover3-yearsandcanbesafelystoredontheshelfforatleast1yearwithoutsensorperformance

degradation.Changesinbarometricpressureacrosstherangeof86kPa-108kPahaveanegligbleeffectontheoperation

ofthesensor.

2.7 TruCalSensingTechnologyforCOandH2SElectrochemicalSensors

UsingpatentedpulsechecktechnologyandproprietaryAdaptiveEnvironmentalCompensation(AEC)algorithms,allXCell

sensorswithTruCalverifyoperationbyactivelyadjustingthesensoroutputforchangesinsensitivity.SomeXCellsensors

withTruCalalsoincludeDiffusionSupervision,whichmonitorsthesensorinletforobstructionsthatcouldpreventgasfrom

reachingthesensor.

Everysixhours,anelectricalpulsestimulatestheXCellsensorsimilartohavingactualcalibrationgasapplied,providinga

snapshotofthesensor’ssensitivityatthetimeofthepulse.Usingthissensitivitysnapshot,thesensorcandiagnosesensor

failureslikeelectrodepoisoning,electrolyteleaking,orelectricalconnectivityissues.

AECusesthesensitivitysnapshotsprovidedbythepulsechecktoadjustsensoroutput,compensatingforenvironmental

impactsonsensoraccuracy.IftheAECadjustmentisgreaterthanexpectedbasedontypicalenvironmentalimpact

variations,thetransmitterLED’swillslowlyflashGREEN,alertingusersthatthesensorshouldbecalibratedtoresetthe

AECcycle.UserscanalsoenableaCalibrationAlertfunctionthatwillsendamilli-ampsignalontheanalogoutputtothe

controlroom.Theresultisasensorthatactivelyself-monitorsforoperationandaccuracy,withfarfewermanual

calibrations.

Diffusionsupervisionactivelymonitorsthesensorinletforobstructions.Ifanobstructionisdetected,thesensorwillgointoa

faultmodetoalertusersandthecontrolroomthatitisnotseeinggasduetoanobstruction.Objectsresidingdirectlyonorin

thesensorinletthatresultinasignificantimpacttothegaspathareverylikelytobedetectedbyDiffusionSupervision.

Examplesincludepaint,tape,water,anddirt.Smallamountsofthesematerialscanbevisibleontheinletwhilenot

impactingthegaspathenoughtotriggeraDiffusionSupervisionFault.Afaultsignalwillonlybesentoutwhenthesystem

determinesthattheamountofmaterialthathasaccumulatedonorinsidethesensorinletisnegativelyaffectingthegas

path.

ActualTruCalsensorperformancewilldependontheapplication,backgroundgasexposure,andenvironment.Tovalidate

XCellsensorswithTruCal,itisrecommendedthatusersfollowtheirregularcalibrationcycleandrecordthe“asfound”and

“asleft”values.Thisdatacanbeusedtoextendthetimebetweencalibrationsdependingontherequiredspecificationof

theapplication.

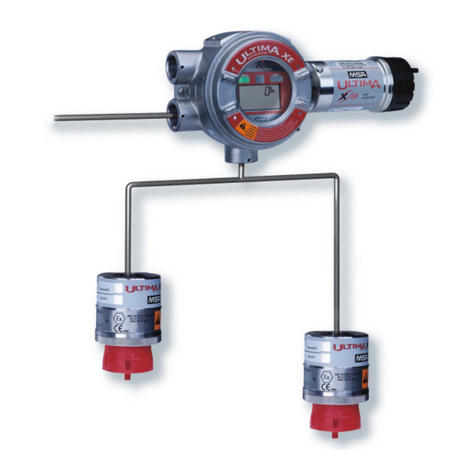

2.8 SafeSwap

TheULTIMAX5000comeswithpatentedSafeSwaptechnology,whichallowsuserstochangeorreplaceXCellsensors

withoutneedingtopowerdowntheinstrument.Foraddedconvenience,theULTIMAX5000comeswithSwapDelay

enabledbydefault;afeaturethatgivesusersa2minutewindowtochangesensorswithouttriggeringafaultcondition.For

moreinformationonSafeSwapandSwapDelay,see4.2.1InstrumentSettings.

WARNING!

• Aspartoftheproductcertification,itwasverifiedthatoptionalcommunicationfunctionsofthisgasdetection

instrumentwhileoperatingatthemaximumtransactionratedonotadverselyaffectthegasdetectionoperationand

9 Ultima X5000 Gas Monitor US

2 Description