Air Science® 120 6th Street \Fort Myers, FL 33907 \T239-489-0024 \Toll Free 800-306-0656 \F800-306-0677 \www.airscience.com

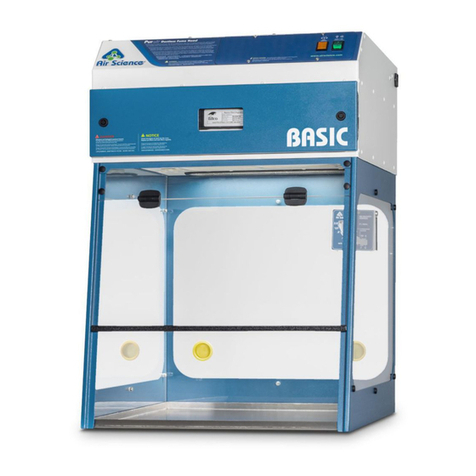

2 \ USER OPERATION MANUAL: Purair FLOW Laminar FLOW Cabinets

Table of Contents

Safety Warnings / Symbols ................................................................3

Limitation of Liability .....................................................................3

Warranty...............................................................................4

Customer Satisfaction Survey ..............................................................4

I. Product Information .............................................................. 5

II. Unpacking Your Cabinet .......................................................... 6

2.1 Step-By-Step Procedure................................................................6

2.2 Packaging Contents ...................................................................7

III. Installing Your Cabinet ........................................................... 8

3.1 Choosing a Suitable Location ...........................................................8

3.2 Environmental / Electrical Condition......................................................8

3.3 Installing Your Cabinet .................................................................9

3.4 Set Up..............................................................................9

3.5 Performance Validation / Certication....................................................13

3.5.1 Importance of Performance Validation / Certication ......................................13

3.5.2 Recertication .....................................................................13

3.5.3 Disclaimer ........................................................................13

IV. Operating Your Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1 Laminar Flow Control System...........................................................14

4.2 Cabinet Start-Up Procedure ...........................................................15

4.3 Working in the Cabinet ...............................................................15

4.4 Cabinet Shutdown Procedure ..........................................................16

4.5 Ergonomics ........................................................................16

V. Maintaining Your Cabinet ........................................................ 17

5.1 Maintenance Schedule ................................................................17

5.2 Disinfecting Agents ..................................................................18

5.3 Event Log Record Form ...............................................................19

5.4 Replacement Parts List................................................................20

VI. Maintenance by Service Personnel ................................................ 21

6.1 Cabinet Airow Balancing .............................................................21

6.2 Filter Changing......................................................................21

6.3 Recertication ......................................................................21

6.4 Leak Testing of HEPA Filters ...........................................................22

VII. Troubleshooting Common Problems............................................... 23

VIII. Filter Information ............................................................. 24

8.1 Filter Description ....................................................................24

IX. Product Specications .......................................................... 25