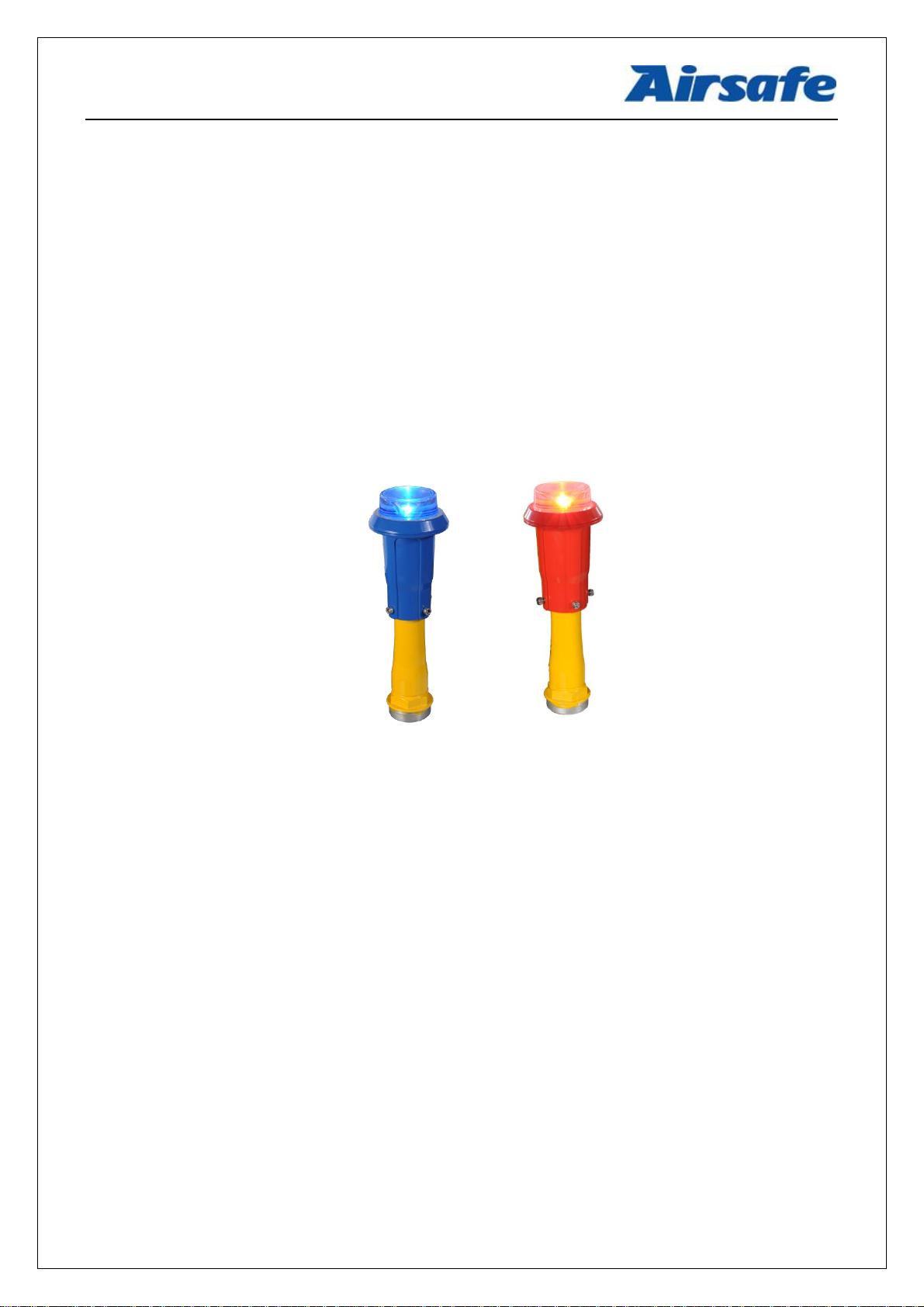

Advanced Airport Lighting System

Table of Content

1.0 Foreword...............................................................................................................................- 1 -

1.1 Illustrations and Meanings.............................................................................................- 2 -

1.2 Safety Rules and Notices ...............................................................................................- 3 -

1.3 Quality Assurance and Responsibility............................................................................- 4 -

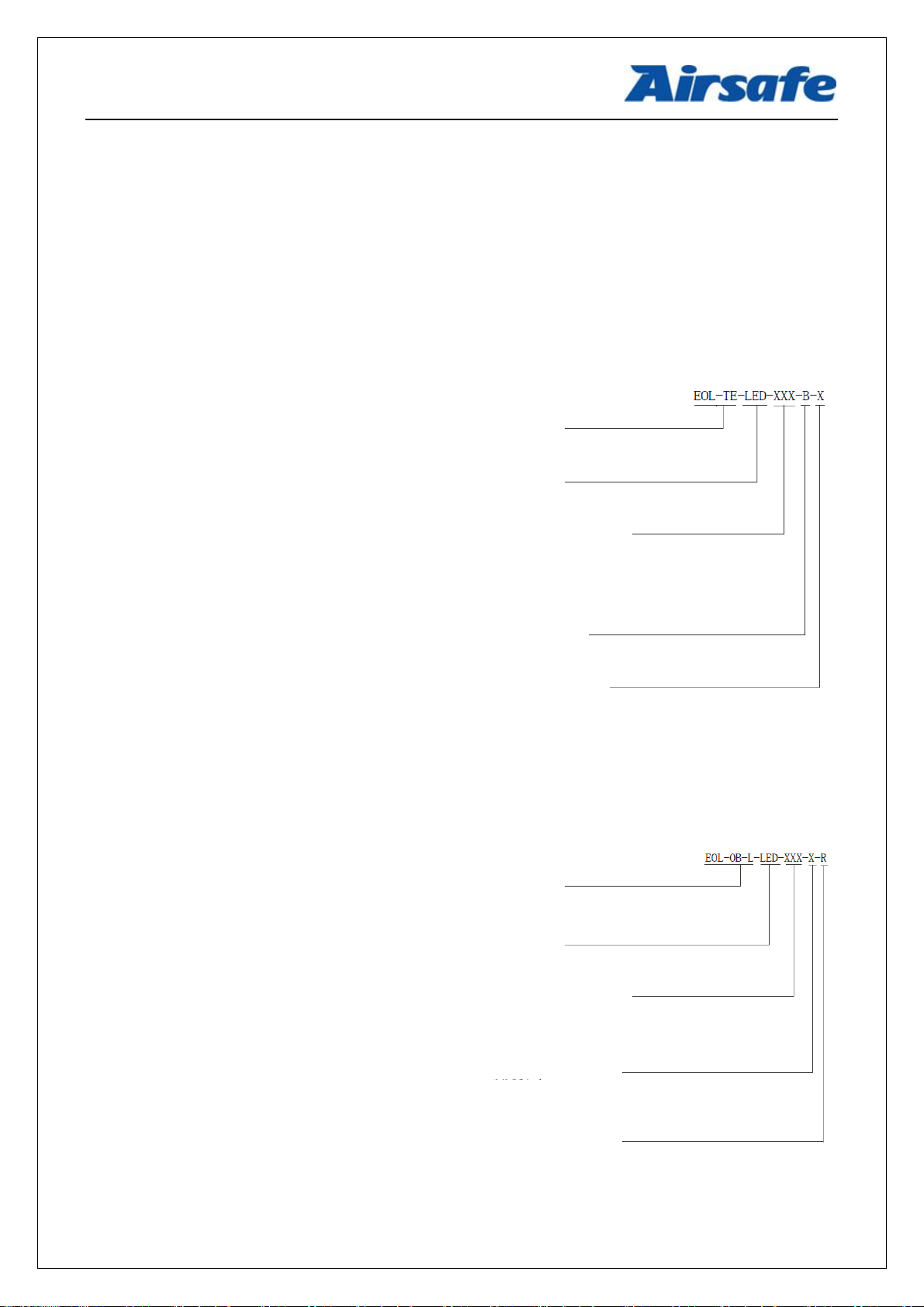

2.0 Introduction to Lighting fixtures............................................................................................- 5 -

2.1 Technical Specifications ................................................................................................- 6 -

2.2 Application Environment...............................................................................................- 7 -

2.3 Application Scope..........................................................................................................- 7 -

2.4 Technical Parameters.....................................................................................................- 7 -

2.5 Technical Features.........................................................................................................- 8 -

2.6 Structure........................................................................................................................- 9 -

2.7 Fault Detection or Lamp Bypass Functions..................................................................- 10 -

3.0 Installation ..........................................................................................................................- 11 -

3.1 Installation Tools .........................................................................................................- 12 -

3.2 Screw and Torsion .......................................................................................................- 12 -

3.3 Installation Method I: Installation of Flange Supporting Pavement ..............................- 13 -

3.6 Level Adjustment of Lighting Fixtures.........................................................................- 16 -

4.0 Operation and Control.........................................................................................................- 17 -

4.1 6.6ALighting Fixture Wiring Diagram ........................................................................- 17 -

4.2 Light Intensity Control of 6.6A Lighting Fixtures ........................................................- 18 -

4.3 Work of Lighting Fixtures with Constant Power Supply...............................................- 18 -

5.0 Replacement of Components of Lighting Fixtures...............................................................- 19 -

5.1 How to Replace Inverse Taper Prism ...........................................................................- 20 -

5.2 How to Replace Lamp and Drive.................................................................................- 21 -

5.3 How to Replace Frangible Pole....................................................................................- 23 -

6.0 Maintenance of Lighting Fixtures........................................................................................- 24 -

6.1 Daily Maintenance.......................................................................................................- 24 -

6.2 Regular Spot Check and Troubleshooting ....................................................................- 25 -

7.0 List of Components and Ordering of Spare Articles and Accessories............................- 26 -

8.0 Packaging, Transportation and Storage................................................................................- 28 -

8.1 Packaging and Weight .................................................................................................- 28 -

8.2 Transportation Mode....................................................................................................- 28 -

8.3 Storage ........................................................................................................................- 28 -