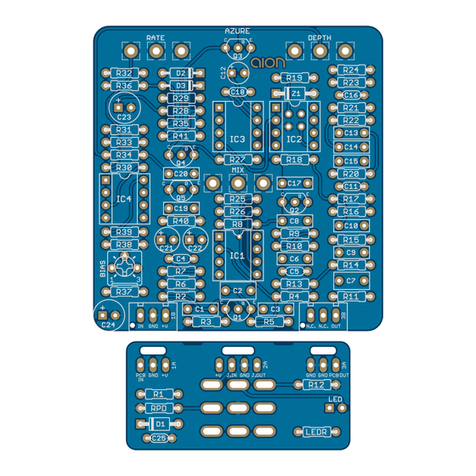

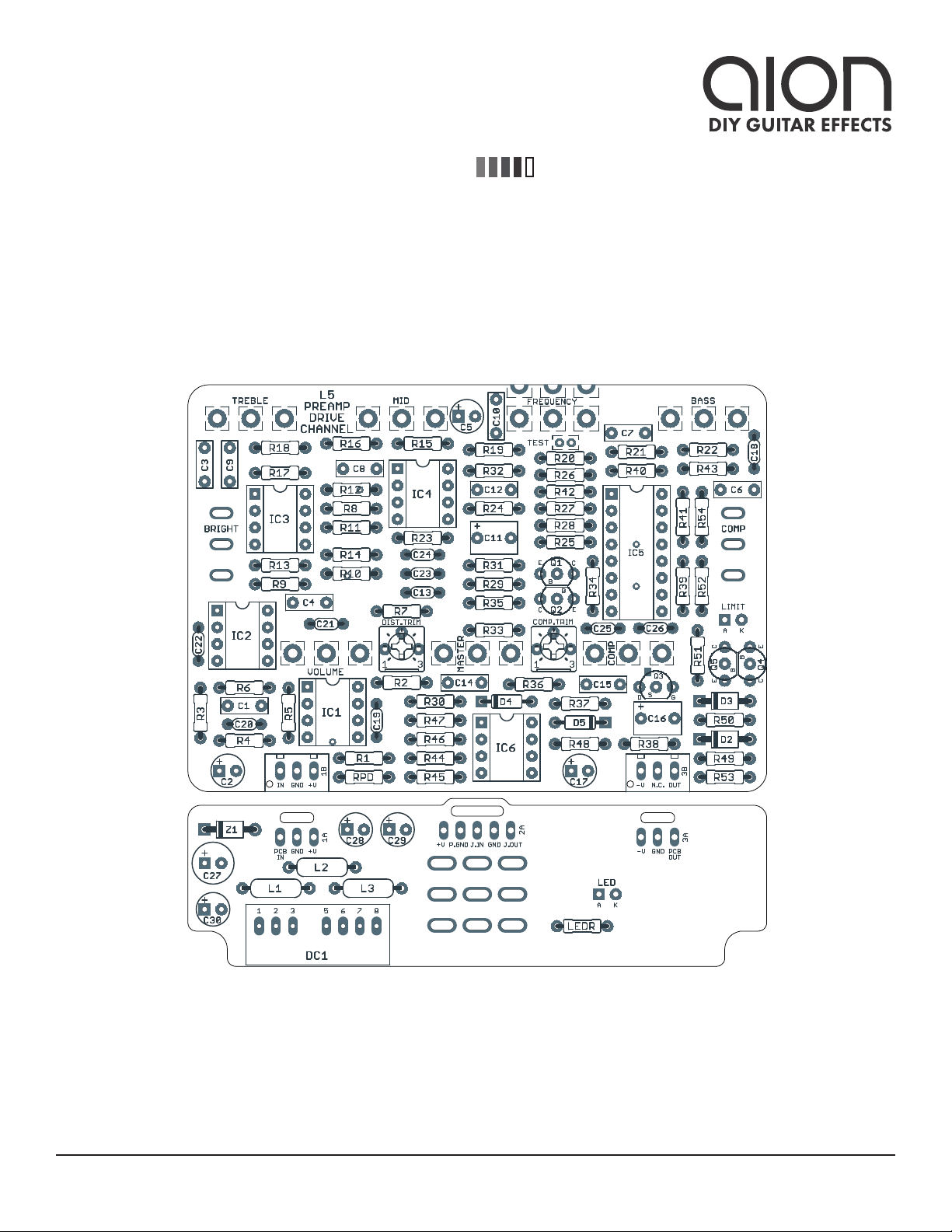

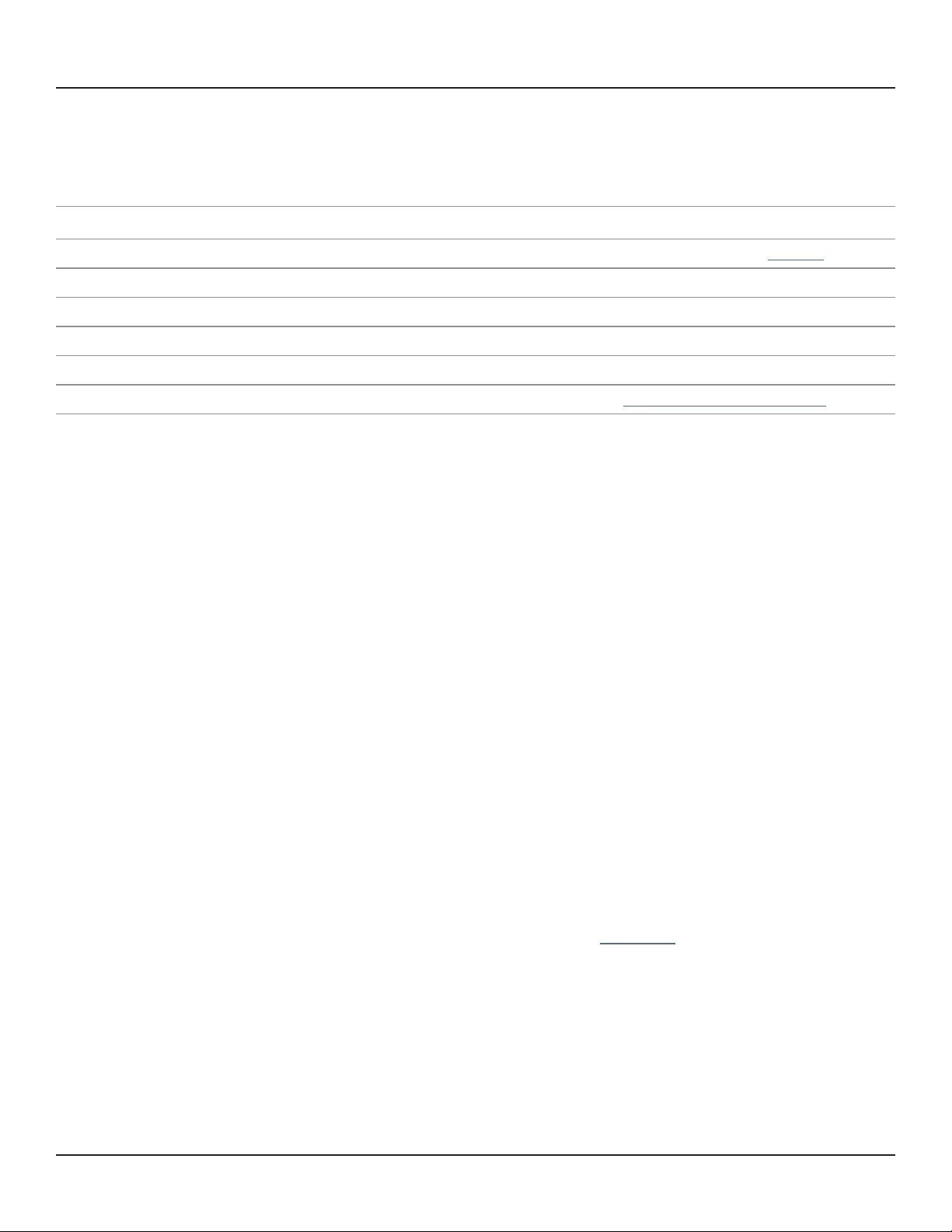

L5 PREAMP DRIVE CHANNEL 6

PARTS LIST, CONT.

PART VALUE TYPE NOTES

C10 68n Film capacitor, 7.2 x 2.5mm

C11 2.2uF Film capacitor, 7.2 x 5mm

C12 10n Film capacitor, 7.2 x 2.5mm

C13 220pF MLCC capacitor, NP0/C0G

C14 330n Film capacitor, 7.2 x 2.5mm

C15 68n Film capacitor, 7.2 x 2.5mm

C16 2.2uF Film capacitor, 7.2 x 5mm

C17 10uF Electrolytic capacitor, 5mm

C18 100pF MLCC capacitor, NP0/C0G

C19 10n MLCC capacitor, X7R

C20 10n MLCC capacitor, X7R

C21 10n MLCC capacitor, X7R

C22 10n MLCC capacitor, X7R

C23 10n MLCC capacitor, X7R

C24 10n MLCC capacitor, X7R

C25 10n MLCC capacitor, X7R

C26 10n MLCC capacitor, X7R

C27 100uF Electrolytic capacitor, 6.3mm

C28 10uF Electrolytic capacitor, 5mm

C29 10uF Electrolytic capacitor, 5mm

C30 47uF Electrolytic capacitor, 5mm

Z1 1N4743A Zener diode, 13V, DO-41

D2 1N4004 Rectifier diode, DO-41

D3 1N4004 Rectifier diode, DO-41

D4 1N914 Fast-switching diode, DO-35

D5 1N914 Fast-switching diode, DO-35

Q1 2N3904 BJT transistor, NPN, TO-92

Q2 2N3904 BJT transistor, NPN, TO-92

Q3 2N5457 JFET, N-channel, TO-92 Substitute. Original uses 2N4303 (PN4303).

Q4 2N3906 BJT transistor, PNP, TO-92

Q5 MPSA13 Darlington BJT, NPN, TO-92

L1 10uH Inductor, 10uH Bourns 78F100J-RC

L2 10uH Inductor, 10uH Bourns 78F100J-RC

L3 10uH Inductor, 10uH Bourns 78F100J-RC

DC1 TEC 3-0923 DC-DC converter, +9V to +/-15V See build notes for alternatives.