4INTER2V4SA,rev.02

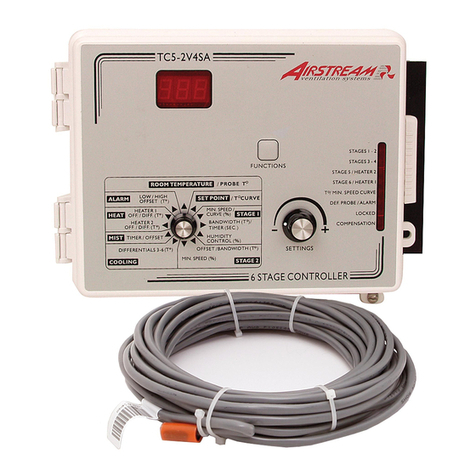

INTER2V4SA

1. Precautions

WARNING: Read and save these in-

structions!

Safety may be jeopardized if the equipment is

used in a manner not specified by the manu-

facturer. Carefully read and keep the following

instructions for future reference.

We strongly recommend installing supplemen-

tary natural ventilation as well as a backup

thermostat on at least one cooling stage.

Although fuses at the input and outputs of

the controller protect its circuits in case of

an overload or over-voltage, we recommend

installing an additional protection device on

the controller’s supply circuit.

The room temperature where the controller

is located must always remain between 32°F

and 104°F (0°C to 40°C). Indoor use only!

To avoid exposing the controller to harmful

gases or excessive humidity, it is preferable

to install it in a corridor.

If the equipment is used in a manner not

specified by the manufacturer, the protec-

tion provided by the equipment may be

impaired.

Do not spray water on the controller! In

order to clean the control, wipe it with a

damp cloth.

Before servicing or cleaning unit, switch

power off at service panel and lock the

switch disconnecting means to prevent

power from being switched accidentally.

When the service disconnecting means

cannot be locked, securely fasten a

prominent warning device, such as a

tag, to the service panel.

2. Features

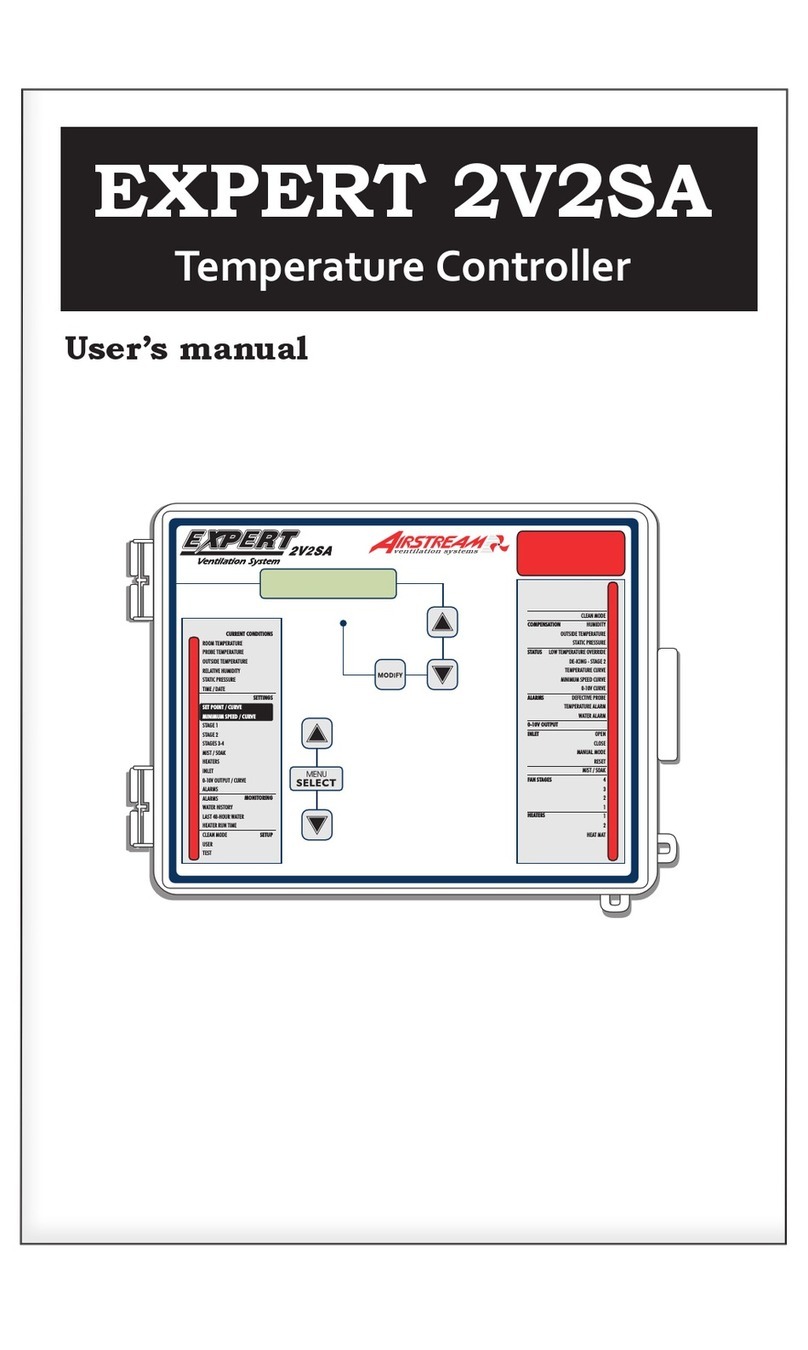

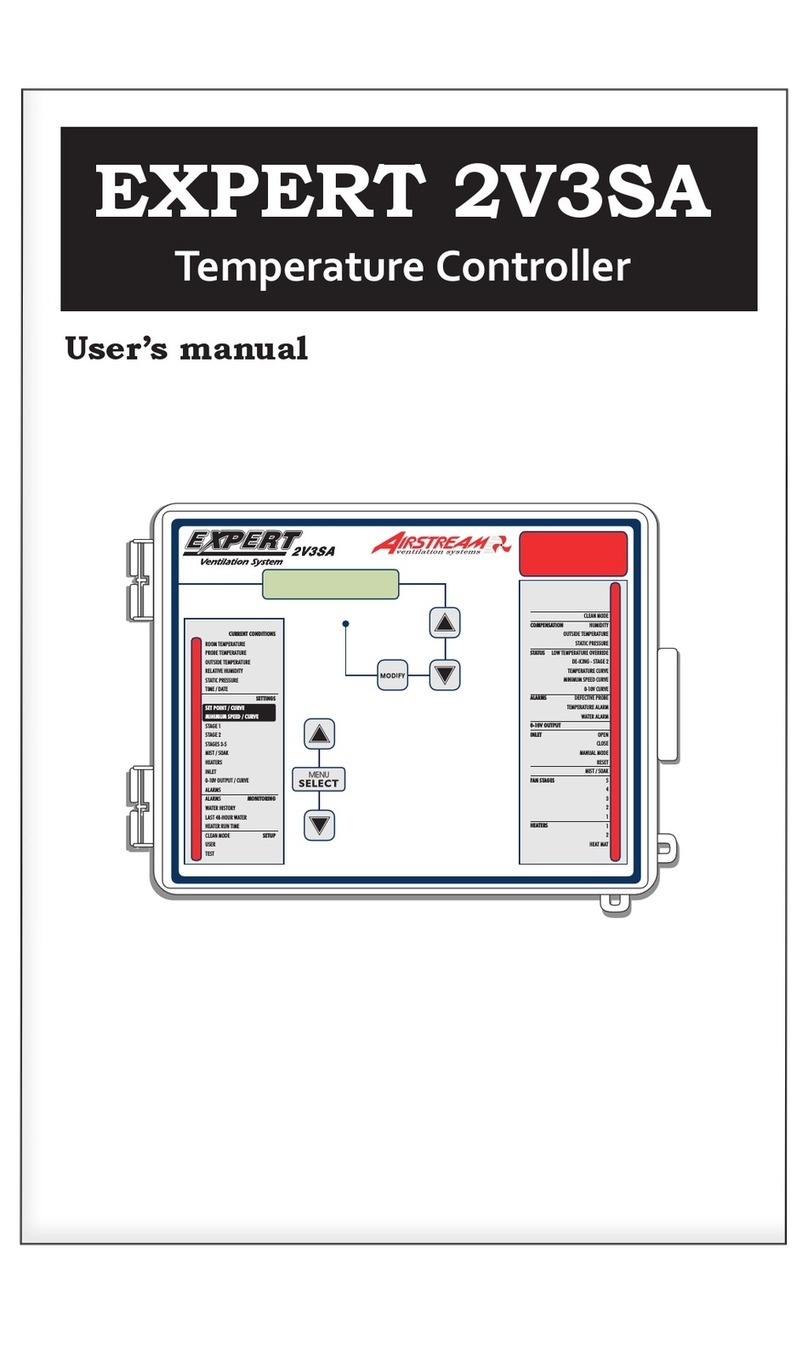

The INTER 2V4SA is an electronic device

used for environmental control in livestock

buildings. It allows the user to maintain a

specified target temperature by controlling

the operation of ventilation and heating equip-

ment. The controller can control two stages

of variable speed fans and two stages of

either constant-speed fans or heating units.

In addition, one of the constant-speed fan

stages can be configured as a mist cooling

stage.

Five-digitdisplay:

A five-digit display provides a high level

of accuracy, allowing the user to specify a

temperature to within one tenth of a degree

(in Fahrenheit or Celsius units).

Pilotlights:

Pilot lights indicating the state of outputs

allow the user to monitor the operation

of the system without having to enter the

building.

Minimumventilationcycles:

When ventilation is not required for cooling,

the first stage fans can be operated either

continuously or intermittently to reduce the

level of humidity and supply oxygen to the

room.

Rampingfunctions:

Ramping functions provide an automatic

adjustment of the set point and minimum

ventilation fan speed over a given period

of time.

Choiceof10motortypes:

The variation in motor speed resulting from a

change in voltage will depend on the make and

capacity of the motor. In order to achieve a high

degree of compatibility between controller and

motor, the user can choose from among ten

different motor types, thus ensuring that the

correct voltage is supplied.

Zonedorcascadingheaters

37

INTER2V4SA,rev.02

INTER2V4SA

i) These initial parameter settings will not be re-

tained in the controller's memory. Each new setting

will replace the preceding one.

ii) If the power supply is cut off, the last parameter

settings will be retained in memory until the power

is restored.

15. FactorySettings

PARAMETER FACTORY

SETTING

RANGE

OFVALUES

Temperature Set Point 25,0°C (77,0°F) -40,0 to 48,9°C

(-40,0 to 120,0°F)

Outside T° Alarm Offset 1,0°C (1,8°F) 0,3 to 20,0°C

(0,5 to 36,0°F)

Stage 1 Minimum Speed 40% 10 % to 100 %

Time On 0 seconds 0 to 900 seconds in increments of 15 sec.

Time Off 15 seconds

Bandwidth 1,0°C (1,8°F) 0,3 to 10,0°C

(0,5 to 18,0°F)

Override Min

Speed

40% 10 to 100%

Humidity

Control

Humidity Set Point 65% 40 to 100%

Compensation

Percentage

60% 0 to 100% of stage 1 min speed

Stage 2 Offset 0,3°C (0,5°F) From set point to 10,0°C (18,0°F)

Bandwidth 1,0°C (1,8°F) 0,3 to 10,0°C (0,5 to 18,0°F)

Min. Speed 40% 10 % to 100 %

De-icing

Cycle Time

1 minute 1 to 720 minutes

De-icing Time 15 seconds 15 to 900 seconds

Stages 3-6 Differential 1,0°C (1,8°F) 0,3 to 10,0°C (0,5 to 18,0°F)

Mist Time On 60 seconds 0 to 900 sec. in increments of 15 sec.

Time Off 10 minutes 0 to 720 minutes

Offset 4,0°C (7,2°F) 0,3 to 20,0°C (0,5 to 36,0°F)

Differential 1,0°C (1,8°F) 0,3 to 10,0°C (0,5 to 18,0°F)

Mist Shut off

humidity level

95% 0 to 100%

Heater Heater Offset 1,0°C (1,8°F) -5,0 to 10,0°C (-9,0 to 18,0°F)

Max. Temperature

Diff. Btwn Zones

4,0°C (7,2°F) 0,3 to 20,0°C (0,5 to 36,0°F)

Alarms High Offset 7,0°C (12,6°F) 0,3 to 20,0°C (0,5 to 36,0°F)

Low Offset 5,0°C (9,0°F) 0,3 to 20,0°C (0,5 to 36,0°F)