3

1. Content

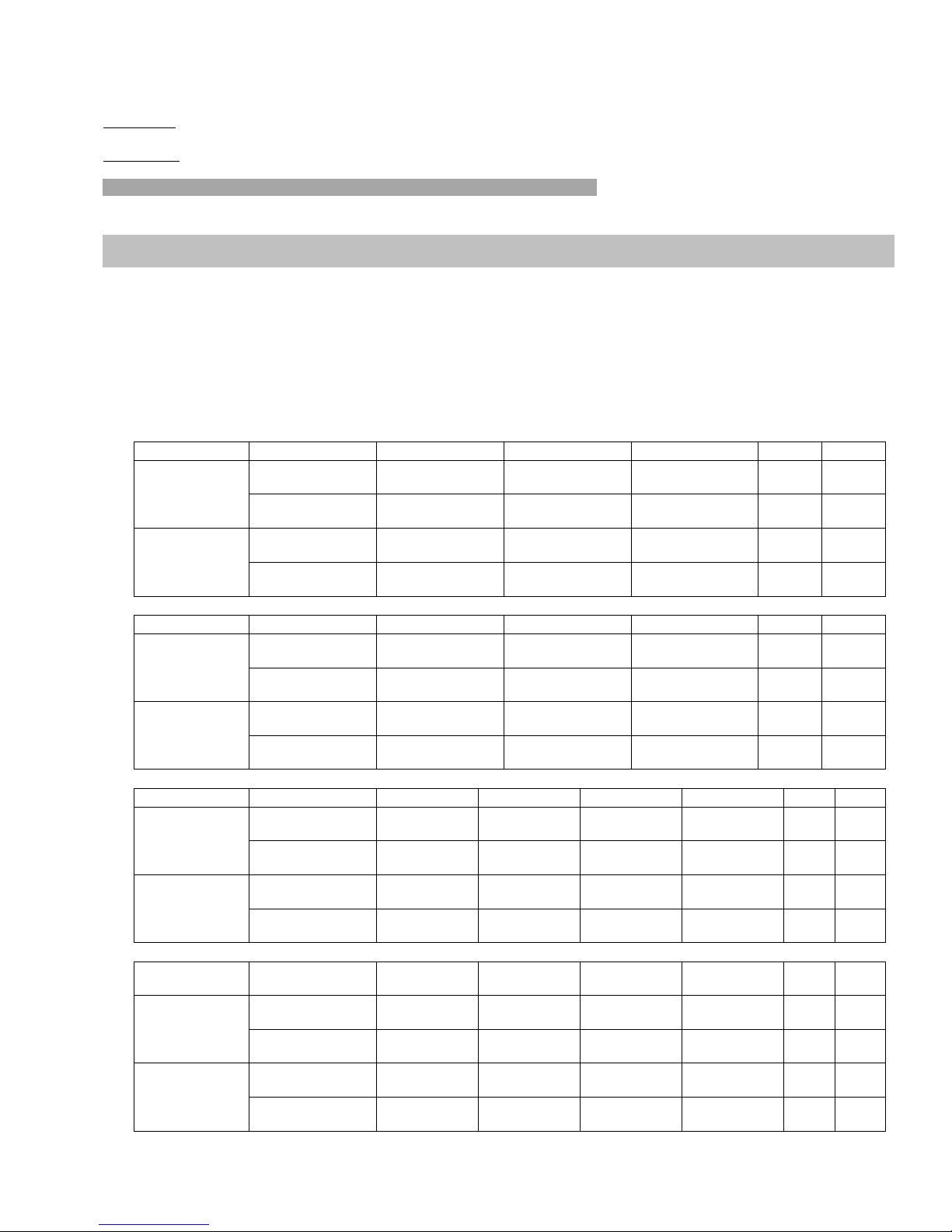

1. Content ........................................................................................................................................................................................3

2. Safety instructions........................................................................................................................................................................4

2.1 General safety...............................................................................................................................................................................4

2.2 Operational safety .........................................................................................................................................................................4

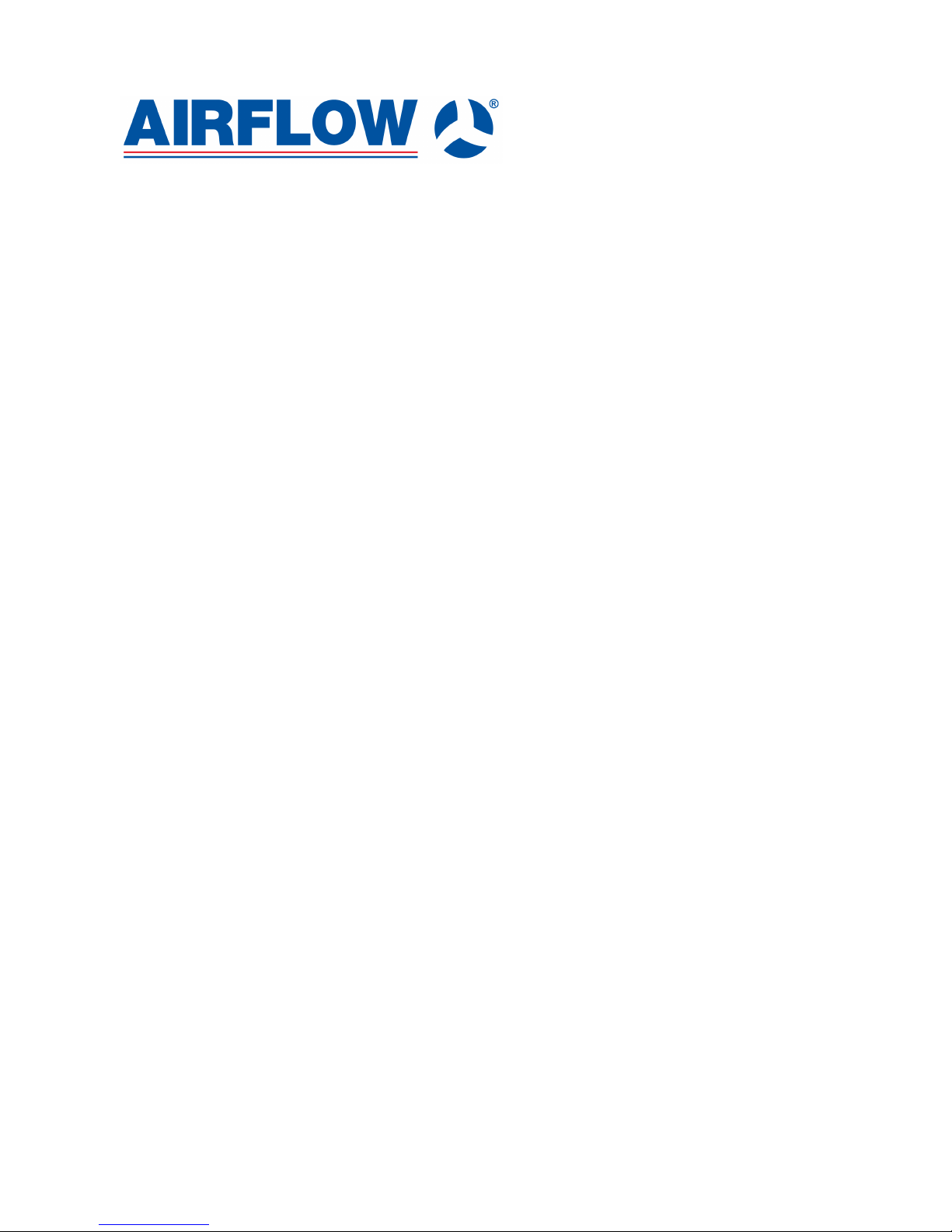

3. Storage and transport ..................................................................................................................................................................4

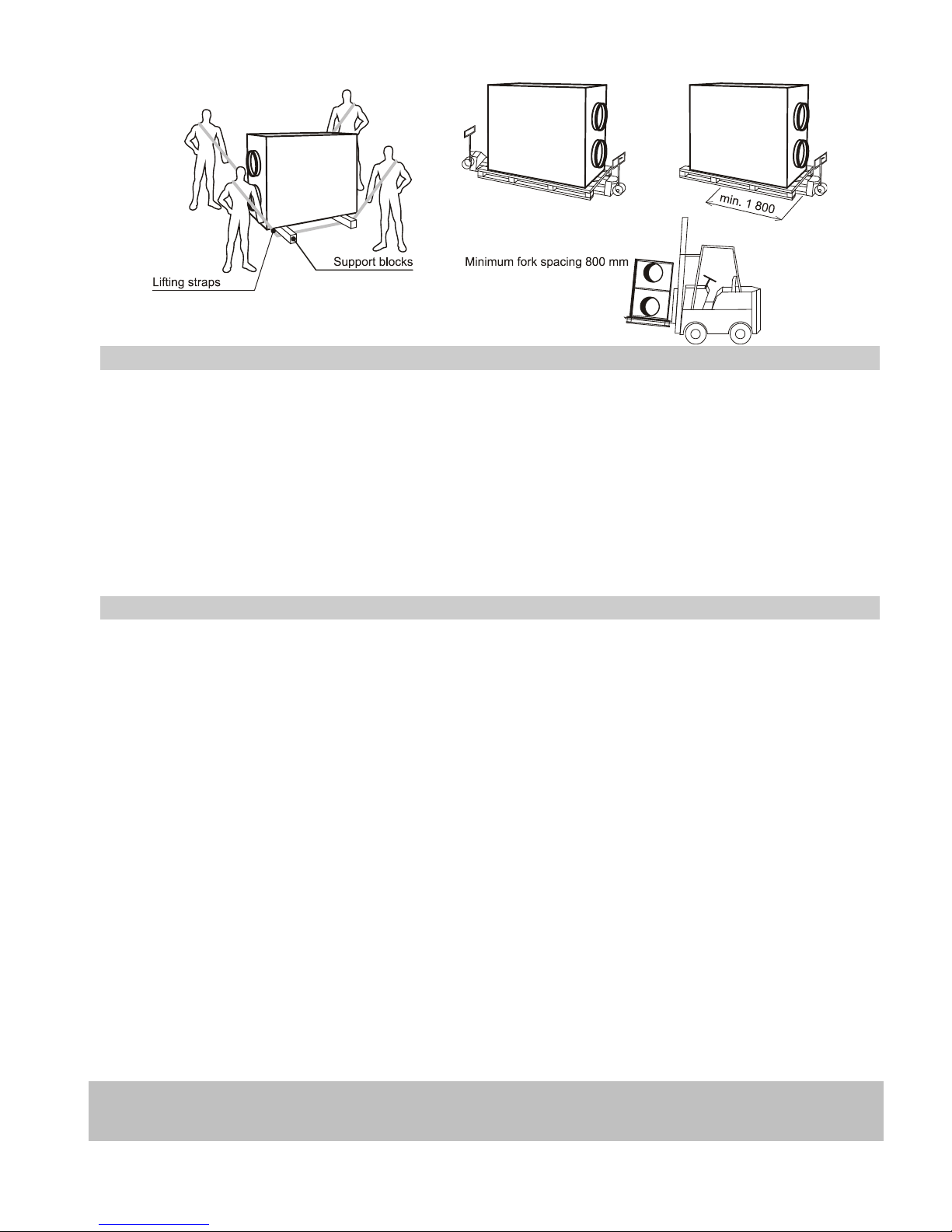

4. Description ...................................................................................................................................................................................5

4.1 General .........................................................................................................................................................................................5

4.2 Intended use .................................................................................................................................................................................5

5. Installation....................................................................................................................................................................................5

5.1 Safety instructions.........................................................................................................................................................................5

5.2 Hygienic instructions for the appliance as per VDI 6022 ...............................................................................................................5

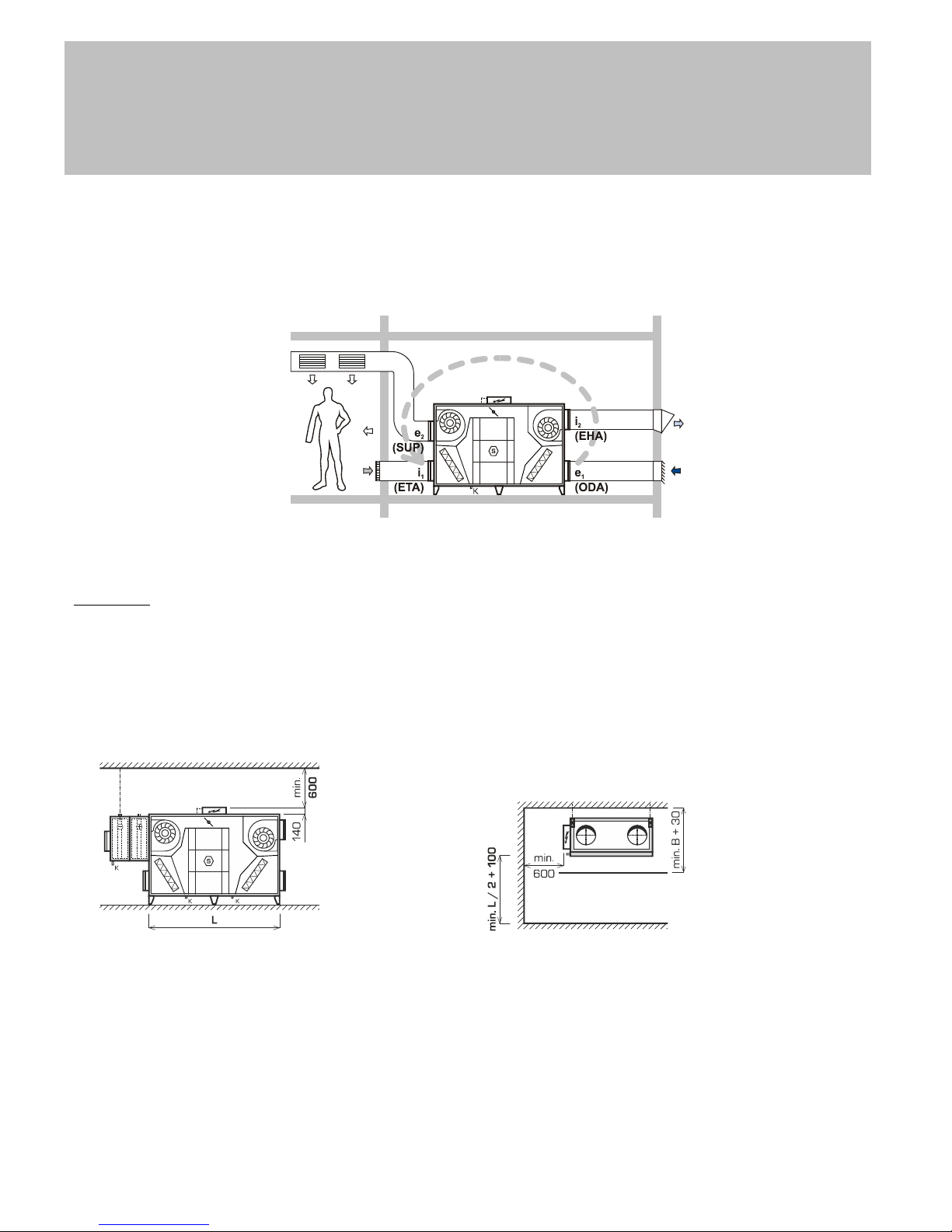

5.3 Identification of ports, connecting the HVAC duct .........................................................................................................................6

5.4 Installation steps ...........................................................................................................................................................................6

5.5 Adjusting the unit - turning ports e2 (SUP) / i2 (EHA)....................................................................................................................7

5.6 Connecting the condensate drain pipe ..........................................................................................................................................7

5.7 Classification of air filters...............................................................................................................................................................8

5.8 Installing air filters..........................................................................................................................................................................8

5.9 Installation, connecting and filling of liquid manometers (optional accessory)...............................................................................9

5.10 Installation and connecting of the hot water air heater (optional accessory) .............................................................................10

5.11 Installation and connecting of the control set of the hot water air heater (optional accessory) ..................................................10

5.12 Installation and connecting of shut-off dampers e1, i1 (optional accessory) .............................................................................10

5.13 Installation of flexible flanges (optional accessory) ...................................................................................................................10

5.14 Installation and connecting of the water chiller to the cool source (optional accessory)............................................................10

5.15 Installation and connection of the control manifold of the water-cooled chiller (optional accessory) .........................................11

5.16 Installation and connecting of the direct chiller (optional accessory).........................................................................................11

5.17 Installation and connecting of the electric heater / pre-heater EPO-V (optional accessory) ......................................................11

5.18 Installation and connecting of manostats to control constant flow rates and pressure (optional accessory) .............................11

6. Electrical connection, commissioning, description of controls....................................................................................................11

7. Hygienic instructions for the appliance as per VDI 6022 ............................................................................................................12

7.1 General instructions ....................................................................................................................................................................12

7.2 Required qualifications of personnel as per the type of activity...................................................................................................12

8. Inspecting the appliance ............................................................................................................................................................13

8.1 Overview of inspections and measures to ensure compliance with hygiene requirements .........................................................13

9. Cleaning and maintenance ........................................................................................................................................................14

9.1 General .......................................................................................................................................................................................14

9.2 Cleaning the cabinet....................................................................................................................................................................14

9.3 Air filters, replacing filter cassettes ..............................................................................................................................................14

9.4 Cleaning heat exchangers (heater / chiller).................................................................................................................................15

9.5 Cleaning the plastic heat recovery exchanger.............................................................................................................................15

9.6 Draining and inspection of the condensate collection tank (not included in delivery) ..................................................................15

9.7 Other minor maintenance............................................................................................................................................................15

10. Failures and troubleshooting......................................................................................................................................................15

11. Repairs, spare parts...................................................................................................................................................................16

12. Warranty.....................................................................................................................................................................................16

13. Visual appendix - manuals .........................................................................................................................................................17

13.1 Connecting the condensate drain line .......................................................................................................................................17

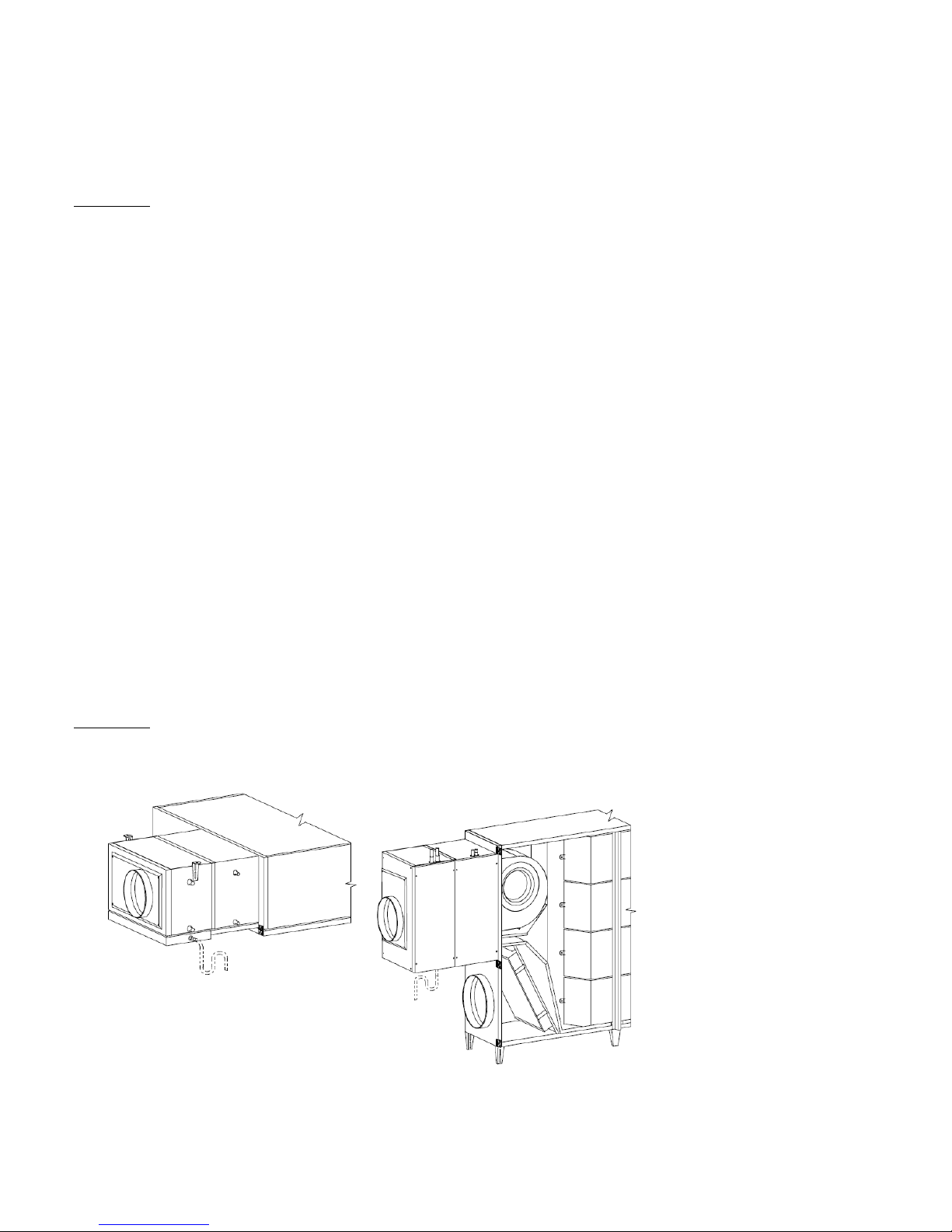

13.2 Rotating the fan.........................................................................................................................................................................18

13.3 Fitting the filters.........................................................................................................................................................................19