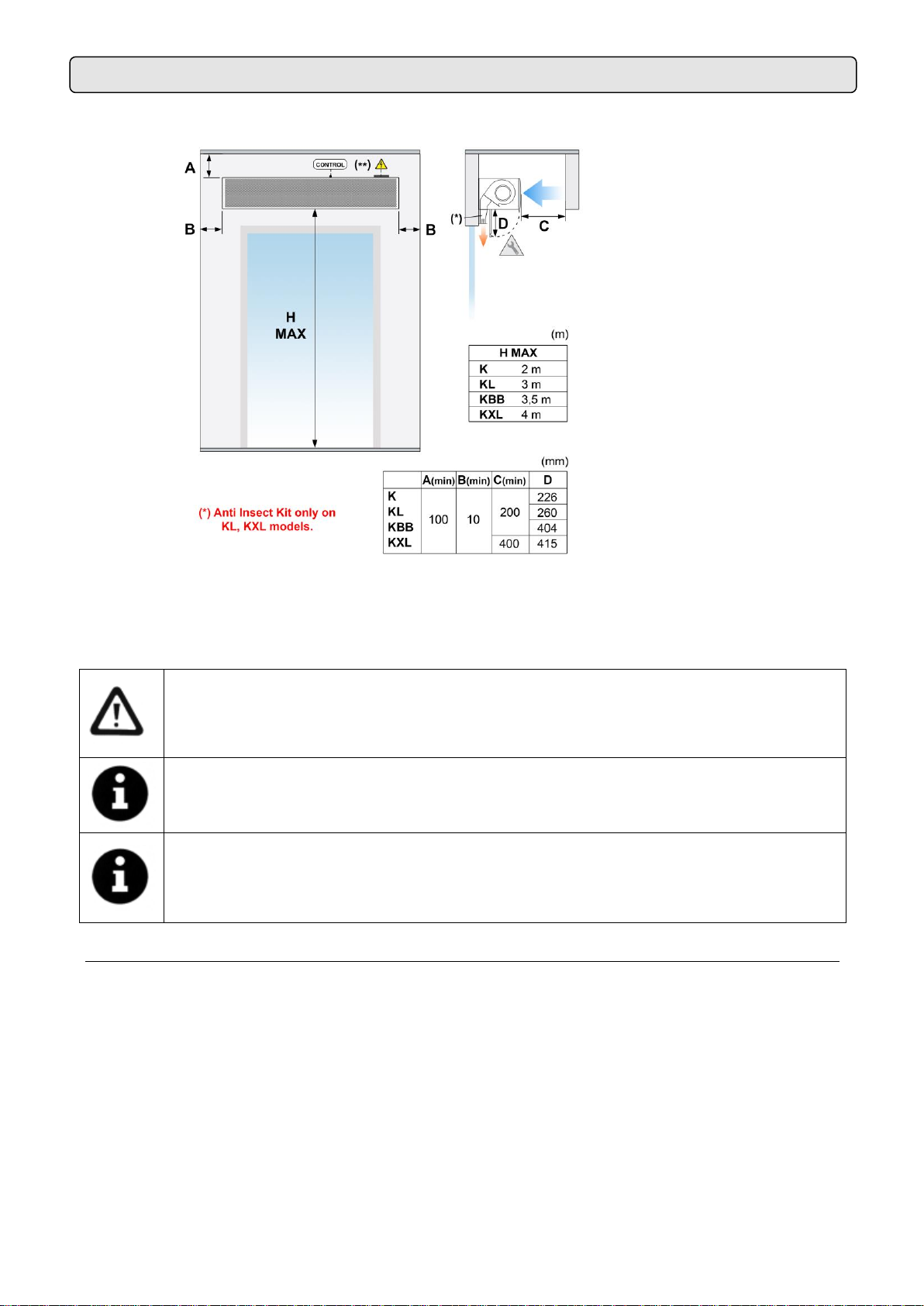

• Must be installed just above the door (not separate from it)

• With the door open, the curtain must be at maximum speed

• The curtain should be on as soon as possible when opening the door:

o By default, the “Hand Auto”control and a door contact supplied allow to automatically have

a low speed with the door closed and the maximum speed when the door is open (in this way

it reaches the maximum flow earlier).

o As an option, there is an advanced “Clever”control that has a delayed door contact that will

not let us open the door until the curtain is on.

o As an option, the door contact supplied can be changed by a motion detector in such a way

that when we perceive the approach of a person we already activate the air curtain and in

this way the curtain reaches maximum speed before opening the door.

o In low consumption EC fans that have a slower start it is more important to always have a

low speed with the door closed, or to install a detector so that they start in advance.

• In the case of indoor odours that encourage the entry of insects, the curtain should be installed

outside to work with clean air. If it is placed outside, it must be protected from the rain with a roof that

prevents the curtain from getting wet.

Power Supply

To connect the power supply there is a black connection box outside the air curtain (located on top).

For curtains, only 230V single-phase current should be connected for the fans or 400Vx3 as an option for the

Fly KL and Fly KXL models.

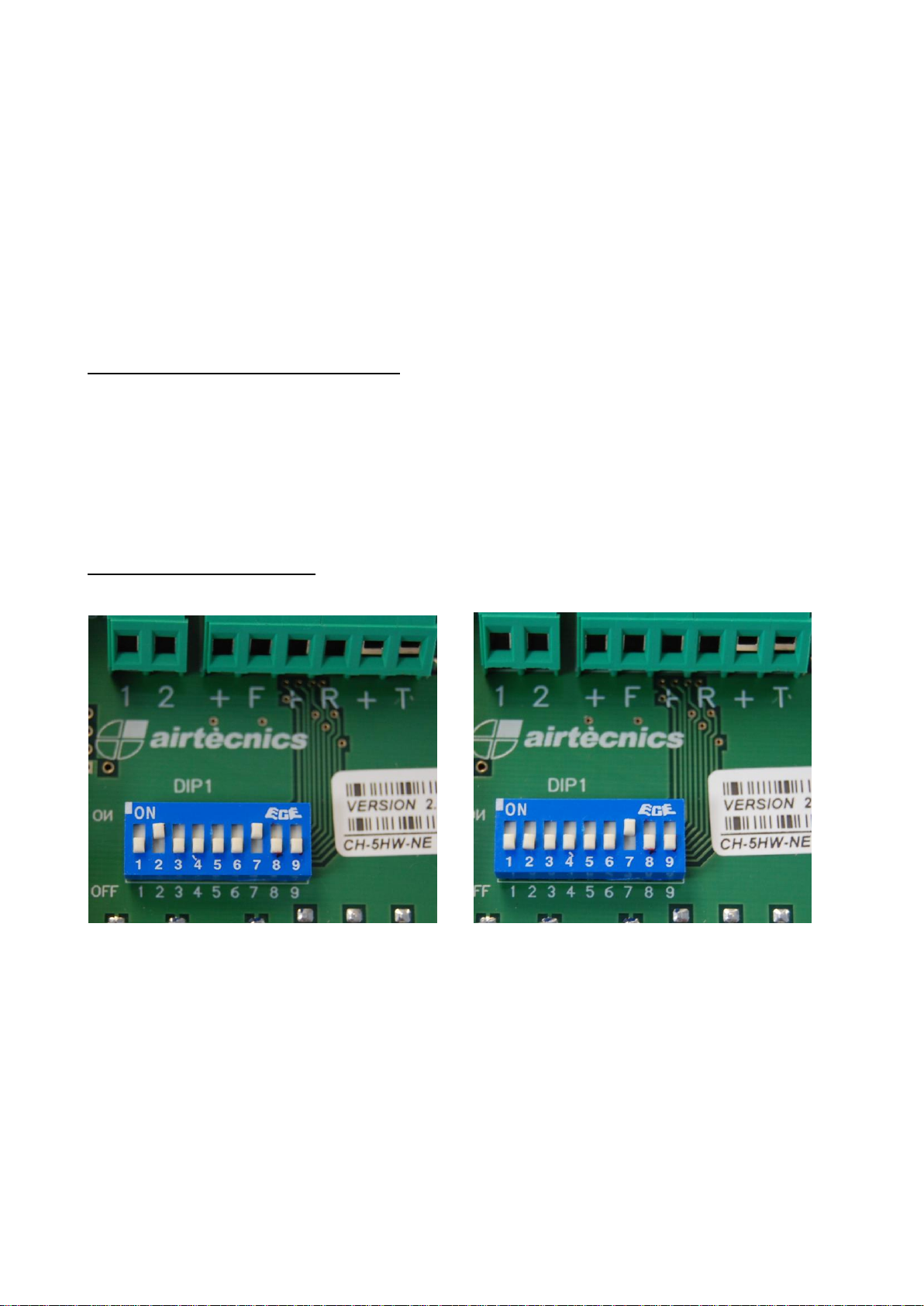

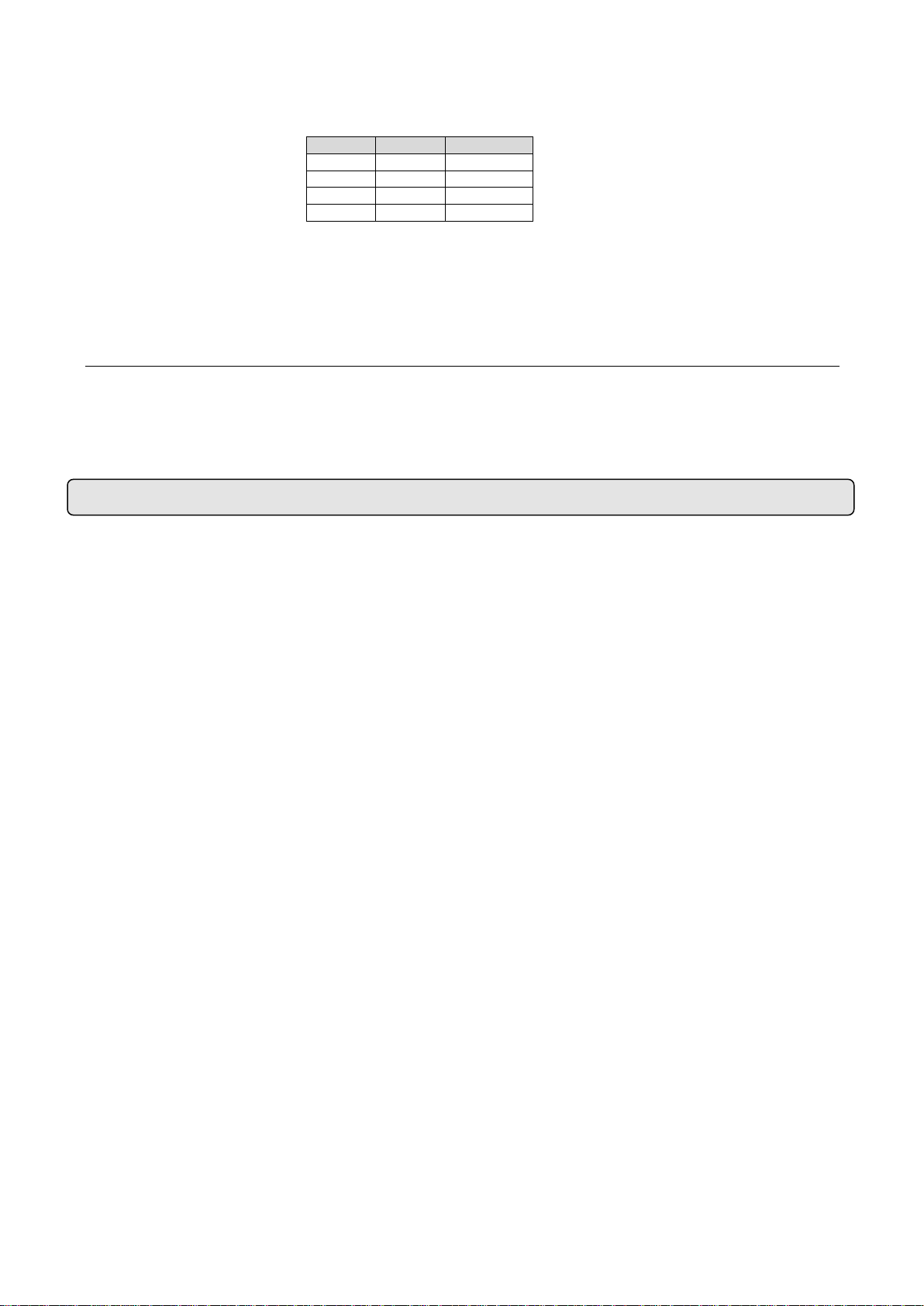

PCBoard and Control

To connect the controller there is a PCBoard (printed circuit) located outside the air curtain (located on top).

There is no need to open the unit to connect it.

Use the 7 (or 10) meters RJ45 cable supplied with the equipment. The communication between the controller

and the PCB is digital and low-voltage.

Optionally, there are different accessories and controllers available, to meet every customer needs (Clever,

door contacts, supports, etc.).

The new total control for ventilation technology is advanced Clever regulation. Leading the new generation of

air curtains management with maximum control providing maximum energy saving. For more information ask

for Clever Control manual.

Fixing

Units are provided of several external suspension points, depending on the weight and length of each model

(see exact situation of the points at the air curtains characteristics page).

Generally, air curtains are installed horizontally, for vertical installation use the foot kit (see accessories

section).

The fixing of the air curtain should be managed according to the weights of each unit shown on the technical

data page. The installation can be made through threaded rods, cable tensors or other supports. See

available supports in the accessories section.