2ITA-6 rev.02

TABLE OF CONTENTS

PRECAUTIONS ............................................................ 3

FEATURES .................................................................. 4

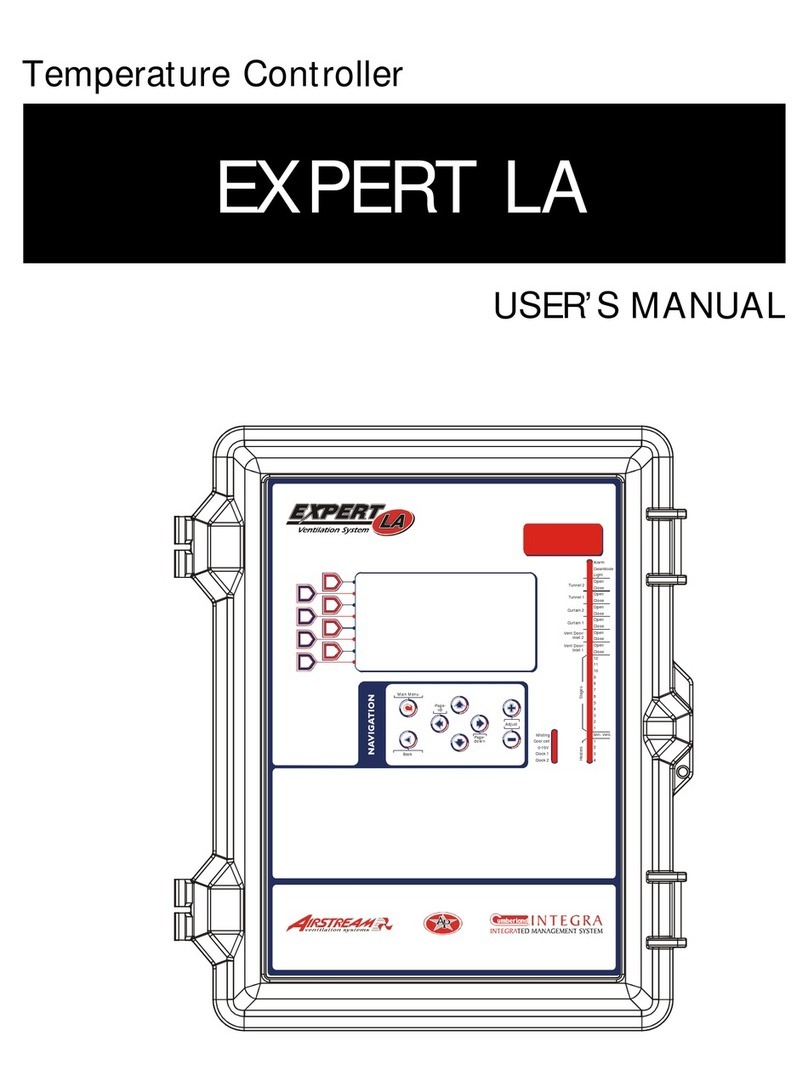

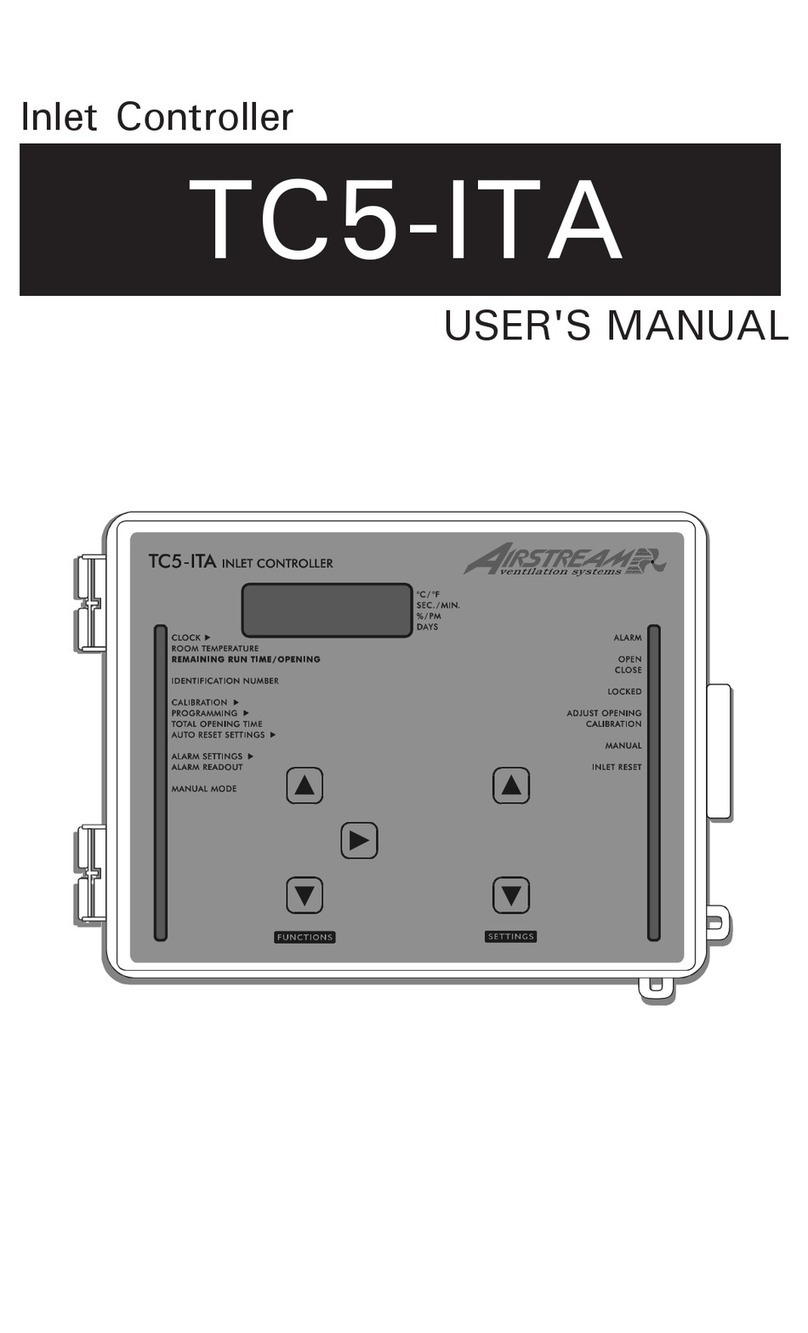

LOCATION OF THE CONTROLS..................................... 5

Status Leds ........................................................................ 5

Internal Switches ................................................................. 6

INSTALLATION PROCEDURE ........................................ 7

Equipment List .................................................................... 7

Mounting Instructions ........................................................... 7

Connections ........................................................................ 7

Identification Numbers & End of Line Jumpers ......................... 10

Comlink-2 Location & Connection ......................................... 12

Identifying Primary and Slave Units ....................................... 13

Seasonal Programs ............................................................. 14

Verify ITA-6 Operation (Manual Mode) .................................. 14

ITA-6 OPERATION ..................................................... 15

Basic Principle of Operation ................................................. 15

Calibration ........................................................................ 18

CONTROLLER FUNCTIONS ......................................... 20

Identification Number ......................................................... 20

Total Opening Time ............................................................ 21

Opening Display (Time / %) .................................................. 21

Programming Inlet Openings ................................................ 22

Remaining Run Time / Opening Menu ..................................... 23

Resetting the Inlet Position .................................................. 24

Temperature Alarms .......................................................... 27

Alarms - Readout ............................................................... 29

Room Temperature ............................................................ 30

TROUBLESHOOTING GUIDE ....................................... 31

TECHNICAL SPECIFICATIONS .................................... 32

INDEX ...................................................................... 33