Table of Contents

1.General Information ..................................................................................................................................

2.Safety Warnings .........................................................................................................................................

3.Symbols........................................................................................................................................................

4.Important Information ..............................................................................................................................

5.Limitation of liability .................................................................................................................................

5.Warranty .....................................................................................................................................................

6.Tec nical specifications...............................................................................................................................

6.1.General describtions ..................................................................................................................................

6.2.Mesuring method ......................................................................................................................................

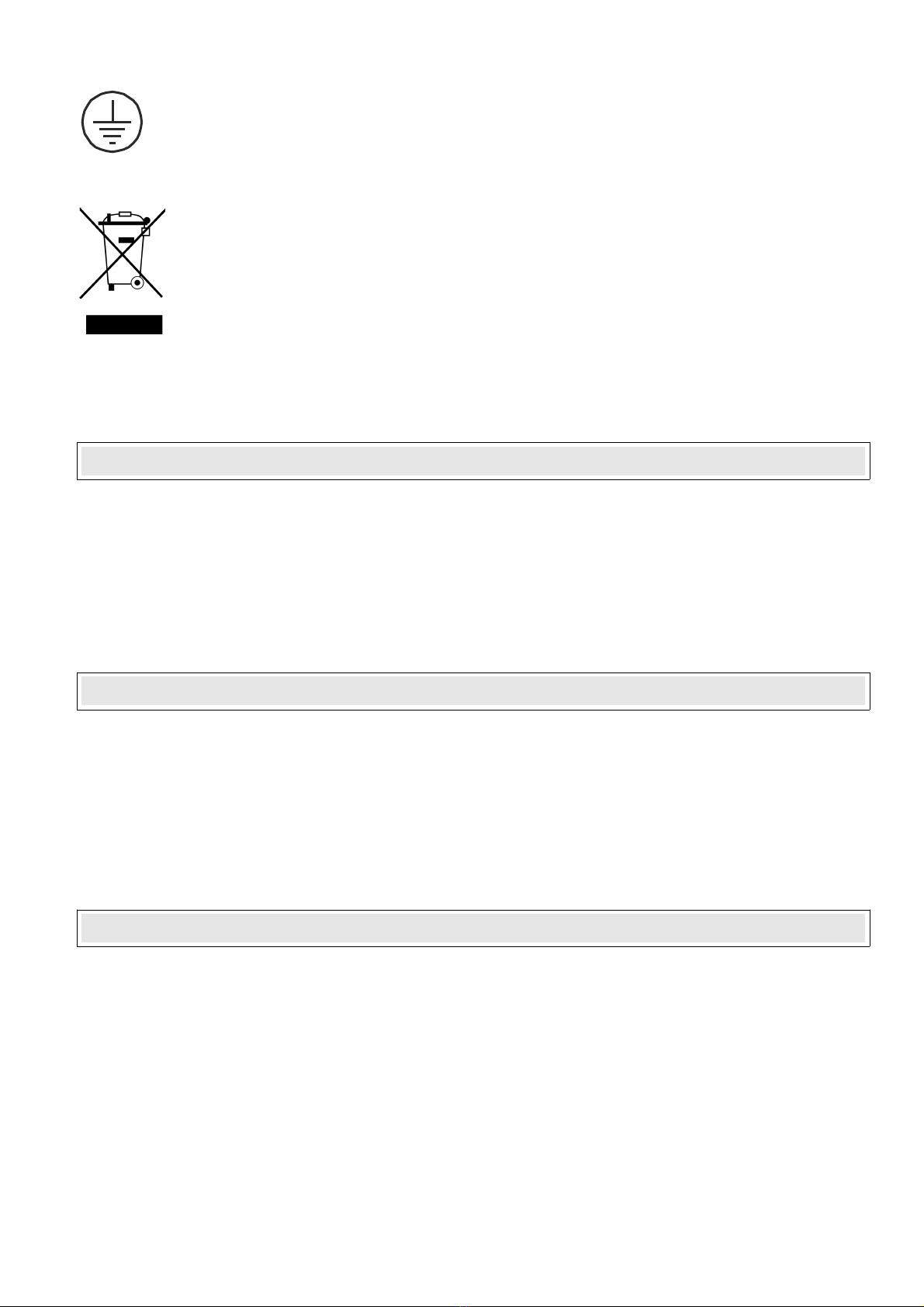

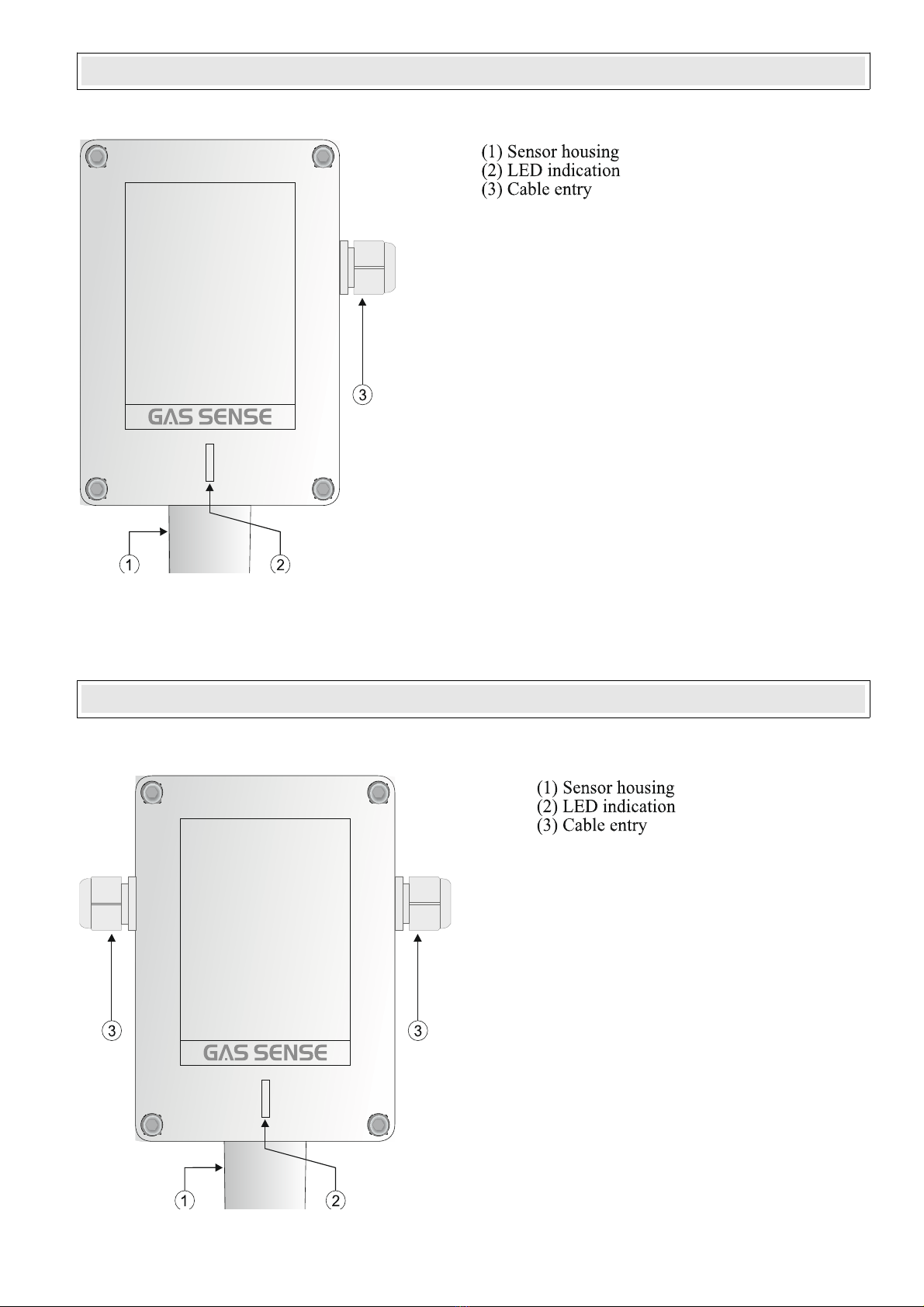

7.Front view....................................................................................................................................................

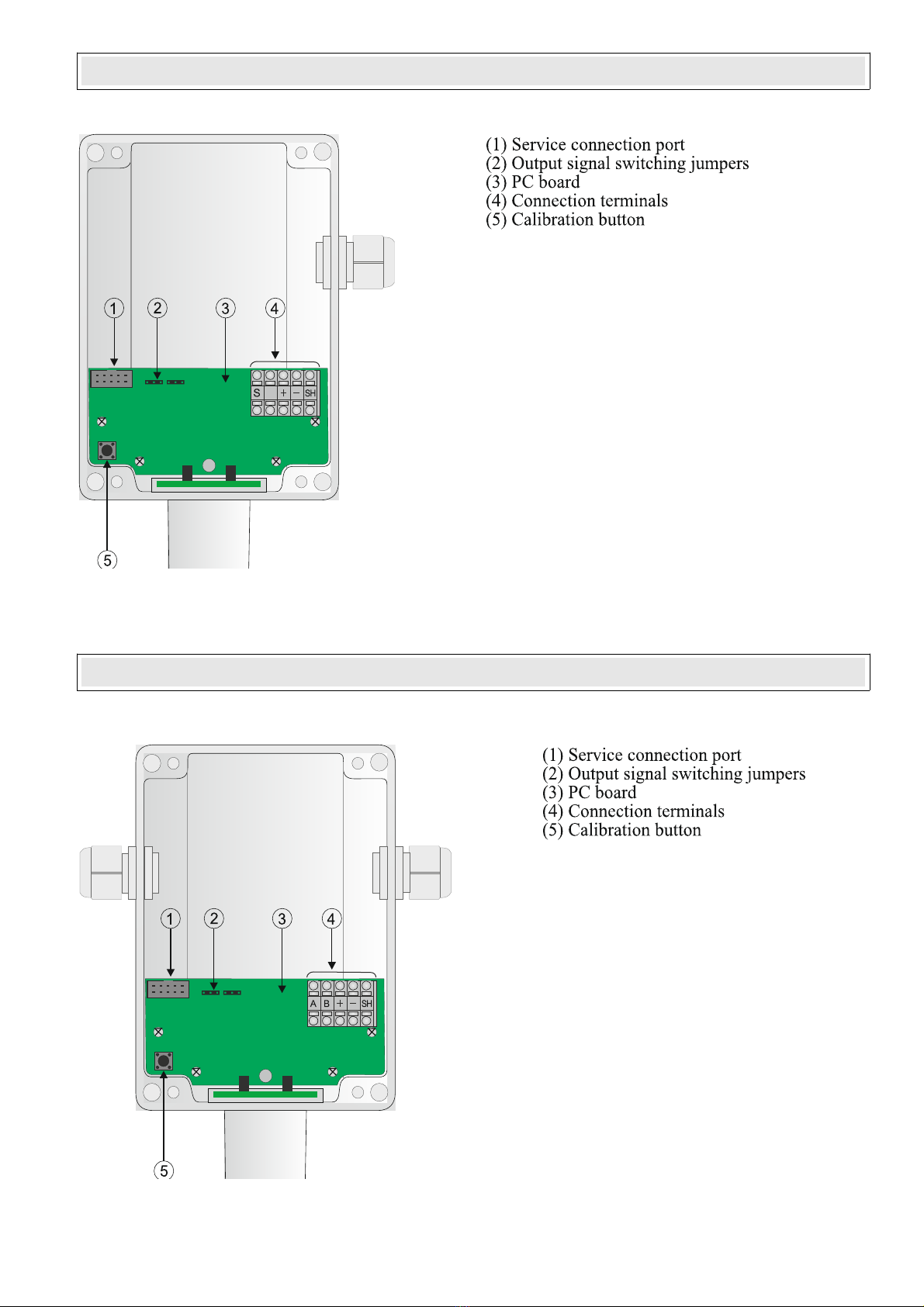

8.Inside view....................................................................................................................................................

9.Installation and wiring...............................................................................................................................

9.1.Mounting the sensor ..................................................................................................................................

9.2.Mechanical mounting ................................................................................................................................

9.3.Electrical connection .................................................................................................................................

9.4.Analogue gas detector GS-300.A ..............................................................................................................

9.5.Addressable gas detector GS-300. .........................................................................................................

10.Operating instructions .............................................................................................................................

10.1.Initial stabilisation ...................................................................................................................................

10.2.Working mode .........................................................................................................................................

10.3.Alarm 1 ...................................................................................................................................................

10.4.Alarm 2 ...................................................................................................................................................

10.5.Alarm 3 ...................................................................................................................................................

10.6.FAULT ....................................................................................................................................................

11.Sensor callibration ...................................................................................................................................

12.Maintenance and servicing......................................................................................................................

Cleaning ..........................................................................................................................................................

Servicing .........................................................................................................................................................

Servicing frequency ........................................................................................................................................

13.Ordering codes .........................................................................................................................................

14.Declaration of Conformity.......................................................................................................................