MB

3

WARNINGS AND SAFETY NOTICES

General Information

The device may not be used by children or by persons with diminished physical, sensory or mental

capacity or lack of experience and knowledge unless supervised or having received instruction.

Supervise children to ensure that they do not play with the device.

1. This manual contains important information about instructions and safety concerning AirMaid® ozone

generator (hereinafter referred to as the generator). Read this manual carefully before installation,

commissioning or performing service and maintenance on the generator.

2. The generator is intended only for ozone treatment of air in accordance with the instructions in this

manual.

3. The generator uses high voltage to create an electric discharge which generates ozone (O). Ozone sig-

nificantly reduces odours. Absolent CKV AB disclaims any liability if the product is not used according

to the manufacturer’s instructions in this manual.

4. Never clean the generator with chemical cleaning agents. Water or liquid shall not be sprayed onto or

inside the generator. The cleaning of the ozone cell (CGC) shall be done while following the instructions

in this manual.

Troubleshooting and Service Information

1. The user can troubleshoot the generator by following the steps and procedures described in the

System Test section in this manual. If the user needs to have the generator serviced, the user shall

contact the closest authorised service partner or Absolent CKV’s technical support.

2. All repairs on the generator must be performed by a service partner authorised by Absolent CKV AB.

Use a ladder or a stable work platform when installing or servicing the generator if the installation or

service must be done at a height.

The power supply to the generator must be cut off before any service or maintenance.

Make sure that all parts have been installed before you turn on the generator again.

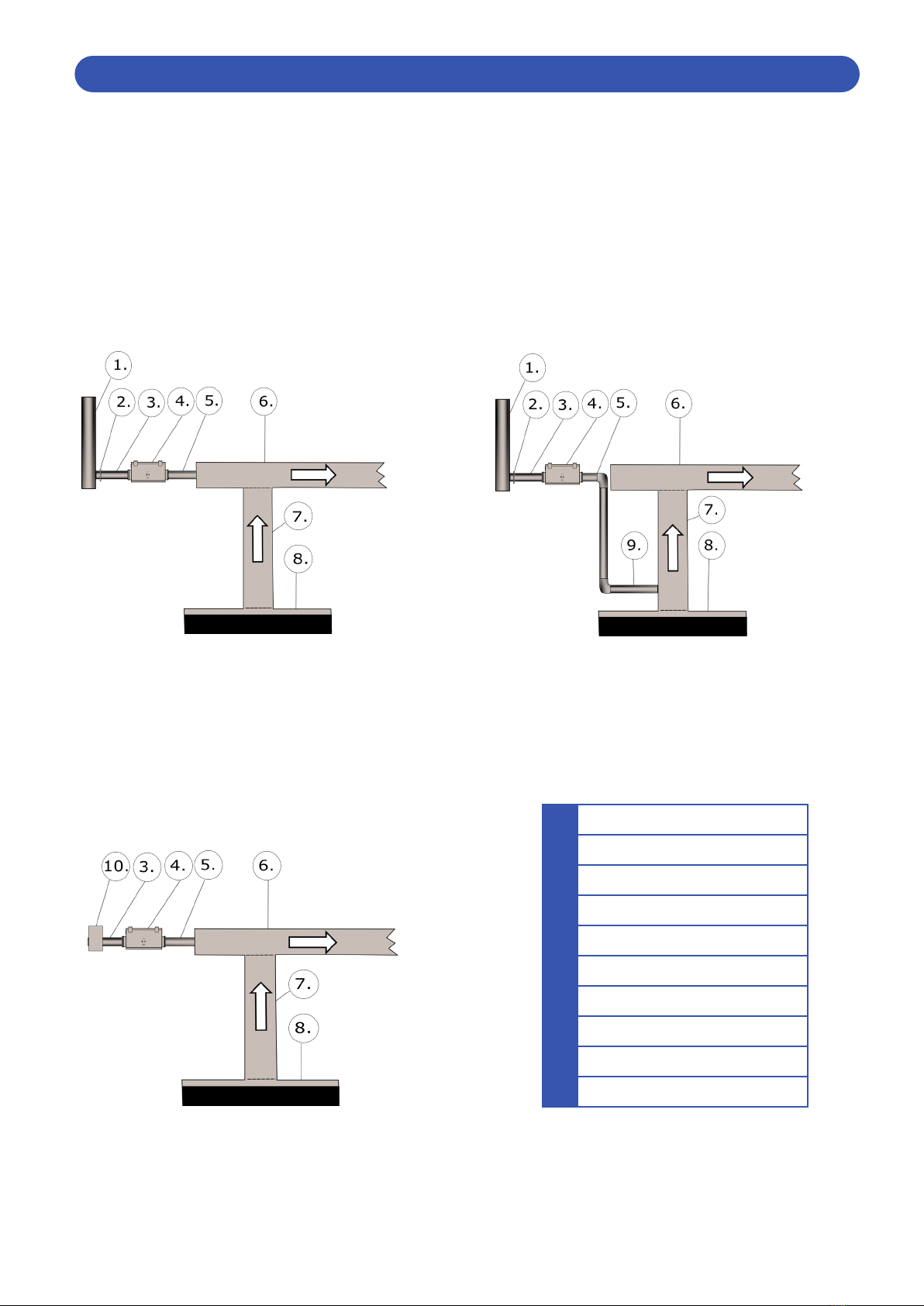

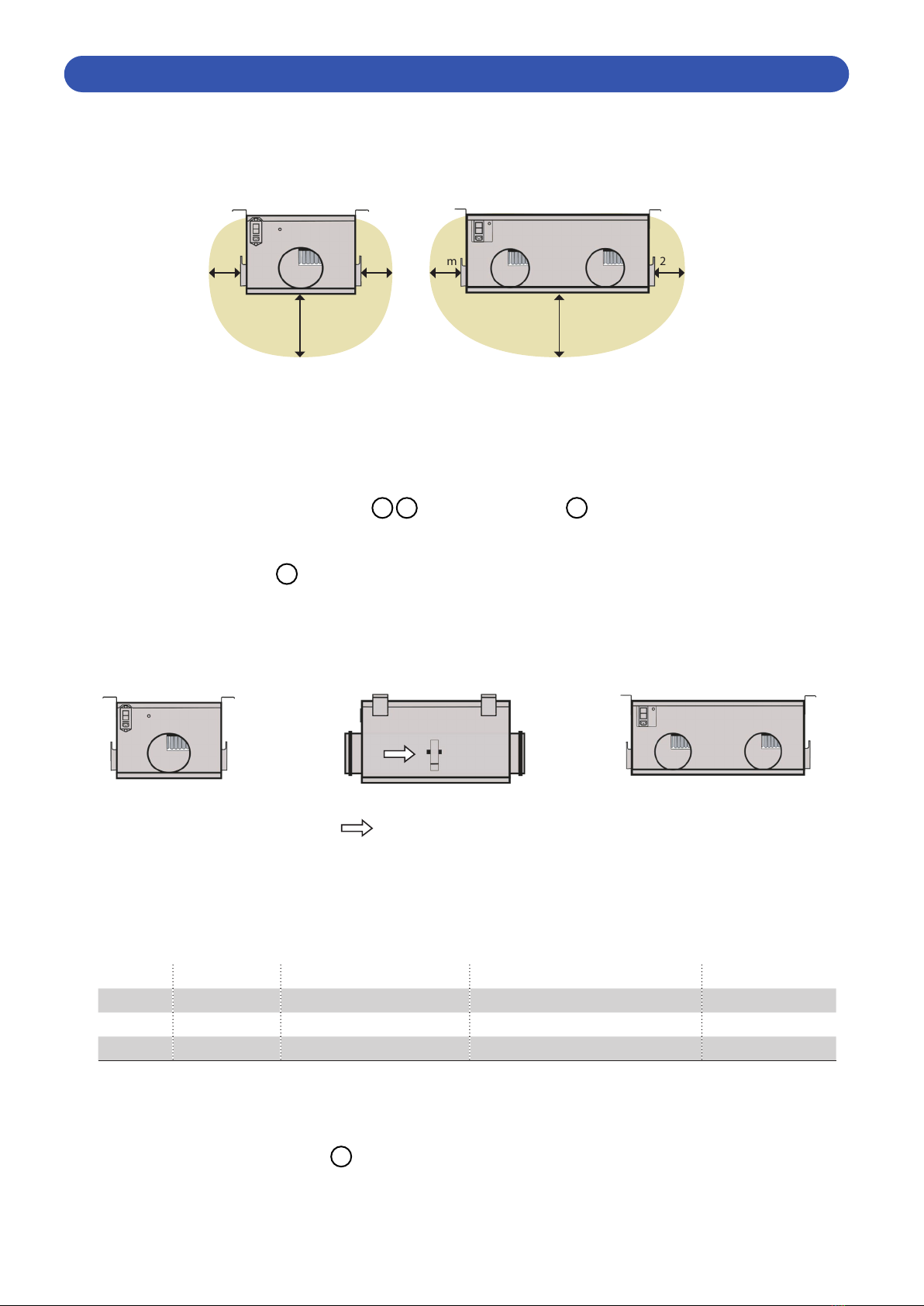

This user manual describes a typical AirMaid® 5000V/10000V/20000V/30000V ozone generator

installation. The installation can vary depending on local rules and regulations relating to building

materials, ventilation systems or the layout of the building/room. Deviations are possible but always

consult the manufacturer before such installation.

The generator produces ozone. If the generator is used by persons who have not read this manual,

there is a risk of injury such as eye or lung irritation. Always follow local regulations and the

recommendations of government organisations that inspect the regulations or the work environment.

This guide describes a typical installation in a commercial kitchen exhaust duct. The product can also be used

in other applications as long as the specific requirements according to the guide are fulfilled.

The device may not be used by children or by persons with diminished physical, sensory or mental capacity

or lack of experience and knowledge unless supervised or having received instruction. Supervise children to

ensure that they do not play with the device.