1. Check Product

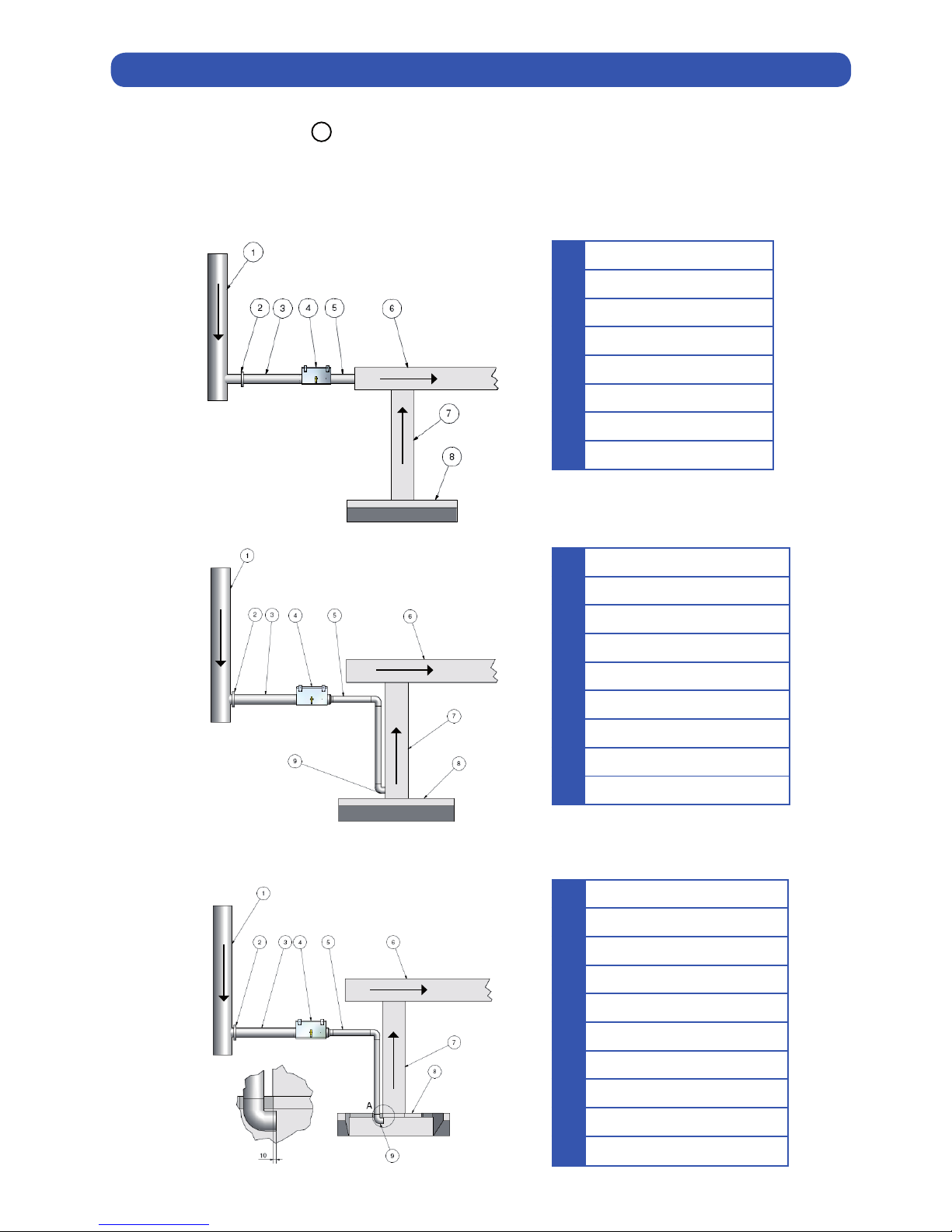

2. System Overview

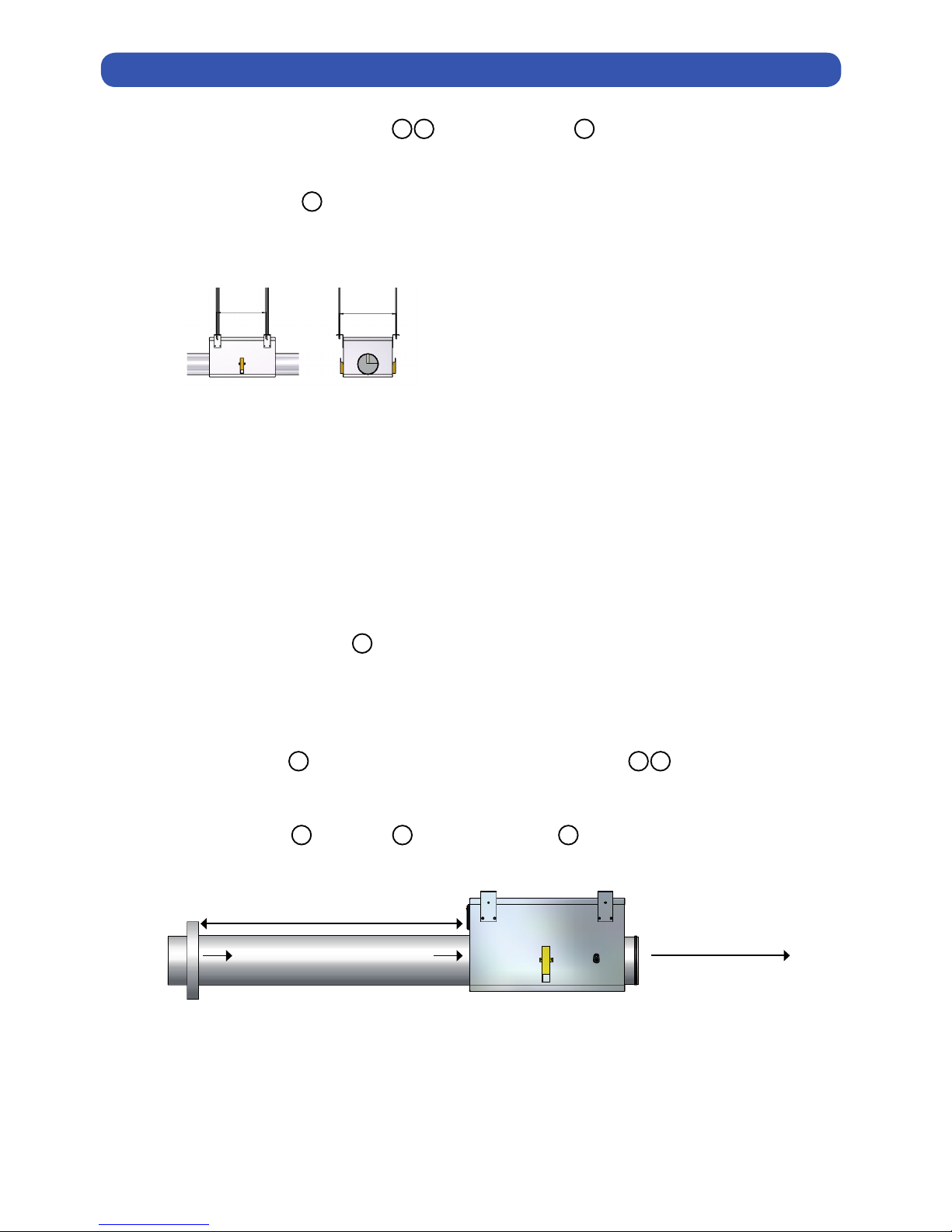

3. Installation Guidelines

4. Electrical connection and settings

5. System Test

6. Service and Maintenance

7. Technical Specication

8. Airmaid® Warranty Application

Check that the shipment consists of the components below and that there are no visible damages. Any discrepancy must

always be reported to the distributor or manufacturer. Read through the complete guide before starting the installation.

1 x AirMaid® Ozone Generator 1 x AirMaid® Alarm Panel

CONTENT

1 CHECK PRODUCT

LIMITED WARRANTY FOR INTERZON EQUIPMENT

This warranty is subject to the following conditions.

To validate this warranty, the warranty application for the product must be mailed to Interzon within ten (10)

days after installation.

A new product is warranted to be free from defects and/or workmanship for a period of 2 years from the date of

the original installation.

A spare part is warranted to be free from defects and/or workmanship for a period of ninety (90) days from the

date of the original installation.

The warranty for new equipment covers the repair or replacement of the defective part and includes labor

charges according the recommended hours by Interzon and maximum kilometer charges of 300 km round trip.

The warranty for spare parts covers only the repair or replacement of the defective part and does not include any

labor charges for the removal and installation of any parts, travel or other expenses incidental to the repair or

replacement of a part.

Any claim must be presented to either Interzon or the distributor from whom the product was purchased. No

allowance will be granted for repairs made by anyone else without Interzon written consent. If damage occurs

during shipping, notify the sender at once so that a claim can be led.

The above limited warranty does not apply to damage resulting from accident, alteration, misuse or if the serial

number is removed or defaced.

2

This guide describes a typical installation in a commercial kitchen exhaust duct. The product can also be used

in other applications as long as the specic requirements according to the guide are fullled.

The device may not be used by children or by persons with diminished physical, sensory or mental capacity

or lack of experience and knowledge unless supervised or having received instruction. Supervise children to

ensure that they do not play with the device.