7.2.2.3 GENERAL SAFETY RULES

• Multiple hazards. Read and understand the safety instructions before

installing, operating, repairing, maintaining, changing accessories on, or

working near the power tool. Failure to do so can result in serious bodily

injury.

• Onlyqualiedandtrainedoperatorsshouldinstall,adjustorusethepower

tool.

• Donotmodifythispowertool.Modicationsmayreducetheeffectiveness

of safety measures and increase the risks to the operator.

• Donotdiscardthesafetyinstructions–givethemtotheoperator.

• Do not use a tool if the tool has been damaged.

• Warningsshallbegivenagainsttheriskofexplosionorreduetothe

material being processed;

• Warningsshallbegivenagainsttheriskofcutting.

7.2.2.4 PROJECTILE HAZARDS

• Failureoftheworkpiece,ofaccessories,orevenofthetoolitselfmay

generatehighvelocityprojectiles.

• Always wear impact-resistant eye protection during operation of the tool.

The grade of protection required should be assessed for each use.

7.2.2.5 ENTANGLEMENT HAZARDS

• Entanglement hazard - choking, scalping and/or lacerations can occur if

neckware,hairorglovesarenotkeptawayfromtoolandaccessories.

7.2.2.6 OPERATING HAZARDS

• Useofthetoolmayexposetheoperator’shandstohazardsincluding

crushing,impacts,cutsandabrasionsandheat.Wearsuitableglovesto

protect hands.

• Operators and maintenance personnel must be physically able to handle

the bulk, weight and power of the tool.

• Holdthetoolcorrectly:bereadytocounteractnormalorsuddenmove-

ments–havebothhandsavailable.

• Maintain a balanced body position and secure footing.

• Keep hands away from rotating or reciprocation accessories, spindles or

othermovingparts.

• Releasethestartandstopdeviceinthecaseofaninterruptionofthe

energy supply

• Use only lubricants recommended by the manufacturer.

7.2.2.7 REPETITIVE MOTIONS HAZARDS

• Whenusingapowertool,youmayexperiencediscomfortinyourhands,

arms, shoulders, neck, or other parts of your body.

• While using a power tool, position your body in a comfortable posture.

Maintainsecurefootingandavoidawkwardoroff-balancedpostures.

Changingyourpostureduringextendedtasksmayhelpavoiddiscomfort

and fatigue.

• Ifyouexperiencesymptomssuchaspersistentorrecurringdiscomfort,

pain, throbbing, aching, tingling, numbness, burning sensation, or stiff-

ness, do not ignore these warning signs. Promptly tell your employer and

consultaqualiedhealthprofessional.

7.2.2.8 ACCESSORY HAZARDS

• Only use sizes and types of accessories and consumables that are recom-

mended by the power tool manufacturer.

7.2.2.9 WORKPLACE HAZARDS

• Slips, trips and falls are major causes of workplace injury. Be aware of

slippery surfaces caused by use of the tool and also of trip hazards caused

by the air line or hydraulic hose.

• Proceedwithcareinunfamiliarsurroundings.Hiddenhazardsmayexist,

such as electricity or other utility lines.

• Thispowertoolisnotintendedforuseinpotentiallyexplosiveatmo-

spheres and is not insulated from coming into contact with electric power.

• Make sure there are no electrical cables, gas pipes etc. that could cause a

hazard if damaged by use of the tool.

7.2.2.10 DUST AND FUME HAZARDS

• Dust from some work processes can cause cancer, birth defects or other

respiratory diseases. Risk assessment of these hazards and implementa-

tion of appropriate controls is essential.

• Ifthepneumatictoolisusedinadustlledenvironmentexhaustaircan

cause a dust hazard

• Dusts and fumes generated when using power tools can cause ill health

(forexample:cancer,birthdefects,asthmaand/ordermatitis);riskas-

sessment of these hazards and implementation of appropriate controls of

is essential.

• Risk assessment should include dust created by the use of the tool and

thepotentialfordisturbingexistingdust.

• Operate and maintain the power tool as recommended in these instruc-

tions, to minimize dust or fume emissions

• Directtheexhaustsoastominimizeddisturbanceofdustinadustlled

environment

• Where dusts or fumes are created, the priority shall be to control them at

the point of emission.

• Allintegralfeaturesoraccessoriesforthecollection,extractionor

suppression of airborne dust or fumes should be correctly used and

maintainedinaccordancewiththemanufacturer’sinstructions.

• Select, maintain and replace the consumable/inserted tool as recom-

mendedintheseinstructions,topreventanunnecessaryincreaseindust

or fumes

• Use respiratory protection as instructed by your employer or as required

by occupational health and safety regulations;

7.2.2.11 NOISE HAZARDS

• Unprotectedexposuretohighnoiselevelscancausepermanent,

disabling, hearing loss and other problems such as tinnitus (ringing,

buzzing,whistlingorhummingintheears);

• Risk assessment of these hazards and implementation of appropriate

controls of is essential.

• Appropriate controls to reduce the risk may include actions such as

dampingmaterialstopreventworkpiecesfrom‘ringing’

• Use hearing protection as instructed by your employer or as required by

occupational health and safety regulations;

• Operate and maintain the power tool as recommended in these instruc-

tions,topreventanunnecessaryincreaseinnoiselevels;

• Select, maintain and replace the consumable/inserted tool as recom-

mendedintheseinstructions,topreventanunnecessaryincreasein

noise.

7.2.2.12 VIBRATION HAZARDS

• Exposuretovibrationcancausedisablingdamagetothenervesand

blood supply of the hands and arms;

• Wear warm clothing when working in cold conditions and keep your

hands warm and dry;

• Ifyouexperiencenumbness,tingling,painorwhiteningoftheskinin

yourngersorhands,stopusingthepowertool,andtellyouremployer.

Youshouldalsoseekmedicaladvicefromaqualiedoccupationalhealth

professional.

• Operate and maintain the power tool as recommended in these instruc-

tions,topreventanunnecessaryincreaseinvibration;

• Select, maintain and replace the consumable/inserted tool as recom-

mendedintheseinstructions,topreventanunnecessaryincreasein

vibrationlevels;

• Support the weight of the tool in a stand, tensioner or balancer, because

the operator can then use a lighter grip to support the tool.

• Hold the tool with a light but safe grip taking account of the required

handreactionforces,becausetheriskfromvibrationisgenerallygreater

when the grip force is higher.

7.2.3 ADDITIONAL SAFETY INSTRUCTIONS FOR PNEUMATIC POWER

TOOLS - AIR SUPPLY & CONNECTION HAZARDS

• Airunderpressurecancausesevereinjury.

• Always shut off air supply, drain hose of air pressure and disconnect tool

from air supply when not in use, before changing accessories or when

making repairs.

• Neverdirectairatyourselforanyoneelse.

• Whippinghosescancausesevereinjury.Alwayscheckfordamagedor

loosehosesandttings.

• Wheneveruniversaltwistcouplings(clawcouplings)areused,lockpins

must be installed.

• Donotexceedthemaximumairpressurestatedonthetool.

• Use whip check safety cables to safeguard against possible hose to tool

and hose to hose connection failure.

• Nevercarryanairtoolbythehose.

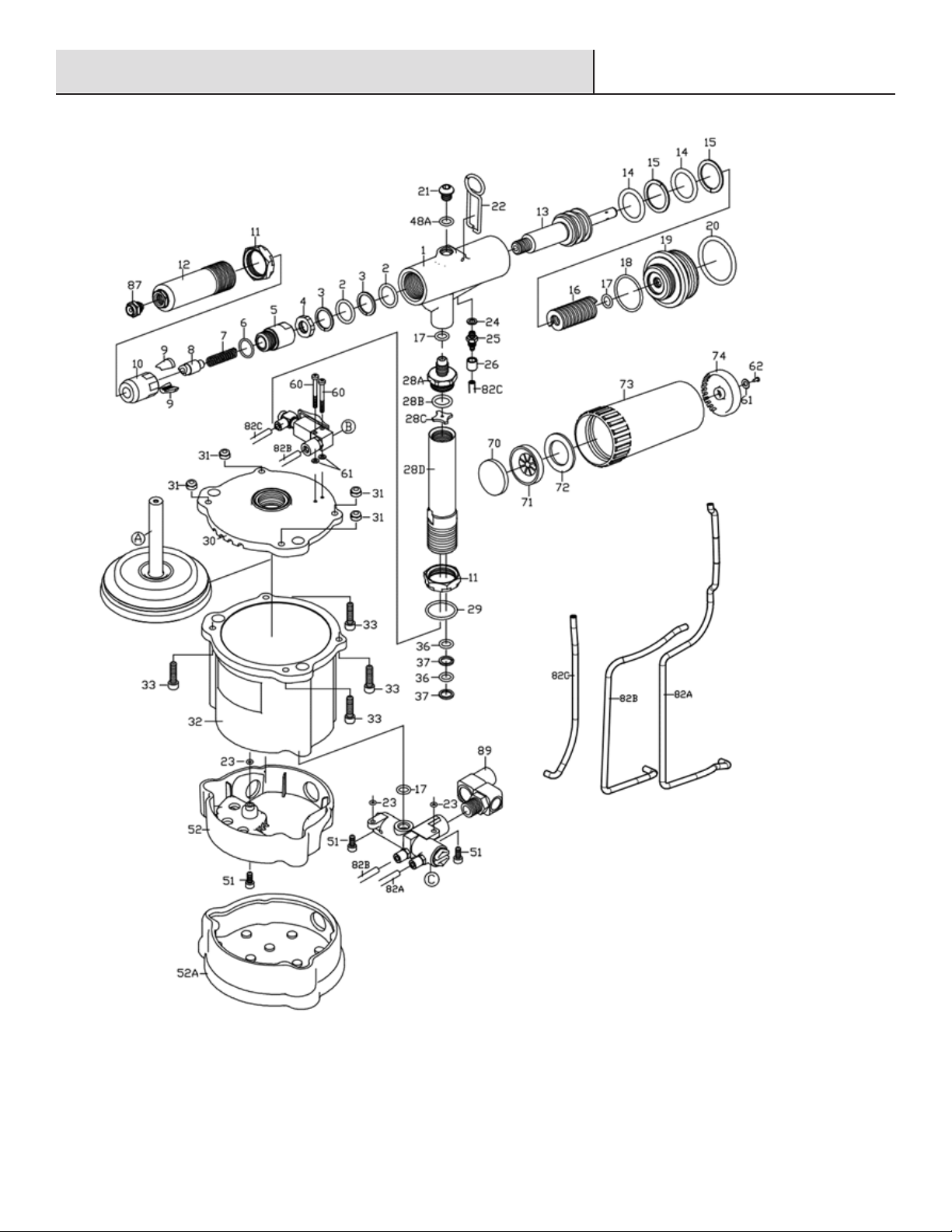

MODEL# 6410 3/16-IN. AIR HYDRAULIC RIVETER

MODEL# 6420 1/4-IN. AIR HYDRAULIC RIVETER

Operation Manual & Parts List