(5) Manual - Air curtain - SMART

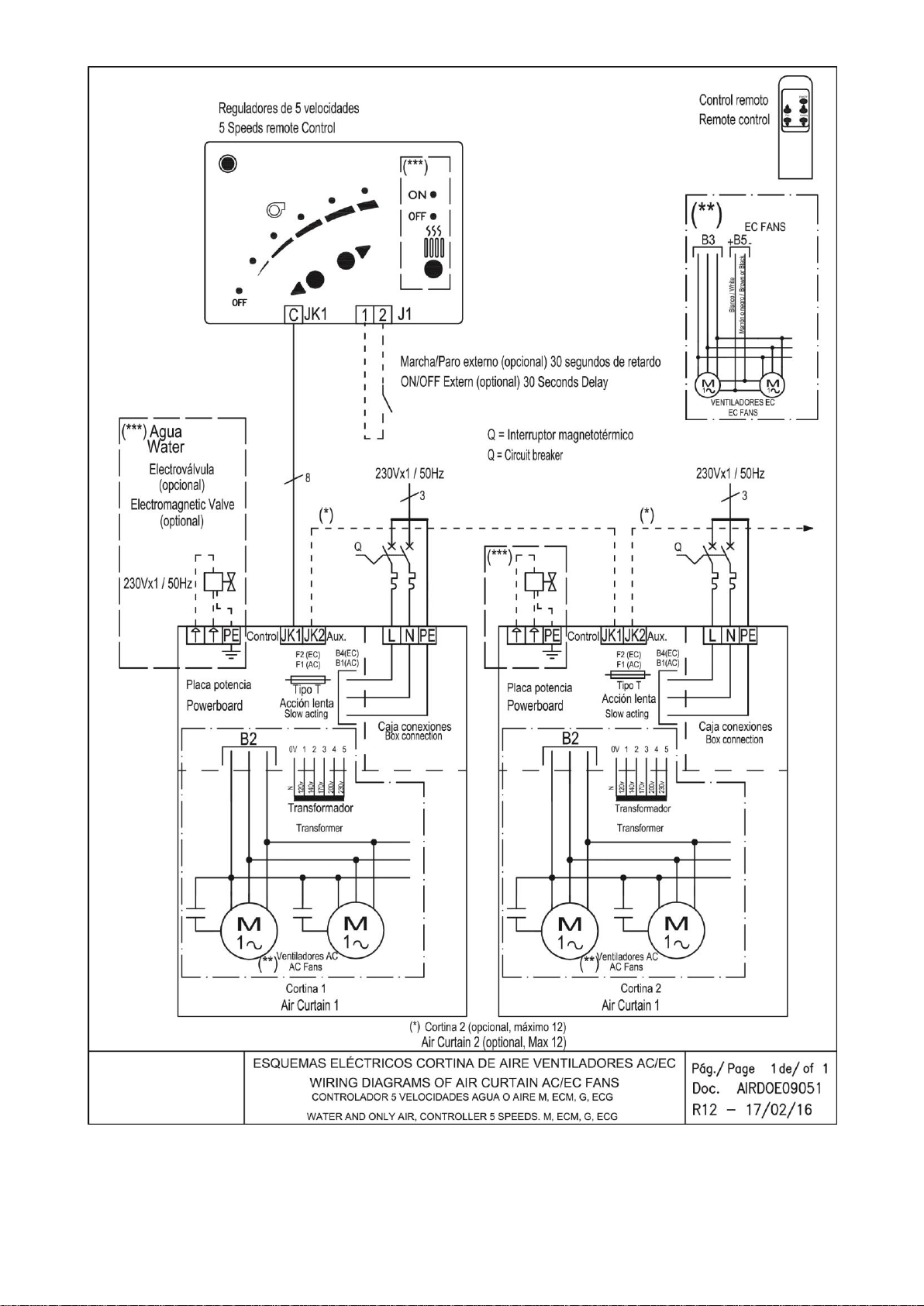

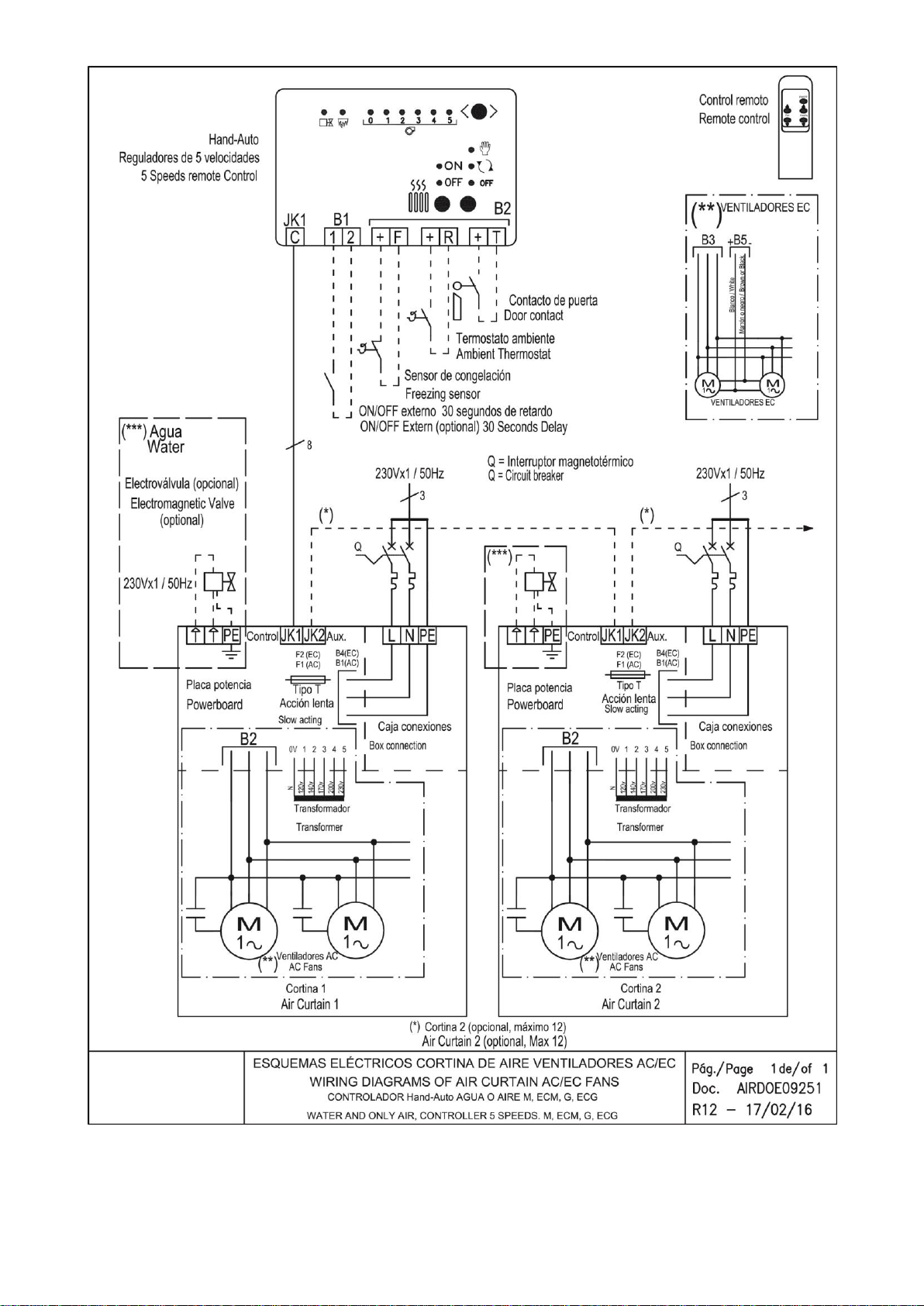

Power Supply

To connect the power supply there is a black connection box outside the air curtain (located on top).

For an ambient air or water heated air curtain just connect the single phase 230Vx1.

In case of an air curtain with electrical heating we will also connect the three phase 400Vx3 of the electrical

element. Optionally under request the power supply of the water coil or electrical element can be three phase

230Vx3 or single phase 230Vx1 depending on each model (special wiring diagram will be enclosed).

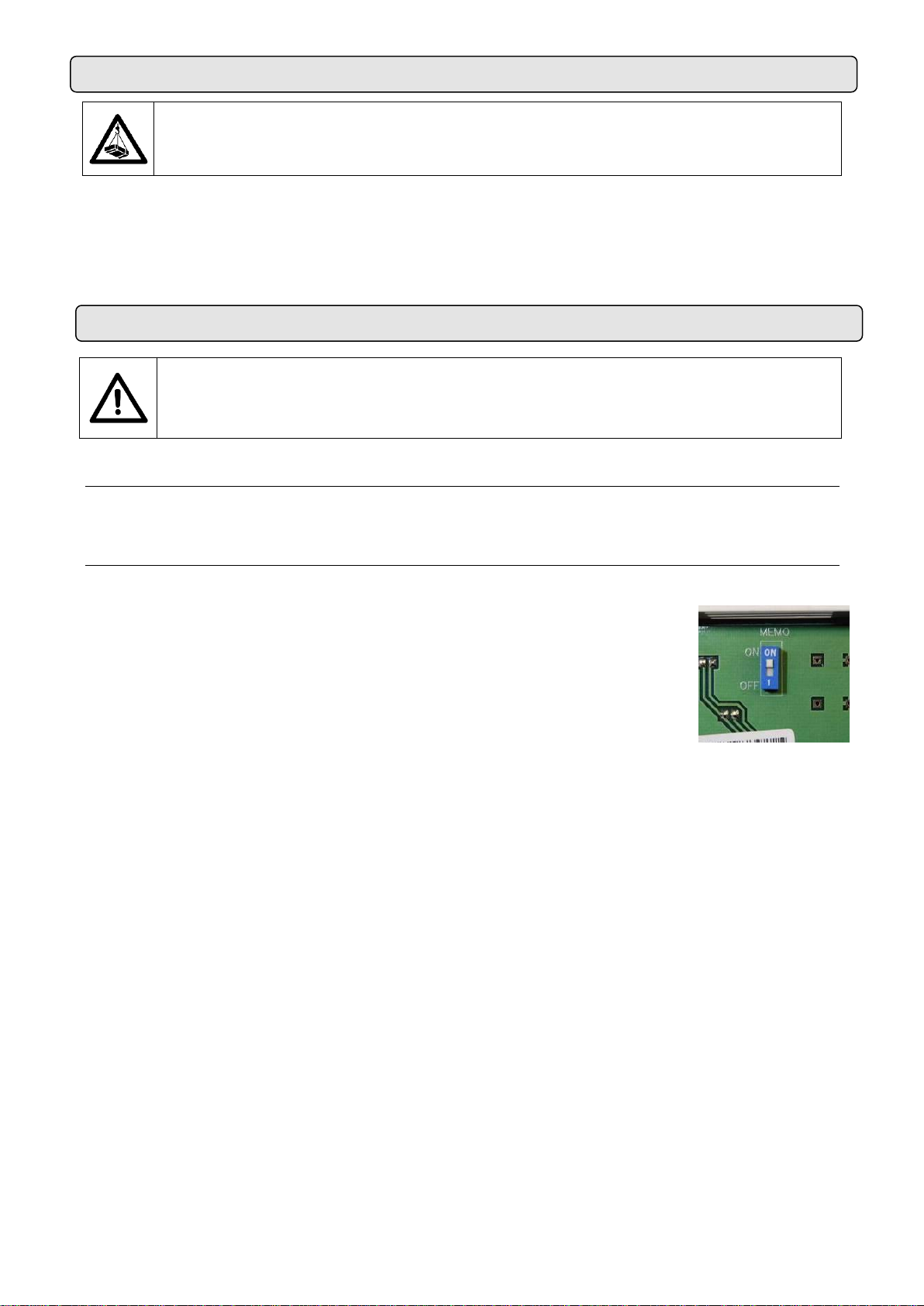

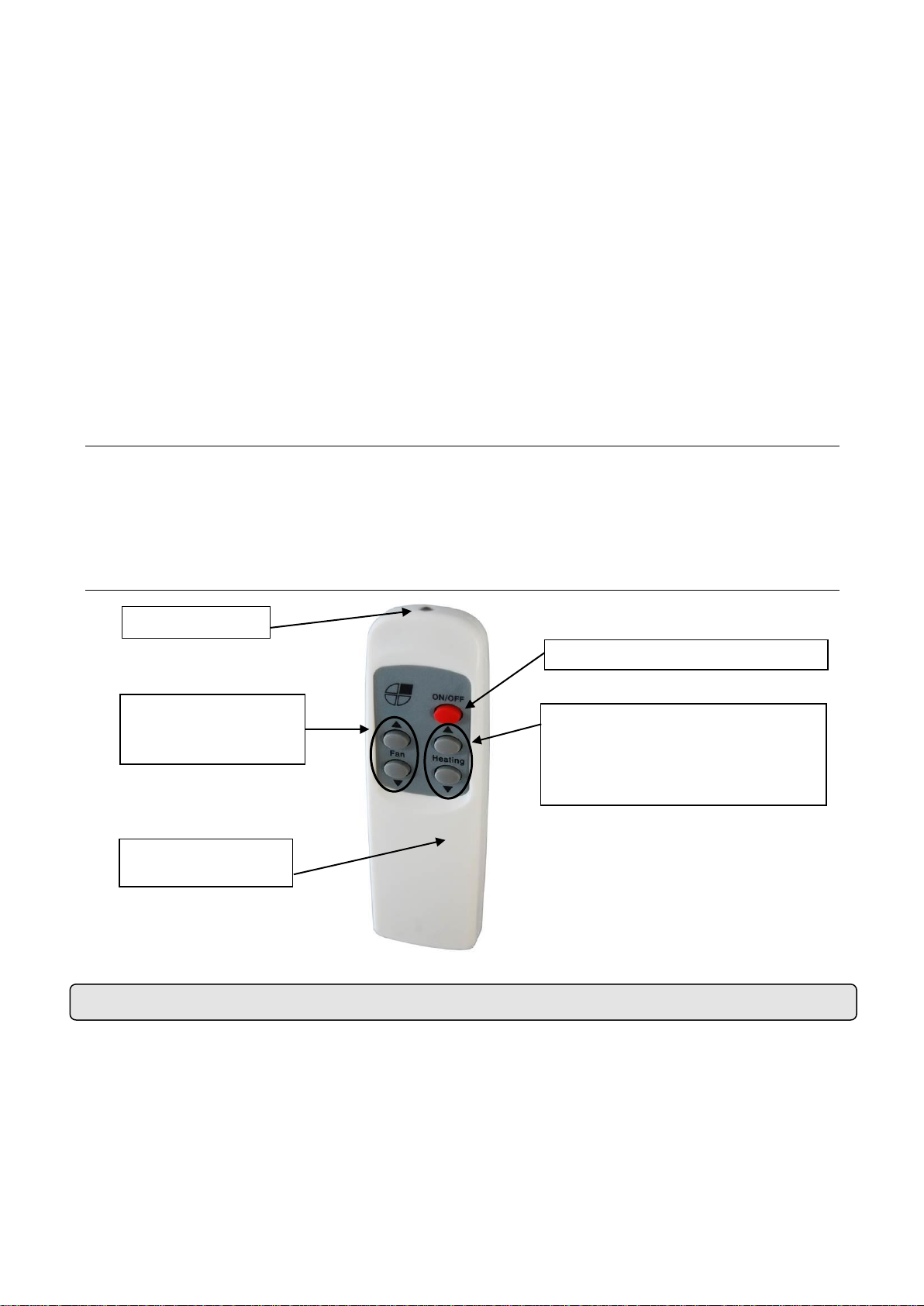

PCBoard and Control

To connect the controller there is a PCBoard (printed circuit) located outside the air curtain (located on top).

There is no need to open the unit to connect it.

Use the 7 meters RJ45 cable supplied with the equipment. The communication between the controller and

the PCB is digital and low-voltage.

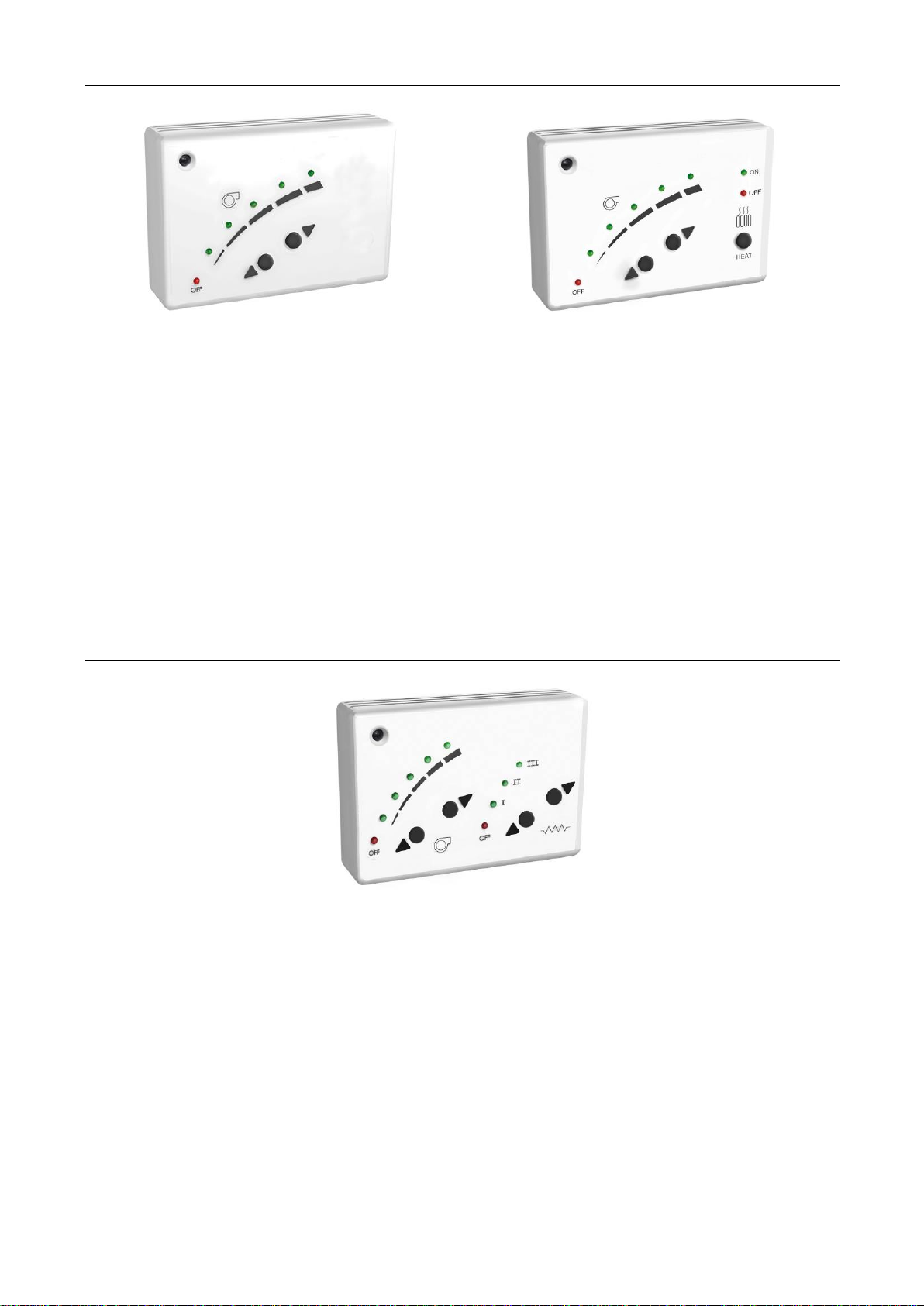

Optionally, there are different accessories and controllers available, to meet every customer needs (Clever

Control, thermostats, hand-auto, door contacts, anti-freezing sensor, supports, valves, etc.).

The new total control for ventilation technology is advanced Clever regulation. Leading the new generation of

air curtains management with maximum control providing maximum energy saving. Clever automatically

adapts the functioning of the air curtain to the entrance climatic conditions in order to keep the comfort and

energy saving. For more information ask for Clever Control manual.

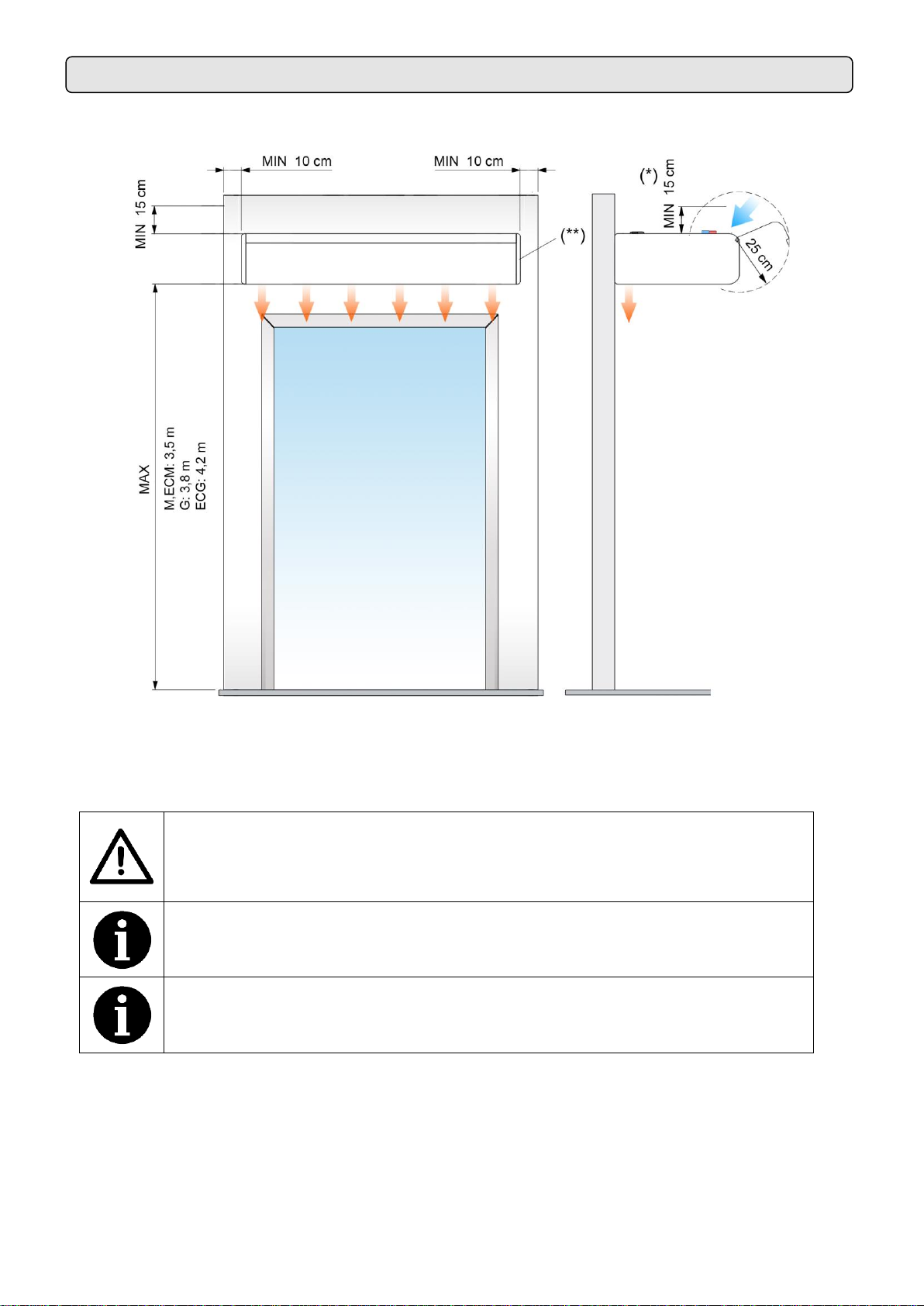

Fixing

Units are provided of several external suspension points, depending on the weight and length of each model

(see exact situation of the points at the air curtains characteristics page).

The fixing of the air curtain should be managed according to the weights of each unit shown on the technical

data page. The installation can be made through threaded rods, cable tensors or other supports. See

available supports in the accessories section.

Water coils

Water heated air curtains have a PCBoard with an output of 230Vx1 to install an electro valve

(open/close water entrance) or any other device.

It is recommended:

Close the hot water circulation (by turning the electrovalve OFF) to avoid fan overheating while the

unit is OFF. Electrovalve is optional.

Install 2 cutoff water valves (supply and return) in order to disassemble the equipment easily.

Install a bleeding valve at the highest part of the water heating circuit.

The ambient temperature should be always over +4ºC, otherwise it will be necessary to provide an anti-frost

protection device.

Water coils have a drainage point placed at the end part of the intake manifolds area.

Some special units are provided with condensation tray prepared to work with cold water. In this case, these

units can’t work at high ventilation speed (depending on model, length and power it will be a speed

limitation). Intake air speed should not be higher than 3m/s because water drops can appear on the outlet.

Electrical elements

The heater element has 9 resistances bars that combined give 2 stages of heating. The control is made by 3

PRBEO when power stage is less than 27kW or by contactors when it is higher than 30kW.

All electrical elements are protected electrically and electronically against overheating (see “Operating

instructions”section).

The electrical controllers have the option to install an external thermostat that turns on/off the heating in order

to control the temperature.

During the first uses scent can be emitted but it disappears in a few days.