441-622-099 Type 595XP Page 3

1.1 Pre-Installation Requirements

1.1.1 Environment: Suitable for installation in the following locations:

Intrinsically safe operation in hazardous locations outdoors (NEMA 4X, CSA. ENC. 4 & IP65)

Explosion Proof Installation in hazardous locations outdoors (NEMA 4X, CSA. ENC. 4 & IP65)

See section 1.5, 1.6 and 1.7 for Factory Mutual (FM), Canadian Standards (CSA) and ATEX

approvals.

The I/P transducer enclosure contains aluminum and is considered to constitute a potential

risk of ignition by impact or friction. Care must be taken into account during installation

to prevent impact or friction.

All wiring must be made to all local and national codes appropriate to the area of

installation.

1.1.2 Electrical Input: 4-20 mA dc current source. It is recommended that shielded cable be used and that the

shield be grounded to unit and earth ground. See Figure 1 on page 4 for location of ground screw.

1.1.3 Air supply: Clean, dry, oil free instrument air filtered to 40 micron.

Clean all pipe lines to remove dirt and scale prior to installation. Failures attributable to

instrument air supply contamination are not covered by the warranty.

1.1.4 ATEX Specific Conditions of Use

The user shall permanently mark the protection type chosen by adding a tick mark in the appropriate

box that corresponds to the type of hazardous area installation (i.e. Ex db, Ex tb, Ex ia, Ex nAnL or

Ex nL). See figure 2.

Once the type of protection has been marked, it shall not be changed.

The flameproof joints of the equipment are not intended to be repaired.

Consult the manufacturer if repair of the flameproof joints is necessary.

Refer to the manufacturer’s instructions to reduce the potential of an electrostatic charging hazard

due to impact or friction on the equipment enclosure.

1.2 Mounting

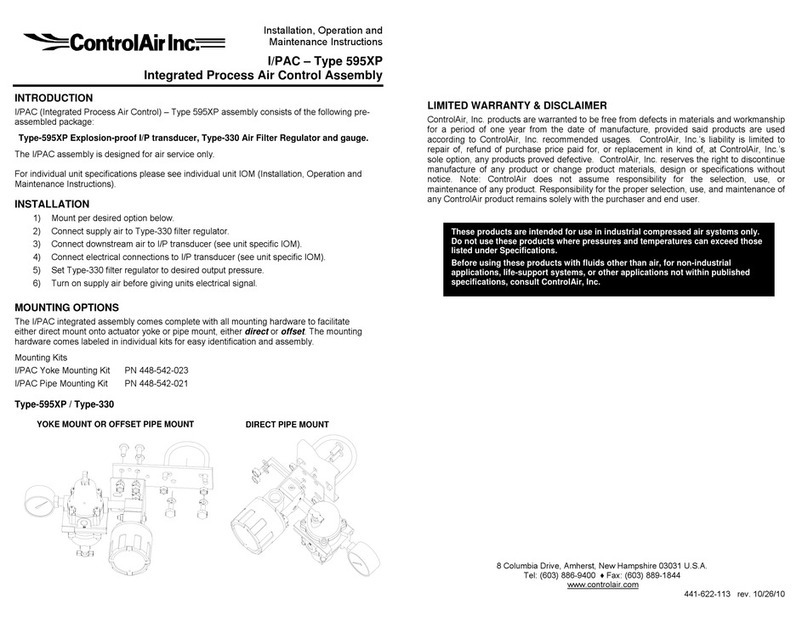

1.2.1 The Type 595XP has been designed to mount inline, to a standard valve yoke (bracket included with

unit), or to a 2” (5.1 cm) pipe (optional mounting kit 448-542-016 required).

1.3 Pneumatic Connections

1.3.1 Clean all pipe lines to remove dirt and scale prior to installation.

1.3.2 Supply air must be filtered to 40 microns and free of moisture and lubricants.

1.4 Electrical Connections

1.4.1 The Type 595XP is supplied with a 1/2" NPT electrical conduit connection as standard and “K2” option,

M20 x 1.5 for ATEX “K” option (see Figure 1).

1.4.2 A two (2) position terminal block that is wire ready is supplied for 22-12 AWG wire. Wire should be

stripped approximately 1/4" before insertion. The terminals are labeled “+” and “-“ on the terminal board

(see Figure 1).

1.4.3 It is recommended that shielded cable be used and that the shield be grounded at the unit (ground screw

provided) and to earth ground.

Observe polarity. Reverse polarity will not damage the unit, but unit will not operate.

Conduit should be connected to prevent condensation from collecting in the unit.

1. INSTALLATION AND APPROVALS

WARNING

NOTE

DANGER

CAUTION