3

General Information

To maintain a healthy indoor environment, closely controlled ventilation is essential. There are

many pollutants that will affect the indoor air quality: human body waste products in the shape of

CO2, dead skin, perspiration and moisture. Add to this the waste products of cooking (cooking

smells), showering (moisture), gases from building materials and the waste products of pets.

Without proper ventilation this would be the perfect environment for the growth of mould,

subsequent damage to the decoration and fabric of a home and to the health of its occupants.

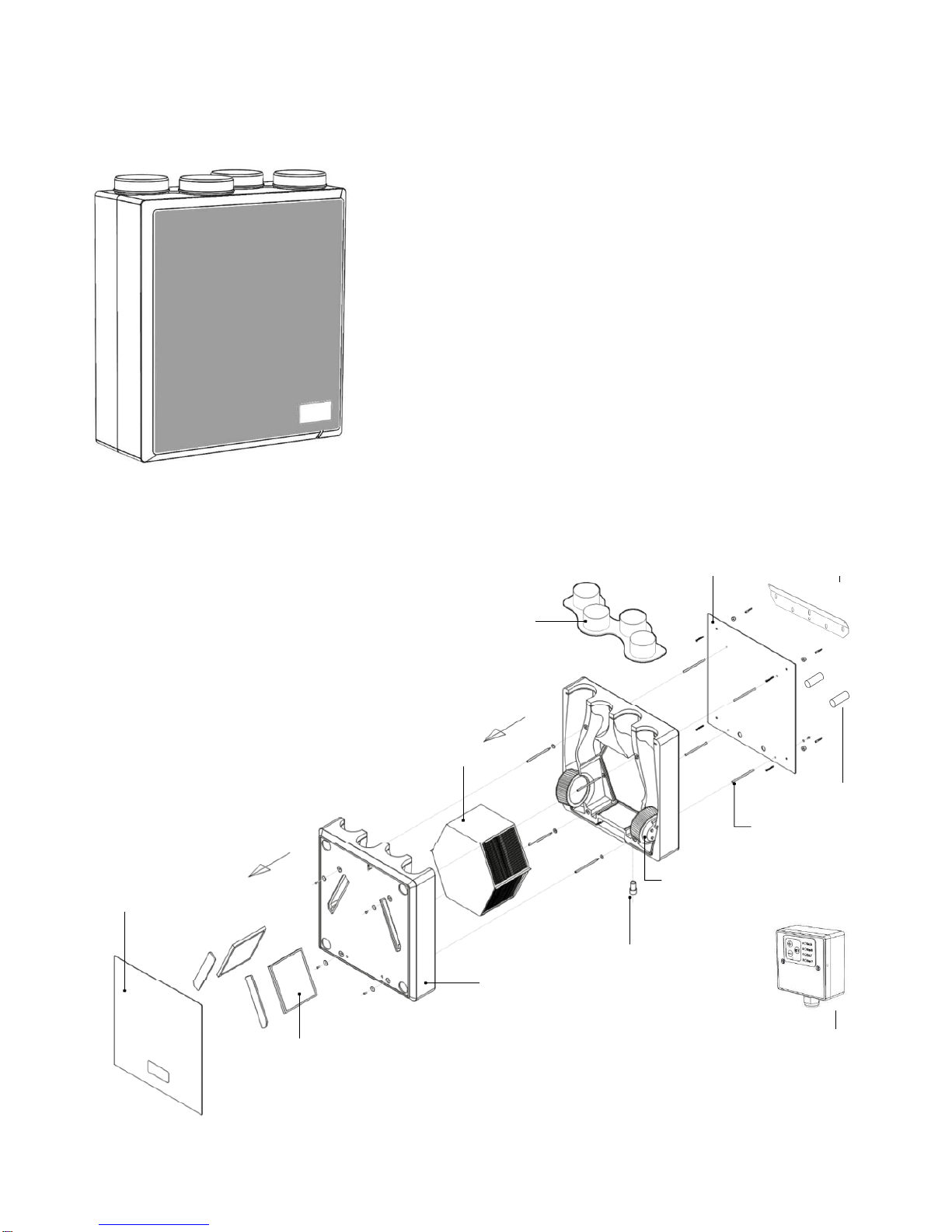

The Heat Recovery unit is fitted with two, low energy EC fans with a constant (100% adjustable) air

volume.

The exhaust fan ensures that warm, damp and polluted air as near as possible to the source is

extracted. The exhausted air has to be replaced with fresh air, so the heat recovery unit not only

has an exhaust fan, but is also fitted with a supply fan and air filters.

The supply air, which in winter is colder than the inside air, is heated in the heat recovery unit using

the heat of the exhaust air by means of the heat exchanger. This heat exchanger has a maximum

efficiency of 91%, so a minimum loss of heat takes place and the supply air temperature enters the

home at a comfortable level.

In exceptionally cold weather or winter conditions it is possible that the exchanger may freeze due

to sub-zero, cold incoming air. Therefore the unit must be sited in a frost-free location.

Alternatively, an in-duct heater may be used to protect the heat exchanger from freezing.

The filters in the unit ensure that the fresh supply air is clean as it enters the home. Also, the

extract air from the property is filtered to protect the heat exchanger from unwanted contamination.

These filters must be inspected regularly, initially every month, and cleaned. Each property will

contaminate the filters at a different rate. The filters should be replaced annually or after a

maximum of two cleaning cycles. Regular filter maintenance will ensure the integrity and

performance of the unit.

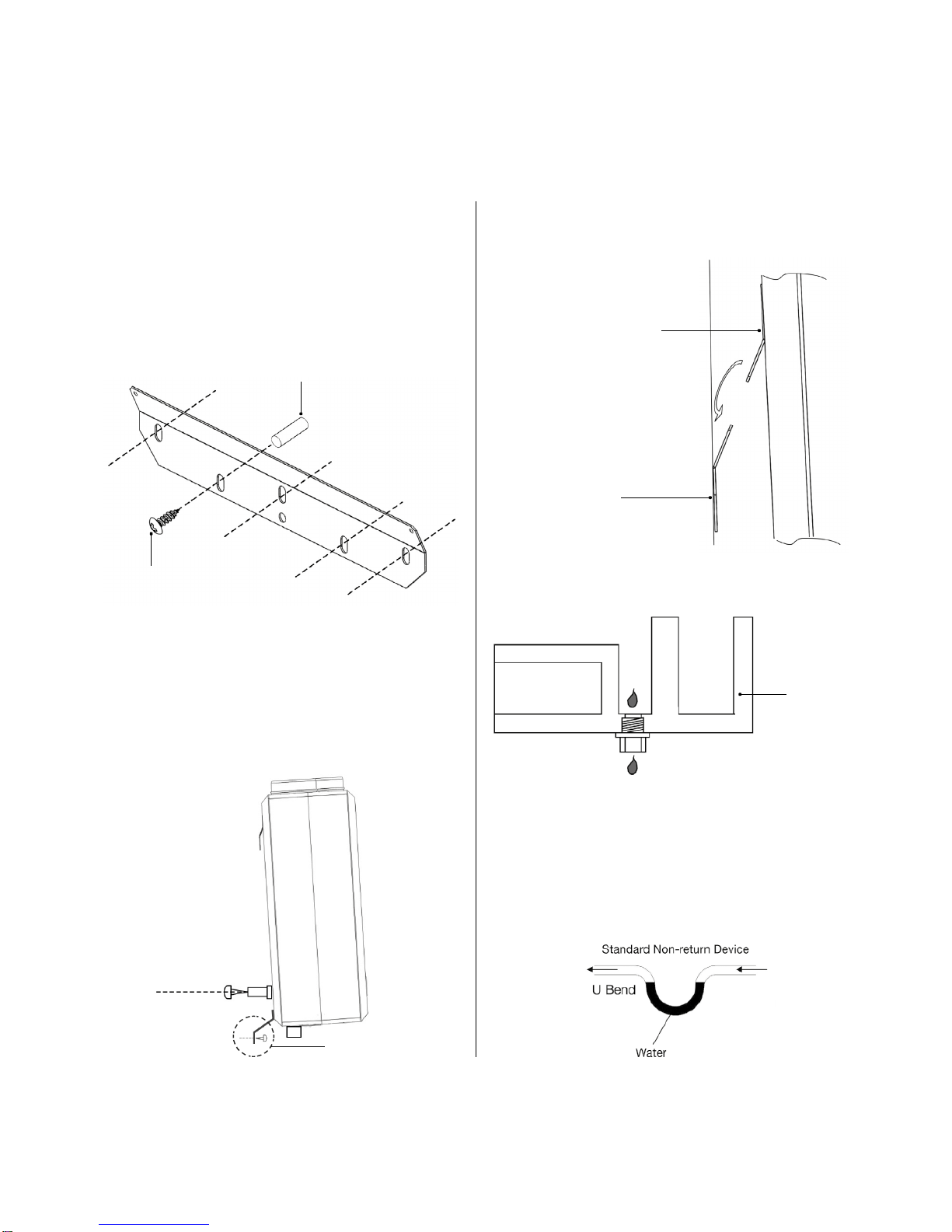

The unit’s condensate drain must be installed and connected to the household drainage system

and must be insulated if installed outside the insulated envelope of the building

If the ductwork passes through an unheated area (loft or similar location), it must be insulated with

an insulation material that complies with the latest Building Regulations.

DO NOT switch off the unit – it is designed to run continuously. If the unit is switched off,

indoor pollutants and moisture levels may increase which could endanger your health or

damage your home.

In the event of a power failure or the unit being turned off, restart the unit at High Speed.

This MVHR unit has a soft start.

It is important to follow the advice in this user manual and correctly maintain the system to

ensure a healthy indoor environment.