CHROMA PARAMETRIC BOOST 5

BUILD NOTES

Making the dual 10kA/10kC “Balance” pot

The main reason the SP-1 has never been cloned before is due to the odd 10kA/10kC Balance pot.

This pot is unique to the pedal, and to custom-order it from Alpha would mean ordering at least 1,000

minimum. This has historically made the SP-1 prohibitive to DIYers wanting to build their own.

Fortunately, dual 10kA pots are available, and it’s very easy to switch out the top wafer of these pots

since the top wafer is identical in construction to the wafers used in single pots.

But, here’s the catch: since the top wafer is upside down, its taper is actually mirrored. The top wafer of

a dual 10kA pot is the same as a 10kC. Because of this, you will need to pull the replacement wafer from

a single 10kA pot, which will give you the correct “C” taper when used upside-down in a dual pot.

So for this, you will need one 10kA dual pot (preferably right-angle PCB mount) and one 10kA single pot

(preferably straight-pin PCB mount). It’s recommended to order at least two 10kA single pots in case

you break one while taking it apart.

Once you have the dual 10kA and single 10kA pots, follow these steps for making the dual pot.

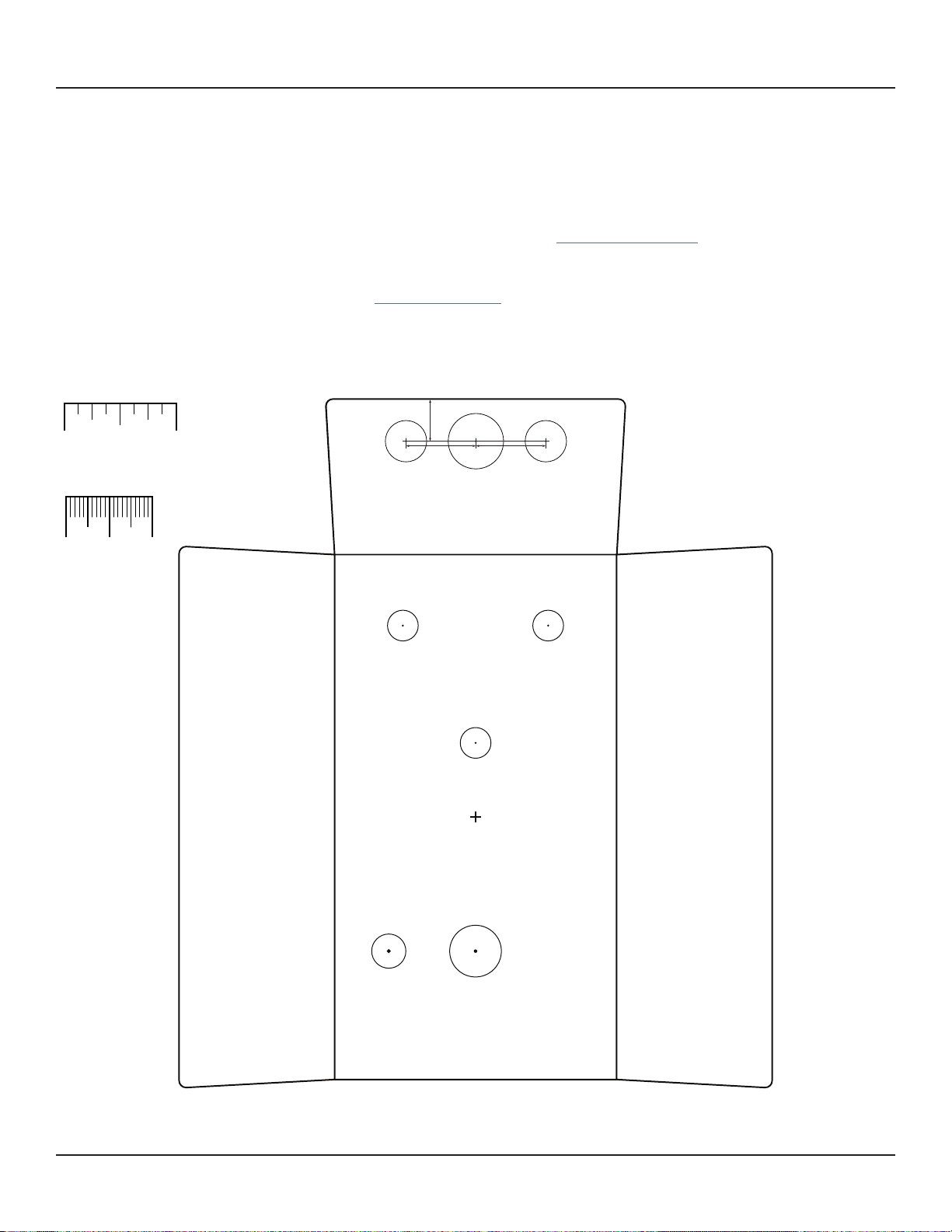

1. Start with a 10kA dual pot (right

angle PCB mount) and a 10kA single

pot (straight-pin PCB mount).

4. On the single pot, break away

all the black plastic from the metal

shaft, taking care not to scratch

the carbon on the wafer itself. This

will take a fair amount of force.

You could also use a utility knife or

Dremel tool to cut it away.

2. On the dual pot, bend out the

four tabs with needle-nose pliers to

separate the top wafer.

5. Once the plastic has been broken

away, set aside the wafer and throw

the rest away. (Note that this photo

shows a solder-lug wafer, which

won’t fit the PCB without cutting

down the lugs. Use a straight-pin pot

as shown in step 1.)

3. On the single pot, bend out the

four tabs near the nut to separate

the metal cover from the rest.

6. Place the 10kA wafer on the dual

pot as shown, carbon side down, and

bend the four tabs inward to secure

it in place. Bend the pins straight

upward. This wafer will act as a

C-taper pot since it is upside-down.