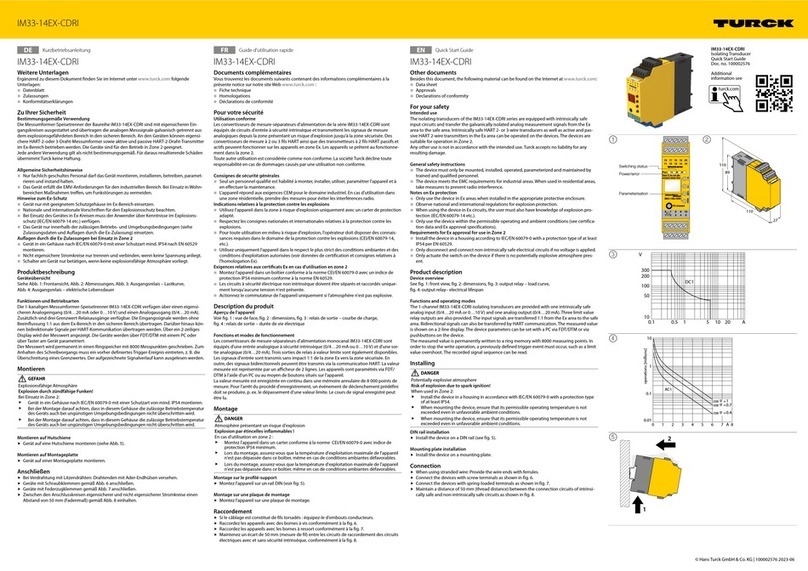

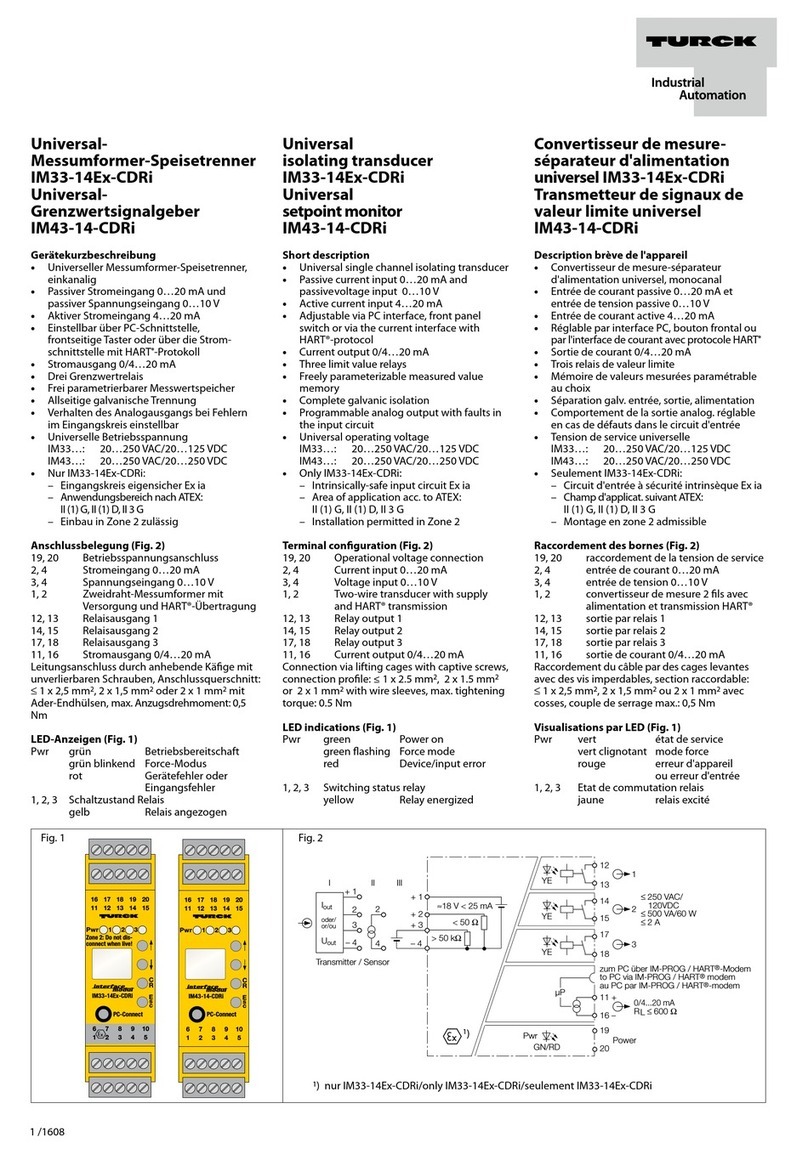

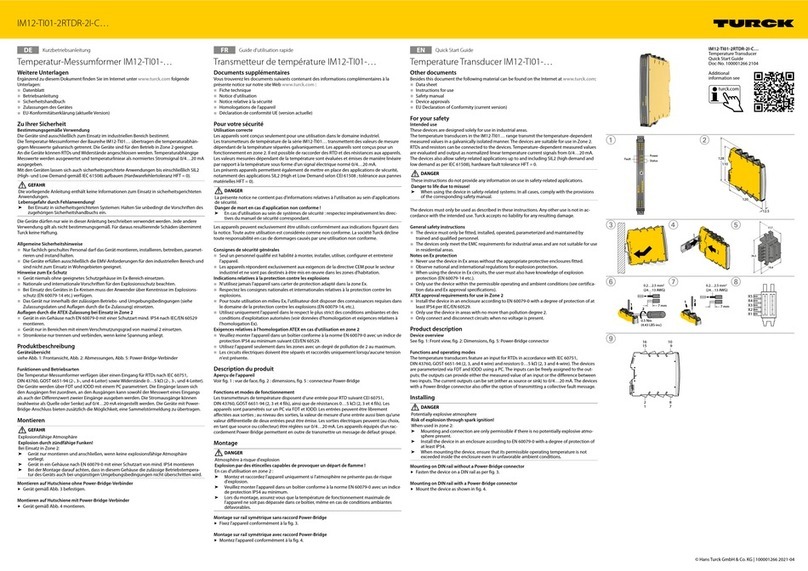

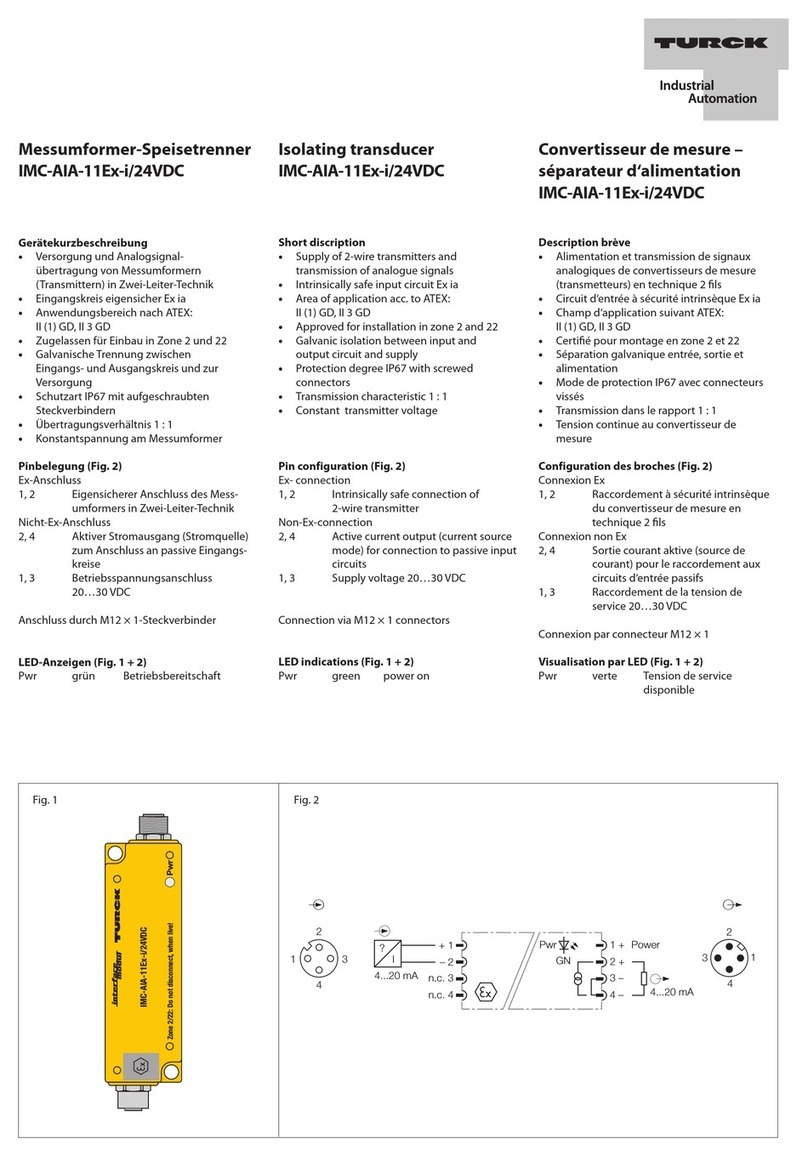

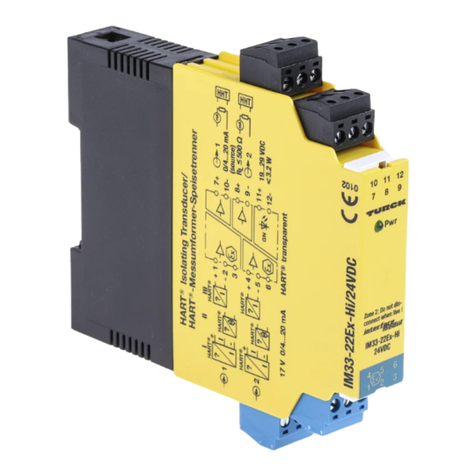

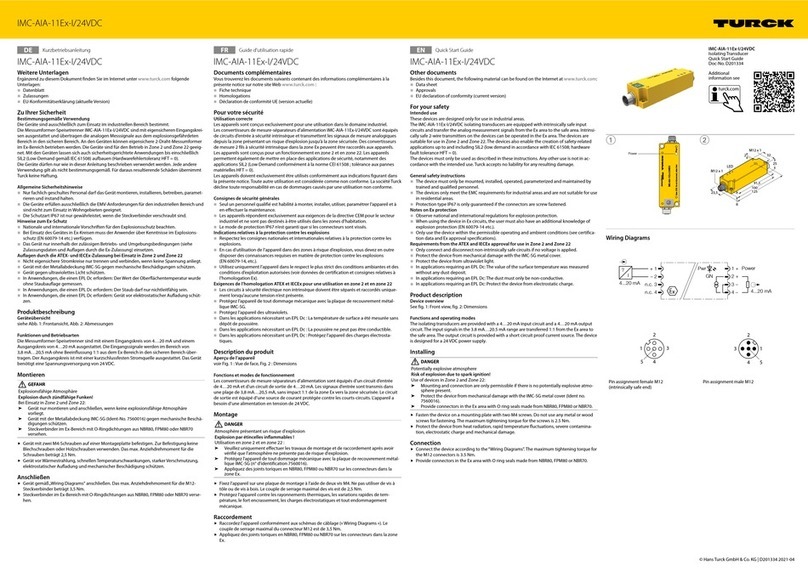

IME-AIA-11Ex-Hi/24VDC

D201247 0908 *D201247ßß0908*

EC-Type examination certificate

0102

No. ..........TÜV 08 ATEX 554801 / TÜV 08 ATEX 554909 X /IECEx TUN 08.0014 X

U0.............................................................................................................. ≤23 V

I0........................................................................................................ ≤64,5 mA

P0........................................................................................................ ≤799 mW

Characteristic curve............................................................................... trapezoidal

Li/Ci................................................................................................negligible/22 nF

L0/C0

– [Ex ia] IIB.........................................................4,9/1/0.2 mH / 358/418/718 nF

– Ex nL IIC................................................................................ 0,2 mH / 188 nF

– Ex nL IIB..................................................................... 20/10 mH / 768/958 nF

Tamb .....................................................................................................-25...+70 °C

II (1) G [Ex ia] IIB / II (1) D [Ex iaD]

II 3 G Ex nA [nL] IIC/IIB T4

Konformitätserklärung Nr. 3263 M

Declaration of Conformity

Diese Konformitätserklärung entspricht der Europäischen Norm EN 45014 ”Allgemeine Kriterien für Konformitätserklärungen von

Anbietern”. Die Grundlage der Kriterien sind internationale Dokumente, insbesondere ISO/IEC Leitfaden 22, 1982: ”Information on

manufacturer’s declaration of conformity with standards or other technical specifications”.

This “Declaration of Conformity“ complies with the European Standard EN 45014 ”General criteria for a supplier’s declaration of

conformity”. These criteria are based on the relevant international documentation, particularly the ISO/IEC Guide 22, 1982:

”Information on the manufacturer’s declaration of conformity with standards or other technical specifications”.

Wir

/ We

HANS TURCK GMBH & CO KG

WITZLEBENSTR. 7, D - 45472 MÜLHEIM A.D. RUHR

erklären in alleiniger Verantwortung, dass die Produkte

declare under our sole responsibility that the products

Speisetrenner Typ IME-AIA-11Ex-Hi/24VDC

auf die sich die Erklärung bezieht, mit den folgenden Normen übereinstimmen

to which this declaration relates are in conformity with the following standards

EN 61326:2006

und wo anwendbar

and where applicable

EN 60079-0:2004 EN 60079-11:2007 EN 61241-11:2006 EN 60079-15:2005

Gemäß den Bestimmungen der Richtlinie

(falls zutreffend)

Following the provisions of Directive (if applicable)

EMV - Richtlinie

/ EMC Directive

2004 / 108 / EG 15. Dez. 2004

Richtlinie ATEX 100a

/ Directive ATEX 100a

94 / 9 / EG 23. März 1994

Weitere Normen

additional standards

Aussteller der EG-Baumusterbescheinigung:

TÜV NORD CERT GmbH

Langemarckstraße 20, 45141 Essen

Kenn-Nr. 0044, Registriernummer: TÜV 08 ATEX 554801 Kennzeichnung II (1) GD

Aussteller der ATEX Prüfbescheinigung:

Kenn-Nr. 0044, Registriernummer: TÜV 08 ATEX 554909 X Kennzeichnung II 3 G

Mülheim, den 28.10.2008

(i.V. W. Stoll)

Ort und Datum der Austellung /

Place and date of issue

Name und Unterschrift des Befugten /

Name and signature of authorized person

Internet: www.turck.com →www.turck.de →Download

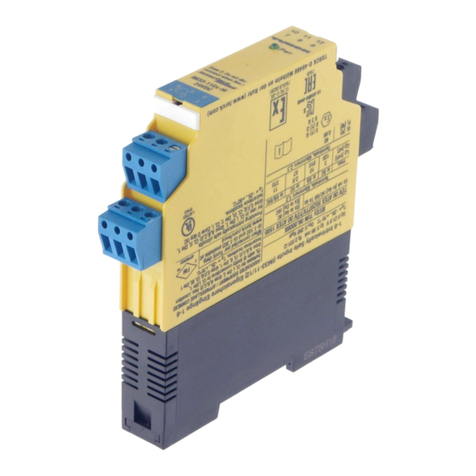

Important information on use of devices

with intrinsically safe circuits

This device is equipped with circuits featuring protection

type „intrinsic safety“ for explosion protection per

EN 60079-11 at terminals which are marked in blue.

The intrinsically safe circuits are approved by the au-

thorised bodies for use in those countries to which the

approval applies.

For correct usage in explosion hazardous areas

please observe and follow the national regulations and

directives strictly.

Non-intrinsically save circuits have to be installed accor-

ding to the national regulations.

Following please find some guidelines referring to the

frame-work directive of the European Union 94/9/EC

(ATEX).

This device is classified as an associated apparatus which

is equipped with intrinsically safe and non-intrinsically

safe circuits. Therefore it may only be installed in the non-

explosion hazardous area in dry clean and well monitored

locations.

If a declaration of conformity or declaration of the manu-

facturer as a category 3 device exists, the device may be

installed in zone 2 and zone 22. Special instructions for

safe operation must be observed. .

It is permitted to connect intrinsically safe equipment

to the intrinsically safe connections of this device.

All electrical equipment must comply with the regulations

applying to use in the respective zone of the explosion

hazardous area.

If the intrinsically safe circuits lead into explosion hazar-

dous areas subject to dust hazards, i.e. zones 0 and 1 or

20 and 21, it must be ensured that the devices which are

to be connected to these circuits, meet the requirements

of category 1GD or 2GD and feature an according

approval.

When interconnecting devices i.e. connecting intrinsically

save circuits to other circuits, it is required to keep and

provide a proof of intrinsic safety (EN 60079-14, chap.

12.2.5).

Once that intrinsically safe circuits have been connected to

the non-intrinsically safe circuit, it is not permitted to use

the device subsequently as intrinsically safe equipment.

The governing regulations cover installation of intrinsically

safe circuits, mounting to external connections, cable

characteristics and cable installation. Cables and terminals

with intrinsically safe circuits must be marked (use light

blue for coloured marking) and separated from non-

intrinsically safe circuits or feature appropriate isolation

(EN 60079-14).

Those areas of the contacts related to the intrinsically safe

circuits have to be indicated in light blue on the top side of

the device such that mismach is not possible.

Appropriate cables have to be used for wiring.

If field wireable connectors should be used together with

intrinsically save circuits, the connector ends have to be

protected with wire end sleeves (plus collar).

Please observe the specified clearances between the

intrinsically safe connections of this device and the earthed

components and connections of other devices.

The approval expires if the device is repaired, modified or

opened by a person other than the manufacturer or an ex-

pert, unless the device-specific instruction manual explicitly

permits such interventions.

Visible damages of the device’s housing (e. g. black-brown

discolouration due to heat accumulation, perforation or

deformation) indicate a serious error and the device must

be turned off immediately. When using associated appara-

tus it is required to check the connected intrinsically safe

equipment too. This inspection may only be carried out by

an expert or the manufacturer.

Operation of the devices is only permissible in accordance

with the allowed specifications which are printed on the

housing and/or listed in the documentation.

Prior to initial set-up or after every alteration of the

interconnection assembly it must be assured that the

relevant regulations, directives and framework conditions

are observed, that operation is error-free and that all safety

regulations are fulfilled. Mounting and connection of the

device may only be carried out by qualified and trained

staff familiar with the relevant national and international

regulations of explosion protection.

The most important data from the EC type examinati-

on certificate are listed on the right side. All valid national

and international approvals covering Turck devices are

obtainable via the Internet (www.turck.com). Further infor-

mation on explosion protection is available on request.

Subject to change without notice •© Hans Turck GmbH & Co. KG 2008

Hans

T

urck

GmbH

&

Co.

KG

•Witzlebenstraße 7 •45472 Mülheim/Ruhr •Germany •Tel. +49 (0) 208/4952-0 •Fax +49 (0) 208/4952-264 •[email protected] •www.turck.comì