120 6th Street, Fort Myers, Florida, 33907 USA, www.Airscience.com, Tel: 239-489-0024, Fax: 239-489-0922

- 5 -

WARRANTY TERMS AND CONDITIONS

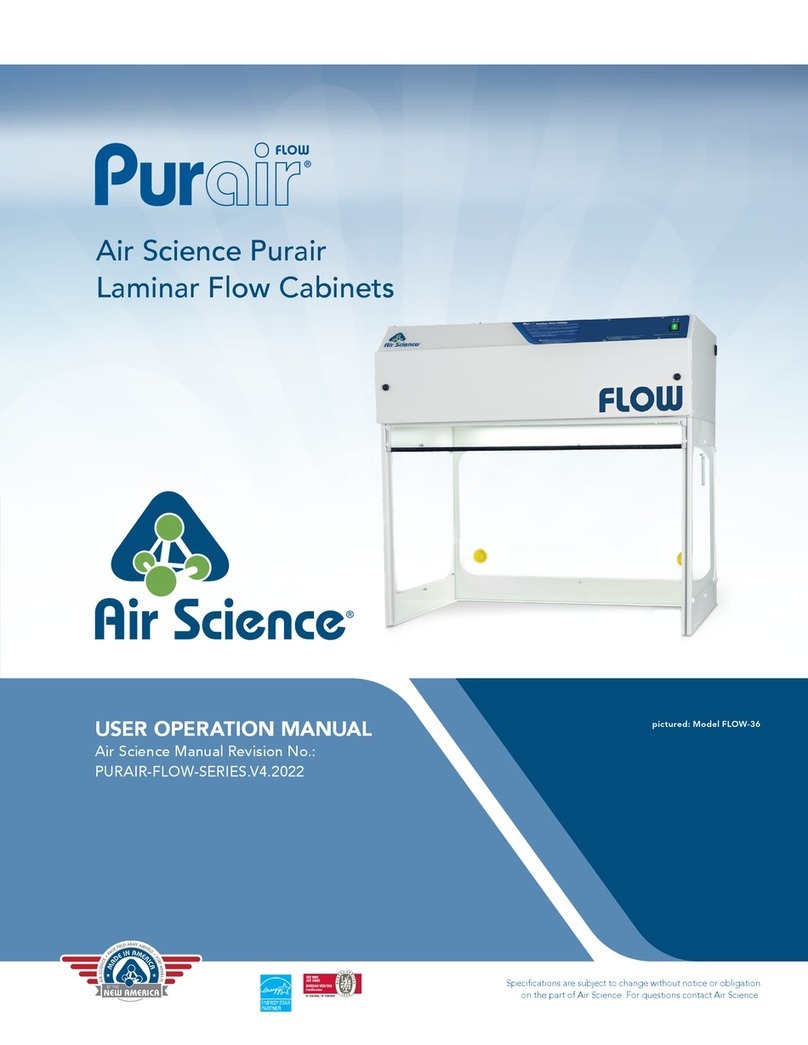

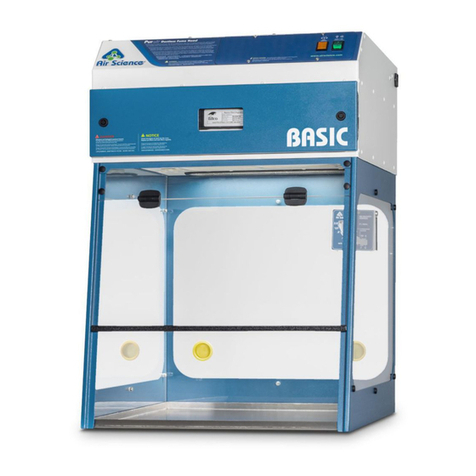

Our laminar flow cabinets have been designed to provide operator safety with an easy to use cabinet.

You can rest assured that with proper maintenance, these hoods will reward you with years of trouble free

service and protection.

Air Science value your business, so your satisfaction is important to us, so please complete and return

our customer satisfaction survey at the end of this manual.

Should you be unfortunate to receive product that appears to be damaged or defective or does not

appear to be working satisfactorily, then please contact our experienced technicians for assistance at the

address shown at the foot of this page.

The Air Science range of cabinets has been carefully designed to produce a system that will provide

product safety in an easy to use system. However, basic safety precautions should always be followed

when:

Using an electrical product; and

Handling hazardous substances.

Air Science products come with a 2-year limited warranty beginning on the date of shipment from the Air

Science. Air Science's limited warranty covers defects in materials and workmanship. Air Science's

liability under this limited warranty shall be, at our option, to repair or replace any defective parts of the

equipment, provided if proven to the satisfaction of Air Science that these parts were defective at the time

of being sold.

This limited warranty does not cover:

Installation (inside delivery handling) damage.

Products with missing or defaced serial numbers

Consumables such as filters (HEPA, ULPA, carbon, pre-filters) and fluorescent / UV bulbs

Problems that result from:

External causes such as accident, abuse, misuse, problems with electrical power, improper

operating environmental conditions

Servicing that is not carried out by Air Science personnel or their appointed agents, or in the case

of electrical work by a qualified electrician

Usage that is not in accordance with these product instructions

Failure to follow these product instructions

Failure to perform preventive maintenance

Problems caused by using accessories, parts, or components not supplied or approved by Air

Science

Damage by fire, floods, or acts of God

Customer modifications to the product

ALL EXPRESS AND IMPLIED WARRANTIES FOR THE PRODUCT, INCLUDING BUT NOT LIMITED

TO ANY IMPLIED WARRANTIES AND CONDITIONS OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE LIMITED IN TIME TO THE TERM OF THIS LIMITED WARRANTY. NO

WARRANTIES, WHETHER EXPRESS OR IMPLIED, WILL APPLY AFTER THE LIMITED WARRANTY

PERIOD HAS EXPIRED. AIR SCIENCE DOES NOT ACCEPT LIABILITY BEYOND THE REMEDIES

PROVIDED FOR IN THIS LIMITED WARRANTY OR FOR SPECIAL, INDIRECT, CONSEQUENTIAL

OR INCIDENTAL DAMAGES, INCLUDING, WITHOUT LIMITATION, ANY LIABILITY FOR THIRD-

PARTY CLAIMS AGAINST YOU FOR DAMAGES, FOR PRODUCTS NOT BEING AVAILABLE FOR

USE, OR FOR LOST WORK. AIR SCIENCE LIABILITY WILL BE NO MORE THAN THE AMOUNT

YOU PAID FOR THE PRODUCT THAT IS THE SUBJECT OF A CLAIM. THIS IS THE MAXIMUM

AMOUNT FOR WHICH AIR SCIENCE IS RESPONSIBLE. FLORIDA LAW GOVERNS THIS

WARRANTY