1. Disconnect the negative battery terminal.

2. Mount the Smart-Ride in a dry location away from hot exhaust and any moving components.

3. Determine where the LCD Controller will be mounted.

4. Connect the LCD controller to the Relay Control Box.

5. Wire according to diagram on page 1.

a.Power Loom

i. Connect the Black wires (Pin 1 & Pin 3) to (-) Ground.

ii. Connect the Red wire (Pin 2) to constant +12V.

iii. Connect the Yellow (Pin 4) to the Compressor (less than 40amp) or Compressor Relay

(over 40amp draw).

1.This output is only designed to supply power to a compressor that requires less than

40 amps. Larger compressors must have a relay installed in between the Smart-Ride

and the Compressor. (Wiring Schematics)`

iv. Connect the White wire (Pin 5)to an Ignition wire. This wire will turn the LCD Controller

On. When the ignition turns on it will also activate Preset #1 if that option has been turned on

(See Screen #2 instructions for details).

v. Connect the Green Wire to constant +12V (Pin 6). This wire will supply power to the inter-

nal relay that powers the Yellow Wire.

b.Valve Loom

i. Connect each wire to its corresponding valve as shown on the Non-PnP Wiring Schematic.

ii. If you have purchased this Smart-Ride controller with one of Airbagit.com's Air Engine

valve assemblies, or Air Force then the Valve Loom will plug right into the Air Engine's white 9

pin plug. See Air Engine Wiring Schematic.

The system will now have control of the valves but will not display pressures or heights until

the sensors are installed.

c. Pressure Sending units (RED). (SMART-RIDE P and SMART-RIDE HP Models Only)

After the each Pressure Sending unit is installed you will see the tank pressure displayed on the

LCD Controller.

i. Install the pressure sending units and plug into the red sockets on the relay control box as

indicated on page 1. Note: Pressure Sending units are to be tightened with the included

spanner wrench only, Tightening by hand will damage the sending unit.

ii. Smart-Ride P Models with speed control adjusters will need to make sure that the pres

sure sender is installed between the bag and the speed control adjuster. Installing the pres

sure sender after the speed control valve will cause inaccurate readings thus affecting the

units ability to reach its preset values.

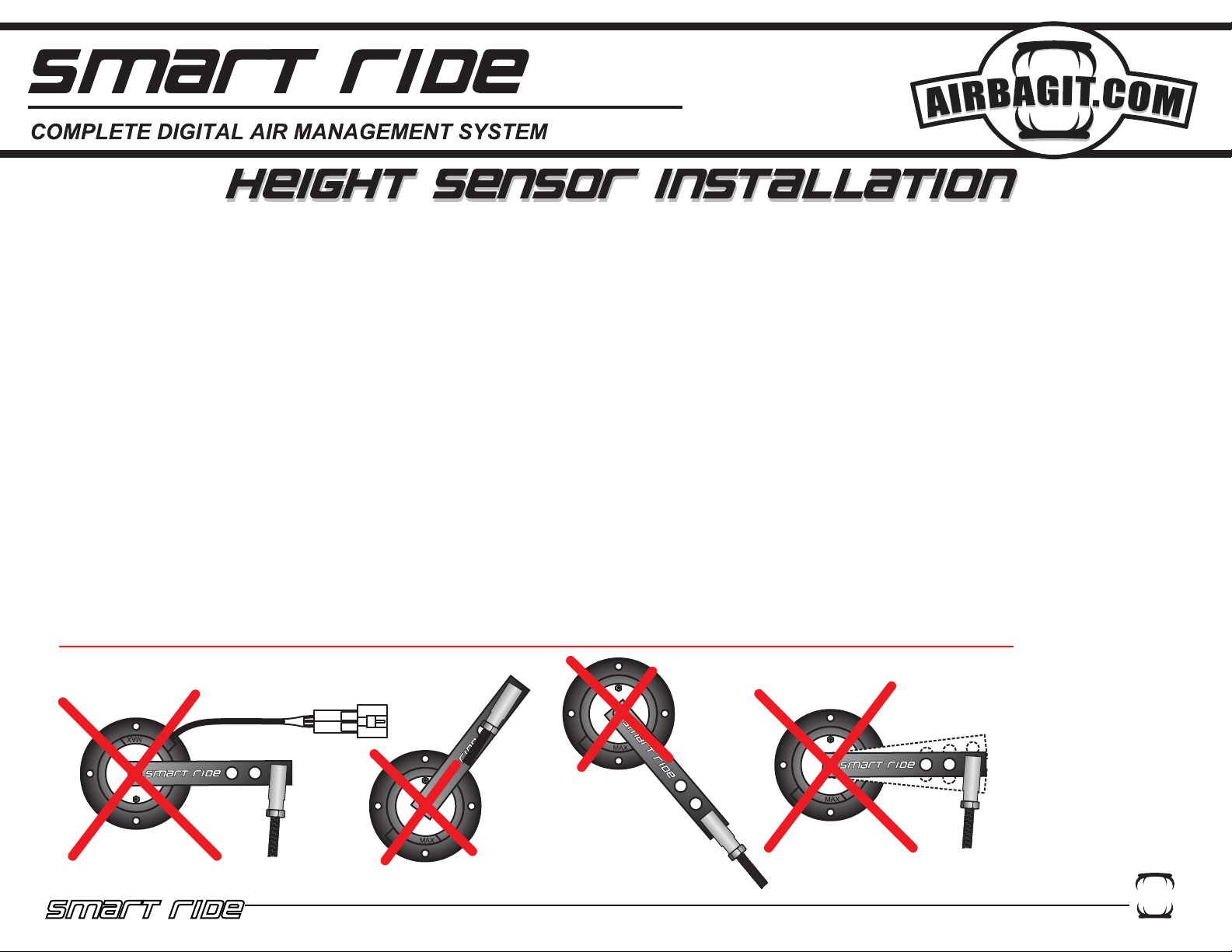

d. Height Sensors (BLUE). (SMART-RIDE H and SMART-RIDE HP Models Only)

i. SEE HEIGHT SENSOR INSTALLATION INSTRUCTIONS

e. Optional Inputs (These should be installed after the system has been completely installed and

setup)

i. NOTE: THESE ARE ONLY TO BE CONNECTED IF YOU INTEND ON USING ATHIRD

PARTY CONTROLLER I.E. 12 CHANNEL REMOTE, ORALARM SYSTEM. If you do not

intend on controlling the Smart-Ride with anything other than the Smart-Ride LCD Controller

then leave this loom unplugged.

ii. In order to use the optional third party inputs you will need to supply each wire with +12V.

This is not a constant +12V but momentary power that is supplied by a third party controller.

3