TABLE OF CONTENTS

1. INTRODUCTION............................. 4

1.1. Precautions ................................... 4

1.2. Symbols of the Manual...................... 4

1.3. Features ....................................... 5

2. MOUNTING INSTRUCTIONS............ 7

2.1. Installing the Controller on the Wall .. 7

2.2. Connections .................................. 7

2.2.1. Sensor Inputs.................................. 7

2.2.2. Alarm Connection ............................ 7

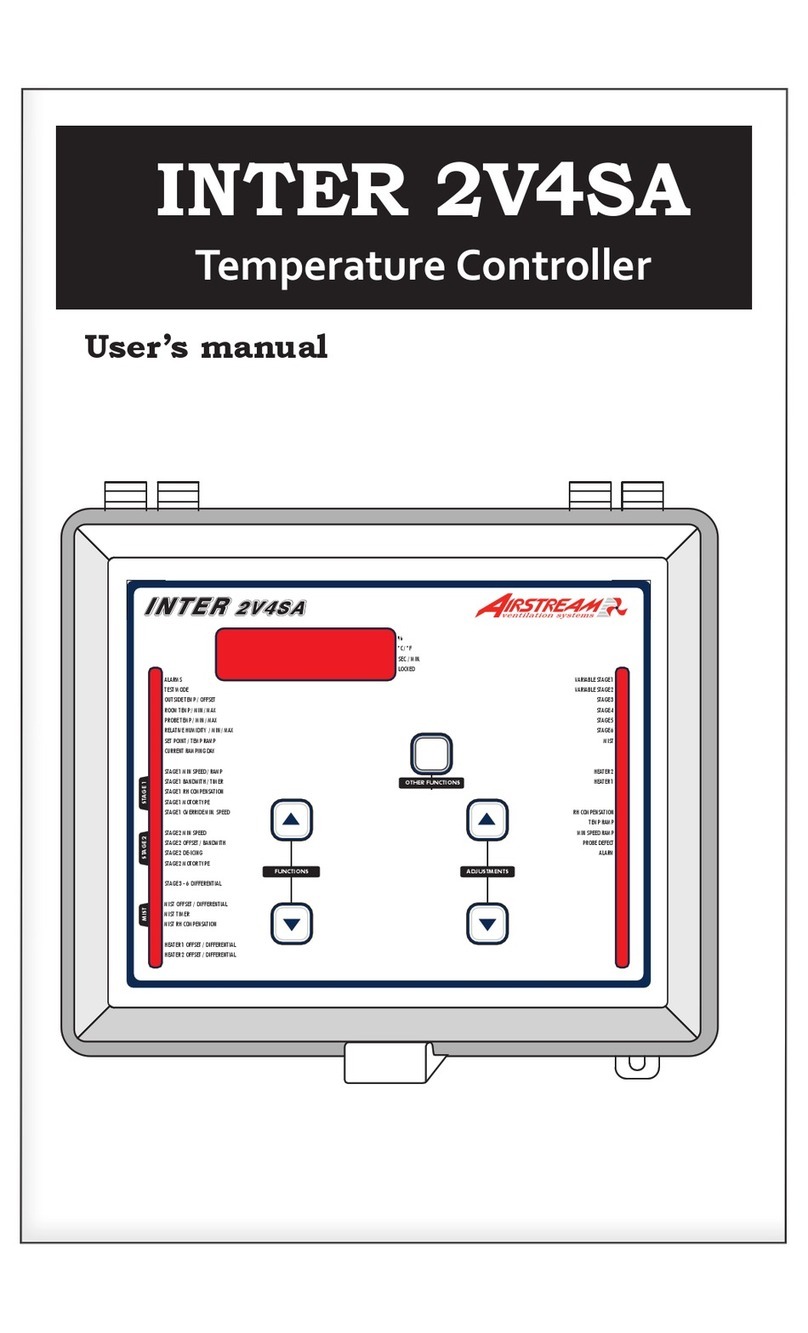

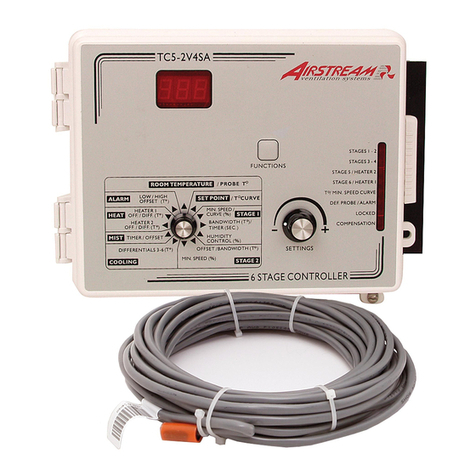

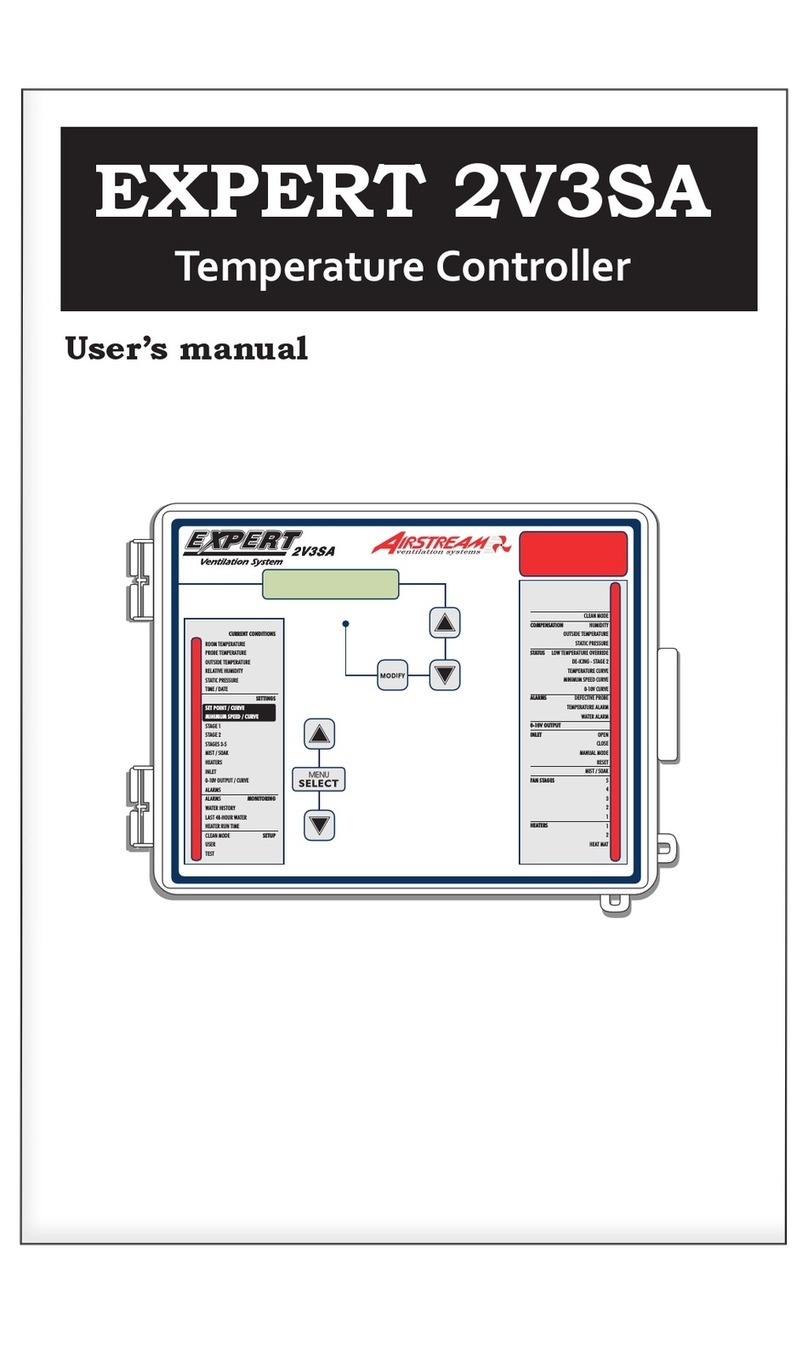

3. USER INTERFACE .......................... 8

3.1. Location of the Controls ................. 8

3.2. Parameter Adjustment .................... 8

4. INSTALLATION SETUP ................. 10

4.1. Time and Date............................. 10

4.2. Setting the Day Number................ 10

4.3. Selecting Type of Motor ............... 10

4.4. User Setup Menu ......................... 11

4.5. Clean Mode................................. 16

4.6. Test Mode .................................. 17

5. TEMPERATURE SET POINTS ......... 18

5.1. Set Point Settings ........................ 18

5.2. Set Point Curve ........................... 18

6. COOLING.................................... 20

6.1. Minimum Ventilation .................... 20

6.1.1. Principle of Operation ..................... 20

6.1.2. Timer Settings............................... 20

6.1.3. Stage 2 in Min Ventilation............... 21

6.1.4. Min Ventilation Curve..................... 22

6.2. Fan Stages.................................. 23

6.2.1. Principle of Operation ..................... 23

6.2.2. Fan Stage Start Temperature........... 24

6.2.3. Minimum Fan Speed....................... 24

6.2.4. Adjusting # of Degrees to Reach 100%

of Stages 1 & 2 ............................ 24

6.3. Outside Temperature Compensation ..

25

6.3.1. Compensation on Stage 1 Min Speed25

6.3.2. Compensation on the Number of De-

grees to Reach Full Speed of Stages 1

& 2.............................................. 25

6.4. Merging Fan Stages ..................... 27

6.4.1. Merging Fan Stages 1 & 2 .............. 27

6.4.2. Merging Stages 2 and 3 ................. 27

6.4.3. Nbr of Degrees to 100% of Stage 3. 28

6.5. De-icing Stage 2 Fans................... 28

6.6. 0-10V Fan Output........................ 29

7. MIST COOLING ........................... 31

8. SOAKING.................................... 32

9. RH COMPENSATION .................... 33

10. HEATERS.................................... 34

10.1. Regular Heating Stages................. 34

10.2. Zoned Heating ............................. 34

10.3. Heating Timers ............................ 34

10.4. Heater Settings............................ 35

10.5. 0-10V Heater .............................. 35

10.6. 0-10V Heat Mat .......................... 37

10.7. 0-10V Heating Curve.................... 38

11. AIR INLET & CHIMNEY DAMPERS . 39

11.1. Principle of Operation ................... 39

11.2. Inlet & Chimney Settings .............. 40

11.2.1. Actuator Reset .............................. 41

11.2.2. Manual Opening of the Actuators..... 43

11.3. Static Pressure Compensation on the

Inlet 44

12. MONITORING FUNCTIONS............ 46

12.1. Alarms........................................ 46

12.1.1. Managing the Alarms ..................... 46

12.1.2. Alarm Conditions ........................... 47

12.1.3. Alarm Settings .............................. 48

12.2. Water Consumption ..................... 49

12.2.1. History ......................................... 49

12.2.2. Water Consumption of the Last 48

Hours........................................... 49

12.3. Heater Run Time History ............... 50

13. CURRENT CONDITIONS................ 50

13.1. Current Room Temperature ........... 50

13.2. Probe Temperatures ..................... 51

13.3. Outside Temperature .................... 51

13.4. Current Humidity Level ................. 52

13.5. Current Pressure Level.................. 52

13.6. Current Speed of the Variable Fans 52

14. TECHNICAL SPECIFICATIONS ....... 53

15. MEMORY CARD .......................... 54

16. INSTALLATION REPORT ............... 55

3

EXPERT 2V2SA, rev. 10

EXPERT 2V2SA