3

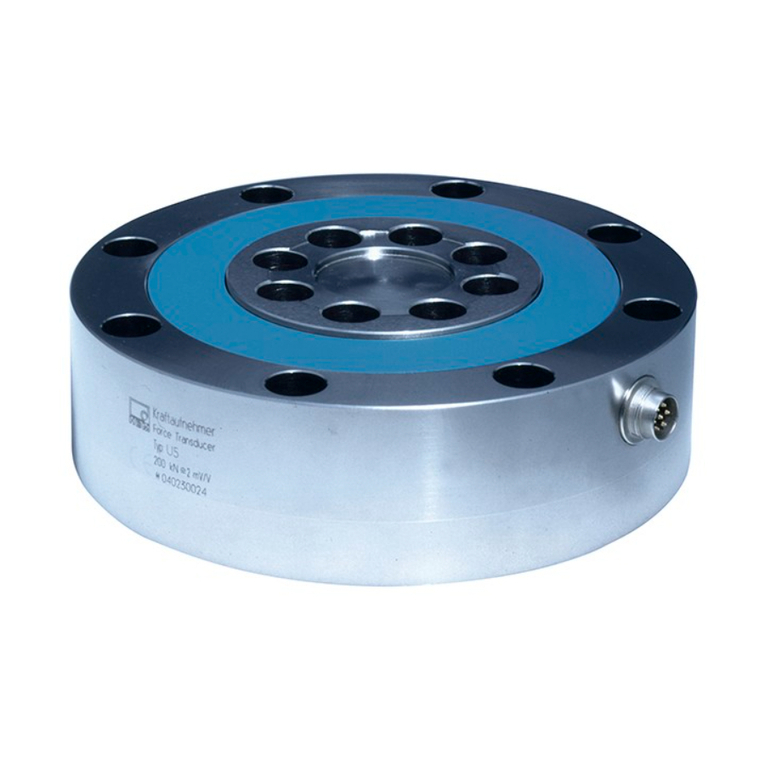

U5

HBM 29.6.00

Contents Page

Safety instructions 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Scope of supply 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Applicationinformation 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Structure and mode of operation 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Measuring element 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Housing 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Conditionson site 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Ambient temperature 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Moisture 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Deposits 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Mechanicalinstallation 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Important measures for installation 11. . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 General installation guidelines 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Installation for tensile loading/compressive loading 13. . . . . . . . . . . . .

5.3.1 Installation without adapter 13. . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 Installation with tensile force adapter and knuckle eye 14. . . .

5.3.3 Installation with two knuckle eyes 15. . . . . . . . . . . . . . . . . . . . . .

5.3.4 Installation with compressive force adapter 17. . . . . . . . . . . . .

6 Electrical connection 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Order code 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Instructions for cabling 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Specifications(VDI/VDE2638) 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Dimensions Standard Version 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Dimensions mounting accessories for measurement

of compressive/tensile torce 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Knuckle eyes/thrust piece 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Declaration of conformity 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:

[email protected]SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:

[email protected]