General: 01905 823 298 | www.akw-ltd.co.uk6

6

COMMISSIONING

Commissioning

Application Abbreviated Designation Mixed Water Temperature (°C)

Shower -HP-S, LP-SE 41 Maximum

Purpose

Since the installed supply conditions are likely to be different from those applied in the

laboratory tests, it is appropriate, to carry some simple checks and tests out on each mixing

valve at commissioning to provide a performance reference point for future in-service tests.

Procedure

Check that:

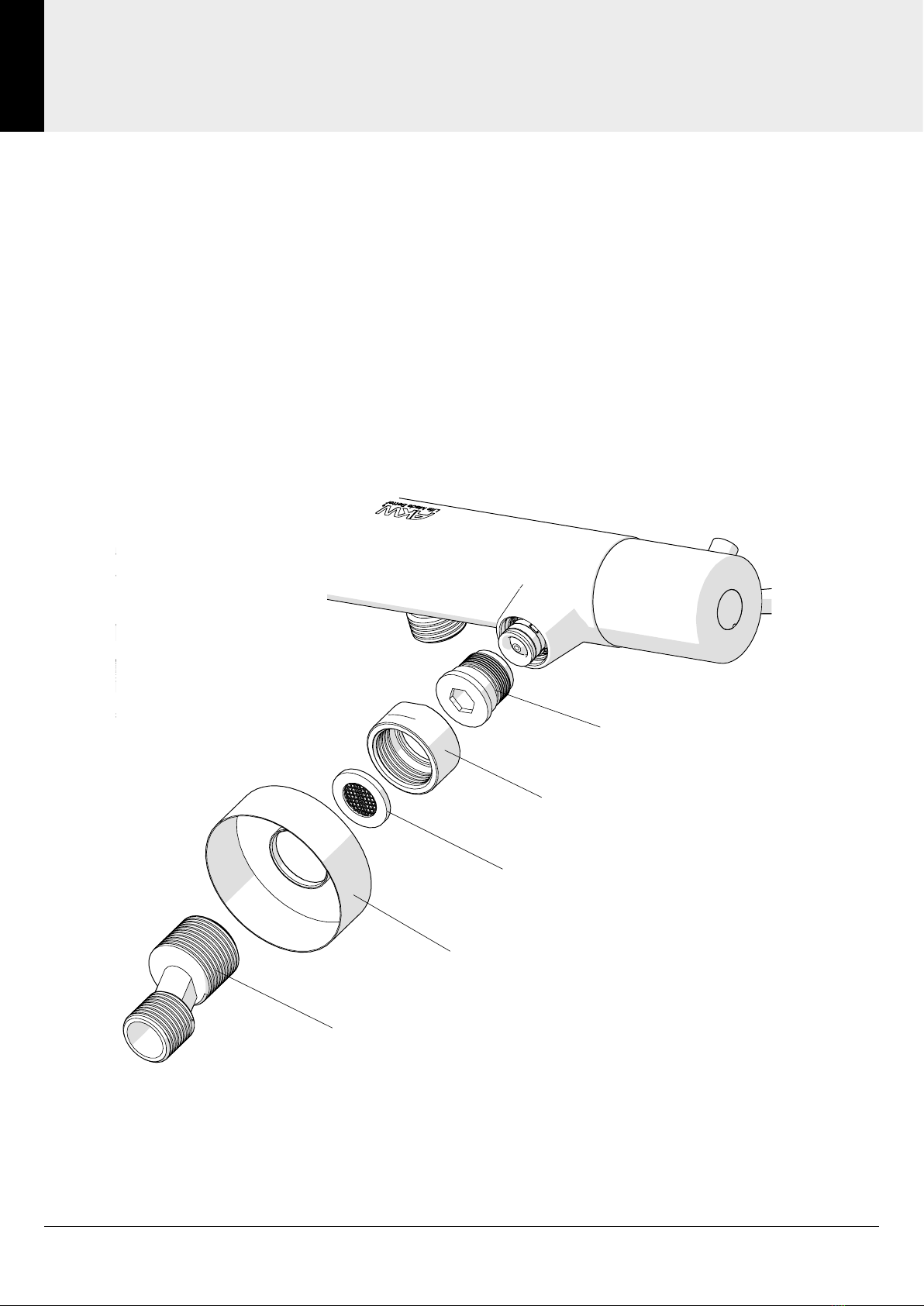

a. The designation of the SMV-001 mixing valve matches the intended application.

b. The supply pressures are balanced and within the range of operating pressures for the

designation of the valve.

c. The supply temperatures are within the range permitted for the valve.

To adjust the temperature of the mixed water see page 8 and then carry the following

sequence out:

a. Record the temperature of the hot and cold water supplies (see page 13).

b. Record the temperature of the mixed water at the largest draw-off ow rate.

c. Record the temperature of the mixed water at a smaller draw-off ow rate.

d. Isolate the cold water supply to the mixing valve and monitor the mixed water temperature.

e. Record the maximum temperature achieved as a result of (d) and the nal stabilised temperature.

f. Record the equipment, thermometer etc. used for these measurements.

Maximum Temperature

The maximum blend temperature obtainable by the user should be limited to prevent

accidental selection of a temperature that is too hot.

The SMV-001 mixer valve is fully performance tested and the maximum override temperature

is pre-set to 41°C under ideal installation conditions at the factory. Site conditions and

personal preference may dictate that the maximum temperature be reset following

installation.

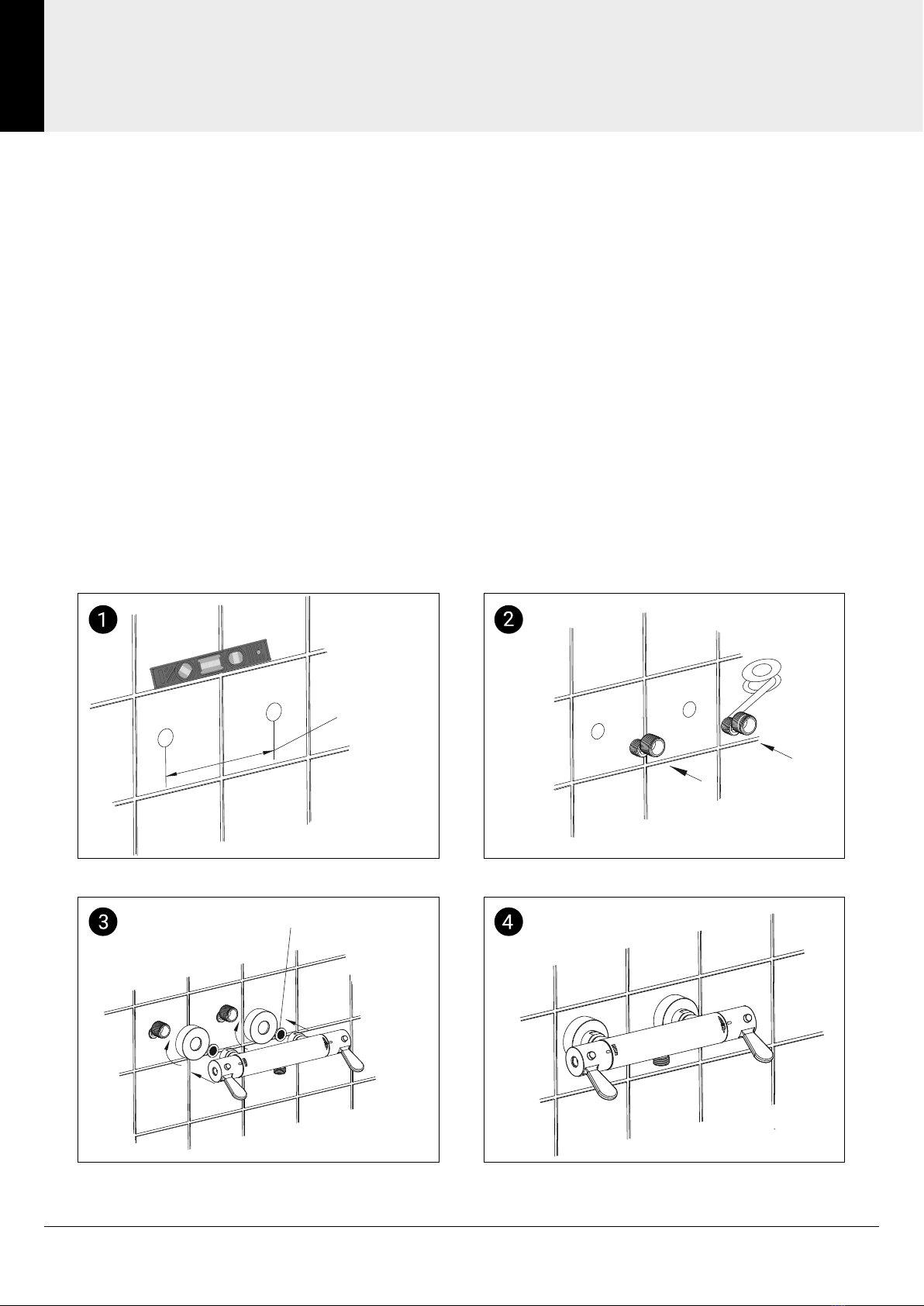

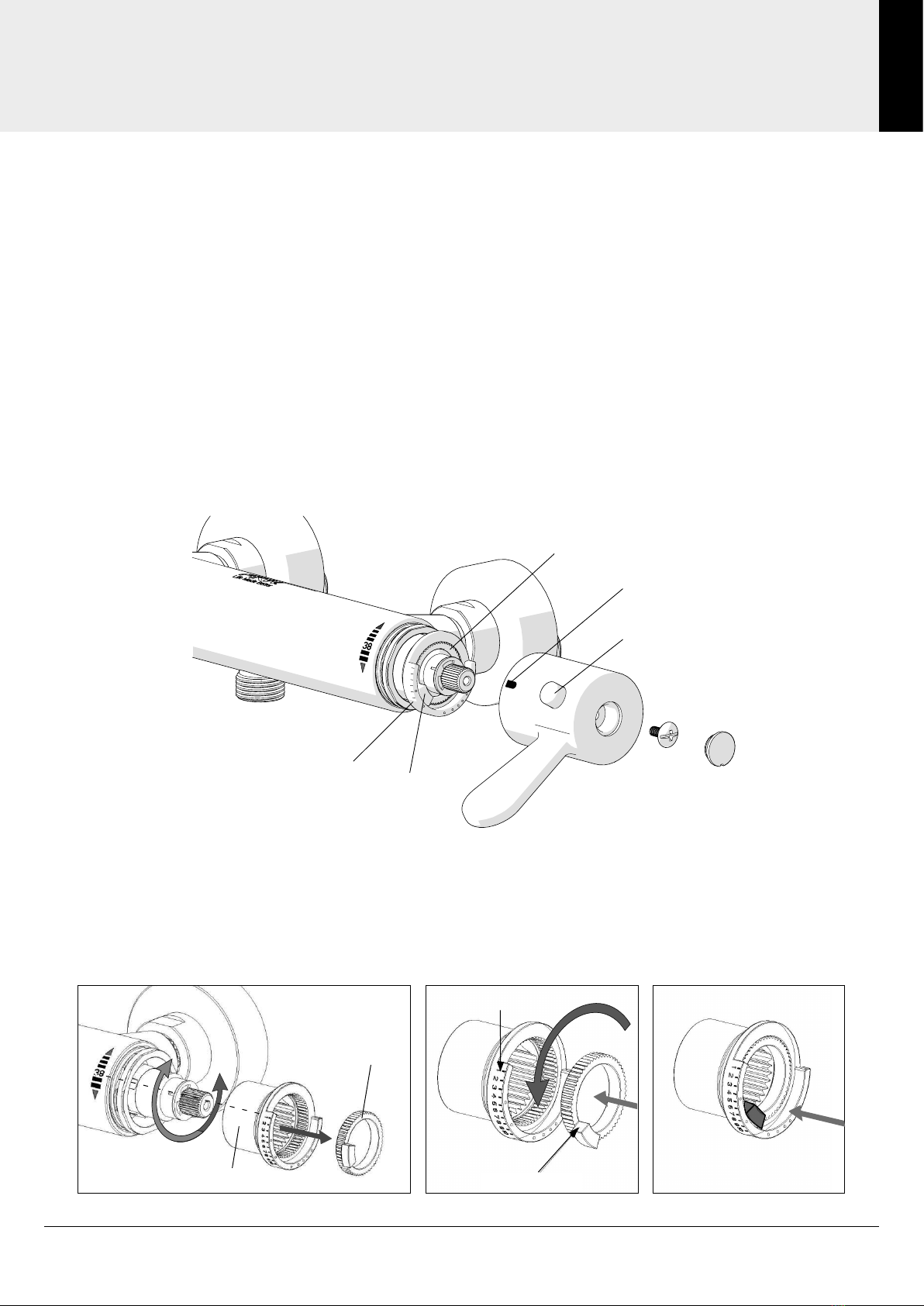

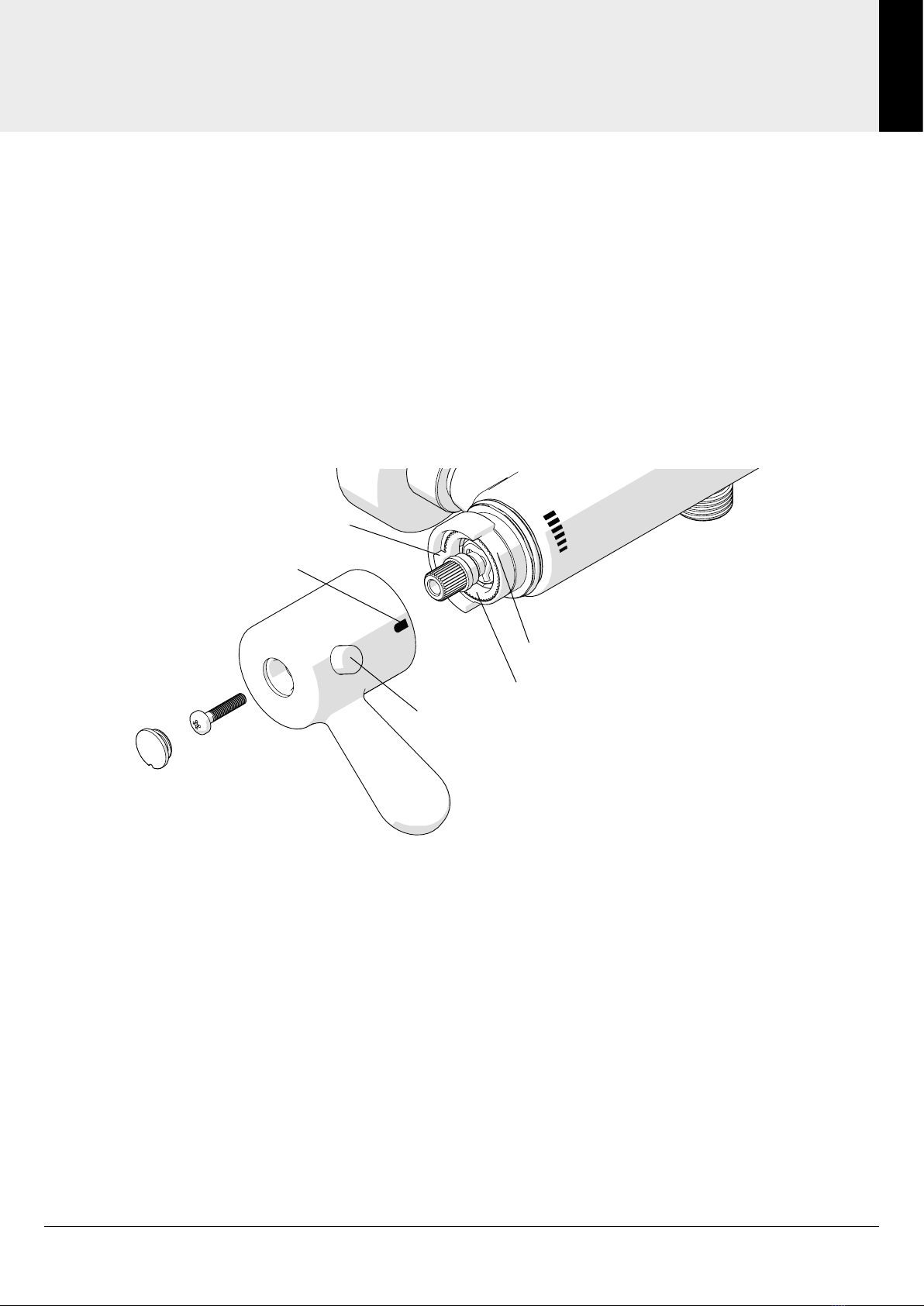

Maximum Temperature Setting

Make sure that an adequate supply of hot water is available at the hot inlet of the SMV-001

Mixer. The minimum temperature of the hot water must be at least 10°C above the desired

blend temperature. However, during resetting, this should be close to the typical storage

maximum to offset the possibility of any blend shift due to uctuating supply temperatures.

Make sure that both inlet isolating valves are fully open.

Temperatures should always be measured using a thermometer with proven accuracy.