2TC5-2V4SA rev.06

TABLE OF CONTENTS

PRECAUTIONS .............................................................. 3

FEATURES..................................................................... 4

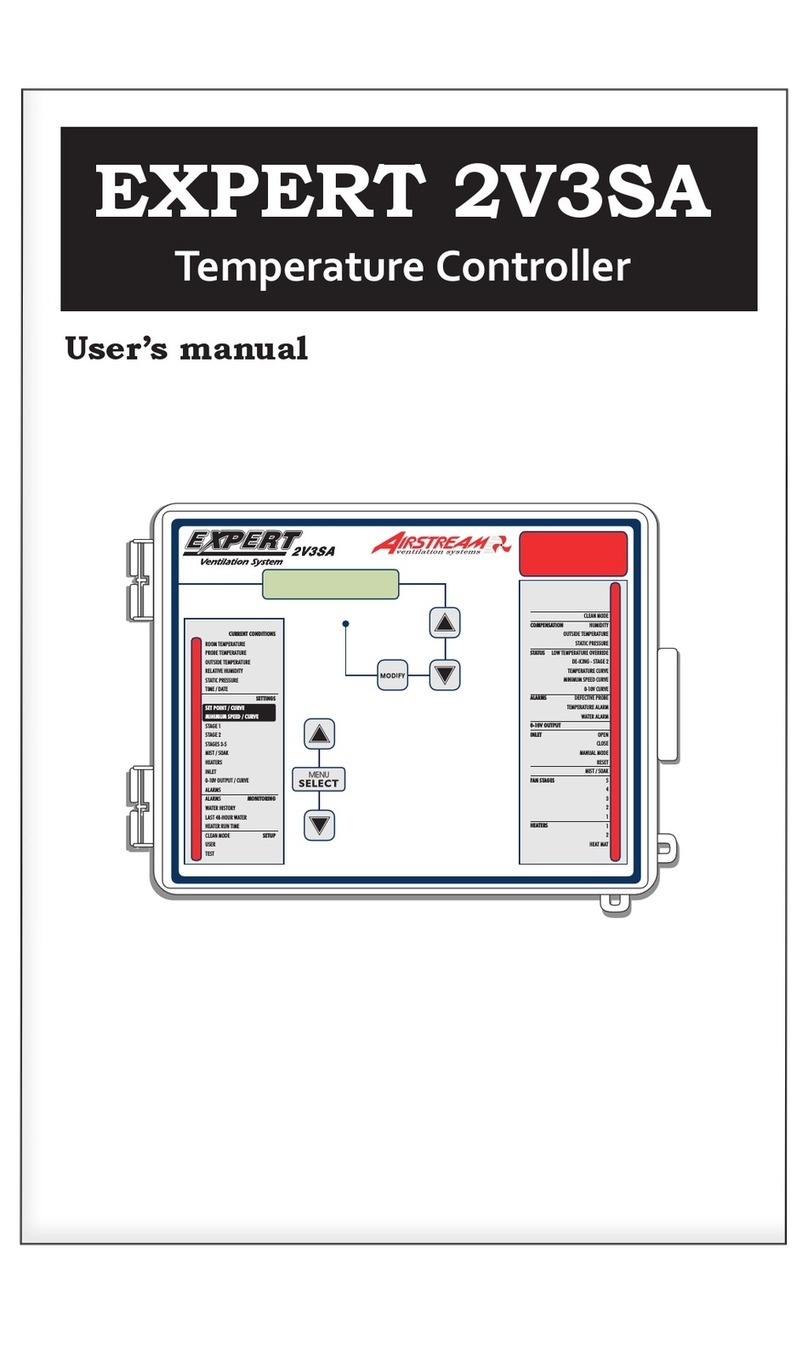

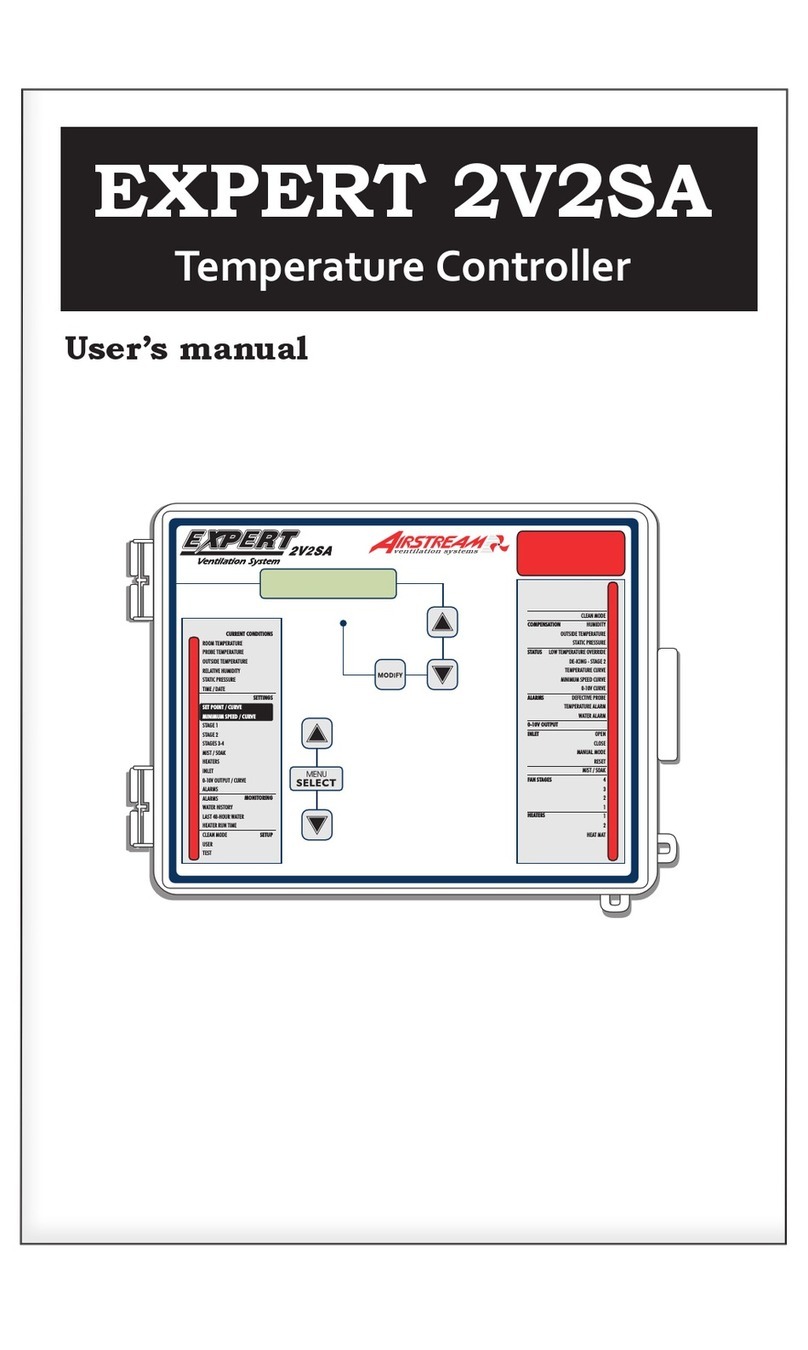

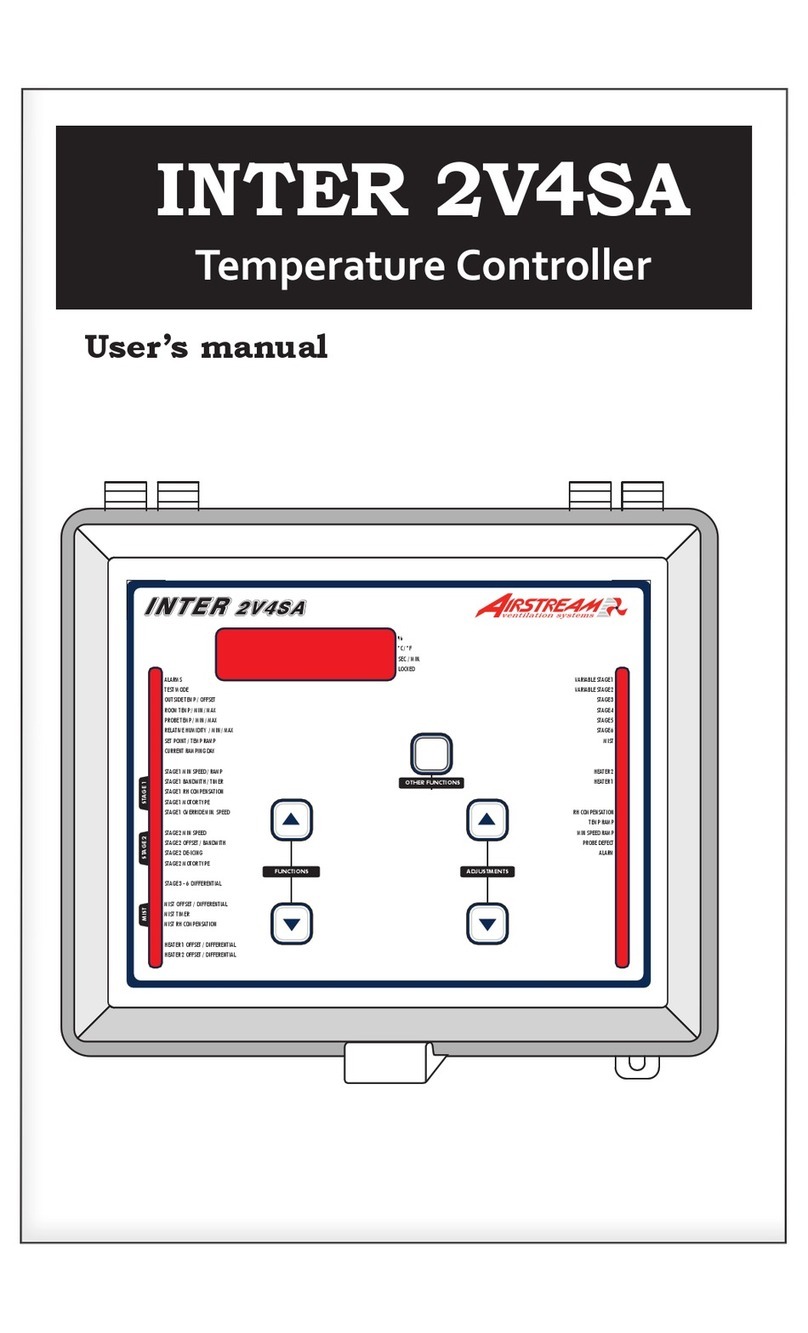

LOCATION OF THE CONTROLS................................... 6

ControllerStatusLeds ...................................................... 7

InternalSwitches............................................................... 7

INSTALLATION .............................................................. 8

MountingInstructions ........................................................ 8

Connections ..................................................................... 8

MotorTypes ..................................................................... 9

Heating/CoolingOption ....................................................10

TemperatureProbes ........................................................11

CHANGING THE PARAMETER SETTINGS .................. 14

UsingtheDisplay..............................................................14

LockingtheParametersSettings...................................... 15

TEMPERATURE SETTINGS .......................................... 16

TemperatureUnits ............................................................16

ViewingTemperatures .....................................................16

TemperatureSetPoint .....................................................19

TemperatureCurve...........................................................20

VENTILATION SETTINGS.............................................. 24

CoolingOperation ............................................................24

MinimumVentilationCycle................................................26

HumidityCompensation ...................................................28

MinimumSpeedCurve ..................................................... 31

DifferentialSettings ..........................................................37

De-icing of Stage 2 Fans..................................................39

Mist Cooling .....................................................................41

HEATER SETTINGS....................................................... 44

ALARM SETTINGS......................................................... 49

TEST MODE.................................................................... 50

TROUBLESHOOTING GUIDE........................................ 51

TECHNICAL SPECIFICATIONS..................................... 55

FACTORY SETTINGS .................................................... 56

GLOSSARY..................................................................... 58

Page