8

© 2021 AKW 14-009-105-01

WarrantyWarranty

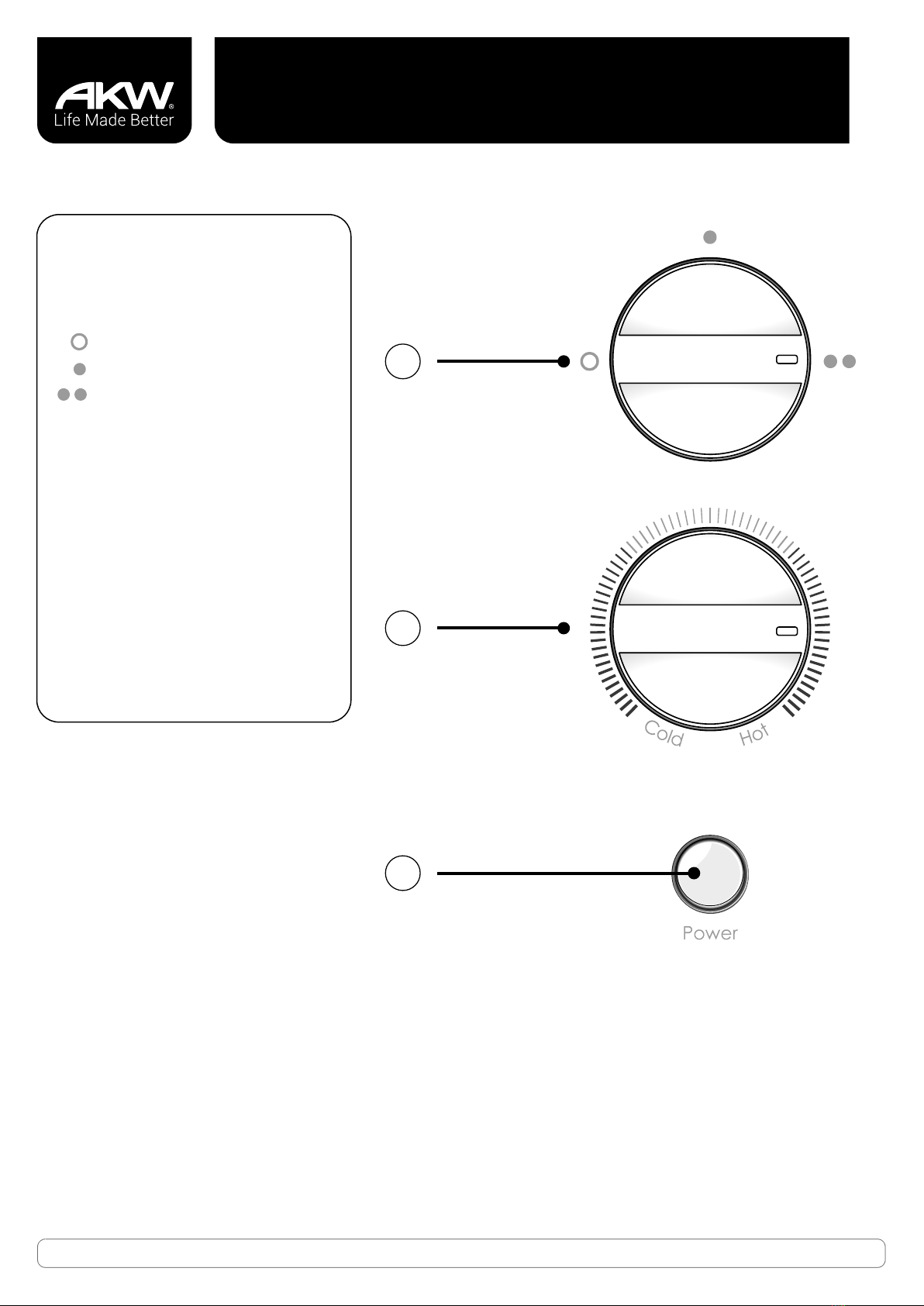

User

AKW guarantee your shower against any defects in manufacturing or materials for

3 years from the date of installation. Please ensure you have completed the warranty

card enclosed and return to AKW within 30 days to activate this warranty offer.

Alternatively visit www.akw-ltd.co.uk/warranty and complete the online registration

form. Within this period AKW will decide to repair or replace as we may choose.

Failure to activate warranty in set period will mean potential charges should a visit to

site be required by an AKW Maintenance Engineer. Any action taken under this

warranty does not extend the stated 3-year expiry date. Contact information can be

located on the back page. This guarantee is in addition to your statutory and other

legal rights. None of the foregoing affects your statutory rights.

Not covered by this warranty:

• Damage or defects that result from inappropriate use or accidental damage,

incorrect installation, or lack of maintenance including but not limited to the build

up of limescale, system debris or pipe scaling, grime, dirt or water-borne debris.

• Damage resulting from inappropriate cleaning or water ingress.

• Damage resulting from water freezing.

• Damage resulting from PRD activation from either a blocked hose or a blocked

shower handset.

• If the product is taken apart.

• Damage or defects that result from repairs or modifications undertaken by

persons who are not installers or AKW service engineers.

• Malfunction resulting from incorrect use.

• Failure to install in accordance with the installation instructions or performance

issues arising from incorrect installation.

• Claim for a defect identified at the point of delivery, once the product is fitted

(unless authorisation from AKW Medi-Care Limited has been granted).

• In-situ impact damage.

• Water, electrical, pressure or isolation issues.

• Wear and tear from routine maintenance, cleaning, adjustments, corrosion or

erosion.

If you need any advice or if you have any questions please contact the Technical

enquiries helpdesk with your model number and date of purchase.

For technical faults always refer to the trouble shooting guide before contacting your

local installer for assistance. If your installer should need further assistance then

contact the technical helpline on 01905 560219.

Warranty

3yr